User talk:Hoskir: Difference between revisions

| (321 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

='''REVISION REQUEST | ='''REVISION REQUEST 4036'''= | ||

== | ==106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity== | ||

'''1. Chemical Analysis''' | |||

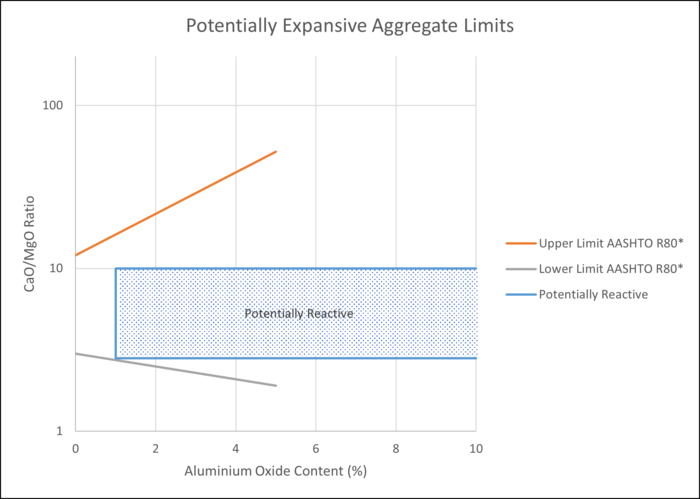

The chemical analysis of aggregate reactivity is an objective, quantifiable and repeatable test. MoDOT will perform the chemical analysis per the process identified in ASTM C 25 for determining the aggregate composition. The analysis determines the calcium oxide (CaO), magnesium oxide (MgO), and aluminum oxide (Al<sub>2</sub>O<sub>3</sub>) content of the aggregate. The chemical compositions are then plotted on a chart with the CaO/MgO ratio on the y-axis and Al<sub>2</sub>O<sub>3</sub> percentage on the x-axis per Fig. 2 in AASHTO R 80. Aggregates are considered potentially reactive if the Al<sub>2</sub>O<sub>3</sub> content is greater than or equal to 1.0% and the CaO/MgO ratio is either greater than or equal to 3.0 or less than or equal to 10.0 (see chart below). See flow charts in 106.3.2.93.2 for approval hierarchy. CaO, MgO and Al2O3 shall be analyzed by instrumental analysis only. | |||

[[File:106.3.2.93.1_Potentially_Expansive_Aggregate_Limits-01.png|700px]] | |||

<nowiki>*</nowiki> MoDOT’s upper and lower limits of potentially reactive (shaded area) aggregates. | |||

'''2. Petrographic Examination''' | |||

A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum: | |||

* Quarry name and ledge name; all ledges if used in combination | |||

* MoDOT District quarry resides | |||

* Date sample was obtained; date petrographic analysis was completed | |||

* Name of petrographer and company/organization affiliated | |||

* Lithographic descriptions with photographs of the sample(s) examined | |||

* Microphotographs of aggregate indicating carbonate particles and/or other reactive materials | |||

* Results of the examination | |||

* All conclusions related to the examination | |||

See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer. | |||

'''3. Concrete Prism/Beam Test''' | |||

ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy. | |||

''' | ='''REVISION REQUEST 4143'''= | ||

==751.36.5 Design Procedure== | |||

*Structural Analysis | |||

*Geotechnical Analysis | |||

*Drivability Analysis | |||

===751.36.5.1 Design Procedure Outline=== | |||

*Determine foundation load effects from the superstructure and substructure for Service, Strength and Extreme Event Limit States. | |||

*If applicable, determine scour depths, liquefaction information and pile design unbraced length information. | |||

*Determine if downdrag loadings should be considered. | |||

*Select preliminary pile size and pile layout. | |||

*Perform a Static Pile Soil Interaction Analysis. Estimate Pile Length and pile capacity. | |||

*Based on pile type and material, determine Resistance Factors for Structural Strength (<math>\, \phi_c</math> and <math>\, \phi_f</math>). | |||

*Determine: | |||

**Maximum axial load effects at toe of a single pile | |||

**Maximum combined axial & flexural load effects of a single pile | |||

**Maximum shear load effect for a single pile | |||

**Uplift pile reactions | |||

*Determine Nominal and Factored Structural Resistance for single pile | |||

**Determine Structural Axial Compression Resistance | |||

**Determine Structural Flexural Resistance | |||

**Determine Structural Combined Axial & Flexural Resistance | |||

**Determine Structural Shear Resistance | |||

*Determine method for pile driving acceptance criteria | |||

*Determine Resistance Factor for Geotechnical Resistance (<math>\, \phi_{stat}</math>) and Driving Resistance (<math>\, \phi_{dyn}</math>). | |||

*If other than end bearing pile on rock or shale, determine Nominal Axial Geotechnical Resistance for pile. | |||

*Determine Factored Axial Geotechnical Resistance for single pile. | |||

*Determine Nominal pullout resistance if pile uplift reactions exist. | |||

*Check for pile group effects. | |||

*Resistance of Pile Groups in Compression | |||

*Check Drivability of all pile (bearing and friction pile) using the Wave equation analysis. | |||

*Review Static Pile Soil Interaction Analysis and pile lengths for friction pile. | |||

*Show proper Pile Data on Plan Sheets ([https://epg.modot.org/index.php/751.50_Standard_Detailing_Notes#E2._Foundation_Data_Table Foundation Data Table]). | |||

===751.36.5.2 Structural Resistance Factor (ϕ<sub>c</sub> and ϕ<sub>f</sub>) for Strength Limit State=== | |||

{| style="margin: 1em auto 1em auto" | |||

== | |||

{|style=" | |||

|- | |- | ||

| | |align="right" width="850"|'''LRFD 6.5.4.2''' | ||

|} | |} | ||

''' | '''For integral end bent simple pile design,''' use Φ<sub>c</sub> = 0.35 for CIP steel pipe piles and HP piles. See [[751.35 Concrete Pile Cap Integral End Bents#751.35.2.4.2 Pile Design|Figure 751.35.2.4.2]]. | ||

''' | '''For pile at all locations where integral end bent simple pile design is not applicable,''' use the following: | ||

:The structural resistance factor for axial resistance in compression is dependent upon the expected driving conditions. When the pile is subject to damage due to severe driving conditions where use of pile point reinforcement is necessary: | |||

::Steel Shells (Pipe): <math> \phi_c </math>= 0.60 | |||

::HP Piles: <math> \phi_c </math>= 0.50 | |||

:When the pile is subject to good driving conditions where use of pile point reinforcement is not necessary: | |||

::Steel Shells (Pipe) Piles: <math> \phi_c </math>= 0.70 | |||

::HP Piles: <math> \phi_c </math>= 0.60 | |||

:For HP piles, pile point reinforcement is always required when HP piles are anticipated to be driven to rock and proofed. Driving HP piles to rock is considered severe driving conditions for determination of structural resistance factor. However, driving HP piles through overburden not likely to impede driving to deep rock or preboring to rock for setting piles are two situations that could be considered as less than severe. Further, driving any steel pile through soil without rubble, boulders, cobbles or very dense gravel could be considered good driving conditions for determination of structural resistance factor. Consult the Structural Project Manager or Structural Liaison Engineer. | |||

:The structural resistance factor for combined axial and flexural resistance of undamaged piles: | |||

::Axial resistance factor for HP Piles: <math> \phi_c </math>= 0.70 | |||

::Axial resistance for Steel Shells (Pipe): <math> \phi_c </math>= 0.80 | |||

::Flexural resistance factor for HP Piles or Steel Shells: <math> \phi_f </math>= 1.00 | |||

:For Extreme Event Limit States, see LRFD 10.5.5.3. | |||

<div id="751.36.5.3 Geotechnical Resistance"></div> | |||

===751.36.5.3 Geotechnical Resistance Factor (ϕ<sub>stat</sub>) and Driving Resistance Factor (ϕ<sub>dyn</sub>)=== | |||

The factors for Geotechnical Resistance (<math> \phi_{stat}</math>) and Driving Resistance (<math> \phi_{dyn}</math>) may be different because of the reliability of the different methods used to determine the nominal bearing resistance. Caution should be used if the difference in factors for Geotechnical Resistance and Driving Resistance are great as it can lead to issues with pile overruns. Also see [[#751.36.5.9 Estimate Pile Length and Check Pile Capacity|EPG 751.36.5.9]]. | |||

''' | '''Geotechnical Resistance Factor, ϕ<sub>stat</sub>:''' | ||

The Geotechnical Resistance factor is based on the static method used by the designer in determining the nominal bearing resistance. Unlike the Driving Resistance factor the Geotechnical Resistance factor can vary with the soil layers. If Geotechnical Resistance factors are not provided by the Geotechnical Engineer, the static method and resistance factors shall be selected from the table below. The values provided in LRFD Table 10.5.5.2.3-1 are only applicable if the end of drive criteria is based off the total pile penetration which is not recommended. For Extreme Event Limit States see LRFD 10.5.5.3. | |||

{|border="1" style="text-align:center; width: 750px" cellpadding="5" align="center" cellspacing="0" | |||

|+ '''Table - Static Analysis Resistance Factors used for Pile Length Estimates''' | |||

! Pile Type !! Soil Type !! Static Analysis Method !! Side Friction<sup>1</sup><br><math> \phi_{stat}</math> !! End Bearing<br><math> \phi_{stat}</math> | |||

