616.13 Work Zone Capacity, Queue and Travel Delay

When lane closures are required for road construction, rehabilitation, or maintenance activities, the capacity of the roadway may be greatly reduced. Capacities differ for interstates, freeways, multiple-lane routes and two-lane roadways due to the number of closed lanes, how the project will affect the surrounding roadways, and geometrics of the roadway. When the reduction is too great the traveling public may experience unacceptable travel delays through the work zone, vehicles queuing (a line of vehicles) upstream of the work zone and possible frustration of the motorist.

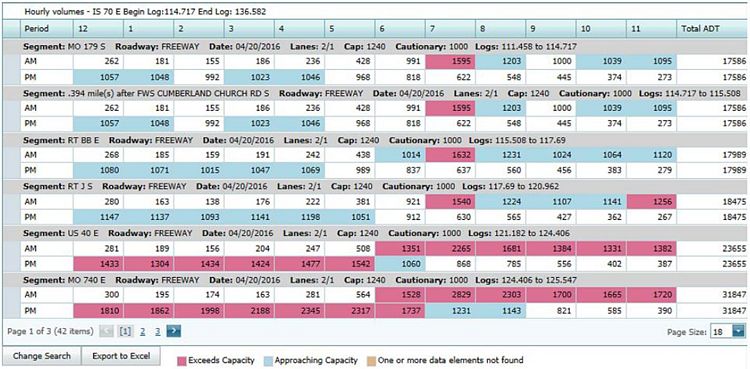

Typical estimation for capacity restriction is outlined in the MoDOT Work Zone Guidelines. To help MoDOT personnel view capacity restrictions and cautionary zones, the Transportation Management System (TMS) provides the restrictions in a color coded Traffic Segment Hourly Volume (TSHV) table. Directions of how to use the TSHV table are available.

The TSHV table provides time periods when lane closures are in a cautionary zone or a capacity restriction, which are color coded blue and red, respectively.

The cautionary zone is a triggering point for a review of the location or area the work will be performed. Normally, there should not be a capacity or travel delay concern, but due to history, narrow lanes, climbing grades, etc., the capacity may be reduced to a level of concern for delays or queuing. If there is a queuing or delay concern, work may be required to be performed during off-peak hours (i.e., nighttime and/or weekends) when necessary.

When the hourly volume reaches the capacity restriction level, work should be scheduled during off-peak hours. Off-peak hours could consist of the time between rush-hour, per example; some locations only work between the hours of 9 am and 3pm. Many locations are taking advantage of nighttime or weekend hours due the lower volume of traffic.

Due to different types of work, there may be times when lane closures are necessary during the hours exceeding the Capacity Restriction levels. The TSHV table does not provide information about possible delays or queuing of traffic due to capacity restrictions.

Over the years, software programs have been developed to estimate the length of vehicles queued upstream from the work zone taper. The queue length is normally calculated in miles. The queue length is based on the number of vehicles in the number of open lanes upstream of the work zone taper. These software programs may also provide an estimate of travel delays in minutes.

Contents

- 1 616.13.1 Urban and Rural Significant Projects with Major Surrounding Network Systems

- 2 616.13.2 Interstate, Freeways and Multi-lane Roadways

- 3 616.13.3 Capacity Restriction for Different Climbing Grades

- 4 616.13.4 Capacity Guidelines for Ramps

- 5 616.13.5 Travel Delay or Travel Time

- 6 616.13.6 Advance Warning and Advanced Work Zone Traffic Strategy Selection

- 6.1 616.13.6.1 Temporary Traffic Control Devices

- 6.2 616.13.6.2 Changeable Message Signs (CMS) and Dynamic Message Signs (DMS)

- 6.3 616.13.6.3 Smart Work Zone (SWZ) Strategy Selection

- 6.4 616.13.6.4 Designated Detour or Relief Route

- 6.5 616.13.6.5 Maintain Same Number of Lanes

- 6.6 616.13.6.6 Public Information

- 7 616.13.7 Traffic Pacing

616.13.1 Urban and Rural Significant Projects with Major Surrounding Network Systems

Depending on the location and duration, urban and rural significant projects may entail an in-depth analysis of the surrounding network of roads. Due to the complexity, project analysis of these larger projects should start as early in the planning phase as practical. With early analysis, the planner or designer can make an appropriate cost estimate for traffic management to the early budget requests and the appropriate temporary traffic control devices to mitigate possible traffic concerns. Various traffic analysis tools and techniques can be utilized to evaluate these situations. The district Traffic offices should be able to help determine an appropriate analysis methodology and support any technical analysis to determine the potential work zone impacts.

