|

|

| (96 intermediate revisions by the same user not shown) |

| Line 1: |

Line 1: |

| ='''REVISION REQUEST 4023'''=

| |

|

| |

| ===751.24.2.1 Design===

| |

|

| |

| Designs of Mechanically Stabilized Earth (MSE) walls shall be completed by consultants or contractors in accordance with Section 11.10 of LRFD specifications, FHWA-NHI-10-024 and FHWA-NHI-10-025 for LRFD. [https://www.modot.org/bridge-pre-qualified-products-list Bridge Pre-qualified Products List (BPPL)] provided on MoDOT's web page and in Sharepoint contains a listing of facing unit manufacturers, soil reinforcement suppliers, and wall system suppliers which have been approved for use. See [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=11 Sec 720] and [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=14 Sec 1010] for additional information. The Geotechnical Section is responsible for checking global stability of permanent MSE wall systems, which should be reported in the Foundation Investigation Geotechnical Report. For MSE wall preliminary information, see [[751.1_Preliminary_Design#751.1.4.3_MSE_Walls|EPG 751.1.4.3 MSE Walls]]. For design requirements of MSE wall systems and temporary shoring (including temporary MSE walls), see [[:Category:720_Mechanically_Stabilized_Earth_Wall_Systems#720.2_Design_Requirements|EPG 720 Mechanically Stabilized Earth Wall Systems]]. For staged bridge construction, see [[751.1_Preliminary_Design#751.1.2.11_Staged_Construction|EPG 751.1.2.11 Staged Construction]].

| |

|

| |

| For seismic design requirements, see [https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Design_Flowchart.pdf Bridge Seismic Design Flowchart]. References for consultants and contractors include Section 11.10 of LRFD, FHWA-NHI-10-024 and FHWA-NHI-10-025.

| |

|

| |

| '''Design Life'''

| |

|

| |

| * 75 year minimum for permanent walls (if retained foundation require 100 year than consider 100 year minimum design life for wall).

| |

|

| |

| '''Global stability:'''

| |

|

| |

| Global stability will be performed by Geotechnical Section or their agent.

| |

|

| |

| '''MSE wall contractor/designer responsibility:'''

| |

|

| |

| MSE wall contractor/designer shall perform following analysis in their design for all applicable limit states.

| |

|

| |

| :* External Stability

| |

| ::* Limiting Eccentricity

| |

| ::* Sliding

| |

| ::* Factored Bearing Pressure/Stress ≤ Factored Bearing Resistance

| |

| :* Internal Stability

| |

| ::* Tensile Resistance of Reinforcement

| |

| ::* Pullout Resistance of Reinforcement

| |

| ::* Structural Resistance of Face Elements

| |

| ::* Structural Resistance of Face Element Connections

| |

| :* Compound Stability

| |

| :: Capacity/Demand ratio (CDR) for bearing capacity shall be ≥ 1.0

| |

| :: <math>Bearing\ Capacity\ (CDR) = \frac{Factored\ Bearing\ Resistance}{Maximum\ Factored\ Bearing\ Stress} \ge 1.0</math>

| |

| :: Strength Limit States:

| |

| :: Factored bearing resistance = Nominal bearing resistance from Geotech report X Minimum Resistance factor (0.65, Geotech report) LRFD Table 11.5.7-1

| |

|

| |

| :: Extreme Event I Limit State:

| |

| :: Factored bearing resistance = Nominal bearing resistance from Geotech report X Resistance factor

| |

| :: Resistance factor = 0.9 LRFD 11.8.6.1

| |

|

| |

| :: Factored bearing stress shall be computed using a uniform base pressure distribution over an effective width of footing determined in accordance with the provisions of LRFD 10.6.3.1 and 10.6.3.2, 11.10.5.4 and Figure 11.6.3.2-1 for foundation supported on soil or rock.