''' | |||

{ | |||

|- | |- | ||

| rowspan="4" | '''CIP Piles - Steel Pipe Shells''' || Clay || Alpha - Tomlinson || <math> \phi_{dyn}</math><sup>2</sup> || <math> \phi_{dyn}</math><sup>2</sup> | |||

|- | |- | ||

| rowspan="3" | Sand || Nordlund<sup>3</sup> || 0.45 - Gates<br>0.45 - WEAP<br>0.55 - PDA || 0.45 - Gates<br>0.45 - WEAP<br>0.55 - PDA | |||

|- | |- | ||

| | | LCPC<sup>4</sup> || 0.70 || 0.45 | ||

|- | |- | ||

| | | Schmertmann<sup>5</sup> || 0.50 || 0.50 | ||

| | |} | ||

| | |||

| | {|border="0" style="text-align:left; width: 750px" align="center" cellspacing="0" | ||

|- | |||

|- | |- | ||

| | | <sup>1</sup> For mixed soil profiles the lowest applicable resistance factor for clay or sand may be used to simplify the analysis. | ||

|- | |- | ||

| | | <sup>2</sup> ϕ<sub>dyn</sub> = see following section. | ||

|- | |- | ||

| | | <sup>3</sup>The Nordlund method is recommended for sand layers in mixed soil profiles where CPT data is not available. | ||

|- | |- | ||

| | | <sup>4</sup>The resistance factors associated with the LCPC method are not statistically calibrated for reliability, but studies have shown this method to be one of the most reliable methods for predicting soil behavior from CPT data. | ||

|- | |- | ||

| | | <sup>5</sup>Per LRFD 10.7.3.8.6g the Schmertmann method shall only be used for sands and nonplastic silts with CPT data. | ||

|- | |- | ||

| | | For more detailed guidance see [https://www.modot.org/media/54989 SEG 25-001 New Policy for Friction Pile]. | ||

|} | |} | ||

''' | '''Driving Resistance Factor, ϕ<sub>dyn</sub>:''' | ||

< | |||

The | The Driving Resistance factor shall be selected from LRFD Table 10.5.5.2.3-1 based on the method to be used in the field during construction to verify nominal axial compressive resistance. | ||

{| border="1 | {|border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" | ||

! Pile Driving Verification Method !! Resistance Factor,<br/><math> \phi_{dyn}</math> | |||

|- | |- | ||

| | | FHWA-modified Gates Dynamic Pile Formula<br/>(End of Drive condition only) || 0.40 | ||

|- | |- | ||

| | | Wave Equation Analysis (WEAP) || 0.50 | ||

|- | |- | ||

| | | Dynamic Testing (PDA) on 1 to 10% piles || 0.65 | ||

|- | |- | ||

| | | Other methods || Refer to LRFD Table 10.5.5.2.3-1 | ||

|} | |} | ||

Use [https://epg.modot.org/index.php/751.50_Standard_Detailing_Notes#G7._Steel_HP_Pile EPG 751.50 Standard Detailing Note G7.3] on plans as required for end bearing piles driven to rock. This requirement shall apply to any type of rock meaning weak to strong rock including stronger shales where HP piling is anticipated to meet refusal. The verification method shown on the plans is only used to verify the nominal axial compressive resistance prior to reaching practical refusal. If the practical refusal criterion is met the field verification method shown on the plans is no longer considered valid. | |||

For end bearing piles tipped in shale, sandstone, or rock of uncertain strength at any loading where the likelihood of pile damage is increased, the Foundation Investigation Geotechnical Report (FIGR) should give a recommendation for dynamic pile testing (PDA) or no PDA. For most end bearing piles, where a recommendation for field verification is not given in the FIGR, the designer will need to determine whether gates or WEAP is required for the pile driving verification method based on the loading demands on the pile or other factors. | |||

required | |||

For piles bearing on hard rock with MNACR less than 600 kips, FHWA-modified Gates Dynamic Pile Formula should be listed as verification method, and practical refusal criterion should control end of driving criteria. FHWA-modified Gates Dynamic Pile Formula is not considered accurate for pile loading (Minimum Nominal Axial Compressive Resistance) exceeding 600 kips. When pile loading exceeds 600 kips, use wave equation analysis, dynamic testing, or other method. Consideration should be given to using additional piles to reduce the MNACR below 600 kips. | |||

Under special circumstances when rock limits or conditions are nonuniform, WEAP should be considered in order to limit pile damage since it requires further scrutiny of the site conditions with the proposed pile driving system. | |||

Dynamic Testing is recommended for projects with friction piles where the soil profile is comprised primarily of sand. For bridges where the soil profile is comprised primarily of clays or evenly mixed clays and sands the recommended verification method is WEAP. When WEAP is specified as the pile driving criteria for friction pile, provide standard note E2.28 below the foundation table. For more detailed guidance see [https://www.modot.org/media/54989 SEG 25-001 New Policy for Friction Pile]. | |||

===751.36.5.4 Downdrag and Losses to Geotechnical Resistance due to Scour and Liquefaction=== | |||

Downdrag and Losses to Geotechnical Resistance due to Scour and Liquefaction (kips), '''LRFD 10.7.3.6, 10.7.3.7, and AASHTO Guide Specifications for LRFD Seismic Bridge Design (SGS) 6.8.''' | |||

Downdrag, liquefaction and scour all reduce the available skin friction capacity of piles. Downdrag <math>\, (DD)</math> is unique because it not only causes a loss of capacity, but also applies a downward force to the piles. This is usually attributed to embankment settlement. However, downdrag can also be caused by a non-liquefied layer overlying a liquefied layer. Review geotechnical report for downdrag and liquefaction information. | |||

===751.36.5.5 Preliminary Structural Nominal Axial Design Capacity (PNDC) of an individual pile === | |||

The PNDC equations provided herein assume the piles are continually braced. This assumption is applicable for the portion of piling below ground or confined by solid wall encasement. If designing a pile bent structure, scour exists or liquefaction exists, then the pile shall be checked considering the appropriate unbraced length. | |||

'''Structural Steel HP Piles''' | |||

:<math>\, PNDC = 0.66^\lambda F_y A_S</math> | |||

:Since we are assuming the piles are continuously braced, then <math>\,\lambda</math>= 0. | |||

:{| | |||

|<math>\, F_y</math>||is the yield strength of the pile | |||

|- | |||

|<math>\, A_S</math>||is the area of the steel pile | |||

|} | |||

'''Welded or Seamless Steel Shell (Pipe) Cast-In-Place Piles (CIP Piles)''' | |||

{| | :<math>\, PNDC = 0.85 f'_c Ac+F_y A_{st}</math> | ||

:{| | |||

|<math>\, F_y</math>||is the yield strength of the pipe pile | |||

|- | |- | ||

|valign="top"|<math>\, A_{st}</math>||is the area of the steel pipe (deducting 12.5 % ASTM tolerance and 1/16 inch corrosion where appropriate.) | |||

|- | |- | ||

| | |<math>\, f'_c</math>||is the concrete compressive strength at 28 days | ||

|- | |- | ||

| | |<math>\, Ac</math>|| is the area of the concrete inside the pipe pile | ||

|} | |} | ||

:Maximum Load during pile driving = <math>\, 0.90 (f_y A_{st})</math> | |||

Welded or Seamless Steel Shell shall be ASTM A252 Modified Grade 3 (50 ksi). ASTM A252 states “the wall thickness at any point shall not be more than 12.5% under the specified nominal wall thickness.” AASHTO recommends deducting 1/16” of the wall thickness due to corrosion (LRFD 5.13.4.5.2). Corrosion need not be considered at construction stage and for drivability analysis and static analysis. For drivability analysis and static analysis deduct 12.5% of specified nominal wall thickness (ASTM A252). For structural design deduct 12.5 % (ASTM A252) and 1/16” for corrosion (LRFD 5.13.4.5.2) from specified nominal wall thickness. | |||

===751.36.5.6 Preliminary Factored Axial Design Capacity (PFDC) of an Individual Pile === | |||

:PFDC = Structural Factored Axial Compressive Resistance – Factored Downdrag Load | |||

===751.36.5.7 Design Values for Steel Pile=== | |||

====751.36.5.7.1 Integral End Bent Simple Pile Design ==== | |||

The following design values may be used for integral end bents where the simple pile design method is applicable per [[751.35 Concrete Pile Cap Integral End Bents#751.35.2.4.2 Pile Design|EPG 751.35.2.4.2 Pile Design]]. These values are not applicable for soils subject to liquefaction or scour where unbraced lengths may alter the design. | |||

=====751.36.5.7.1.1 Design Values for Individual HP Pile===== | |||

<center> | |||

F<sub>y</sub> = 50 ksi. End Bearing Piles (HP piles) anticipated to be driven to rock. | |||

{|border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" | |||

!Pile Size!!A<sub>s</sub><br/>Area,<br/>sq. in.!!Structural<br/>Nominal<br/>Axial<br/>Compressive<br/>Resistance<br/>PNDC<sup>1,2</sup>,<br/>kips!!Φ<sub>c</sub><br/>Structural<br/>Resistance<br/>Factor<sup>4,5</sup>,<br/>LRFD 6.5.4.2!!Structural<br/>Factored<br/>Axial<br/>Compressive<br/>Resistance<sup>2,3,4</sup>,<br/>kips!!0.9*ϕ<sub>da</sub>*F<sub>y</sub><br/>Maximum<br/>Nominal<br/>Driving<br/>Stress,<br/>LRFD 10.7.8,<br/>ksi | |||

|- | |||

|HP 12x53|| 15.5|| 775|| 0.35|| 271|| 45.00 | |||

|- | |||

|HP 14x73|| 21.4|| 1070|| 0.35|| 375|| 45.00 | |||

|- | |||

|colspan="6" align="left"|'''<sup>1</sup>''' Structural Nominal Axial Compressive Resistance for fully embedded piles only. <br/><br/> Minimum Nominal Axial Compressive Resistance = Required nominal driving resistance, R<sub>ndr</sub><br/> = (Maximum factored axial loads / ϕ<sub>dyn</sub>) ≤ Structural nominal axial compressive resistance, PNDC LRFD 10.5.5.2.3<br/><br/> | |||

