Difference between revisions of "Category:150 Quality Management"

m (adding links) |

m (added links) |

||

| Line 27: | Line 27: | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/ITS%20Checklist.pdf ITS Checklist] | |[http://www.modot.org/business/contractor_resources/Quality_Management/ITS%20Checklist.pdf ITS Checklist] | ||

|- | |- | ||

| − | |[http://www.modot.org/business/contractor_resources/Quality_Management/MOT%20Lane%20Closure%20Checklist.doc | + | |[http://www.modot.org/business/contractor_resources/Quality_Management/MOT%20Lane%20Closure%20Checklist.doc Lane Closure Checklist] |

|- | |- | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Hold%20Points.docx Hold Points] | |[http://www.modot.org/business/contractor_resources/Quality_Management/Hold%20Points.docx Hold Points] | ||

| Line 49: | Line 49: | ||

|'''Forms ''' | |'''Forms ''' | ||

|- | |- | ||

| − | |Absorption Worksheet | + | | [[media:150 Absorption Worksheet.xlsx|Absorption Worksheet]] |

|- | |- | ||

| − | |Asphalt Inspection Worksheet v5.01 | + | |[[media:150 Asphalt Inspection Cumulative.xls|Asphalt Inspection Worksheet v5.01 Cumulative Gradation]] |

|- | |- | ||

| − | |Asphalt Inspection Worksheet v4.61 Non-Cummulative Gradation | + | |[[media:150 Asphalt Inspection NonCumulative.xls|Asphalt Inspection Worksheet v4.61 Non-Cummulative Gradation]] |

|- | |- | ||

| − | |Compaction Test C709ND | + | |[[media:150 Compaction Test.xlsx|Compaction Test C709ND]] |

|- | |- | ||

| − | |Concrete Pour Card | + | |[[media:150 Concrete Pour Card.xlsx|Concrete Pour Card]] |

|- | |- | ||

| − | |Concrete Placement Test Record | + | |[[media:150 Concrete Placement Test Record.xlsx|Concrete Placement Test Record]] |

|- | |- | ||

| − | |Consensus | + | |[[media:150 Consensus Tests.xlsx|Consensus Tests]] |

|- | |- | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Daily%20Inspection%20Report.pdf Daily Inspection Report] | |[http://www.modot.org/business/contractor_resources/Quality_Management/Daily%20Inspection%20Report.pdf Daily Inspection Report] | ||

|- | |- | ||

| − | |DCP Test | + | |[[media:150 DCP Test|DCP Test]] |

|- | |- | ||

| − | |Ditch Liner | + | |[[media:150 Ditch Liner|Ditch Liner]] |

|- | |- | ||

| − | |Embankment Monitoring | + | |[[media:150 Embankment Monitoring.xlsx|Embankment Monitoring]] |

|- | |- | ||

| − | |Embankment Protection | + | |[[media:150 Embankment Protection.xlsx|Embankment Protection]] |

|- | |- | ||

| − | |Gradation Worksheet | + | |[[media:150 Gradation Worksheet.xlsx|Gradation Worksheet]] |

|- | |- | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Land%20Disturbance%20Inspection%20Record.docx Land Disturbance Inspection Record] (MoDOT performs this inspection) | |[http://www.modot.org/business/contractor_resources/Quality_Management/Land%20Disturbance%20Inspection%20Record.docx Land Disturbance Inspection Record] (MoDOT performs this inspection) | ||

|- | |- | ||

| − | |Low Slump Concrete | + | |[[media:150 Low Slump Concrete.xlsx|Low Slump Concrete]] |

|- | |- | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Material%20Receiving%20Inspection%20Report.pdf Materials Receiving Inspection Report] | |[http://www.modot.org/business/contractor_resources/Quality_Management/Material%20Receiving%20Inspection%20Report.pdf Materials Receiving Inspection Report] | ||

|- | |- | ||

| − | |Materials Request for Transfer | + | |[[media:150 Materials Request for Transfer.docx|Materials Request for Transfer]] |

|- | |- | ||

|[[media:150 Misc Concrete.xlsm|Miscellaneous Concrete]] | |[[media:150 Misc Concrete.xlsm|Miscellaneous Concrete]] | ||