| |

|

| |

| :: B’ = L – 2e

| |

|

| |

| :: Where,

| |

| ::: L = Soil reinforcement length (For modular block use B in lieu of L as per LRFD 11.10.2-1)

| |

| ::: B’ = effective width of footing

| |

| ::: e = eccentricity

| |

| ::: Note: When the value of eccentricity e is negative then B´ = L.

| |

|

| |

| ::Capacity/Demand ratio (CDR) for overturning shall be ≥ 1.0

| |

| ::<math>Overtuning\ (CDR) = \frac{Total\ Factored\ Resisting\ Moment}{Total\ Factored\ Driving\ Moment} \ge 1.0</math>

| |

|

| |

| ::Capacity/Demand ratio (CDR) for eccentricity shall be ≥ 1.0

| |

| ::<math>Eccentricity\ (CDR) = \frac{e_{Limit}}{e_{design}} \ge 1.0</math>

| |

|

| |

| ::Capacity/Demand ratio (CDR) for sliding shall be ≥ 1.0 LRFD 11.10.5.3 & 10.6.3.4

| |

| ::<math>Sliding\ (CDR) = \frac{Total\ Factored\ Sliding\ Resistance}{Total\ Factored\ Active\ Force} \ge 1.0</math>

| |

|

| |

| ::Capacity/Demand ratio (CDR) for internal stability shall be ≥ 1.0

| |

|

| |

| ::Eccentricity, (e) Limit for Strength Limit State: LRFD 11.6.3.3 & C11.10.5.4

| |

| ::: For foundations supported on soil or rock, the location of the resultant of the reaction forces shall be within the middle two-thirds of the base width, L or (e ≤ 0.33L).

| |

|

| |

| ::Eccentricity, (e) Limit for Extreme Event I (Seismic): LRFD 11.6.5.1

| |

| :::For foundations supported on soil or rock, the location of the resultant of the reaction forces shall be within the middle two-thirds of the base width, L or (e ≤ 0.33L) for γ<sub>EQ</sub> = 0.0 and middle eight-tenths of the base width, L or (e ≤ 0.40L) for γ<sub>EQ</sub> = 1.0. For γ<sub>EQ</sub> between 0.0 and 1.0, interpolate e value linearly between 0.33L and 0.40L. For γ<sub>EQ</sub> refer to LRFD 3.4.

| |

|

| |

| :::Note: Seismic design shall be performed for γ<sub>EQ</sub> = 0.5

| |

|

| |

| ::Eccentricity, (e) Limit for Extreme Event II:

| |

| :::For foundations supported on soil or rock, the location of the resultant of the reaction forces shall be within the middle eight-tenths of the base width, L or (e ≤ 0.40L).

| |

|

| |

| '''General Guidelines'''

| |

|

| |

| * Drycast modular block wall (DMBW-MSE) systems are limited to a 10 ft. height in one lift.

| |

|

| |

| * Wetcast modular block wall (WMBW-MSE) systems are limited to a 15 ft. height in one lift.

| |

|

| |

| * For Drycast modular block wall (DMBW-MSE) systems and Wetcast modular block wall (WMBW-MSE) systems, top cap units shall be used and shall be permanently attached by means of a resin anchor system.

| |

|

| |

| * For precast modular panel wall (PMPW-MSE) systems, capstone may be substituted for coping and either shall be permanently attached to wall by panel dowels.

| |

|

| |

| * For precast modular panel wall (PMPW-MSE) systems, form liners are required to produce all panels. Using form liner to produce panel facing is more cost effective than producing flat panels. Standard form liners are specified on the [https://www.modot.org/mse-wall-msew MSE Wall Standard Drawings]. Be specific regarding names, types and colors of staining, and names and types of form liner.

| |

|

| |

| * MSE walls shall not be used where exposure to acid water may occur such as in areas of coal mining.

| |

|

| |

| * MSE walls shall not be used where scour is a problem.

| |

|

| |

| * MSE walls with metallic soil reinforcement shall not be used where stray electrical ground currents may occur as would be present near electrical substations.