'''<sup>2</sup>''' Axial Compressive Resistance values shown above shall be reduced when downdrag is considered. | |||

<br/><br/>'''<sup>3</sup>''' Maximum factored axial load per pile ≤ Structural factored axial compressive resistance. | |||

<br/><br/>'''<sup>4</sup>''' Values are applicable for Strength Limit States. | |||

<br/><br/>'''<sup>5</sup>''' Use (Φ<sub>c</sub>) = 0.35 instead of 0.5 for structural resistance factor (LRFD 6.5.4.2) | |||

<br/><br/><br/>'''Notes: | |||

<br/><br/>ϕ<sub>dyn</sub> = Resistance factor of the dynamic method to be used to estimate nominal pile resistance during pile installation. LRFD Table 10.5.5.2.3-1 | |||

<br/><br/>For more information about selecting pile driving verification methods refer to [[751.36_Driven_Piles#751.36.5.3_Geotechnical_Resistance_Factor_.28.CF.95stat.29_and_Driving_Resistance_Factor_.28.CF.95dyn.29|EPG 751.36.5.3 Geotechnical Resistance Factor (ϕ<sub>stat</sub>) and Driving Resistance Factor (ϕ<sub>dyn</sub>)]]. | |||

<br/><br/>Drivability analysis shall be performed for all HP piles using Delmag D19-42. Do not show minimum hammer energy on plans. | |||

<br/><br/>Check drivability for all HP Pile in accordance with [[#751.36.5.11 Check Pile Drivability|EPG 751.36.5.11]] | |||

<br/><br/>For additional design requirements, see [[#751.36.5.1 Design Procedure Outline|EPG 751.36.5.1]]. | |||

|} | |||

</center> | |||

=== | =====751.36.5.7.1.2 Design Values for Individual Cast-In-Place (CIP) Pile===== | ||

<center> | |||

Modified Grade 3 F<sub>y</sub> = 50 ksi; F'<sub>c</sub> = 4 ksi; Structural Axial Compressive Resistance Factor, (Φ<sub>c</sub>)<sup>1,3</sup> = 0.35 | |||

{|border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" | |||

|- | |||

! colspan="8" | Unfilled Pipe For Axial Analysis<sup>2</sup> | |||

|- | |||

! Pile Outside Diameter O.D., in. !! Pile Inside Diameter I.D., in. !! Minimum Wall Thickness, in. !! Reduced Wall thick. for Fabrication (ASTM A252), in. !! A<sub>s</sub>,<sup>4</sup><br/>Area<br/>of<br/>Steel<br/>Pipe,<br/>sq. in. !! Structural<br/>Nominal<br/>Axial<br/>Compressive<br/>Resistance<br/>P<sub>n</sub><sup>5,6,7</sup>,<br/>kips !! Structural<br/>Factored Axial<br/>Compressive<br/>Resistance<sup>1,7,8</sup>,<br/>kips !! 0.9*ϕ<sub>da</sub>*F<sub>y</sub>*A<sub>s</sub><br/>Maximum<br/>Nominal<br/>Driving<br/>Resistance<sup>6</sup>,<br/>LRFD 10.7.8,<br/>kips | |||

|- | |||

| rowspan="2" | 14 || 13 || 0.5 || 0.44 || 18.47 || 923 || 323 || 831 | |||

< | |||

* | |||

|- | |- | ||

| 12.75 || 0.625<sup>9</sup> || 0.55 || 22.84 || 1142 || 400 || 1028 | |||

|- | |- | ||

| | | rowspan="2" | 16 || 15 || 0.5 || 0.44 || 21.22 || 1061 || 371 || 955 | ||

|- | |- | ||

| | | 14.75 || 0.625<sup>9</sup> || 0.55 || 26.28 || 1314 || 460 || 1183 | ||

|- | |- | ||

| | | rowspan="2" | 20 || 19 || 0.5 || 0.44 || 26.72 || 1336 || 468 || 1202 | ||

| | |||

| | |||

|- | |- | ||

| | | 18.75 || 0.625 || 0.55 || 33.15 || 1658 || 580 || 1492 | ||

|- | |- | ||

| | | rowspan="3" | 24 || 23 || 0.5 || 0.44 || 32.21 || 1611 || 564 || 1450 | ||

|- | |- | ||

| | | 22.75 || 0.625 || 0.55 || 40.03 || 2001 || 700 || 1801 | ||

|- | |- | ||

| | | 22.5 || 0.75 || 0.66 || 47.74 || 2387 || 835 || 2148 | ||

|- | |- | ||

| | | colspan="8" align="left" | | ||

| | '''<sup>1</sup>'''Values are applicable for Strength Limit States. | ||

'''<sup>2</sup>''' Use to determine preliminary number of pile and pile size. For piles predominantly embedded and tipped in cohesionless soils the maximum loads provided in [[#751.36.5.10 Pile Nominal Axial Compressive Resistance|EPG 751.36.5.10]] will control. | |||

'''<sup>3</sup>''' Use (Φ<sub>c</sub>) = 0.35 instead of 0.6 for structural axial compressive resistance factor (LRFD 6.5.4.2). Since ϕ<sub>dyn</sub> >> Φ<sub>c</sub> the maximum nominal driving resistance may not control. | |||

'''<sup>4</sup>''' Corrosion NOT considered at construction stage and for drivability analysis and static analysis. For drivability analysis and static analysis use reduced pipe nominal wall thickness, 12.5%, for fabrication (ASTM A252). | |||

'''<sup>5</sup>''' Structural Nominal Axial compressive resistance for fully embedded piles only. | |||

'''<sup>6</sup>''' Minimum Nominal Axial Compressive Resistance = Required nominal driving resistance, R<sub>ndr</sub> | |||

= | = Maximum factored axial loads / ϕ<sub>dyn</sub> ≤ Structural nominal axial compressive resistance, P<sub>n</sub> and LRFD 10.5.5.2.3 | ||

≤ Maximum nominal driving resistance. | |||

'''<sup>7</sup>''' Axial Compressive Resistance values shown above shall be reduced when downdrag is considered. | |||

'''<sup>8</sup>''' Maximum factored axial load per pile ≤ Structural factored axial compressive resistance. | |||

'''<sup>9</sup>''' 5/8” wall thickness is less commonly available than the smaller wall thicknesses of pipe pile. | |||

: | '''Notes: ''' | ||

Drivability analysis shall be performed for all CIP piles (unfilled pipe) using Delmag D19-42. Do not show minimum hammer energy on plans. | |||

Check drivability for all CIP Pile in accordance with [[#751.36.5.11 Check Pile Drivability|EPG 751.36.5.11]]. | |||

Require dynamic pile testing for field verification for all CIP piles on the plans. <br/>ϕ<sub>dyn</sub> = 0.65 = Dynamic Testing resistance factor to be used to estimate nominal pile resistance during pile installation. This value may be increased if static load testing is specified per LRFD Table 10.5.5.2.3-1. | |||

[[ | For additional design requirements, see [[#751.36.5.1 Design Procedure Outline|EPG 751.36.5.1]]. | ||

|} | |} | ||

</center> | |||

====751.36.5.7.2 General Pile Design==== | |||

The following design values are recommended for general use where the simple pile design method is not applicable per [[751.35 Concrete Pile Cap Integral End Bents#751.35.2.4.2 Pile Design|EPG 751.35.2.4.2 Pile Design]]. These values are not applicable for soils subject to liquefaction or scour where unbraced lengths may alter the design. | |||

=====751.36.5.7.2.1 Design Values for Individual HP Pile===== | |||

<center> | |||

= | F<sub>y</sub> = 50 ksi. End Bearing Piles (HP piles) anticipated to be driven to rock. | ||

{|border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" | |||

!Pile Size!!A<sub>s</sub><br/>Area,<br/>sq. in.!!Structural<br/>Nominal<br/>Axial<br/>Compressive<br/>Resistance<br/>PNDC<sup>1,2</sup>,<br/>kips!!Φ<sub>c</sub><br/>Structural<br/>Resistance<br/>Factor<sup>4</sup>,<br/>LRFD 6.5.4.2!!Structural<br/>Factored<br/>Axial<br/>Compressive<br/>Resistance<sup>2,3,4</sup>,<br/>kips!!0.9*ϕ<sub>da</sub>*F<sub>y</sub><br/>Maximum<br/>Nominal<br/>Driving<br/>Stress,<br/>LRFD 10.7.8,<br/>ksi | |||

|- | |||

|HP 12x53|| 15.5|| 775|| 0.5|| 388|| 45.00 | |||

|- | |||

|HP 14x73|| 21.4|| 1070|| 0.5|| 535|| 45.00 | |||

= | |||

= | |||

= | |||

|- | |- | ||

|[[ | |colspan="6" align="left"|'''<sup>1</sup>''' Structural Nominal Axial Compressive Resistance for fully embedded piles only. Structural Nominal Axial Compressive Resistance for unsupported piles shall be determined in accordance with LRFD 10.7.3.13.1. (i.e., intermediate pile cap bent).<br/><br/> Minimum Nominal Axial Compressive Resistance = Required nominal driving resistance, R<sub>ndr</sub><br/> = (Maximum factored axial loads / ϕ<sub>dyn</sub>) ≤ Structural nominal axial compressive resistance, PNDC LRFD 10.5.5.2.3<br/><br/> | ||

'''<sup>2</sup>''' Axial Compressive Resistance values shown above shall be reduced when downdrag is considered. | |||

<br/><br/>'''<sup>3</sup>''' Maximum factored axial load per pile ≤ Structural factored axial compressive resistance. | |||

<br/><br/>'''<sup>4</sup>''' Values are applicable for Strength Limit States. Modify value for other Limit States. | |||