|- | |- | ||

| − | |Moisture Content Worksheet | + | |[[media:150 Moisture Content.xlsx|Moisture Content Worksheet]] |

|- | |- | ||

| − | |Moisture Correction Factor | + | |[[media:150 Moisture Correction Factor.xlsx|Moisture Correction Factor]] |

|- | |- | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Nonconformance%20Report.pdf Nonconformance Report (NCR)] | |[http://www.modot.org/business/contractor_resources/Quality_Management/Nonconformance%20Report.pdf Nonconformance Report (NCR)] | ||

| Line 95: | Line 95: | ||

|[[media:150 Pavement Marking Report.xlsx|Pavement Marking Report]] | |[[media:150 Pavement Marking Report.xlsx|Pavement Marking Report]] | ||

|- | |- | ||

| − | |Plasticity Index Worksheet | + | |[[media:150 Plasticity Index.xlsx|Plasticity Index Worksheet]] |

|- | |- | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Pile%20Driving.docx Pile Driving] | |[http://www.modot.org/business/contractor_resources/Quality_Management/Pile%20Driving.docx Pile Driving] | ||

| Line 101: | Line 101: | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Profilograph%20Report.docx Profilograph Report] | |[http://www.modot.org/business/contractor_resources/Quality_Management/Profilograph%20Report.docx Profilograph Report] | ||

|- | |- | ||

| − | |Rock Base Density and Thickness | + | |[[media:150 Rock Base Density and Thickness.xlsx|Rock Base Density and Thickness]] |

|- | |- | ||

| − | |Rock Base Quantites, Gradation | + | |[[media:150 Rock Base Quantites Gradation.xlsx| Rock Base Quantites, Gradation and PI]] |

|- | |- | ||

|[[media:150 Sample Labels.docx|Sample Labels]] | |[[media:150 Sample Labels.docx|Sample Labels]] | ||

|- | |- | ||

| − | |Standard Proctor Test | + | |[[media:150 Standard Proctor Test.xls|Standard Proctor Test]] |

|- | |- | ||

| − | |Subgrade Density | + | |[[media:150 Subgrade Density.xlsx|Subgrade Density]] |

|- | |- | ||

|[[media:150 Temporary Erosion Control.xlsx|Temporary Erosion Control]] | |[[media:150 Temporary Erosion Control.xlsx|Temporary Erosion Control]] | ||

| Line 117: | Line 117: | ||

|[http://www.modot.org/business/contractor_resources/Quality_Management/Traffic%20Control%20Inspection%20Report.pdf Traffic Control Inspection Report] | |[http://www.modot.org/business/contractor_resources/Quality_Management/Traffic%20Control%20Inspection%20Report.pdf Traffic Control Inspection Report] | ||

|- | |- | ||

| − | |Uniformity of Concrete Worksheet | + | |[[media:150 Uniformity of Concrete.xlsx|Uniformity of Concrete Worksheet]] |

|} | |} | ||

| Line 230: | Line 230: | ||

:<u>Requests for Transfer</u> | :<u>Requests for Transfer</u> | ||

| − | :The “RequestsforTransfer” folder is the required storage location for all Request for Transfer of Inspected Material reports. The standard [[Request for Transfer of Inspected Material]] report is available. If the procedure described in the first paragraph of [[#150.1.3 Naming Convention|EPG 150.1.3 Naming Convention]] is followed and added to the beginning of the file name of the Request for Transfer of Inspected Material report from the MoDOT QM website, the correct file name will be produced. The following is the correct file naming convention for the standard Request for Transfer of Inspected Material report that shall be used: | + | :The “RequestsforTransfer” folder is the required storage location for all Request for Transfer of Inspected Material reports. The standard [[media:150 Materials Request for Transfer.docx|Request for Transfer of Inspected Material]] report is available. If the procedure described in the first paragraph of [[#150.1.3 Naming Convention|EPG 150.1.3 Naming Convention]] is followed and added to the beginning of the file name of the Request for Transfer of Inspected Material report from the MoDOT QM website, the correct file name will be produced. The following is the correct file naming convention for the standard Request for Transfer of Inspected Material report that shall be used: |