| |

|

| |

| * No utilities shall be allowed in the reinforced earth if future access to the utilities would require that the reinforcement layers be cut, or if there is a potential for material, which can cause degradation of the soil reinforcement, to leak out of the utilities into the wall backfill, with the exception of storm water drainage.

| |

|

| |

| * All vertical objects shall have at least 4’-6” clear space between back of the wall facing and object for select granular backfill compaction and soil reinforcement skew limit requirements. For piles, see pipe pile spacers guidance.

| |

|

| |

| * The interior angle between two MSE walls should be greater than 70°. However, if unavoidable, then place [[751.50_Standard_Detailing_Notes#J._MSE_Wall_Notes_.28Notes_for_Bridge_Standard_Drawings.29|EPG 751.50 J1.41 note]] on the design plans.

| |

|

| |

| * Drycast modular block wall (DMBW-MSE) systems and Wetcast modular block wall (WMBW-MSE) systems may be battered up to 1.5 in. per foot. Modular blocks are also known as “segmental blocks”.

| |

|

| |

| * The friction angle used for the computation of horizontal forces within the reinforced soil shall be greater than or equal to 34°.

| |

|

| |

| * For epoxy coated reinforcement requirements, see [[751.5 Structural Detailing Guidelines#751.5.9.2.2 Epoxy Coated Reinforcement Requirements|EPG 751.5.9.2.2 Epoxy Coated Reinforcement Requirements]].

| |

|

| |

| * All concrete except facing panels or units shall be CLASS B or B-1.

| |

|

| |

| * The friction angle of the soil to be retained by the reinforced earth shall be listed on the plans as well as the friction angle for the foundation material the wall is to rest on.

| |

|

| |

| * The following requirement shall be considered (from 2009_FHWA-NHI-10-024 MSE wall 132042.pdf, page 200-201) when seismic design is required:

| |

| :* For seismic design category, SDC C or D (Zones 3 or 4), facing connections in modular block faced walls (MBW) shall use shear resisting devices (shear keys, pin, etc.) between the MBW units and soil reinforcement, and shall not be fully dependent on frictional resistance between the soil reinforcement and facing blocks. For connections partially dependent on friction between the facing blocks and the soil reinforcement, the nominal long-term connection strength T<sub>ac</sub>, should be reduced to 80 percent of its static value.

| |

|

| |

| * Seismic design category and acceleration coefficients shall be listed on the plans for categories B, C and D. If a seismic analysis is required that shall also be noted on the plans. See [[751.50_Standard_Detailing_Notes#A._General_Notes|EPG 751.50 A1.1 note]].

| |

|

| |

| * Plans note ([[751.50_Standard_Detailing_Notes#J._MSE_Wall_Notes_.28Notes_for_Bridge_Standard_Drawings.29|EPG 751.50 J1.1]]) is required to clearly identify the responsibilities of the wall designer.

| |

|

| |

| * Do not use Drycast modular block wall (DMBW-MSE) systems in the following locations:

| |

|

| |

| ::* Within the splash zone from snow removal operations (assumed to be 15 feet from the edge of the shoulder).

| |

|

| |

| ::* Where the blocks will be continuously wetted, such as around sources of water.

| |

|

| |

| ::* Where blocks will be located behind barrier or other obstacles that will trap salt-laden snow from removal operations.

| |

|

| |

| * Do not use Drycast modular block wall (DMBW-MSE) systems or Wetcast modular block wall (WMBW-MSE) systems in the following locations:

| |

|

| |

| ::* For structurally critical applications, such as containing necessary fill around structures.

| |

|

| |

| ::* In tiered wall systems.

| |

|

| |

| * For locations where Drycast modular block wall (DMBW-MSE) systems and Wetcast modular block wall (WMBW-MSE) systems are not desirable, consider coloring agents and/or architectural forms using precast modular panel wall (PMPW-MSE) systems for aesthetic installations.