616.13.2 Interstate, Freeways and Multi-lane Roadways

Due to MoDOT’s large highway system, interstate, freeway, and multi-lane work zones may be located anywhere from the rural and urban areas to the flat and hilly terrain. Normally, these roadways have larger volumes and higher speed limits. When volumes exceed the capacity restriction level, ideally work should be performed when the volumes are lower, such as, off-peak, nighttime, weekends, etc. However, there are times when work has to be performed through the capacity restriction time periods, due to the type of work, longevity of the project, etc. Whenever a lane closure is performed during the capacity restriction time period, a potential for queuing and delays may occur. To assist the planner, designer, construction inspector, contractor work zone specialist, and maintenance personnel, the University of Missouri-Columbia has helped developed a user-friendly software program, MoDOT Work Zone Impact Analysis Spreadsheet, to provide an estimate of queues and delays to the traveling public.

For contract projects, work zone capacity should be analyzed early in the planning and design stages so enough time will be provided for designing the work zone and budgeting for possible use of advance warning strategies. Smart work zone strategies can also be considered at this stage. The spreadsheet also gives recommendations on smart work zone strategies to include. Instructional videos on how to use the smart work zone functions of the spreadsheet are listed below:

For maintenance projects, history may have shown locations that do not queue or delay due to the type and location of work, percentage of trucks, etc. If the work area has not shown queue and delays, the spreadsheet analysis may not be warranted.

MoDOT Work Zone Impact Analysis Spreadsheet

To provide user friendly features, the spreadsheet uses an excel database program, which requires a limited amount of data from the user. The spreadsheet has color-coded (blue, orange and yellow) fields that require information which can be obtained from the TMS database.

The WZ Impact Analysis Spreadsheet Directions provides guidance on how to use the spreadsheet.

The spreadsheet consists mainly of two parts: existing conditions and work zone details. When calculating the capacity of the work zone, the program accounts for different factors that affect the capacity (ex. location of workers and/or equipment to the travel lane, travel lane width, and number of trucks). The spreadsheet is used to calculate the queue lengths, delay of travel, and cost of the travel delay based on the estimated capacity.

616.13.2.1 Work Location

Studies have shown that the location of the physical work (workers/equipment) to the traveling public may adjust the base work zone capacity (1600 passenger car/hour/lane) as much as ±10%. The MoDOT Work Zone Impact Analysis Spreadsheet provides capacity based on worker/equipment locations, worker protection, or moving traffic away from the work area (ramp by-pass, crossover on divided highway).

616.13.2.2 Travel Lane Width

Reducing the travel lane width will reduce the free-flow speed, which will cause a decrease capacity through the work zone. Currently, speeds are not used to estimate capacity within the work zone, but an adjustment factor is used to calculate the capacity based on the different lane widths. The MoDOT Work Zone Impact Analysis Spreadsheet includes a reduction factor based on the travel lane width.

616.13.3 Capacity Restriction for Different Climbing Grades

Interstate, freeway and multi-lane roadways with a continuous climbing grade may reduce the work zone roadway capacity, especially when large percentages of heavy vehicles (trucks, buses, RV, etc.) are present. If the grades are steep and long enough, the heavier vehicles speed may be reduce to a “crawl” speed.

Due to the length and weight of the larger vehicles, they cannot be compared with passenger vehicles (cars/small trucks). Large vehicles are normally calculated as equivalent trucks.

616.13.4 Capacity Guidelines for Ramps

Ramps located near work zones may disrupt traffic flow due to the interaction of traffic entering or exiting the on/off ramps.

MoDOT’s spreadsheet does not address individual ramps. If the work zone is located 500 ft. upstream or downstream of the on/off ramps, the TMS hourly volume should be based on the highest upstream or downstream volumes from the ramp.

Closing ramps may be an option to reduce the volume into the work zone, which may relieve queuing and delay concerns. When closing ramps, the traveling public should have a detour route.

616.13.5 Travel Delay or Travel Time

Travel delay or increased travel time may be calculated within the different work zone software. There may be times that queue lengths and travel delays develop on projects that were not calculated within the software programs.

