903.16 Design Aspects of MoDOT Signing

903.16.1 Scope of Signs and Signing

Standard. The extent of signing by contract on any project is determined early in the project scope. Structural guide signs and supports (overhead or post-mounted) are paid for by contract, regardless of the type of facility. Sheet signs and supports are supplied by contract for all route classifications and project conditions. Unless otherwise agreed to among departments or divisions, the following are general guidelines for the extent of contract signing.

Guidance. Regulatory and warning signs should be used conservatively because these signs tend to lose effectiveness if they are used to excess. If used, route signs and directional signs should be used frequently because they promote reasonably safe and efficient operations by keeping road users informed of their location.

Support. When preparing signing plans, consistency and coordination with existing signing is critical. This does not mean poor signing should be replaced in kind for the sake of consistency. Consistent application of legend styles, abbreviations, control cities, wording, and arrow placement are important for proper driver guidance and expectancy. This is accomplished by routinely applying standards. Signing is basically for the first-time driver, not repeat traffic. An example of poor signing would be having two advance guide signs for the same exit listing different control cities. Another example would be using local cities for general guidance instead of standard control cities. It is important to have consistent signing throughout the state of Missouri.

Guide sign standards in EPG 903.4, 903.5, and as shown on the standard plans are used whenever possible. Conditions that require deviation from these standards are held to a minimum and justified. Design variances require district justification at the preliminary sign location stage. Signing variances are also noted in the plans. Some deviations from design standards may require approval as outlined in EPG 131.1.

903.16.2 Plan Development Procedure

Standard. The preparation of signing plans requires the cooperation and coordination between the district and Central Office.

When using preexisting structures to accommodate larger new signs, consideration shall be given to the dimensions and load capacity of the existing structure. The larger signs shall properly fit on the existing structure and not exceed the structure’s design capacity.

When the need arises to modify the legend of a sign not built to current standards, the entire sign shall be replaced.

Guidance. Bridge Division should be consulted for mounting signs directly on bridges and other structures.

Sign visibility from a distance is critical. Sign locations should be coordinated with other design features that include, but are not limited to bridges, highway lighting, traffic signals, drainage structures, overhead utilities, underground utilities and horizontal and vertical alignments that decrease sign visibility.

The district should prepare proposed sign locations and review the plans for standards and quality control.

When the sign is mounted on a truss, all signs on the truss not built to current standards should be replaced after considering the age, future conditions and detail of the sign.

It is recommended that all non-standard signs be identified, with justification for the non-standard designs.

For preliminary discussions, only the sign location plan showing existing and proposed signing is recommended. Sign details, cross-sections, tabulation sheets, computer generated sign designs or other detailed information should not be completed at this time. Once the preliminary location plan is agreed on, the district is to prepare D-29 and D-30, truss data sheets and template cross-sections for trusses and post-mounted signs. Truss cross-sections should not be drawn on the same sheets as ground mounted sign cross-sections. The districts, or consultants, are responsible for accuracy of the preliminary and final detail design.

The district finalizes the plans and is to submit them to Design with the roadway plans, or as a separate project if so programmed. Typical signing location plans for interchanges are shown in EPG 903.15. Design Division is available for consultation during any part of the plan preparation process.

All non-standard and special signs are detailed by Central Office Highway Safety and Traffic and the district, or consultant, is responsible for incorporating the signs in Form D-31. A Sign Design Order Form (Design Form D-28) should be completed for all non-standard and special signs and sent to the signing section of Central Office Highway Safety and Traffic, allowing 30 working days for the review and design to be completed. Each sign should be identified as an overhead or post-mounted sign. Traffic should be provided with a date the sign designs need to be returned for review. The return date needs to allow enough time to design and quantify the trusses, bases and posts.

Option. Central Office Design or Highway Safety and Traffic Division may provide comments on the preliminary layout at the district's request. It is suggested that districts form review teams from various departments to review plans at the preliminary layout stage, and at final design. After the district reviews plans, Design Division may be consulted for review at the district's discretion.

Two or more segments of alignment may be shown on one sheet. For ease of design, review and construction, sign locations for interchanges are completely shown on one sheet.

In complex areas where many signs exist and will be replaced, proposed signing and existing signing may be shown separately on different plan sheets to avoid clutter and plan confusion; however, combined is preferred, if possible.