| |

|

| |

| * For slab drain location near MSE Wall, see [[751.10 General Superstructure#General Requirements for Location and Spacing of Slab Drains|EPG 751.10.3.1 Drain Type, Alignment and Spacing]] and [[751.10 General Superstructure#751.10.3.3 General Requirements for Location of Slab Drains|EPG 751.10.3.3 General Requirements for Location of Slab Drains]].

| |

|

| |

| * Roadway runoff should be directed away from running along face of MSE walls used as wing walls on bridge structures.

| |

|

| |

| * Drainage:

| |

|

| |

| :*Gutter type should be selected at the core team meeting.

| |

|

| |

| :* When gutter is required without fencing, use Type A or Type B gutter (for detail, see [https://www.modot.org/media/16880 Std. Plan 609.00]).

| |

|

| |

| :* When gutter is required with fencing, use Modified Type A or Modified Type B gutter (for detail, see [https://www.modot.org/media/16871 Std. Plan 607.11]).

| |

|

| |

| :* When fencing is required without gutter, place in tube and grout behind the MSE wall (for detail, see [https://www.modot.org/bridge-standard-drawings MSE Wall Standard Drawings - MSEW], Fence Post Connection Behind MSE Wall (without gutter).

| |

|

| |

| :* Lower backfill longitudinal drainage pipes behind all MSE walls shall be two-6” (Min.) diameter perforated PVC or PE pipe (See Sec 1013) unless larger sizes are required by design which shall be the responsibility of the District Design Division. Show drainage pipe size on plans. Outlet screens and cleanouts should be detailed for any drain pipe (shown on MoDOT MSE wall plans or roadway plans). Lateral non-perforated drain pipes (below leveling pad) are permitted by Standard Specifications and shall be sized by the District Design Division if necessary. Lateral outlet drain pipe sloped at 2% minimum.

| |

|

| |

| ::* Identify on MSE wall plans or roadway plans drainage pipe point of entry, point of outlet (daylighting), 2% min. drainage slopes in between points to ensure positive flow and additional longitudinal drainage pipes if required to accommodate ground slope changes and lateral drainage pipes if required by design.

| |

|

| |

| ::* Adjustment in the vertical alignment of the longitudinal drainage pipes from that depicted on the MSE wall standard drawings may be necessary to ensure positive flow out of the drainage system.

| |

|

| |

| ::* Identify on MSE wall plans or roadway plans the outlet ends of pipes which shall be located to prevent clogging or backflow into the drainage system. Outlet screens and cleanouts should be detailed for any drain pipe.

| |

|

| |

| :* For more information on drainage, see [[#Drainage at MSE Walls|Drainage at MSE Walls]].

| |

|

| |

| '''MSE Wall Construction: Pipe Pile Spacers Guidance'''

| |

|

| |

| For bridges not longer than 200 feet, pipe pile spacers or pile jackets shall be used at pile locations behind mechanically stabilized earth walls at end bents. Corrugated pipe pile spacers are required when the wall is built prior to driving the piles to protect the wall reinforcement when driving pile for the bridge substructure at end bents(s). Pile spacers or pile jackets may be used when the piles are driven before the wall is built. Pipe pile spacers shall have an inside diameter greater than that of the pile and large enough to avoid damage to the pipe when driving the pile. Use [[751.50 Standard Detailing Notes#E1. Excavation and Fill|EPG 751.50 Standard Detailing Note E1.2a]] on bridge plans.

| |

|

| |

| For bridges longer than 200 feet, pipe pile spacers are required and the pile spacer shall be oversized to mitigate the effects of bridge thermal movements on the MSE wall. For HP12, HP14, CIP 14” and CIP 16” piles provide 24-inch inside diameter of pile spacer for bridge movement. Minimum pile spacing shall be 5 feet to allow room for compaction of the soil layers. Use [[751.50 Standard Detailing Notes#E1. Excavation and Fill|EPG 751.50 Standard Detailing Note E1.2b]] on bridge plans.