<br/><br/><br/>'''Notes: | |||

<br/><br/>ϕ<sub>dyn</sub> = Resistance factor of the dynamic method to be used to estimate nominal pile resistance during pile installation. LRFD Table 10.5.5.2.3-1 | |||

<br/><br/>For more information about selecting pile driving verification methods refer to [[751.36_Driven_Piles#751.36.5.3_Geotechnical_Resistance_Factor_.28.CF.95stat.29_and_Driving_Resistance_Factor_.28.CF.95dyn.29|EPG 751.36.5.3 Geotechnical Resistance Factor (ϕ<sub>stat</sub>) and Driving Resistance Factor (ϕ<sub>dyn</sub>)]]. | |||

<br/><br/>Drivability analysis shall be performed for all HP piles using Delmag D19-42. Do not show minimum hammer energy on plans. | |||

<br/><br/>Check drivability for all HP Pile in accordance with [[#751.36.5.11 Check Pile Drivability|EPG 751.36.5.11]] | |||

<br/><br/>For additional design requirements, see [[#751.36.5.1 Design Procedure Outline|EPG 751.36.5.1]]. | |||

|} | |} | ||

</center> | |||

=====751.36.5.7.2.2 Design Values for Individual Cast-In-Place (CIP) Pile===== | |||

<center> | |||

Modified Grade 3 F<sub>y</sub> = 50 ksi; F'<sub>c</sub> = 4 ksi; Structural Resistance Factor, (Φ<sub>c</sub>)<sup>'''1'''</sup> = 0.6 | |||

{|border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" | |||

! colspan="8" | Unfilled Pipe For Axial Analysis<sup>2</sup> !! colspan="5" | Concrete Filled Pipe For Flexural Analysis<sup>3</sup> | |||

{| | |- | ||

! Pile Outside Diameter O.D., in. !! Pile Inside Diameter I.D., in. !! Minimum Wall Thickness, in. !! Reduced Wall thick. for Fabrication (ASTM A252), in. !! A<sub>s</sub>,<sup>4</sup> Area of Steel Pipe, sq. in. !! Structural Nominal Axial Compressive Resistance, P<sub>n</sub><sup>5,6,7</sup>, kips !! Structural Factored Axial Compressive Resistance<sup>1,7,8</sup>, kips !! 0.9*ϕ<sub>da</sub>*F<sub>y</sub>*A<sub>s</sub> Maximum<br/>Nominal<br/>Driving<br/>Resistance<sup>5,6</sup>, LRFD 10.7.8, kips !! Reduced Wall Thick. for Corrosion (1/16"), LRFD 5.13.4.5.2, in. !! A<sub>st</sub>,<sup>9</sup> Net Area of Steel Pipe, sq. in. !! A<sub>c</sub> Concrete Area, sq. in. !! Structural Nominal Axial Compressive Resistance PNDC<sup>5,7,10</sup>, kips !! Structural Factored Axial Compressive Resistance<sup>1,7,10</sup>, kips | |||

|- | |- | ||

| | | rowspan="2" | 14 || 13 || 0.5 || 0.44 || 18.47 || 923 || 554 || 831 || 0.375 || 15.76 || 133 || 1239 || 743 | ||

|- | |- | ||

| | | 12.75 || 0.625<sup>'''11'''</sup> || 0.55 || 22.84 || 1142 || 685 || 1028 || 0.484 || 20.14 || 128 || 1441 || 865 | ||

|- | |- | ||

| | | rowspan="2" | 16 || 15 || 0.5 || 0.44 || 21.22 || 1061 || 637 || 955 || 0.375 || 18.11 || 177 || 1506 || 904 | ||

|- | |- | ||

| | | 14.75 || 0.625<sup>'''11'''</sup> || 0.55 || 26.28 || 1314 || 788 || 1183 || 0.484 || 23.18 || 171 || 1740 || 1044 | ||

|- | |- | ||

| | | rowspan="2" | 20 || 19 || 0.5 || 0.44 || 26.72 || 1336 || 801 || 1202 || 0.375 || 22.83 || 284 || 2105 || 1263 | ||

|- | |- | ||

| | | 18.75 || 0.625 || 0.55 || 33.15 || 1658 || 995 || 1492 || 0.484 || 29.27 || 276 || 2402 || 1441 | ||

|- | |- | ||

| | | rowspan="3" | 24 || 23 || 0.5 || 0.44 || 32.21 || 1611 || 966 || 1450 || 0.375 || 27.54 || 415 || 2790 || 1674 | ||

| | |||

| | |||

|- | |- | ||

| | | 22.75 || 0.625 || 0.55 || 40.03 || 2001 || 1201 || 1801 || 0.484 || 35.36 || 406 || 3150 || 1890 | ||

|- | |- | ||

| | | 22.5 || 0.75 || 0.66 || 47.74 || 2387 || 1432 || 2148 || 0.594 || 43.08 || 398 || 3506 || 2103 | ||

|- | |- | ||

| | | colspan="13" align="left" | | ||

'''<sup>1</sup>''' Values are applicable for Strength Limit States. Modify value for other Limit States. | |||

'''<sup>2</sup>''' Use to determine preliminary number of pile and pile size. For piles predominantly embedded and tipped in cohesionless soils the maximum loads provided in [[#751.36.5.10 Pile Nominal Axial Compressive Resistance|EPG 751.36.5.10]] will control. | |||

''' | '''<sup>3</sup>''' Pipes placed in prebored holes in rock can use filled pipe capacity for axial plus flexural resistance. Therefore, number of piles should be based on this capacity assuming rock is infinitely more stiff. This recognizes that pile driving is not a concern. | ||

'''<sup>4</sup>''' Corrosion NOT considered at construction stage and for drivability analysis and static analysis. For drivability analysis and static analysis use reduced pipe nominal wall thickness, 12.5%, for fabrication (ASTM A252). | |||

'''<sup>5</sup>''' Structural Nominal Axial compressive resistance for fully embedded piles only. Value in table is a raw number and is the value used to determine the factored resistance. Structural Nominal Axial Compressive Resistance for unsupported piles shall be determined in accordance with LRFD 10.7.3.13.1. (i.e. Intermediate pile cap bent). | |||

'''<sup>6</sup>''' Minimum Nominal Axial Compressive Resistance = Required nominal driving resistance, R<sub>ndr</sub> | |||

= Maximum factored axial loads / ϕ<sub>dyn</sub> ≤ Structural nominal axial compressive resistance, P<sub>n</sub> and LRFD 10.5.5.2.3 | |||

≤ Maximum nominal driving resistance. | |||

'''<sup>7</sup>''' Axial Compressive Resistance values shown above shall be reduced when downdrag is considered | |||

'''<sup>8</sup>''' Maximum factored axial load per pile ≤ Structural factored axial compressive resistance | |||

< | '''<sup>9</sup>''' Net area of steel pipe, A<sub>st</sub>, assumes a 12.5% fabrication reduction (ASTM A252) and 1/16" (LRFD 5.13.4.5.2) reduction in pipe nominal wall thickness for corrosion. | ||

''' | '''<sup>10</sup>''' Use for lateral load analysis. Resistance value includes filled pipe based on net area of steel pipe, A<sub>st</sub> (12.5% fab. reduction and 1/16” corr. reduction in nominal pipe wall thickness). | ||

'''<sup>11</sup>''' 5/8” wall thickness is less commonly available than the smaller wall thicknesses of pipe pile. | |||

'''Notes: | |||

Drivability analysis shall be performed for all CIP piles (unfilled pipe) using Delmag D19-42. Do not show minimum hammer energy on plans. | |||

Check drivability for all CIP Pile in accordance with [[#751.36.5.11 Check Pile Drivability|EPG 751.36.5.11]]. | |||

Require dynamic pile testing for field verification for all CIP piles on the plans. | |||

ϕ<sub>dyn</sub> = 0.65 = Dynamic Testing resistance factor to be used to estimate nominal pile resistance during pile installation. This value may be increased if static load testing is specified per LRFD Table 10.5.5.2.3-1. | |||

For additional design requirements, see [[#751.36.5.1 Design Procedure Outline|EPG 751.36.5.1]]. | |||

|} | |||

</center> | |||

===751.36.5.8 Additional Provisions for Pile Cap Footings=== | |||

'''Pile Group Layout:''' | |||

P<sub>u</sub> = Total Factored Vertical Load. | |||

Preliminary Number of Piles Required = <math>\, \frac{Total\ Factored\ Vertical\ Load}{PFDC}</math> | |||

Layout a pile group that will satisfy the preliminary number of piles required. Calculate the maximum and minimum factored load applied to the outside corner piles assuming the pile cap/footing is perfectly rigid. The general equation is as follows: | |||

Max. Load = <math>\, \frac {P_u}{Total\ No.\ of\ Piles} + \frac {M_{ux} Y_i}{\Sigma Y_i^2} + \frac {M_{uy} X_i}{\Sigma X_i^2}</math> | |||

Min. Load = <math>\, \frac {P_u}{Total\ No.\ of\ Piles} - \frac {M_{ux} Y_i}{\Sigma Y_i^2} - \frac {M_{uy} X_i}{\Sigma X_i^2}</math> | |||

The maximum factored load per pile must be less than or equal to PFDC for the pile type and size chosen. If not, the pile size must be increased or additional piles must be added to the pile group. Reanalyze until the pile type, size and layout are satisfactory. | |||

'''Pile Uplift on End Bearing Piles and Friction Piles:''' | |||

:'''Service - I Limit State:''' | |||

::Minimum factored load per pile shall be ≥ 0. | |||

::Tension on a pile is not allowed for conventional bridges. | |||

:'''Strength and Extreme Event Limit States:''' | |||

::Uplift on a pile is not preferred for conventional bridges. | |||

::Maximum Pile Uplift load = │Minimum factored load per pile│ - │Factored pile uplift resistance│ ≥ 0<sup>'''1'''</sup> | |||