When delays occur in the field, delay time will be calculated by the following equation:

- Delay Time = Twz - Tp

- Where:

- Twz = Time to travel through WZ

- Tp = Time to travel through area at posted WZ speed limit

Project personnel will determine these travel times and update DMS/CMS messages, as needed, at regular intervals and as conditions change. Possible methods to estimate travel times include:

- driving the limits of the work zone,

- establishing times based on predetermined queue lengths,

- monitoring travel times of vehicles traveling through the work zone or

- automated means.

The spreadsheet, Travel Time for Work Zones, calculates the delay time within the advance warning area or the activity area (buffer and work space and end taper). You are invited to field test Travel Time for Work Zones and forward your comments to Highway Safety and Traffic Division – Work Zone Section (573) 526-0123 or (573) 526-4329.

616.13.6 Advance Warning and Advanced Work Zone Traffic Strategy Selection

Below are several examples of strategies to inform the public or reduce work zone queues and delays, but they are not all inclusive.

616.13.6.1 Temporary Traffic Control Devices

Proper set-up of the temporary traffic control (TTC) devices is designed to provide the maximum safety and mobility through a work zone. Through the years, studies have been conducted to design the different components of the work zone. There are times (geometrics of roadway, etc.) when the work zone may have the speed limit reduced, but the amount of spacing and location of the TTC devices should be based on the posted speed limit (before the work zone).

616.13.6.2 Changeable Message Signs (CMS) and Dynamic Message Signs (DMS)

CMS are portable signs and DMS are stationary signs both of which are capable of displaying several messages in a sequence and display pertinent traffic operational and guidance information as well as advising drivers of unexpected work zone traffic and routing conditions.

CMS and/or DMS depending on the location may alleviate driver frustration with queues and delays by informing the traveling public with pertinent information.

When used, distance to end of work zone, in miles, with estimated travel times, in five-minute increments, will be displayed on a properly delineated CMS or DMS board. These boards will be located in advance of any potential traffic queue. Additional boards may be used as needed. The recommended display for these messages is as follows:

Unless travel time is provided through automated means, CMS and DMS boards will display the following recommended messages when workers are not present and traffic delay can be expected.

CMS and DMS boards may display meaningful messages when workers are not present, no traffic delay can be expected, and travel time is not provided through automated means.

When needed, commission-owned CMS and DMS units should be used unless justified otherwise. The core team should review the districts quantity of CMS boards to verify the district’s ability to supply the project before plans are finalized.

616.13.6.3 Smart Work Zone (SWZ) Strategy Selection

Through the years, the advancement of technology has produced a variety of strategies and techniques to provide improved warning and real-time work zone traffic information to the traveling public. MoDOT is committed to providing safe and efficient movement of traffic through work zones and protecting workers within the work zones.

The MoDOT Work Zone Impact Analysis Spreadsheet has been enhanced to also provide guidance in the selection of the appropriate smart work zone (SWZ) strategies (listed below) for a given work zone. The enhancements to the spreadsheet also include preliminary cost estimates for each SWZ strategy. This was done as part of MoDOT’s TSMO initiative. More information about TSMO can be found in EPG 909 Transportation Systems Management and Operations.

To ensure the safety of traffic and workers in work zones, the enhanced Work Zone Impact Analysis Spreadsheet should be utilized during the project planning and scoping phase of project development. Performing this exercise at this stage allows for the appropriate strategies and costs to be included in the project scope and STIP.

Smart Work Zone Strategy Description

The smart work zone strategies described below are:

- Construction Vehicle Warning System

- Dynamic Late (Zipper) Merge System

- Queue Warning System

- Portable Rumble Strips

- Speed Warning System

- Work Zone ITS and Temporary Traffic Incident Management System

- Travel Time Advisory System

- Travel Time Advisory System with Alternate Routes.

Construction Vehicle Warning System

One of the crucial aspects of the establishment and maintenance of a work zone is safe access and egress points for construction vehicles. These points are key determinants when it comes to ensuring the safety of both the traveling public and construction workers on a project.

The usage of detectors and CMS helps in notifying the motorists when a construction vehicle is planning to enter or exit from work zones. This display of messages can prepare travelers for a slowdown or potential merging conflicts due to construction vehicles. These warnings also reduce the frequency of incidents where motorists following work vehicles.