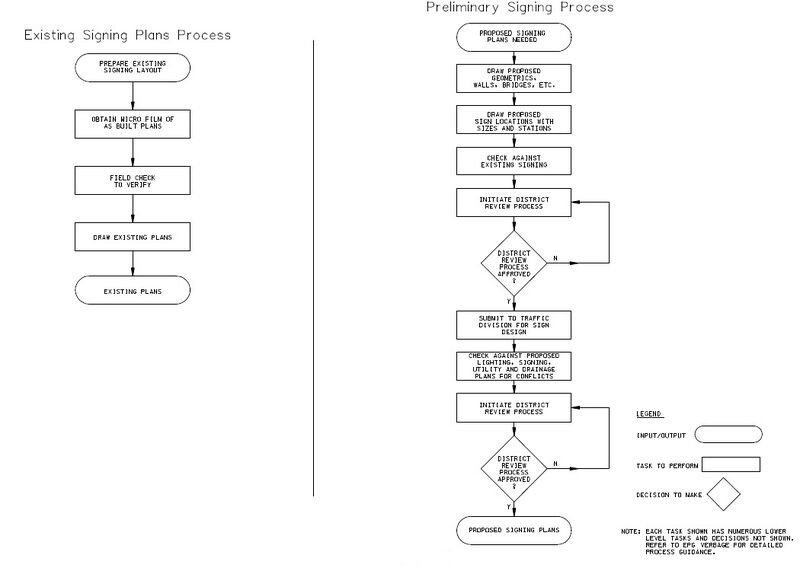

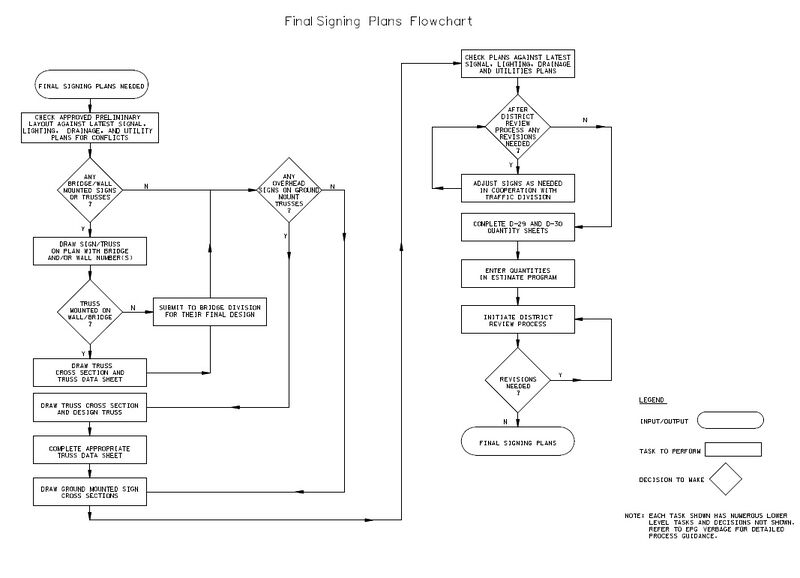

Support. Figure 903.16.2.1 and 903.16.2.2 show the steps taken from early plan development to final design.

|

|

Location plans show the proposed pavement geometrics, the sign location, sign number, station, width and height, sign code (if applicable) and special or standard legend. Sign sizes are shown as width x height, in feet and/or inches for sheet signs, and in feet only for structural signs. Tabulated removals and general information are shown for existing signs. The standard sign code (e.g. R5-1a, W10-1, etc.) is shown for signs found in the SMS Sign Catalog.

Signs are numbered in a logical order. Existing signs that are removed or remain in place are not numbered. Multiple signs on a single mount are further indicated with lower-case letters (e.g. 45(a), 45(b), 45(c)). If signs are added or deleted at a later date, renumbering all signs is not required. If signs are added, signs may be numbered 43, 43A, 43B, etc., or the next highest sign number may be used. If signs are deleted, a general note listing voided signs is provided.

Existing signs are shown with dashed lines and are listed as a removal item where appropriate. Existing signs to be relocated to new posts and new signs on existing posts are numbered and noted as such. Existing signs in poor condition should be replaced.

When replacing signs for many miles of roadway to be let in sections, it is desirable to generate an overall sign location plan to coordinate guide sign placement through numerous projects. For this situation it is not necessary to show signs other than guide signs. It is recommended to show the limits of each project on this location plan. Signs are identified as truss, bridge- or post-mounted or as strapped to a signal post or column. If applicable, truss type (cantilever, span and butterfly) and location are shown. Whether the truss is box or tubular does not need to be noted on preliminary location plan, but is shown on the final plan. A standard legend identifying symbols is used to alleviate crowding on plans. Typical location plans at interchanges are shown in EPG 903.15.

When staged projects are scheduled in unison or closely together, complete signs are provided with the inappropriate legend covered until needed. Legends to be covered are noted on the plans, and the engineer is to approve the covering method. No direct pay is made for covering legends. When structural signs should be erected with only part of the legend in place at the initial time of construction, the sign and legend are shown on the plans with solid lines, and the legend to be placed at a later date is shown with dashed lines. A note is included indicating the dashed legend will be provided by future construction. The omitted legend is included in the roadway contract, which completes the sign.

When the legend of an existing sign built to current standards is modified, the existing sign and legend are shown with dashed lines and the legend to be added is shown with solid lines. Sufficient information is provided to show series, type, size and spacing of new legend on the sign detail sheet.

The district prepares tabulation sheets on Forms D-29 (Sign Posts, Footings, Delineators and Mileposts), D-30 (Signs) and Data Sheets D-32, D-33 and D-34. These forms are available as MicroStation seed files.

On Form D-29, all signs are listed in order according to sign number. This form includes truss footing and pedestal concrete quantities.

On Form D-30, all standard signs are totaled on the left-hand side of the sheet. The right-hand side is used to list special signs and provides an overall summary of all sign types.

Truss data sheet forms are completed for all trusses. Form D-32 is used for cantilever and butterfly box trusses. Form D-33 is used for span and span-cantilever box trusses. Form D-34 is the truss data sheet used for all tubular sign supports.

Design variances require district justification at the preliminary sign location stage. Signing variances are also noted in the plans. Some deviations from design standards require approval.

Overhead sign support structure foundations are not placed in gore areas or other areas with high exposure to traffic. See EPG 903.17 for additional overhead sign support structure information.

903.16.3 Types of Fabricated Signs

Support. There are two types of sign material available, structural (ST) and sheet (SH).

Sheet signs are sheet aluminum, usually one-piece units, and have several available thicknesses as indicated in the standard plans.

Structural signs are usually made of multiple extruded panels. These signs are used primarily for guide signs on expressways and freeways, but may be found on other routes on a limited basis, and are used on all overhead-mounted signs, including “LOW CLEARANCE” and exit number panels, signs greater than 6 ft. wide, and signs greater than 30 sq. ft. in area.

Extruded panels are composed of a 1 ft. tall "E" shaped aluminum substrate, assembled to a desired height and cut to a uniform width for each sign. These panels are bolted together to form the larger “blank” substrate needed for structural signs.