:::'''Note:''' Compute maximum pile uplift load if value of minimum factored load is negative. | |||

::::<sup>'''1'''</sup> The minimum factored load (maximum tensile load) per pile should preferably not result in uplift for the Strength and Extreme Event Limit States. Pile uplift for the Strength and Extreme Event limit states may be permitted by SPM or SLE based on infrequent uplift load cases and small magnitudes of uplift. This decision is based on the presumed difficulty of a pile cap footing to rotate, specifically for it to be able to rotate on piles driven to rock. When pile uplift is allowed, the necessity of top pile cap reinforcement shall be investigated and the standard anchorage detail for HP pile per [[#751.36.4.1 Structural Steel HP Pile - Details|EPG 751.36.4.1 Structural Steel HP Pile - Details]] shall be used. | |||

'''Resistance of Pile Groups in Compression''' '''LRFD 10.7.3.9''' | |||

If the cap is not in firm contact with the ground and if the soil at the surface is soft, the individual nominal resistance of each pile (751.36.5.5) shall be multiplied by an efficiency factor, <math>\eta</math>, based on pile spacing. | |||

===751.36.5.9 Estimate Pile Length and Check Pile Capacity=== | |||

====751.36.5.9.1 Estimated Pile Length==== | |||

'''Friction Piles:''' | |||

Estimate the pile length required to achieve the minimum nominal axial compressive resistance, MNACR, or required driving resistance, R<sub>ndr</sub>, for establishment of contract pile quantities. Perform a static analysis using one of the methods given in EPG [[751.36_Driven_Piles#751.36.5.3_Geotechnical_Resistance_Factor_(ϕstat)_and_Driving_Resistance_Factor_(ϕdyn)|751.36.5.3 Geotechnical Resistance Factor (ϕ<sub>stat</sub>) and Driving Resistance Factor (ϕ<sub>dyn</sub>)]] to determine the nominal resistance profile of the soil. For each soil layer the appropriate resistance factor, ϕ<sub>stat</sub>, shall be applied to account for the reliability of the static analysis method to create a factored resistance profile. The penetration depth would then occur at the location where the factored resistance profile intercepts the factored load. The relationship between the static axial compressive resistance and required driving resistance for a uniform soil profile with a constant static resistance factor is given as follows: | |||

:{| style="margin: 1em auto 1em auto" | |||

| | |||

|- | |- | ||

|ϕ<sub>dyn</sub> x R<sub>ndr</sub> = ϕ<sub>stat</sub> x R<sub>nstat</sub> ≥ Factored Load||width="450"| ||LRFD C10.7.3.3-1 | |||

|} | |} | ||

Where: | |||

:ϕ<sub>dyn</sub> = see [[#751.36.5.3 Geotechnical Resistance|EPG.751.36.5.3]] | |||

:R<sub>ndr</sub> = Required nominal driving resistance = MNACR | |||

:ϕ<sub>stat</sub> = Static analysis resistance factor per [[751.36_Driven_Piles#751.36.5.3_Geotechnical_Resistance_Factor_(ϕstat)_and_Driving_Resistance_Factor_(ϕdyn)|EPG 751.36.5.3]] or as provided by the Geotechnical Engineer. Factors for side friction and end bearing may be different. | |||

:R<sub>nstat</sub> = Required nominal static resistance | |||

Use soil profiles from borings and mimic soil characteristics as closely as possible in computations or software to calculate the geotechnical resistance and for estimating the length of pile. For more detailed guidance see [https://www.modot.org/media/54989 SEG 25-001 New Policy for Friction Pile]. | |||

It is not advisable to design pile deeper than available borings or to reach capacity within the bottom 3 to 5 feet of borings. If a longer pile depth is needed to meet design requirements then request Geotechnical Section to provide deeper borings or increase the number of piles which will reduce load per pile as well as the required pile length. | |||

For friction pile the top five feet of soil friction resistance may be neglected with SPM or SLE approval for possible disturbance from MSE wall excavation prior to driving pile. | |||

'''End Bearing Piles:''' | |||

The estimated pile length is the distance along the pile from the cut-off elevation to the estimated tip elevation considering any penetration into rock. The estimated tip elevation shall not be shown on plans for end bearing piles. | |||

The geotechnical material above the estimated end bearing tip elevation shall be reviewed for the presence of glacial till or similar layers. If these layers are present, then a static analysis shall be performed to verify if the required pile resistance is reached at a higher elevation due to pile friction capacity. | |||

====751.36.5.9.2 Check Pile Geotechnical Capacity (Axial Loads Only)==== | |||

Use the same methodology outlined in [[#751.36.5.9.1 Estimated Pile Length|EPG 751.36.5.9.1 Estimated Pile Length]]. | |||

====751.36.5.9.3 Check Pile Structural Capacity (Combined Axial and Bending)==== | |||

Structural design checks which include lateral loading and bending shall be accomplished using the appropriate structural resistance factors. | |||

===751.36.5.10 Pile Nominal Axial Compressive Resistance === | |||

The | The minimum nominal axial compressive resistance, MNACR, or required driving resistance, R<sub>ndr</sub>, must be calculated and shown on the final plans. The factored axial compressive resistance will be used to verify the pile group layout and loading. The minimum nominal axial compressive resistance will be used in construction field verification methods to obtain the required nominal driving resistance. | ||

: Minimum Nominal Axial Compressive Resistance, MNACR = Required Nominal Driving Resistance, R<sub>ndr</sub> | |||

: = Maximum factored axial loads/ϕ<sub>dyn</sub> | |||

:ϕ<sub>dyn</sub> = Resistance factor of the dynamic method used to estimate nominal pile resistance during pile installation. LRFD 10.5.5.2.3.1 | |||

The value of R<sub>ndr</sub> shown on the plans shall be the greater of the value required at the '''Strength limit state and Extreme Event limit state'''. This value shall not be greater than the structural nominal axial compressive resistance of the steel HP pile nor shall it exceed the maximum nominal driving resistance of the steel shell for CIP piles. See [[#751.36.5.5 Preliminary Structural Nominal Axial Design Capacity (PNDC) of an individual pile |EPG 751.36.5.5]]. LRFD 10.7.7 | |||

For friction piles predominantly embedded and tipped in cohesionless soils the minimum nominal axial compressive resistance shall be limited to the values shown in the following table. Approval from the SPM, SLE or owner's representative is required before exceeding the limits provided in this table. | |||

{| border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" | |||

{| | |+ '''Maximum Axial Loads for Friction Pile in Cohesionless Soils''' | ||

! rowspan="3" | Pile Type !! rowspan="3" | Minimum Nominal<br/>Axial Compressive<br/>Resistance (R<sub>ndr</sub>)<sup>'''1'''</sup><br/>(kips)<br/> !! colspan="3" | Maximum Factored Axial Load (kips) | |||

|- | |- | ||

! Dynamic Testing !! Wave Equation<br/>Analysis !! FHWA-modified<br/>Gates Dynamic<br/>Pile Formula | |||

|- | |- | ||

! ϕ<sub>dyn</sub>= 0.65 !! ϕ<sub>dyn</sub> = 0.50 !! ϕ<sub>dyn</sub> = 0.40 | |||

|- | |- | ||

| | | CIP 14” || 210 || 136 || 105 || 84 | ||

|- | |- | ||

| | | CIP 16” || 240 || 156 || 120 || 96 | ||

|- | |- | ||

| | | CIP 20” || 300 || 195 || 150 || 120 | ||

|- | |- | ||

| | | CIP 24” || 340 || 221 || 170 || 136 | ||

| | |||

| | |||

| | |||

| | |||

|- | |- | ||

| colspan="5" align="left" | <sup>'''1'''</sup> The minimum nominal axial compressive resistance values are correlated to match the maximum design tonnage values used in past ASD practice. A factor of safety of 3.5 is used to determine the equivalent R<sub>ndr</sub>. | |||

|} | |} | ||

===751.36.5.11 Check Pile Drivability=== | |||

Drivability of the pile through the soil profile shall be investigated using the GRLWEAP wave equation analysis program. The static axial compressive resistance profile used in the wave equation analysis shall be determined using one of the approved static methods given in [[751.36_Driven_Piles#751.36.5.3_Geotechnical_Resistance_Factor_(ϕstat)_and_Driving_Resistance_Factor_(ϕdyn)|EPG 751.36.5.3]]. | |||

Drivability analysis shall be performed by the designer for all pile types (bearing pile and friction pile) using the Delmag D19-42 hammer with manufacturer recommendations. The drivability analysis shall confirm that the pile can be driven to the minimum tip elevation, rock elevation or reach the minimum nominal axial compressive resistance prior to refusal and without overstressing the pile. If the drivability analysis shows overstress or refusal prior to reaching the desired depth a lighter or heavier hammer from the table below may be used to confirm constructability. The drivability analysis is not intended to confirm that a pile can be driven through rock (shales, sandstones, etc…) where the likelihood of pile damage is increased and PDA is recommended to reduce loads and monitor pile stresses in the field. The drivability analyses performed by the designer does not waive the responsibility of the contractor in selecting the appropriate pile driving system per Sec 702.3.5 (also discussed below). | |||

Use soil profiles from borings and mimic soil characteristics as closely as possible for computations or in software to perform drivability analysis of any kind of pile. | |||

'''Structural steel HP Pile:''' | |||

Drivability analysis shall be performed for the box shape of the pile (i.e., not the perimeter). | |||

Drivability shall be performed considering existing condition without considering any excavation/ disturbance (i.e., possible disturbance to top 5 feet of soil from MSE wall excavation prior to driving pile), liquefaction or future scour loss. | |||