Dynamic Late Merge/Zipper Merge

One strategy that is available for 4-lane divided facilities in heavily congested areas (volumes greater than 1500 vehicles per hour) is the Dynamic Late Merge, which is more commonly referred to as the Zipper Merge. The Zipper Merge can increase work zone safety by reducing queue lengths. The Zipper Merge JSP contains all of the specifications for this WZITS tool along with the Dynamic Late Merge/Zipper Merge Figure showing the standard layout of the merge along with the appropriate messaging.

The Zipper Merge system should be considered for temporary traffic control situations where a lane closure reduces the mainline roadway from two continuous lanes to one lane. Considerations include the estimated traffic volumes, duration of the lane closure and the effects of congestion and large traffic queues at the particular project location.

The Zipper Merge system should be considered for deployment as part of a project’s temporary traffic control plan when the following conditions are anticipated:

- The lane closure will be in place for 2 or more days in a static work zone i.e. not in a mobile operation.

- The traffic volumes exceed 1500 vehicles/hour for at least 2 hours per day.

- During congested periods, the estimated traffic queue lengths (without the zipper merge implemented) will potentially encroach on upstream intersection/interchange operations.

The Central Office Traffic Division Work Zone section is available as a resource for the use of the WZITS technology.

Queue Warning System

A Queue Warning system is used to inform travelers about upcoming congested or stopped traffic conditions. The queue warning system informs drivers of an impending traffic situation and to avoid emergency braking and queue-related collisions.

This system typically consists of roadside sensors and Portable Changeable Message Signs (PCMS) placed upstream of the work zone. The basic principle of this system is when sensors detect slowing or stopped vehicles, it sends signals to the PCMS where warning signs are displayed advising travelers about an impending traffic queue. The sensors and PCMS should be placed in such a way that if the queue reaches within 1-2 miles (based on the speed and length of work zone) of PCMS, it should start displaying the warning signs alerting the approaching motorists of queue conditions.

Temporary Rumble Strips

Temporary rumble strips are a strategy for reducing distracted driving and achieving MoDOT’s work zone safety goals. Temporary rumble strips are comprised of a series of raised elongated bumps placed upon the surface of the roadway to provide an audible and vibratory alert to drivers of the upcoming work zone.

Speed Warning System

The regulation of speed during construction is necessary to maintain travelers’ and workers’ safety as well as making sure of timely completion of the road work. Speed warning systems are speed displays using intelligent transportation system (ITS) technologies that give the driver information about their speed as well as the posted advisory speed. The speed displays are portable and can be used in the work zone wherever excessive speeding is a problem.

Work Zone Intelligent Transportation System and Temporary Traffic Incident Management System

Through the years, the advancement of technology has produced work zone intelligent transportation systems (WZITS) that can provide real-time data to the traveling public.

Instead of having a person being present to change the CMS or DMS through notification, the WZITS may be equipped with sensors, communication technology, computers, internet connection, etc. This technology can collect traffic volume, speed, etc. and then provide the traveling public with the accurate and real-time information for that particular work zone.

The nonstandard Work Zone Intelligent Transportation System special provision is available as a guide for use in a project.

A WZITS will improve detection in work zones, both by use of CCTV cameras and traffic sensors to monitor traffic flow and determine problem areas.

The prompt detection and clearance of traffic incidents in a work zone aids in avoiding secondary crashes and minimizes associated delays.

A Temporary Traffic Incident Management (TTIM) system can be defined as the coordinated, preplanned use of technology, processes, and procedures to reduce the duration and impact of incidents in a work zone. By significantly reducing the time to assess the incident details and needs, and to notify the appropriate responders, the clearing of the incident will be performed much more expediently.

Travel Time Advisory System

A travel time advisory system consists of travel times through a work zone. Travelers seek accurate, timely, and reliable information regarding their travel routes in a convenient form. Apart from benefitting the individual motorist, travel time information can lead to system-wide benefits when many users respond in a predictable way to the information they received.

The benefits of travel time information for work zones include less stressful conditions for the motorists and more predictable and safe travel conditions.

Work zones are infamous for travel delays and lead to traffic conditions that violate traveler’s expectations. Hence, the usage of travel times becomes important rather than a good-to-have for work zones. Travel time systems gather real-time traffic information in work zones with the help of sensors, video cameras, and communicate the scenario to upstream motorists with the help of portable Changeable Message Signs (PCMS).