There are two types of reflective sheeting available to MoDOT:

- MoDOT Type III High Intensity Prismatic (R2)

- MoDOT Type VII Prismatic (R4).

Guidance. Generally, R2 sheeting should be used on all sign backgrounds. R3 sheeting should be used on all legend and symbols on guide signs.

903.16.4 Ground Mounted Sign Supports

903.16.4.1 Ground Mounted Sign Installation

Guidance. Signs should be ground-mounted whenever possible unless mounting overhead is justified or required.

Standard. If signs are placed on existing supports, they shall meet other placement criteria contained in this article.

Utility and light poles shall not be used to mount signs as they are either not the property and maintenance responsibility of MoDOT or are not designed to carry the additional wind loading a sign adds to the structure.

Option. In areas with space restrictions, available sign truss columns, signal poles, bridge columns, or other significant MoDOT structures, excluding roadway lighting structures, may be used to mount flat sheet aluminum signs.

903.16.4.2 Lateral Offset

Guidance. The provisions below should be applied unless specifically stated otherwise in the EPG for a particular sign or object marker. See Figures 903.1.13.1 and 903.1.13.2 which illustrate typical examples of the lateral offset requirements contained in this portion of the article.

Maximum offset will depend on roadway geometrics, profiles, and cross-sections, which all affect the visibility of the sign. Signs are generally to be placed no more than 15 ft. from the edge of shoulder.

Ground-mounted signs placed in a gore only requires a minimum of 2 ft. lateral offset from edges of shoulder, face of barrier walls or guard rail.

For divisional and channelizing islands, a 2 ft. lateral offset should be maintained between the edge of sign and the front face of curb. For islands with restricted width the sign should not extend beyond the curb face.

Option. Deviation from the standard lateral offset may be used if a signs effectiveness and visibility are maintained to account for variations in roadside features. For example, to avoid placing signposts in the flow line of a ditch, avoiding drainage structures, pull boxes or sidewalks.

Option. Lesser lateral offsets may be used in business, commercial or residential areas where limited space is available to place signs due to limited right of way, sidewalks or other restrictions which keep the sign from being installed at the correct offset. In these cases, the edge of the sign may be placed up to, but not beyond the face of the curb making every effort to maximize the offset with the space available.

Support. See EPG 903.1.16 for additional information on Lateral Offset.

903.16.4.3 Mounting Height

Support. See EPG 903.1.15 for additional information on Mounting Height.

903.16.4.3.1 Mounting Height – U-Channel, Wood, Perforated Square Steel Tube (PSST), Pipe Posts and 4 in. Square Steel Posts

Support. There are typically two mounting heights for signs on u-channel, wood, PSST, pipe posts and 4 in. square steel posts, 5 feet and 7 feet. Traditionally, the 5-foot mounting height has been applied to “rural” areas and the 7-foot mounting high applied to “urban” areas or within incorporated city limits. However, the term “urban” has more to do with the conditions the signs are being installed within and less about being located within an incorporated city limit. The purpose of the 7-foot mounting height is to provide clearance for passing bicycle and pedestrian traffic, making the sign more visible over parked vehicles along the roadway and permits improved sight distance to drivers permitting them to see below the sign.

Standard. Standard Plans 903 shall be referenced for specific installation and mounting height details. The details in Standard Plans 903 and EPG 903.16.4 shall apply to all signs unless specifically stated otherwise for a specific sign or object marker elsewhere in the EPG.

The minimum mounting height of a sign shall be measured vertically from the bottom of the sign to the elevation of the near edge of the pavement. Minimum sign mounting heights shall be as follows:

- Sign located in rural areas – 5 feet,

- Sign located in urban areas – 7 feet,

- Signs located on freeways and expressways – 7 feet.

The length of post measured from the bottom of the sign to the ground shall also be a minimum of 5 feet. If the length of any post within a sign assembly measures less than 5 feet from the bottom of the sign to the ground, the minimum sign mounting height shall be increased to achieve the minimum 5-foot post length.

Option. Signs may be installed at 5 feet within the boundaries of incorporated city limits if the all following conditions apply:

- The sign is located outside of business, commercial or residential areas where there are no high densities of entrances and cross street intersections

- There is no on street parking

- There are no sidewalks with bicycle or pedestrian traffic

If a secondary sign is mounted below the primary sign on the same signpost(s), the mounting height for the assembly, measured from the near edge of the pavement to the bottom of the secondary sign, may be 1 foot lower than the minimums listed above.

Guidance. Signs located outside of incorporated city limits that are located in areas having characteristics of an urban area, such as around businesses, heavy residential areas, areas with on street parking and areas with sidewalks which support bicycle and pedestrian traffic, should be installed at 7 feet.

Support. Figure 903.1.13.1 illustrates typical examples of the mounting height requirements contained for signs installed on U-Channel, Wood, PSST and Pipe Posts.

903.16.4.3.2 Mounting Height – Wide Flange (I-Beam) Posts

Support. Installing signs at the proper mounting height is critical not only for the sign to be seen and function, but also to the functionality of the breakaway design. Proper mounting height is more critical for breakaway function on Wide Flange posts compared to all other posts due to the hinge component of this post design. As with the other post types, mounting heights for Wide Flange posts are listed as “nominal” as excessive mounting heights have the same negative effects for these installations as exists with the other post types. Wide Flange post mounting heights are greater than other posts, so in areas with back slopes it is recommended to seek out a flatter location in advance or downstream of the original installation to keep the sign as low as possible.

Minimum mounting heights for Wide Flange post installations are not related to rural or urban classifications, but are directly related to how the breakaway system functions. Standard Plans 903 provides details on the nominal mounting heights on wide flange posts. Key details to focus on are:

- No wide flange post can be shorter than 7’ 9” measured from the hinge to the top of the stub.