[[image:105.23.1.3 request.jpg|center|520px]] | [[image:105.23.1.3 request.jpg|center|520px]] | ||

| Line 272: | Line 272: | ||

'''Traffic Control Reports''' | '''Traffic Control Reports''' | ||

| − | The “TrafficControlReports” folder is the required storage location for all traffic control inspection reports. The [ | + | The “TrafficControlReports” folder is the required storage location for all traffic control inspection reports. The [http://www.modot.org/business/contractor_resources/Quality_Management/MOT%20Lane%20Closure%20Checklist.doc Lane Closure Checklist] and the [http://www.modot.org/business/contractor_resources/Quality_Management/Traffic%20Control%20Inspection%20Report.pdf Traffic Control Inspection Report] are available. The following is the correct file naming convention for the traffic control reports that shall be used: |

[[image:105.23.1.3 traffic.jpg|center|500px]] | [[image:105.23.1.3 traffic.jpg|center|500px]] | ||

Revision as of 06:58, 3 June 2014

Quality Management (QM) is a pro-active and efficient method of incorporating quality into the planning and scheduling of all project activities. The contractor works together with the engineer to develop a quality management plan that ensures the quality of materials and workmanship meets or exceeds the contract requirements. This comprehensive plan is dynamic and is specific to the project.

The contractor assumes the primary role of managing quality and performs the quality control inspection and testing. This role includes documenting all inspection and testing, as well as material receiving. The engineer provides quality assurance to verify the contractor is providing adequate quality management per the contract requirements.

Pre-activity meetings are held before the start of each new activity to discuss the work plan for that activity, including any required inspection and testing. Hold points are established at specific stages for the engineer to review the inspection and testing for compliance before the work can proceed. The contractor provides a schedule each week that identifies the activities planned for the next two weeks, including anticipated hold points. The contractor is also responsible for providing an electronic filing system that assembles all documentation.

Good quality management saves time and money. The inclusion of quality in the contractor’s planning process reduces the likelihood for re-work. Giving the contractor the primary role for inspection and testing eliminates duplication of quality control and opens up more opportunities for efficiencies.

Basic steps in the QM process:

- A base Inspection and Test plan (ITP) is provided by MoDOT. The base ITP, which includes a complete list of work items, is reduced by the contractor to only include the work items needed for the project. Additions to the ITP may be necessary for any unique items or Job Special Provisions requirements.

- Contractor prepares and submits a draft Quality Management Plan (QMP) to the Resident Engineer at least two weeks prior to the pre-construction conference. A sample plan is available.

- Resident Engineer reviews the draft QMP provides feedback to the contractor on any additions or changes. A meeting may be necessary to review details.

- The approved QMP is used to guide the contractor QC staff in their Quality Management duties.

- To store project QC documents, the contractor utilizes a MoDOT-provided SharePoint site, or the contractor may provide their own file sharing site if approved by the engineer.

- The contractor provides all Quality Control, in accordance with the Quality Management Job Special Provision and the QMP. MoDOT conducts Quality Assurance to verify the performance and accuracy of QC.

- All necessary QC documentation must be uploaded to the file sharing site for the work performed each pay period in order for the engineer to process payment.

- Modifications to the Quality Management Plan may be necessary as the work progresses.

- A review is necessary at project closeout to verify that all required documentation is present.

Contents

150.1 Required File Structure and Naming Convention for Contractor Quality Management Documents

This subarticle establishes policy for retaining project documentation.

Each document saved should be reopened to confirm that a readable copy has been successfully saved.

Quality Management documentation is to be retained electronically as specified in the JSP.

150.1.1 Location

The contractor shall establish a Document Control Procedure for producing and uploading the required Quality Management documents to a web-based electronic storage site provided by MoDOT (Microsoft SharePoint), or to an alternate storage site provided by the contractor and approved by the engineer. This process will allow efficient sharing of documents among authorized users. Any proposed alternate site shall provide equal or better efficiency in document sharing as the MoDOT provided site. If an alternate site is utilized, upon completion of the project the contractor shall provide all files to the engineer on an approved electronic media.