''' | '''Hammer types:''' | ||

{| border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" | |||

{| | |+ '''Pile Driving Hammer Information For GRLWEAP''' | ||

! colspan="3" | Hammer used in the field per survey response (2017) | |||

| | |||

|- | |- | ||

! | ! GRLWEAP ID !! Hammer name !! No. of Responses | ||

|- | |- | ||

| | | 41 || Delmag D19-42<sup>1</sup> || 13 | ||

|- | |- | ||

| | | 40 || Delmag D19-32 || 6 | ||

|- | |- | ||

| | | 38 || Delmag D12-42 || 4 | ||

|- | |- | ||

| | | 139 || ICE 32S || 4 | ||

|- | |- | ||

| | | 15 || Delmag D30-32 || 2 | ||

|- | |- | ||

| | | || Delmag D25-32 || 2 | ||

|- | |- | ||

| | | 127 || ICE 30S || 1 | ||

|- | |- | ||

| | | 150 || MKT DE-30B || 1 | ||

|- | |- | ||

| colspan="3 | | colspan="3" | <sup>'''1</sup>''' Delmag series of pile hammers is the most popular, with the D19-42 being the most widely used. | ||

|} | |} | ||

The contractor is responsible for determining the driving system required to successfully drive the pile to the minimum tip elevation and to reach the minimum nominal axial compressive resistance specified on the plans. The contractor is required to perform a drivability analysis to select an appropriate hammer size to ensure the pile can be driven without overstressing the pile and to prevent refusal of the pile prior to reaching the minimum tip elevation. The contractor shall plan pile driving activities and submit hammer energy requirements to the engineer for approval before driving. There is an exception to the contractor’s responsibility for the drivability analysis when WEAP is specified as the driving criteria for friction pile. When WEAP is specified for friction pile an inspector’s chart will be provided for the contractor in the electronic deliverables. For more detailed guidance see [https://www.modot.org/media/54989 SEG 25-001 New Policy for Friction Pile]. | |||

Practical refusal is defined at 20 blows/inch or 240 blows per foot. | |||

Driving should be terminated immediately once 30 blows/inch is encountered. | |||

:{| style="margin: 1em auto 1em auto" | |||

{| | |||

|- | |- | ||

| ''' | |'''Nominal Driving Stress'''||width="840"| ||'''LRFD 10.7.8''' | ||

|} | |} | ||

:Nominal driving stress ≤ 0.9*ϕ<sub>da</sub>*F<sub>y</sub> | |||

::For structural steel HP pile, Maximum nominal driving stress = 45 ksi | |||

::For CIP pile, Maximum nominal driving resistance, see [[#751.36.5.7.2.1 Design Values for Individual HP Pile|EPG 751.36.5.7.1.2]] or [[#751.36.5.7.2.2 Design Values for Individual Cast-In-Place (CIP) Pile|EPG 751.36.5.7.2.2]] (unfilled pipe for axial analysis). | |||

If analysis indicates the piles do not have sufficient structural or geotechnical strength or drivability issues exist, then consider increasing the number of piles. | |||

===751.36.5.12 Information to be Included on the Plans=== | |||

See [https://epg.modot.org/index.php?title=751.50_Standard_Detailing_Notes#A1._Design_Specifications.2C_Loadings_.26_Unit_Stresses EPG 751.50 A1 Design Specifications, Loadings & Unit Stresses] for appropriate design stresses to be included in the general notes. | |||

See [https://epg.modot.org/index.php?title=751.50_Standard_Detailing_Notes#E2._Foundation_Data_Table EPG 751.50 E2 Foundation Data Table] for appropriate data to be included in the foundation data table for HP pile and CIP pile and any additional notes required below the table. See [https://www.modot.org/pile-pile Bridge Standard Drawings “Pile”] for CIP data table. | |||

<br><br> | |||

<hr style="border:none; height:2px; background-color:red;" /> | |||

<br><br> | |||

=== | === E2. Foundation Data Table === | ||

The following table is to be placed on the design plans and filled out as indicated. | |||

'''(E2.1) <font color="purple">[MS Cell] (E2.1)</font color="purple"> (Example: Use the underlined parts in the bent headings for bridges having detached wing walls at end bents only.) ''' | |||

<center> | |||

{|border="1" style="text-align:center;" cellpadding="5" cellspacing="0" | |||

|- | |- | ||

| | !colspan="8" style="background:#BEBEBE"| Foundation Data<sup>1</sup> | ||

|- | |- | ||

| colspan="2" | | !rowspan="2" style="background:#BEBEBE"|Type!!rowspan="2" style="background:#BEBEBE" colspan="2"|Design Data!!colspan="5" style="background:#BEBEBE"| Bent Number | ||

|- | |- | ||

| | !style="background:#BEBEBE"|1 <u>(Detached<br/>Wing Walls<br/>Only)</u> !!style="background:#BEBEBE"|1 <u>(Except<br/>Detached<br/>Wing Walls)</u> !!style="background:#BEBEBE"|2 !!style="background:#BEBEBE"| 3 !!style="background:#BEBEBE"|4 | ||

|- | |- | ||

| | |rowspan="11"|'''Load<br/>Bearing<br/>Pile'''|| colspan="2" align="left" width="300"|CECIP/OECIP/HP Pile Type and Size||CECIP 14"||CECIP 14"||CECIP 16"|| OECIP 24"||HP 12x53 | ||

|- | |- | ||

| | |colspan="2" align="left" width="300"|Number [[image:751.50 ea.jpg|34px|right]]||6||8||15||12||6 | ||

|- | |||

|colspan="2" align="left" width="300"|Approximate Length Per Each [[image:751.50 ft.jpg|20px|right]]||50||50||60||40||53 | |||

===751. | |||

|- | |- | ||

| colspan="2" | [[image:751. | |colspan="2" align="left" width="300"|Pile Point Reinforcement[[image:751.50 ea.jpg|34px|right]]||All||All|| - ||All||All | ||

|- | |||

| | |||

|- | |- | ||

| | |colspan="2" align="left" width="300"|Min. Galvanized Penetration (Elev.) [[image:751.50 ft.jpg|20px|right]]||303||295<sup>'''4'''</sup>||273||Full Length||300 | ||

|- | |- | ||

| | |colspan="2" align="left" width="300"|Est. Max. Scour Depth 100<sup>'''2'''</sup> (Elev.) [[image:751.50 ft.jpg|20px|right]]|| - || - ||285 || - || - | ||

|- | |- | ||

| | |colspan="2" align="left" width="300"|Minimum Tip Penetration (Elev.) [[image:751.50 ft.jpg|20px|right]]||285||303||270|| - || - | ||

|- | |- | ||

| | |colspan="2" align="left" width="300"|Criteria for Min. Tip Penetration ||Min. Embed.||Min. Embed.|| Scour || - || - | ||

|- | |- | ||

| colspan=" | |colspan="2" align="left" width="300"|Pile Driving Verification Method || DT ||DT ||DT||DT||DF | ||

|- | |- | ||

| colspan=" | |colspan="2" align="left" width="300"|Resistance Factor||0.65|| 0.65|| 0.65|| 0.65|| 0.4 | ||

|- | |- | ||

| colspan=" | |colspan="2" align="left" width="300"|<u>Design Bearing</u><sup>'''3'''</sup> <u>Minimum Nominal Axial</u><br/><u>Compressive Resistance</u> [[image:751.50 kip.jpg|27px|right]]||175||200||300||600||250 | ||

|- | |- | ||

| | |rowspan="2"|'''Spread<br/>Footing||colspan="2" align="left"|Foundation Material || - || - ||Weak Rock||Rock|| - | ||

|- | |- | ||

| colspan=" | |colspan="2" align="left"|<u>Design Bearing</u> <u>Minimum Nominal</u><br/><u>Bearing Resistance</u> [[image:751.50 ksf.jpg|30px|right]]|| - || - ||10.2||22.6|| - | ||

|- | |- | ||

| colspan=" | |rowspan="8"|'''Rock<br/>Socket'''||colspan="2" align="left"|Number [[image:751.50 ea.jpg|34px|right]]|| - || - || 2 ||3|| - | ||

|- | |- | ||

| | |rowspan="3" width="35"|[[image:751.50 Layer 1.jpg|center|24px]]||align="left" width="265"|Foundation Material|| - || - || Rock||Rock|| - | ||

| | |||

|- | |- | ||

| align="left"|Elevation Range [[image:751.50 ft.jpg|20px|right]]|| - || - ||410-403||410-398|| - | |||

|- | |- | ||

| align="left"|<u>Design Side Friction</u><br/><u>Minimum Nominal Axial</u><br/><u>Compressive Resistance</u><br/><u>(Side Resistance)</u> [[image:751.50 ksf.jpg|30px|right]]|| - || - ||20.0||20.0|| - | |||

|- | |- | ||

| | |rowspan="3"|[[image:751.50 Layer 2.jpg|center|21px]]|| align="left" |Foundation Material|| - || - ||Weak Rock|| - || - | ||

|- | |- | ||

| | | align="left"|Elevation Range [[image:751.50 ft.jpg|20px|right]]|| - || - ||403-385|| - || - | ||

|- | |- | ||

| | | align="left"|<u>Design Side Friction</u><br/><u>Minimum Nominal Axial</u><br/><u>Compressive Resistance</u><br/><u>(Side Resistance)</u> [[image:751.50 ksf.jpg|30px|right]]|| - || - ||9.0|| - || - | ||

|- | |- | ||

| | |colspan="2" align="left"|<u>Design End Bearing</u><br/><u>Minimum Nominal Axial</u><br/><u>Compressive Resistance</u><br/><u>(Tip Resistance)</u> [[image:751.50 ksf.jpg|30px|right]]|| - || - ||12||216|| - | ||

|- | |- | ||

| | |colspan="8" align="left"|'''1''' Show only required CECIP/OECIP/HP pile data for specific project. | ||

|- | |- | ||

| | |colspan="8" align="left"|'''2''' Show maximum of total scour depths estimated for multiple return periods in years from Preliminary design which should be given on the Design Layout. Show the controlling return period (e.g. 100, 200, 500). If return periods are different for different bents, add a new line. | ||

|- | |- | ||

| | |colspan="8" align="left"|'''3''' For LFD: For bridges in Seismic Performance Categories B, C and D, the design bearing values for load bearing piles given in the table should be the larger of the following two values: <br/> 1. Design bearing value for AASHTO group loads I thru VI. <br/> 2. Design bearing for seismic loads / 2.0 | ||

|- | |- | ||

| colspan=" | |colspan="8" align="left"|'''4''' It is possible that min. tip penetration (elev.) can be higher than min. galvanized penetration (elev.). | ||