- The hinge point is always below the lowest sign which is attached to the wide flange post.

- Nominal mounting heights vary depending if there is one sign mounted on the posts or two.

- For signs located in areas of back slopes, the minimum mounting height may have to be increased, or the sign installed in a different location, in order to achieve the minimum post length of 7ft. 9 in

Support. See EPG 903.1.15 for additional information on Mounting Height.

903.16.4.4 Ground-Mounted Sign Support Selection

Support. The majority of MoDOT signs are installed and supported on one of 5 types of ground-mounted sign supports or signposts. The selection of signpost is based on many factors, but primarily on the size of sign being installed and the type of roadway the sign is being installed along. There is some overlap in signpost applications; more than one signpost may be applicable to a given installation. The final selection of the post type is based on the attributes needed for a support as discussed in each classification of signpost below.

The number of posts needed to support a sign is primarily based on the width of a sign. Typically, signs 48 inches wide and wider are installed on two or more posts. This requirement is based on two factors, the capacity of the post and the long-term stability of the assembly. A wide sign installed on one post will place a torsional force onto a post and in windy conditions can result in an assembly not staying plumb and, in some cases, an actual failure of the post itself.

Standard. The selection of the proper size of signpost shall be based on the Signpost Selection Guide listed above. These tools will specify if a post type has the capability to support the sign in question and then specify what size post is required based on the requirements of the installation. Before the correct size of PSST or Wide Flange post can be selected, the length of the longest post must first be determined. To determine this, the offset and mounting height must first be determined.

903.16.4.4.1 U-Channel Posts

Support. MoDOT utilizes two primary sizes of U-Channel Posts, a 3 lb/ft high carbon, rerolled rail steel post for sign installations and a low carbon steel 1 lb/ft post for road side delineation.

U-channel posts can be used to support MoDOT’s small signs, such as no parking signs, object markers and chevrons on two lane roadways. U-channel posts are typically not suited to support larger permanent signs as they have limited torsional rigidity and have less ability to hold a larger sign steady in windy conditions. These are typically the most economical posts to use to support smaller signs and given these types of signs tend to be installed closer to the roadway their ability to yield more easily to impacts means they pose less of a damage risk to vehicles. U-channel posts are typically installed by driving the post into the ground without a stub or anchor, however, there is a stub / post installation option available which is detailed in the standard plans.

U-Channel posts are considered breakaway with no additional breakaway devices needing to be added. While there are breakaway devices available for U-channel posts, MoDOT’s use of this type of post for smaller signs typically doesn’t justify their use. A U-channel post’s breakaway is typically a yielding function, meaning as a vehicle impacts the assembly, the post yields and lies down in front of the vehicle so it can pass over the assembly.

Standard. U-channel posts shall be installed in accordance with the details found in Standard Plans 903. Signpost selection tools shall be used to determine sign sizes U-channel posts can support and the number of posts needed.

903.16.4.4.2 Wood Posts

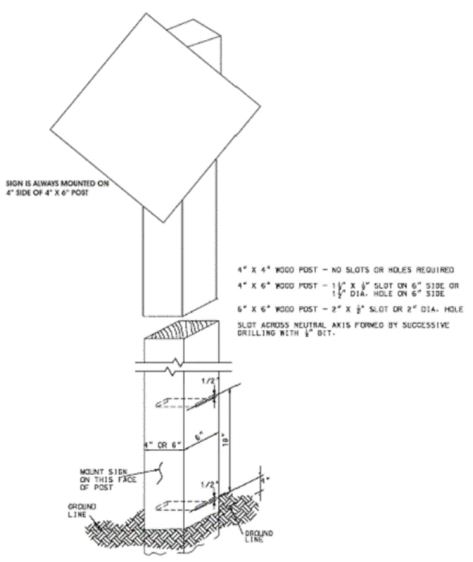

Support. MoDOT’s specs permit three sizes of wood posts to be used: 4 in. x 4 in., 4 in. x 6 in., or 6 in. x 6 in. MoDOT’s wood posts are pressure treated to promote longer life and resist rot and insect damage. Wood posts were once MoDOT’s primary post to support signs on two lane roadways; however, due to issues with material stability PSST posts have become MoDOT’s standard post.

When used, wood posts are capable of supporting most sign assemblies on two lane roadways, from route marker assemblies, speed limit signs, warning signs and distance and destination signs. The use of a high quality wood post and proper installation is the key to a successful installation.

Guidance. The continued use should take into consideration the special characteristics listed in EPG 903.16.4.

Proper installation is also critical for the stability of the sign assembly. The wood post should be placed a minimum of 36 inches into the ground, deeper for larger signs or in areas where the soil is weak or sandy, to keep the signpost plumb. When backfilling the hole, material should be added in lifts, or levels, in order to properly compact the backfill. Loose or fine materials, such as sand, sandy soil or dry concrete mix typically will not provide a long term solid backfill and can result in the post falling out of plumb over time.

MoDOT’s specifications should be followed when purchasing wood signposts. These specifications address a posts load capacity, breakaway attributes and the compatibility between the pressure treatment chemicals and our aluminum signs and sign hardware.

Option. While the soil originally removed from the hole can be used to back fill around the post other alternatives may be used, such as smaller quarry rock with the crushing fines mixed in, concreted mix or expanding polyurethane foam.

Support. Wood posts are considered breakaway without an add-on breakaway device; however, some sizes of post do need special preparation. 4 in. x 4 in. wood post are considered breakaway without any special modifications; however, 4 in. x 6 in. and 6 in. x 6 in. posts must be cross drilled at the base to weaken them so they will break away. The size of the holes and where they are drilled is critical to these posts meeting breakaway requirements. The details for these holes are found in the Standard Plans 903, it is important to note these breakaway holes are drilled in the sides of the post, not in the front of the post where the sign is mounted.