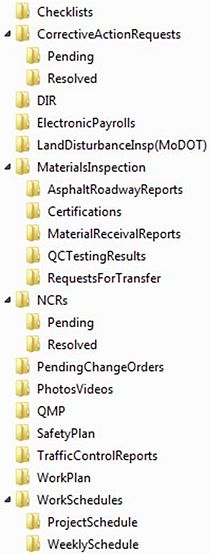

150.1.2 Folder Structure

The contractor shall use the following folder structure for storing project documents. Only the listed folders and subfolders will be allowed to produce consistency throughout the state. Subfolders in any of the listed folders or subfolders are prohibited.

150.1.3 Naming Convention

The contractor shall use the following naming convention as described below. Each file will begin with the following: ContractNo_JobNo_Date. For example: 140221-B01_J3P0001C_YYYYMMDD. The redundant file naming practice will keep the user from overwriting an existing file, if the user has inadvertently navigated to the wrong folder. The Date shall be in the YYYYMMDD format in order for the files to appear in chronological order.

All file name lengths shall be limited to 75 characters maximum.

Any required documentation not listed below, shall follow the naming convention described above with the addition of file descriptions. For example: 140221-B01_J3P0001C_20140328_glassbeadcert.pdf. The file description shall be descriptive enough the user can tell what the document is without opening it and still be within the total file name length limit of 75 characters. The following is a detail of each folder, subfolder, the required standard forms, reports and checklists to be stored when used throughout a project, and the proper naming convention of said files.

Checklists

The 99 standard checklists are presented under "checklists" in the large gray box at top of this article. If the procedure described in the first paragraph of EPG 150.1.3 Naming Convention is followed and added to the beginning of the file name of the checklist from the MoDOT QM website, the correct file name will be produced. All of these files shall be stored in the “Checklists” folder. An example of the correct file name for each file is available.

Corrective Action Requests

The “CorrectiveActionRequsts” folder is the prime folder for two subfolders. The following are the allowed subfolders:

- Pending

- The “Pending” folder is the required storage location for all pending Corrective Action Requests. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies.

- Resolved

- The “Resolved” folder is the required storage location for all resolved Corrective Action Requests. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies.

Daily Inspection Report (DIR)

One standard DIR is available. If the procedure described in the first paragraph of EPG 150.1.3 Naming Convention is followed and added to the beginning of the file name of the DIR from the MoDOT QM website, the correct file name will be produced. The DIR files shall be stored in the “DIR” folder. The following is the correct file naming convention for the standard DIR that shall be used:

Electronic Payrolls

Please refer to EPG 110.3 Prevailing Wages and Records for guidance on electronic payrolls. The folder, “ElectronicPayrolls” is provided in the required folder structure for the storage of electronic payrolls if a contractor chooses to submit payrolls in this manner. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies.

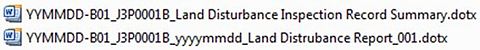

Land Disturbance Inspection (MoDOT)

The “LandDisturbanceInsp(MoDOT)”folder is intended for MoDOT storage of Land Disturbance Reports and the report summary. These reports may be shared with the contractor via this folder. The following is the correct file naming convention for the standard Land Disturbance Report and report summary that shall be used:

Materials Inspection

The “MaterialsInspection” folder is the prime folder for five subfolders. The following are the allowed subfolders for this folder:

- Asphalt Roadway Reports

- The Asphalt Roadway Report (ARR) is a required daily document detailing the days production of asphalt. ARR is a required document to be turned in with final plans. There are two acceptable versions of the ARR, a word document or excel document. The contractor may choose either, but must use the document of choice throughout the project, unless authorized by the engineer to do otherwise. The below listed ARR summary is an optional tool to the contractor for summarizing and tracking quantities. The following is the correct file naming convention for the ARR that shall be used:

- These files shall be stored in the “AsphaltRoadwayReports” folder.

