Category:730 Thermoplastic Pipe Culverts

730.1 Construction Inspection

Construction inspection for thermoplastic pipes has three stages: initial arrival, bedding and installation, and the as-placed inspection.

730.1.1 Arrival

Upon arrival, the pipe may be inspected when practical to ensure it is generally acceptable. This inspection includes checking for damage, proper markings, and that the each type and size of pipe has MoDOT ID#s. If the pipe is not acceptable, inform the contractor that the pipe is non-compliant and that until they remedy the concern use of that pipe is at risk. When plastic pipe arrives at a jobsite, district materials should be notified so they can sample the pipe if necessary.

Each size and type of thermoplastic pipe should have an unique ID#. The associated AASHTOWARE Project (AWP) records should be reviewed by the inspector to confirm that the details recorded there are representative of the material on the job site. A disposition remark should be made on each sample record indicating arrival of the materials, its condition, and the accuracy of the record.

730.1.2 Bedding

Proper bedding of thermoplastic pipe is very important to its long term performance. Bedding requirements including material and layout are found in the standard plans. The thermoplastic pipe and surrounding bedding aggregates form an engineered structural system and any deviation from these requirements requires approval of the engineer. If the contractor requests to deviate from the standard plans, they are responsible for providing stamped engineering drawings showing the alternate bedding for approval.

The bedding process should be inspected when practical, preferably at the start of the run of pipe. This inspection may include verifying the material, checking dimensions, and checking compaction when soil is used.

730.1.3 Post Installation

When required by specification, the contractor will inspect the pipe 30 days after completion of construction activities above a newly laid pipe. This is done to ensure proper installation and performance of the pipe. The resident engineer must assign which pipe runs are to be inspected for Group B and Group C pipe.

Some deflection is allowable in thermoplastic pipe after installation. Excessive deformation can compromise the long term performance of the pipe through a combination of stresses and creep. All Group A thermoplastic culvert runs shall be tested for deflection. When deflection is visibly detected, further investigation is warranted regardless of pipe grouping. When excessive deflection is found the pipe is rejected. Thermoplastic pipe known to be excessively deflected should never be re-laid as it’s strength may be permanently degraded. When deflection is above the limitations in the specification, the contractor may have a professional engineer evaluate the as built structure for possible acceptance with ultimate approval coming from both Bridge Division and Construction and Materials Division.

Measuring deflection may be done by tape measure (or a rod of known length) on larger pipes, mandrels on smaller pipes, or using other technology per the specification. Note that the “actual” internal diameter is often different than the nominal diameter. For example a 12” nominal polypropylene pipe is allowed to be small as 11 13/16” per ASTM F2736. It is very important to use the actual diameter when determining deflection, not the nominal value. The actual diameter of a pipe may be determined by one of these methods:

- 1) Measuring the diameter of a cross-section of pipe in 9 different directions. When the measurements match reasonably, the pipe can be considered round and the average measurement is the actual diameter. If the measurements do not match the pipe is not round, try a different cross section.

- 2) Use manufactures provided or published technical specification for actual diameter.

When a mandrel is used, the diameter of the mandrel should choose based off the actual internal diameter of the pipe minus the 5% deflection value.

Always make sure that when testing the right measurement unit is used. Pipe can be produced in either English or metric units. Make sure the measurements are taken in the same units as the pipe was produced. The Qualified List for each type of pipe will indicate the manufacturer's identification mark and the units (English or metric) that were used to fabricate the pipe.

730.2 Proper Markings

Thermoplastic pipe should at a minimum have an industry quality control stamp. There will not be a MoDOT OK stamp unless the pipe happened to be QA inspected at the plant.

730.3 PVC and Ultraviolet

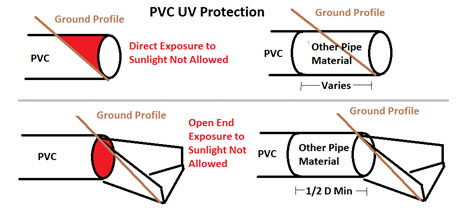

When PVC pipe is used, it must be protected from sunlight to prevent long term deterioration. The specifications provide a basis for protection and it is up to the construction inspector to ensure the pipe is installed correctly and protected. Additional costs to the contractor for materials and effort to protect PVC should not be directly paid for and are considered incidental to the run of pipe.

730.4 Material Inspection and Laboratory Testing

When initiated by headquarters, thermoplastic pipe will be sampled at the jobsite. The district may also sample pipe if there is a specific concern. Care should be made so that sampling does not leave the contractor short of needed pipe. If there is not enough pipe to sample, contact headquarters for additional instructions.