Standard. If wood posts are used, the proper size and number of posts shall be determined by using the post selection tools.

History. One of the earliest issues experienced with wood posts is their tendency to warp and twist, both before and after installation. Keeping a sign plumb and appropriately oriented to the roadway is critical to maintain the sign’s legibility and night time retroreflectivity performance. This aspect of wood posts resulted in significant waste of inventory when the posts warped and twisted before being used and increased work load on signing crews who had to correct warped and twisted posts after installations. Another concern with the use of wood posts was the installation required a hole to be dug, the posts set and property back filled so the sign would remain upright. If soil conditions prohibited a hole being dug deep enough or the back fill not capable for being compacted sufficiently the assembly would fall out of plumb. Along with these installation aspects, a wood post sign assembly can be very heavy, especially when the pressure treated wood is still wet with the pressure treating fluids and this can result in the need for additional people to set the post and/or increased risk of injury setting the post by hand.

Towards the end of MoDOT’s reliance on wood posts a new issue was identified relating to the more environmentally friendly treatment process called ACQ (Ammoniacal Copper Quaternary). ACQ replaced CCA (Chromated Copper Arsenate) for residential applications as CCA had chemical component which were not recommended for routine contact with skin. However, unlike CCA, ACQ (especially early versions) turned out to be very corrosive to metals, especially to aluminum. This corrosive nature requires special fasteners to resist this corrosive effect. Early applications of ACQ in other states realized serious sign corrosion to the point the sign would fall off the post in a matter of a few years. While it appears this has improved, special fasteners with special protective coatings are still recommended for use with ACQ posts. As a result, ACQ posts do not meet MoDOT’s specifications and should not be used to support signs. CCA treated posts are still MoDOT’s standard for wood posts, however, it is not commonly available at local home improvement centers and at many lumber yards. Due to MoDOT’s limited use of this product contract purchasing typically is not economical or possible.

903.16.4.4.3 Perforated Square Steel Tube Posts (PSST)

Support. MoDOT utilizes two sizes of PSST posts, 2 in. and 2.5 in., both being made from 12-gauge steel. PSST became MoDOT’s standard post for most sign installation applications on two lane roadways in the early 2000’s, replacing wood posts. PSST usage has since expanded to some applications on freeways and expressways.

Unlike U-channel or Wood posts, PSST utilizes a ground anchor, or footing, within which the post is then placed. MoDOT has several options in its specifications with respect to ground anchor/foundation systems, the use of each option is heavily based on the soil condition.

The anchor/footing types for PSST are:

- 12-Gauge PSST Anchor – this is the basic direct-driven anchor for 2 in. PSST posts. A 12-gauge anchor does not exist for 2.5 in. PSST posts.

- 7-Gauge Anchor – this is a heavy wall box tube anchor which is the basic direct-driven anchor for 2.5 in. PSST posts. It is also an optional heavy anchor for 2 in. PSST posts in rocky ground where a 12-gauge anchor may deform when driven. The 7-gauge anchor is also the anchor that must be used when installing a concrete or polyurethane footing.

- Omnidirectional, or stabilization, Anchor – this is the appropriate 12-gauge or 7-gauge direct-driven anchor with 4 soil stabilization plates added to the anchor to increase soil surface area to help keep signs plumb in weaker soils and/or in windy areas. A JSP will be needed to specify this anchor type on a project.

- Concrete Footings – In some applications it may be desired to install a concrete footing for PSST, similar to the footings for Pipe Post or Wide Flange Post. Concrete footings provide a stronger foundation compared to the directly-driven anchors listed above. A concrete footing may also be required in cases where the ground is too hard or rocky to direct drive the anchor and a hole may need to be dug in order to install the anchor. All concrete footing installations use a 7-gauge anchor (that only has holes at the top of the tube) because concrete would flow through the holes of a normal 12-gauge PSST anchor.

- Polyurethane Foam Footings – This is an alternate to a concrete footing for PSST post installations. This permits the footing and the sign to be installed in one trip compared to concrete, which requires a second trip to allow the concrete to cure. The installation requirements for an expanding foam footing are the same as a concrete footing except for the diameter of the footing, which is smaller. It is important to make sure the expanding foam used meets MoDOT specifications as not all foam products are acceptable to support a breakaway sign.

The connection between the PSST posts and anchors varies based on the anchor gauge:

- 12-gauge anchor – The connection between a 12-gauge anchor and the PSST post is accomplished using a corner bolt. The corner bolt pulls the post into a corner of the anchor and eliminates any slack or play between the post and the anchor.

- 7-gauge anchor – The fit between a 7-gauge anchor and the PSST post is much looser and the radii of each do not match so a corner bolt will not eliminate the slack or play between these two devices. Shoulder bolts installed at 90-degree angles corrects this issue; the shoulder of the bolt will pass through the holes in the 7-gauge anchor, but not through the holes in the post. As a result, the two bolts push and lock the post in two directions making a solid connection.

- Add-on breakaway devices – when required/used, the manufacture’s recommendations and hardware (if supplied) need to be used to connect the anchor, breakaway and post together.

| POST AND ANCHOR DATA TABLE | ||||||

|---|---|---|---|---|---|---|

| POST | ANCHOR | BREAKAWAY REQUIRED | ||||

| NUMBER OF POSTS | ||||||

| GAUGE | SIZE | GAUGE | DIMENSIONS | 1 | 2 | 3 |

| 12 | 2" x 2" | 12 | 2.25" x 2.25" x 36" | NO | NO | YES |

| 7* | 2.5" x 2.5" x 36" | NO | NO | YES | ||

| 12 | 2.5" x 2.5" | 7 | 3 x 3 x 36" | NO | YES | YES |

| 12 | (2.5"x2.5")+(2.25"x2.25") | 7 | 3 x 3 x 36" | YES | YES | YES |

Breakaway aspects of PSST are a little more complicated compared to other MoDOT posts, the requirement for an add-on breakaway device heavily depends on the size and number of posts needed to support the sign. It is important to follow the guidance found in the signpost selection tools and MoDOT’s standard plans to determine when an add-on breakaway device is required and when it is not. In applications where add-on breakaway devices are not required/used, PSST breaks away like a U-channel post in a yielding fashion, typically staying attached to the ground and lying down in front of the vehicle so the vehicle can pass over the assembly. However, when an add-on breakaway device is used the breakaway function changes and the assembly is designed to break away from the ground and permit the vehicle to pass under the airborne assembly.