- Certifications

- The “Certifications” folder is the required storage location for all material certifications. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies. The following is an example of this naming convention:

- Material Receiving Inspection Reports

- The “MaterialReceivalReports” folder is the required storage location for all Material Receiving Inspection Reports. One standard Material Receiving Inspection Report is available. Naming convention of these files shall follow the procedure described above in the third paragraph of EPG 150.1.3. The 75 character limit also applies. The following is an example of this naming convention:

- QC testing results

- There are 30 standard testing forms available. If the procedure described in the first paragraph of EPG 150.1.3 Naming Convention is followed and added to the beginning of the file name of the standard testing form from the MoDOT QM website, the correct file name will be produced. All of these files shall be stored in the “QCTestingResults” folder. An example of the correct file name for each file is available.

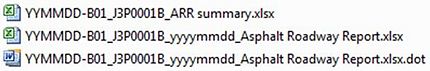

- Requests for Transfer

- The “RequestsforTransfer” folder is the required storage location for all Request for Transfer of Inspected Material reports. The standard Request for Transfer of Inspected Material report is available. If the procedure described in the first paragraph of EPG 150.1.3 Naming Convention is followed and added to the beginning of the file name of the Request for Transfer of Inspected Material report from the MoDOT QM website, the correct file name will be produced. The following is the correct file naming convention for the standard Request for Transfer of Inspected Material report that shall be used:

NCRs

The “NCRs” folder is the prime folder for three subfolders. The following are the allowed subfolders for this folder:

- Pending

- The “Pending” folder is the required storage location for all pending NCRs. One standard NCR form is available. The following is the correct file naming convention for the NCR form that shall be used:

- Resolved

- The “Resolved” folder is the required storage location for all resolved NCRs. One standard NCR form is available. The following is the correct file naming convention for the NCR form that shall be used:

Pending Change Orders

The “PendingChangeOrders” folder is an optional folder for MoDOT to share Change Orders with the contractor to obtain digital signatures. This is only a temporary storage area for Change Orders. All finalized Change Orders shall be stored in the Contract Information Archives. The following is the correct file naming convention for the Change Order file that shall be used:

Photos and Videos

The “PhotosVideos” folder is an optional folder for MoDOT and the contractor to share photos and videos of the project. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies. The following is an example of said naming convention:

QMP

The “QMP” folder is the required storage location for the projects official QMP (Quality Management Plan). A sample QMP is available. The following is the correct file naming convention for the QMP file that shall be used:

Each time the QMP is revised, the latest revision shall be saved with the following naming convention:

Safety Plan

The “SafetyPlan” folder is the required storage location for the projects official Safety Plan. The following is the correct file naming convention for the QMP file that shall be used:

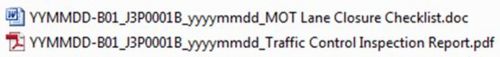

Traffic Control Reports

The “TrafficControlReports” folder is the required storage location for all traffic control inspection reports. The Lane Closure Checklist and the Traffic Control Inspection Report are available. The following is the correct file naming convention for the traffic control reports that shall be used:

Work Plan

The “WorkPlan” folder is the required storage location for the contractors Work Plan. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies.

Work Schedules

The “WorkSchedules” folder is the prime folder for two subfolders. The following are the allowed subfolders for this folder:

- Project Schedule

- The “ProjectSchedule” folder is the required storage location for the contractors Project Schedule. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies.

- Weekly Schedule

- The “WeeklySchedule” folder is the required storage location for the contractors Project Schedule. A Sample Weekly Schedule is available. Naming convention of these files shall follow the procedure described in the third paragraph of EPG 150.1.3 Naming Convention. The 75 character limit also applies.

150.2 Quality Management SiteManager Reporting – MoDOT Staff Only

A SiteManager(SM) sample record shall be created for all QC, QA and QC/QA retained samples. Test data shall be reported on the appropriate templates under the Tests tab on the SM record. The representative quantity shall be reported under the Contract tab on the SM record for the QC samples. The quantity under the Contract tab on the record for the QA independent and QC/QA retained samples shall be “0”. The representative quantity for the test sample will be reported on the Basic Sample Data Tab. When available, the Excel2Oracle spreadsheets should be used by both MoDOT staff and contractors.