The messages of travel time are displayed on CMS activated by the sensors. This information helps drivers understand the magnitude of delay they will encounter and to make an informed decision in how to conduct their travels.

Probe data may be used for travel time measurement where available and volumes provide sufficient sample size.

Travel Time Advisory System with Alternate Routes

On projects where there is an alternate route available which has adequate capacity and minor out-of-distance travel, it may be advantageous to install travel time advisory systems both on the route under construction as well as the alternate route.

This information helps drivers understand the magnitude of delay they will encounter and to make an informed decision in how to conduct their travels. Alternate route travel times can aide travelers in determining whether to travel through a work zone or utilize the designated alternate route.

616.13.6.4 Designated Detour or Relief Route

A project with a designated detour or relief route, when queuing occurs, may provide enough relief to handle the capacity restrictions of a work zone. Over the years, districts have used different strategies of lane reliefs by taking all vehicles or making a separation of light vehicles versus heavy vehicles on the detour or relief routes.

Studies have shown that a typical project may have 5-10 percent of the traffic volume using the detour or relief route on their own initiative. With active guidance (MoDOT personnel, law enforcement, etc.) the detour or relief route volume may be increased. Even though the detour or relief route volume is small, it may be enough to relieve the congestion and allow free-flow traffic.

616.13.6.5 Maintain Same Number of Lanes

For some projects, the capacity of the roadway can be restructured by maintaining the same number of lanes by reducing the lane and/or the shoulder widths.

Depending on the project scope, project duration and traffic delay and impact, adding a lane or utilizing part or all of the shoulder for traffic (shoulder may need to be improved to handle traffic) could be an option for a project to reduce the capacity concerns of the roadway. These decisions should be made early in the planning or design stages, so funds can be designated for this particular enhancement.

Projects with the same number of lanes, in general, provide similar capacities as before the project, which may significantly reduce or eliminate queuing and travel delays.

616.13.6.6 Public Information

Public information (PI) is an important component of transportation management plan within work zones. PI may range in complexity depending on the project location, scope and duration. For example, two projects ranging from a smaller project in the rural area to an urban area or interstate project.

- Rural: Place the information on the Traveler Information Map, CMS boards, local newspaper, social media, and radio station a week or two prior to the start of the project, etc.

- Urban: Place the information on the Traveler Information Map, several media outlets (newspapers, radio stations, television), contact Motor Carrier Service to contact different trucking companies, brochures, CMS/DMS prior to the start and throughout the project, incident response, social media, etc.

The ultimate goal is to provide the earliest information of any congestion concerns to the public, so the travelers can adjust their travel times in an effort to reduce the queuing and delay.

616.13.7 Traffic Pacing

| Traffic Pacing Worksheet |

| Staging Plan Details (Mainline Pacing Details) |

| Traffic Pacing Changeable Message Signs Layout |

Traffic pacing is a traffic control technique that facilitates short duration overhead work operations by pacing traffic at a safe slow speed for a predetermined distance upstream of the work area, rather than being completely stopped. The pacing of vehicles shall be controlled by pilot vehicles (law enforcement vehicles with blue lights flashing) driven by uniformed law enforcement personnel. Any on-ramps or other access points between the beginning point of the pacing area and the work area shall be blocked until the pilot vehicles have passed. Two-way radios shall be used to provide constant communication between the pilot vehicles, contractor’s workers, and the project engineer. Advanced signing warning motorists of the traffic pacing area shall also be provided.

The most applicable location for this technique is on high-volume/high-speed urban and rural freeways and other multi-lane access controlled facilities for work such as overhead utility work, installing overhead sign structures, replacing sign panels, placing bridge girders, and installing cantilever trusses. Utilizing traffic pacing for other types of work should be discussed with Highway Safety and Traffic Division and the Work Zone Coordinator before being allowed.

Preparation of a traffic pacing design shall be completed in order to plan and provide adequate work time to complete the short duration overhead construction. Based on the required work time and other inputs such as traffic volumes, regulatory speed and pacing speed, the traffic control plan defines the allowable pacing hours, pacing distance, location of warning signs, interchange ramp closures and other critical information. The Traffic Pacing Worksheet shall be used when planning to use this traffic control technique, in order to calculate the pacing distance and the time intervals during which a pacing operation may be allowed. Also refer to the Staging Plan Details and Traffic Pacing Changeable Message Signs Layout.