Category:1038 Bearing Pads for Structures

| MGS Information |

| Current General Services Specifications (MGS) By Subject |

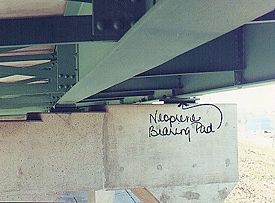

This article establishes procedures for inspectioning elastomeric bearing pads of neoprene, rubber and fabric, or rubber and fiber. Refer to Sec 1038 for MoDOT’s specifications.

1038.1 Apparatus

Rule with suitable graduations to accurately measure the material to be inspected.

1038.2 Procedure

1038.2.1 Certification

The contractor is required to furnish a manufacturer's certification in triplicate, showing typical test results representative of the material and certifying that the material supplied conforms to all the requirements of Sec 1038. The inspector shall carefully check these certifications to ensure compliance with the contract requirements.

Certifications for steel laminates shall attest to the required national standard and grade specified in the specifications. A higher grade will be permitted provided the manufacturer certifies to the higher grade. A lesser grade than that specified, though the properties meet or surpass the specified grade, will not be permitted.

1038.2.2 Inspection

The specified dimensions vary from project to project and bridge to bridge, therefore, the plans must be consulted to determine the required dimensions. The district Construcion and Materials shall verify that the dimensions of the neoprene, polytetrafluoroethylene (PTFE), rubber and fabric pads, or rubber and fiber pads meet the contract requirements. Bridge will be responsible for the inspection of steel bearings, the steel sole plates that are bonded to the neoprene bearing pads and the steel anchor bolts, as defined in Sec 1080.4.7.

If adhesive is specified to bond the neoprene bearing pads to the bearing seat, it should be inspected for compliance, normally to include:

a) Product identification that identifies the adhesive as a two-part epoxy (or as specified).

b) Statement or certification from the pad supplier that the adhesive is recommended for adhering their pad to concrete.

1038.3 Report

Bearing pads shall be reported through AASHTOWARE Project (AWP), and shall show all pertinent formation regarding the material including acceptance method and brand name of the adhesive. The bearing pad certification shall be retained in the district office. The report is to indicate acceptance, qualified acceptance, or rejection. Appropriate remarks, as described in The Rounding Off Method, are to be included in the report to clarify conditions of acceptance or rejection. In some cases, it may not be possible to determine specified dimensions in which case a statement similar to the following shall be shown under the remarks section to denote provisional acceptance:

- "Accepted provided Field Inspection for dimensions shows contract compliance."

Bridge will report in AWP all materials that have been inspected by Bridge.