''' | |||

|} | |} | ||

{|border="2" style="text-align:center;" cellpadding="5" cellspacing="0" | |||

{| style=" | |||

|- | |- | ||

| | | align="left"|'''Additional notes:'''<br/> On the plans, report the following definition(s) just below the foundation data table for the specific method(s) used:<br/> | ||

DT = Dynamic Testing<br/> | |||

DF = FHWA-modified Gates Dynamic Pile Formula<br/> | |||

WEAP = Wave Equation Analysis of Piles<br/> | |||

SLT = Static Load Test<br/><br/>On the plans, report the following definition(s) just below the foundation data table for CIP Pile:<br/>CECIP = Closed Ended Cast-In-Place concrete pile<br/>OECIP = Open Ended Cast-In-Place concrete pile<br/><br/>On the plans, report the following equation(s) just below the foundation data table for the specific foundation(s) used:<br/>'''Rock Socket (Drilled Shafts):'''<br/>Minimum Nominal Axial Compressive Resistance (Side Resistance + Tip Resistance) = Maximum Factored Loads/Resistance Factors<br/>'''Spread Footings:'''<br/>Minimum Nominal Bearing Resistance = Maximum Factored Loads/Resistance Factor <br/>'''Load Bearing Pile:'''<br/>Minimum Nominal Axial Compressive Resistance = Maximum Factored Loads/Resistance Factor | |||

|} | |} | ||

</center> | |||

{|style="padding: 0.3em; margin-left:10px; border:1px solid #a9a9a9; text-align:left; font-size: 95%; background:#f5f5f5" width="700px" align="center" | |||

|- | |||

=== | |colspan="3" align="left"|<b>Guidance for Using the Foundation Data Table:</b> | ||

|- | |||

|rowspan="18"| || rowspan="4"|Pile Driving Verification Method ||width="350px"|DF = FHWA-Modified Gates Dynamic Pile Formula | |||

|- | |||

|DT = Dynamic Testing | |||

|- | |||

|WEAP = Wave Equation Analysis of Piles | |||

|- | |||

|SLT = Static Load Test | |||

|- | |- | ||

| colspan=" | |colspan="7" style="background:#BEBEBE"| | ||

|- | |- | ||

| | |rowspan="7"|Criteria for Minimum Tip Penetration ||Scour | ||

|- | |- | ||

| | |Tension or uplift resistance | ||

|- | |- | ||

| | |Lateral stability | ||

|- | |- | ||

| | |Penetration anticipated soft geotechnical layers | ||

|- | |- | ||

| | |Minimize post construction settlement | ||

|- | |- | ||

| | |Minimum embedment into natural ground | ||

|- | |- | ||

| | |Other Reason | ||

|- | |- | ||

| | |colspan="7" style="background:#BEBEBE"| | ||

|- | |- | ||

| | |colspan="7"|'''Elevation reporting accuracy: Report to nearest foot for min. tip penetration, pile cleanout penetration, max. galvanized depth and est. max. scour depth. (Any more accuracy is acceptable but not warranted.)''' | ||

| | |||

|- | |- | ||

| | |colspan="3"|'''For LFD Design''' | ||

|- | |- | ||

| | |colspan="3"|Use "Design Bearing" for load bearing pile and spread footing and use "Design Side Friction + Design End Bearing" for rock socket (drilled shaft). | ||

|- | |- | ||

| | |colspan="3"|'''For LRFD Design''' | ||

|- | |- | ||

| colspan=" | |colspan="3"|Use "Minimum Nominal Axial Compressive Resistance" for load bearing pile, "Minimum Nominal Bearing Resistance" for spread footing and "Minimum Nominal Axial Compressive Resistance (Side Resistance + Tip Resistance)" for rock socket (drilled shaft). | ||

|} | |||

'''Shallow Footings ''' | |||

( | '''(E2.10) (Use when shallow footings are specified on the Design Layout.)''' | ||

:In no case shall footings of Bents No. <u> </u> and <u> </u> be placed higher than elevations shown <u> </u> and <u> </u>, respectively. | |||

'''Driven Piles''' | |||

( | '''(E2.20) (Use when prebore is required and the natural ground line is not erratic.)''' | ||

:Prebore for piles at Bent(s) No.<u> </u> and <u> </u> to elevation(s) <u> </u> and <u> </u>, respectively. | |||

'''(E2.21) (Use when prebore is required and the natural ground line is erratic.)''' | |||

:Prebore to natural ground line. | |||

<div id="(E2.22) (Use the following note"></div> | |||

'''(E2.22) (Use when estimated maximum scour depth (elevation) for CIP piles is required.) ''' | |||

:Estimated Maximum Scour Depth (Elevation) shown is for verifying <u>Minimum Nominal Axial Compressive Resistance</u> <u>Design Bearing</u> using dynamic testing only where pile resistance contribution above this elevation shall not be considered. | |||

'''(E2.23) (Use when static test piles are required.) The number of piles in table should not include probe piles. If probe piles are specified, place an * beside the number of piles at the bents indicated.''' | |||

: *One concrete probe pile shall be driven in permanent position, one for each bent, at Bents No. <u> </u> and <u> </u>. | |||

'''(E2.24) ''' | |||

:All piles shall be galvanized down to the minimum galvanized penetration (elevation). | |||

'''(E2.25) (Use for all HP pile and when pile point reinforcement is required for CIP pile.)''' | |||

:Pile point reinforcement need not be galvanized. Shop drawings will not be required for pile point reinforcement. | |||

<div id="(E2.26)"></div> | |||

'''(E2.26) (Use for LFD piling design when Design Bearing is determined from service loads and shown on the plans. See guidance on <font color="purple">[MS Cell] (E2.1)</font color="purple"> for specific pile driving verification method. Example: Considered only for widenings, repairs and rehabilitations.) ''' | |||

:All piling shall be driven to a minimum nominal axial compressive resistance equal to <u>3.5</u> <u>2.75</u> <u>2.25</u> <u>2.00</u> times the Design Bearing as shown on the plans. | |||

<div id="(E2.27)"></div> | |||

'''(E2.27) Use for galvanized piles.''' | |||

( | |||

( | |||

:The contractor shall make every effort to achieve the minimum galvanized penetration (elevation) shown on the plans for all piles. Deviations in penetration less than 5 feet of the minimum will be considered acceptable provided the contractor makes the necessary corrections to ensure the minimum penetration is achieved on subsequent piles. | |||

'''(E2.28) Use when WEAP is specified as the pile driving criteria for friction pile. Place an * behind each instance of WEAP in the Foundation Data table. The pay item Pile Wave Analysis shall not be included when this note is used.''' | |||

:<nowiki>*</nowiki>See electronic deliverables file for pile driving inspector’s chart(s). MoDOT will provide alternate charts for different driving systems as needed per request. With the request, the contractor shall provide the hammer manufacturer make and model, and any modifications to the manufacturer’s recommended settings including hammer cushion information. The contractor shall provide the request 30 calendar days before pile driving operations begin. | |||

='''REVISION REQUEST 4151'''= | |||

====127.2.3.3.1 Missouri Unmarked Human Burials Law==== | |||

If human skeletal remains are encountered during construction, their treatment will be handled in accordance with [https://revisor.mo.gov/main/OneChapter.aspx?chapter=194 Sections 194.400 to 194.410, RSMo], as amended. When human remains are encountered, the Contractor shall first stop all work within a 330-ft. or 100-meter radius of the remains, and secondly, shall notify the MoDOT Construction Inspector and/or Resident Engineer who will contact the Historic Preservation section. Historic Preservation staff will in turn notify the local law enforcement (to ensure that it is not a crime scene) and the State Historic Preservation Office (SHPO) as per RSMo 194 or to notify SHPO what has occurred and that it is covered by Missouri’s Cemeteries Law, §§ 214. RSMo. If the contractor is unable to contact appropriate MoDOT staff, the contractor shall initiate the involvement by local law enforcement and the SHPO. A description of the contractor’s actions will be promptly made to MoDOT. | |||

If the human remains are prehistoric, the agency must consult with Indian tribes who have with ancestral, historic, and ceded land connections to the area in which the remains are located to determine the appropriate treatment of the remains. [http://www.modot.org/ehp/TribalMap.htm Tribal consultation] may result in the conclusion that the remains should be preserved in place and construction plans changed to facilitate their preservation. | |||

<br><br> | |||

<hr style="border:none; height:2px; background-color:red;" /> | |||

<br><br> | |||

== | ==127.2.9 Construction Inspection Guidance== | ||

Mitigation by data recovery is usually completed prior to construction if the presence of cultural resources is known. If [http://epg.modot.org/index.php/127.2_Historic_Preservation_and_Cultural_Resources#127.2.8_Artifacts_and_Features artifacts] are discovered during construction activities, the Historic Preservation section must be immediately notified. This will allow an inspection of the site by MoDOT HP staff to determine if further investigation is necessary before construction activities continue. | |||