Standard. If PSST posts are used, they shall be either 2 in. or 2.5 in. 12-gauge posts. The size and number of posts, as well as the requirement for add-on breakaway devices, shall be determined using the post selection tools. PSST posts shall be installed in accordance with Standard Plans 903. PSST posts installed on freeways, expressways, and ramps shall be installed using concrete footings.

Guidance. District operations should be consulted to determine the most appropriate footing for PSST posts alongside other roadways as footing requirements vary based on soil conditions.

903.16.4.4.4 Pipe Posts

History. In 2022, a pipe post capacity evaluation was conducted that resulted in a change to the pipe post load capacity and pipe post inventory. Historically it was believed that pipe posts could support a sign size of up to 30 sq. ft. but the evaluation determined pipe posts could support a sign of up to 58.5 sq. ft. The evaluation also determined that the 3 sizes of pipe post being utilized were redundant. MoDOT historically used 2 ½ in., 3 in., and 4 in. pipe posts, however, the evaluation determined that the sign capacity of a post is determined by the breakaway assembly. The 2 ½ in. and 3 in. pipe posts used the same breakaway design and therefore the 3 in. pipe posts did not have any additional capacity over the 2 ½ in. post. As a result, the 3 in. post is redundant and was discontinued. This decision allows for a simplified inventory and eliminates confusion on pipe size. Maintenance can continue to utilize 3 in. pipe posts until the inventory is depleted but shall not order new 3 in. pipe posts. All existing 3 in. pipe posts shall be treated as 2 ½ in. posts for purposes of choosing posts using the post selection tables. 2 ½ in. pipe posts can be installed on existing 3 in. stubs.

Support. MoDOT utilizes two sizes of pipe post, 2 ½ in. and 4 in. An important fact to understand is pipe post sizes are based on the inside diameter (I.D.) of the pipe post and not the outside diameter, this is the industry standard for pipe measurement. This is critical in selecting the correct pipe from inventory as well as charging out the correct post to keep your inventory levels correct.

Pipe posts have a similar sign capacity as PSST, even though they would appear to be able to carry a larger sign load due to size and thickness of the steel pipe. While the post themselves are far stronger than PSST, it is the breakaway of the pipe post which controls the sign load capacity of the post. The heavy-duty construction of a pipe post is not specifically related to sign load capacity but is more directly related to the durability of the post. Unlike PSST, which must be replaced after each vehicular impact, pipe posts are constructed with much thicker steel so the signpost can be impacted by a vehicle without being damaged and reinstalled for continued use. There are many pipe posts on our right of way that have been there for two or three generations of signs and are still functional so while they are heavier and more expensive, they are a long term investment and are far more durable.

Pipe posts are used for single and double signpost assemblies to support signs up to 58.5 sq.ft. These posts are typically used on freeways and expressways where signs are larger, wind speeds can be higher due to more open right of way and the sign may see larger snow load impact from plows pushing more snow from across multiple lanes to the right side of the roadway.

Pipe posts are also the preferred post to support large route assemblies, especially on freeways and expressways. In the past, Wide Flange posts were once used to support these assemblies (and many remain in place) as the design of the post was well suited to attaching a series of backing bars needed to support the assemblies. However, the multi-direction breakaway and high resistance to torsional or twisting forces makes pipe posts the preferred post over the Wide Flange design.

Pipe posts are designed and fabricated with the breakaway device as part of the post / stub combination; as long as the post and stub breakaway is assembled correctly the post is capable of being impacted from any direction. Details for the assembly of this post system are found in Standard Plans 903, special attention must be paid to the placement of three breakaway bolts, the required and proper placement of all washers within the breakaway and most critically to the proper tightening and torque of the breakaway bolts.

Standard. If Pipe posts are used, they shall be either 2 ½ in. or 4 in. in size. The size and number of posts shall be determined using the post selection tools. Pipe posts shall be installed in accordance with Standard Plans 903.

903.16.4.4.5 Wide Flange (I-Beam) Posts

Support. MoDOT uses 6 sizes of Wide Flange posts, commonly referred to as Design #1, #2, #3, #4, #5 and #6, increasing in size and capacity respectively. Wide Flange posts are typically used to support signs 30 ft2 and larger and are MoDOT’s highest capacity ground-mount sign support. As with Pipe Posts, Wide Flange post are designed to be a more durable post intended to last multiple generations of signs and designed to be able to be impacted by vehicle and then reassembled and reused.

Wide Flange post are designed and used to support large structural signs, signs made using extruded aluminum panels instead of flat sheet aluminum. The cross section of a wide flange post being that of an I-beam permits structure signs to be easily attached to the post using post clips or “dog clamps” instead of using traditional sign bolts. These posts are traditionally used on freeways and expressways only; however, there may be special applications where they may be used on two lane roadways if the size of the sign is too large for other post options.

Wide Flange posts were once the standard to support large route assemblies on freeways and expressways, however, over time two weaknesses were identified that changed this direction, making Pipe posts the better option. The two weaknesses of Wide Flange posts used to support route assemblies are:

- Safety - Route assemblies many times are installed in and around intersections and in these locations it is theoretically possible some assemblies could be impacted from any direction of travel. Single Wide Flange posts are only breakaway in two directions and are not designed to be breakaway if impacted on either side, just the front and back of the sign. Pipe posts are designed as a multi-breakaway post and can be impacted from any direction making them the better option for these installations.

- Torsional / Twisting Force Resistance – Although Wide Flange posts are very strong, they do have a limited resistance to twisting moments when installed as a single post installation. In wind prone locations, sign assemblies on a single Wide Flange post can begin to twist in the wind, and if this continues long enough, it can cause the post to fatigue and break off at the base. Pipe posts have an extreme resistance to twisting and can resist much larger torsional forces compared to wide flange posts.

As with Pipe Posts, Wide Flange posts are fabricated with the breakaway system as part of the post / stub assembly. While Wide Flange posts have a breakaway assembly at ground level like Pipe posts, they also require a hinge system located directly below the sign. The hinge system permits the wide flange post (the portion from the ground to the bottom of the sign) to swing up out of the way of a vehicle when impacted without the upper portion of the post and the sign needing to move. This reduces the mass that a vehicle must move when it impacts the post and in return reduces the impact energy to the car.

Unlike all other MoDOT posts, there are minimum post spacing which must be taken into consideration when selecting the correct number and size of post. Wide Flange Posts are much heavier than any other MoDOT post and hitting two of these posts at the same time in most cases would impart too much energy to the vehicle and would not meet minimum breakaway standards. These special considerations are included in Standard Plans 903 which contains all of the fabrication and installation details for Wide Flange Posts, however, due to their critical nature they are also listed here:

- Wide Flange Post Designs #1 and #2 have no minimum post spacing requirements.

- Wide Flange Post Designs #1 or #2 shall not be installed in three post configurations supporting signs less than 11 feet width.

- Wide Flange Post Designs #3, #4, #5 and #6 shall be spaced at least 7 ft. apart.

The post selection tool is designed to utilize two post installations over three post installations to help address minimum post spacing; it also reduces the number of footings which need to be constructed. However, there are some general rules based on sign size used to judge the number post for different size ranges of signs:

- Signs between 6 ft. and 17 ft. wide will typically be supported on two posts

- Signs wider than 17 ft. will typically be supported by three posts

- Signs of any size are not recommended to be installed on one Wide Flange post

Standard. If Wide Flange posts are used, they shall be either a structural #1, #2, #3, #4, #5 or #6 in design. The size and number of posts shall be determined using the post selection tools. Wide Flange posts shall be installed in accordance with Standard Plans 903.

903.16.4.5 Secondary Sign Supports – Post Extensions

Support. These supports are 3 in. aluminum I-Beam used to attach exit number panels to the top of, or to hang a secondary sign below, structural signs on new installations. Details of these posts are shown in the Standard Plans 903.

Option. There are occasions where modifications and/or additions must be made to existing sign installations where the existing posts are not long enough to support the new sign assembly. In these cases, it is permissible to utilize secondary sign supports to effectively extend the primary signposts to support signs a maximum of 3 feet taller than the existing primary signposts.

Secondary sign supports may only be used to allow taller signs to be installed on existing signposts if the signposts have the capacity to carry the larger sign based on signpost selection tools.

If a new sign assembly is more than 3 ft taller than the existing primary signposts, new signposts shall be installed.

903.16.4.6 Backing Bars

Support. Backing bars are typically used to support and stiffen wide flat sheet signs mounted on single signpost or to help support the individual signs which make up sign assemblies to form one unified sign assembly. Details for backing bars can be found in Standard Plans 903.

903.16.4.7 Breakaway Assemblies

Standard. All signposts installed on right of way shall meet federal breakaway standards and MoDOT standards. Signposts not meeting current standards, but met the standards at the time of their installation, may remain in place until the end of their service life.

Sign trusses and other large sign support structures that are not breakaway shall be protected by acceptable shielding, such as guard rail or barrier wall.

Support. 4 in. x 4 in. wood posts do not need any modification to be breakaway, however 4 in. x 6 in. and 6 in. x 6 in. wood posts will need to be cross drilled to meet breakaway standards. U-Channel posts do not require breakaway modifications if they are direct driven into the ground, however, if the ground stub and slice installation method is used the installation will need to be installed according to the Standard Plans 903 to meet breakaway requirements. PSST will require breakaway devices added in certain applications based on sign and number of posts used for an installation. The signpost selection tools will indicate when a breakaway is required for PSST posts. Pipe and Wide Flange posts have the breakaway devices integrated into the post design.

903.16.4.8 Sign Orientation

Support. The orientation of the face of a sign in relation to the driver and roadway is critical to visibility and legibility, especially at night. The effectiveness of the retroreflective sheeting on a sign can be negatively impacted if the orientation of the sign face is not correct, due to incorrect installation and/or a signpost being damaged and knocked out of alignment.

The orientation of a sign can also help reduce unwanted reflection or glare off of the sign face. The skew angle, shown in Standard Plans 903, is designed to help address this glare issue for tangent sections.

Option. While the standard skew angle is 93 degrees, the skew angle may be adjusted to maintain brightness and avoid glare for signs on curved sections of road.

Support. See EPG 903.1.17 for additional information on Sign Orientation.

903.16.4.9 Sign Mountings

Support. Attaching a sign properly to a sign support is critical in order to properly orient the sign in relation to the driver as well as provide a durable, long life installation.

Standard. Plastic/nylon washers shall be used between the heads of all twist fasteners (such as screws, bolts or nuts) and the sign face to protect the sheeting from the twisting action of the fasteners.

Signs shall be attached to each type of sign support in accordance with Standard Plans 903.