[http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=4 Sec. 107.8.2] and [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=5 Sec. 203.4.8] of the ''Missouri Standard Specifications for Highway Construction'' require the contractor to take steps to preserve any such artifacts that may be encountered and to notify the MoDOT Construction Inspector or Resident Engineer of their presence. If it is necessary to discontinue operations in a particular area to preserve such objects, this section of the specifications is basis for a work suspension. In order to ensure compliance with applicable state laws, the MoDOT Construction Inspector or Resident Engineer cannot release remains or artifacts or allow the contractor to disturb the area within the 330-foot or 100-meter buffer space around these discovered items, until after consultation with MoDOT HP staff and until after all applicable requirements from FHWA or SHPO have been addressed. | |||

===127.2.9.1 Cultural Resources Encountered During Construction=== | |||

If cultural resources are encountered during construction, the contractor shall immediately stop all work within a 330-foot or 100-meter buffer around the limits of the resource and shall not resume without specific authorization from a MoDOT Historic Preservation Specialist. The contractor shall notify the MoDOT Resident Engineer or Construction Inspector, who shall contact the MoDOT HP within 24 hours of the discovery. MoDOT HP shall contact FHWA and SHPO within 48 hours of learning of the discovery and provide an evaluation of the resource and reasonable efforts to see if it can be avoided. FHWA shall make an eligibility and effects determination based upon the preliminary evaluation and consul with MoDOT, and SHPO a minimize or mitigate any adverse effect. FHWA will notify the Council and any tribes that might attach religious and/or cultural significance to the property within 48 hours of this determination. FHWA shall take into account Council and Tribal recommendations regarding the eligibility of the property and proposed actions, and direct MoDOT to carry out the appropriate actions. MoDOT will provide FHWA and SHPO with a report of the actions when they are completed. FHWA shall provide this report to the council and the tribes. | |||

===127.2.9.2 Human Remains Encountered During Construction=== | |||

If human remains are encountered during construction, the contractor shall immediately stop all work within a 330-foot or 100-meter radius of the remains and shall not resume without specific authorization from MoDOT HP Staff, and either the SHPO or the local law enforcement officer, whichever party has jurisdiction over and responsibility for such remains. The contractor shall notify the MoDOT Construction Inspector and/or Resident Engineer who will contact the MoDOT HP section within 24 hours of the discovery. MoDOT HP staff will immediately notify the local law enforcement (to ensure that it is not a crime scene) and the SHPO as per RSMo 194 or to notify SHPO what has occurred and that it is covered by Missouri’s Cemeteries Law, §§ 214. RSMo. MoDOT HP staff will notify FHWA that human remains have been encountered within 24 hours of being notified of the find. If, within 24 hours, the contractor is unable to contact appropriate MoDOT staff, the contractor shall initiate the involvement by local law enforcement and the SHPO. A description of the contractor’s actions will be promptly made to MoDOT. FHWA will notify any Indian tribe that might attach cultural affiliation to the identified remains as soon as possible after their identification. FHWA shall take into account Tribal recommendations regarding treatment of the remains and proposed actions, and then direct MoDOT HP to carry-out the appropriate actions in consultation with the SHPO. MoDOT shall monitor the handling of any such human remains and associated funerary objected, sacred object or objects of cultural patrimony in accordance with the Missouri Unmarked Human Burial Sites Act, §§ 194.400 – 194.410, RSMo. | |||

Latest revision as of 16:04, 3 February 2026

REVISION REQUEST 4036

106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity

1. Chemical Analysis

The chemical analysis of aggregate reactivity is an objective, quantifiable and repeatable test. MoDOT will perform the chemical analysis per the process identified in ASTM C 25 for determining the aggregate composition. The analysis determines the calcium oxide (CaO), magnesium oxide (MgO), and aluminum oxide (Al2O3) content of the aggregate. The chemical compositions are then plotted on a chart with the CaO/MgO ratio on the y-axis and Al2O3 percentage on the x-axis per Fig. 2 in AASHTO R 80. Aggregates are considered potentially reactive if the Al2O3 content is greater than or equal to 1.0% and the CaO/MgO ratio is either greater than or equal to 3.0 or less than or equal to 10.0 (see chart below). See flow charts in 106.3.2.93.2 for approval hierarchy. CaO, MgO and Al2O3 shall be analyzed by instrumental analysis only.

* MoDOT’s upper and lower limits of potentially reactive (shaded area) aggregates.

2. Petrographic Examination

A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum:

- Quarry name and ledge name; all ledges if used in combination

- MoDOT District quarry resides

- Date sample was obtained; date petrographic analysis was completed

- Name of petrographer and company/organization affiliated

- Lithographic descriptions with photographs of the sample(s) examined

- Microphotographs of aggregate indicating carbonate particles and/or other reactive materials

- Results of the examination

- All conclusions related to the examination

See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer.

3. Concrete Prism/Beam Test

ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy.

REVISION REQUEST 4143

751.36.5 Design Procedure

- Structural Analysis

- Geotechnical Analysis

- Drivability Analysis

751.36.5.1 Design Procedure Outline

- Determine foundation load effects from the superstructure and substructure for Service, Strength and Extreme Event Limit States.

- If applicable, determine scour depths, liquefaction information and pile design unbraced length information.

- Determine if downdrag loadings should be considered.

- Select preliminary pile size and pile layout.

- Perform a Static Pile Soil Interaction Analysis. Estimate Pile Length and pile capacity.

- Based on pile type and material, determine Resistance Factors for Structural Strength ( and ).

- Determine:

- Maximum axial load effects at toe of a single pile

- Maximum combined axial & flexural load effects of a single pile

- Maximum shear load effect for a single pile

- Uplift pile reactions

- Determine Nominal and Factored Structural Resistance for single pile

- Determine Structural Axial Compression Resistance

- Determine Structural Flexural Resistance

- Determine Structural Combined Axial & Flexural Resistance

- Determine Structural Shear Resistance

- Determine method for pile driving acceptance criteria

- Determine Resistance Factor for Geotechnical Resistance () and Driving Resistance ().

- If other than end bearing pile on rock or shale, determine Nominal Axial Geotechnical Resistance for pile.

- Determine Factored Axial Geotechnical Resistance for single pile.

- Determine Nominal pullout resistance if pile uplift reactions exist.

- Check for pile group effects.

- Resistance of Pile Groups in Compression

- Check Drivability of all pile (bearing and friction pile) using the Wave equation analysis.

- Review Static Pile Soil Interaction Analysis and pile lengths for friction pile.

- Show proper Pile Data on Plan Sheets (Foundation Data Table).

751.36.5.2 Structural Resistance Factor (ϕc and ϕf) for Strength Limit State

| LRFD 6.5.4.2 |

For integral end bent simple pile design, use Φc = 0.35 for CIP steel pipe piles and HP piles. See Figure 751.35.2.4.2.

For pile at all locations where integral end bent simple pile design is not applicable, use the following:

- The structural resistance factor for axial resistance in compression is dependent upon the expected driving conditions. When the pile is subject to damage due to severe driving conditions where use of pile point reinforcement is necessary:

- Steel Shells (Pipe): = 0.60

- HP Piles: = 0.50

- When the pile is subject to good driving conditions where use of pile point reinforcement is not necessary:

- Steel Shells (Pipe) Piles: = 0.70

- HP Piles: = 0.60

- For HP piles, pile point reinforcement is always required when HP piles are anticipated to be driven to rock and proofed. Driving HP piles to rock is considered severe driving conditions for determination of structural resistance factor. However, driving HP piles through overburden not likely to impede driving to deep rock or preboring to rock for setting piles are two situations that could be considered as less than severe. Further, driving any steel pile through soil without rubble, boulders, cobbles or very dense gravel could be considered good driving conditions for determination of structural resistance factor. Consult the Structural Project Manager or Structural Liaison Engineer.

- The structural resistance factor for combined axial and flexural resistance of undamaged piles:

- Axial resistance factor for HP Piles: = 0.70

- Axial resistance for Steel Shells (Pipe): = 0.80

- Flexural resistance factor for HP Piles or Steel Shells: = 1.00

- For Extreme Event Limit States, see LRFD 10.5.5.3.

751.36.5.3 Geotechnical Resistance Factor (ϕstat) and Driving Resistance Factor (ϕdyn)

The factors for Geotechnical Resistance () and Driving Resistance () may be different because of the reliability of the different methods used to determine the nominal bearing resistance. Caution should be used if the difference in factors for Geotechnical Resistance and Driving Resistance are great as it can lead to issues with pile overruns. Also see EPG 751.36.5.9.

Geotechnical Resistance Factor, ϕstat:

The Geotechnical Resistance factor is based on the static method used by the designer in determining the nominal bearing resistance. Unlike the Driving Resistance factor the Geotechnical Resistance factor can vary with the soil layers. If Geotechnical Resistance factors are not provided by the Geotechnical Engineer, the static method and resistance factors shall be selected from the table below. The values provided in LRFD Table 10.5.5.2.3-1 are only applicable if the end of drive criteria is based off the total pile penetration which is not recommended. For Extreme Event Limit States see LRFD 10.5.5.3.

| Pile Type | Soil Type | Static Analysis Method | Side Friction1 |

End Bearing |

|---|---|---|---|---|

| CIP Piles - Steel Pipe Shells | Clay | Alpha - Tomlinson | 2 | 2 |

| Sand | Nordlund3 | 0.45 - Gates 0.45 - WEAP 0.55 - PDA |

0.45 - Gates 0.45 - WEAP 0.55 - PDA | |

| LCPC4 | 0.70 | 0.45 | ||

| Schmertmann5 | 0.50 | 0.50 |