Support. See EPG 903.1.18 for additional information on Sign Mountings.

903.16.5 Signing Plans

Standard. When signing is a separate project, the plans are assembled in the following order:

- title sheet

- quantity sheets for roadway items

- sign location plan sheets

- special sheets

- traffic control plans

- erosion control plan

- tabulation sheet (D-29)

- tabulation sheet (D-30)

- special sign detail sheets (D-31)

- design data sheets for cantilever and butterfly box trusses (D-32)

- design data sheets for overhead span box trusses (D-33)

- design data sheet for tubular trusses (D-34)

- truss cross-section sheets

- cross-sections for post-mounted signs

- special sheets for bridge-mounted signing

Typically, signing is included with the roadway plans. When this is the case, the plans are assembled together, including the quantity sheets. Separate quantity sheets shall not be generated for signing quantities. The signing plans shall be arranged in the following order:

- sign location plan sheet

- tabulation sheet (D-29)

- tabulation sheet (D-30)

- special sign detail sheets (D-31)

- design data sheets for cantilever and butterfly box trusses (D-32)

- design data sheets for overhead span box trusses (D-33)

- design data sheet for tubular trusses (D-34)

- truss cross-section sheets

- cross-sections for post-mounted signs

- special sheets for bridge-mounted signs

- any miscellaneous special signing detail sheets.

903.16.6 Quantity Computations

Standard. Signs and posts will each be paid for individually. This includes emergency reference markers and object markers. Combined unit prices for sign and support combinations have been discontinued. All signs including stop signs, object markers, emergency reference markers and signal signs shall be totaled on Form D-30 in four categories: Flat Sheet (FS), Flat Sheet Fluorescent (FSF), Structural (ST) and Structural Fluorescent. Structural signs’ width and height are designed to the nearest foot. Each standard, non-standard or special sign shall be calculated to the nearest 0.1 sq. ft., subtotaled to the nearest 0.1 sq. ft., and final pay total should be to the nearest 1.0 sq. ft.

All post quantities shall be calculated and totaled on Form D-29. All post lengths shall be calculated in increments of 0.25 ft. including the length that extends into the concrete footing or ground as shown on the standard plans. All U-channel post lengths shall include the full length of both pieces when overlaps are required. The post length for wide flange and pipe posts shall be multiplied by the pounds per foot (lb/ft) factor, as shown in the standard plans; each sign's posts are subtotaled to the nearest pound; all sign posts are subtotaled; and the final pay totals are shown to the nearest 10 pounds. All U-channel, wood and perforated square steel tube post length quantities shall be totaled and rounded to the nearest foot. For perforated square steel tube posts, an additional pay item shall be included for the anchor sleeve which is paid for by the linear foot for each post used (and may also include a soil plate). See the Post and Anchor Data Table in Standard Plan 903.03 to select the necessary anchor size. Omni-Directional anchors may be used for installation in weak or loose soil conditions.

Concrete for sign support structures shall be totaled on Form D-29. Concrete for overhead structure foundations shall be bolted down. Concrete for all post-mounted sign foundations shall be embedded. Bolted down and embedded quantities shall be calculated for each sign to the nearest 0.01 cubic yard, subtotaled to the nearest 0.01 cubic yard and a final pay total is shown to the nearest 0.1 cubic yard.

Cantilever and butterfly tubular support trusses shall have standard pay items. Span tubular trusses shall require special pay items. Information in the description shall include span length, truss number and span design type. Structure pay items shall include costs for all labor and materials associated with the structure, from the bottom of the base plate up, on up, as a lump sum item. Each span structure shall have a separate pay item. Structure data shall be provided on Form D-34.

All box trusses shall require a special pay item for each truss. All pay item descriptions shall include span length and truss number. Truss pay items shall include costs for all labor and materials associated with the truss, from the bottom of the base plate up, as a lump sum item. Each box truss, regardless of type, shall have a separate pay item.

See Standard Plan 903.00 for payment of delineators. Delineators shall be paid for per each on Form D-29, and include installation, bolts, post and sign.

Perforated Square Steel Tube Post Breakaway assemblies shall be totaled on Form D-29. Breakaway assemblies are incidental for pipe and structural steel posts.

Backing bar lengths and weights shall be shown on Form D-29, and are totaled with the pay item for structural steel posts. No weight deductions shall be made for punched or drilled holes. If no structural steel posts are used on a project, backing bar weights shall be added to pipe post weights.

Signal Sign Mounting Hardware shall be paid for per each on Form D-37A separate from signal signs, which will be paid for by square feet. Signal Sign Hardware will include all mounting hardware necessary to install one sign on the mast arm.

Special pay items shall not be included for items considered to be small amounts of work such as: strapping signs to lighting or signal posts or truss columns; covering inappropriate legends; "EXIT ONLY" panels on new signs; any symbol, arrow, shield or legend on new guide signs; hinge plates; aluminum wide flange posts for connecting service signs and exit number panels to structural guide signs; etc. No additional payment shall be made for hardware. Other than the above, it shall be left to the designer to decide which items require direct pay.

Option. Special pay items for signing may be required. Some examples of special work include: modifying legends, relocating existing signs to new posts, temporary ground mounting guide signs, bridge mounted support brackets, truss painting, pedestal repair, etc. It is left to the designer to decide which items require special pay items.

Support. Most jobs include the removal of existing signs and/or trusses. All removals are listed with other roadway Removal of Improvements. It is preferred to list the type of truss to be removed, number of pedestals, posts, footings and a rough estimate of sign area. Consult the District Traffic Engineer or District Constructions and Materials Engineer about which removals to salvage and where the contractor should deliver the salvaged materials. Items to be salvaged and delivery of these items are mentioned in the job special provisions and this work is paid for under Removal of Improvements.