| |

|

| |

| The bottom of the pipe pile spacers shall be placed 5 ft. min. below the bottom of the MSE wall leveling pad. The pipe shall be filled with sand or other approved material after the pile is placed and before driving. Pipe pile spacers shall be accurately located and capped for future pile construction.

| |

|

| |

| Alternatively, for bridges shorter than or equal to 200 feet, the contractor shall be given the option of driving the piles before construction of the mechanically stabilized earth wall and placing the soil reinforcement and backfill material around the piling. In lieu of pipe pile spacers contractor may place pile jackets on the portion of the piles that will be in the MSE soil reinforced zone prior to placing the select granular backfill material and soil reinforcement. The contractor shall adequately support the piling to ensure that proper pile alignment is maintained during the wall construction. The contractor’s plan for bracing the pile shall be submitted to the engineer for review.

| |

|

| |

| Piling shall be designed for downdrag (DD) loads due to either method. Oversized pipe pile spacers with sand placed after driving or pile jacket may be considered to mitigate some of the effects of downdrag (DD) loads. Sizing of pipe pile spacers shall account for pile size, thermal movements of the bridge, pile placement plan, and vertical and horizontal placement tolerances.

| |

|

| |

| When rock is anticipated within the 5 feet zone below the MSE wall leveling pad, prebore into rock and prebore holes shall be sufficiently wide to allow for a minimum 10 feet embedment of pile and pipe pile spacer. When top of rock is anticipated within the 5 to 10 feet zone below the MSE wall leveling pad, prebore into rock to achieve a minimum embedment (pile only) of 10 feet below the bottom of leveling pad. Otherwise, the pipe pile spacer requires a minimum 5 feet embedment below the levelling pad. Consideration shall also be given to oversizing the prebore holes in rock to allow for temperature movements at integral end bents.

| |

|

| |

| For bridges not longer than 200 feet, the minimum clearance from the back face of MSE walls to the front face of the end bent beam, also referred to as setback, shall be 4 ft. 6 in. (typ.) unless larger than 18-inch pipe pile spacer required. The 4 ft. 6 in. dimension serves a dual purpose:

| |

| :1) the setback ensures that soil reinforcement is not skewed more than 15° for nut and bolt reinforcement connections to clear an 18-inch inside diameter pipe pile spacers by 6 inches per FHWA-NHI-10-24, Figure 5-17C, while considering vertical and horizontal pile placement tolerances

| |

| :2) the setback helps to reduce the forces imparted on the MSE wall from bridge movements that typically are not accounted for in the wall design and cannot be completely isolated using a pipe pile spacer. Increasing the minimum setback shall be considered when larger diameter pile spacers are required or when other types of soil reinforcement connections are anticipated

| |

|

| |

| For bridges longer than 200 feet, the minimum setback shall be 5 ft. 6 in. based on the use of 24-inch inside diameter of pipe pile spacers.

| |

|

| |

| If interference with soil reinforcement is not a concern and the wall is designed for forces from bridge movement, the following guidance for pipe pile spacers clearance shall be used: pipe pile spacers shall be placed 36 in. clear min. from the back face of MSE wall panels to allow for proper compaction; 12 in. minimum clearance is required between pipe pile spacers and leveling pad and 18 in. minimum clearance is required between leveling pad and pile. For isolated pile (e.g, walls skewed from the bent orientation), the pipe pile spacer may be placed 18 in. clear min. from the back face of MSE wall panels.

| |

|

| |

| '''MSE Wall Plan and Geometrics'''

| |

|

| |

| * A plan view shall be drawn showing a baseline or centerline, roadway stations and wall offsets. The plan shall contain enough information to properly locate the wall. The ultimate right of way shall also be shown, unless it is of a significant distance from the wall and will have no effect on the wall design or construction.

| |

|

| |

| * Stations and offsets shall be established between one construction baseline or roadway centerline and a wall control line (baseline). Some wall designs may contain a slight batter, while others are vertical. A wall control line shall be set at the front face of the wall, either along the top or at the base of the wall, whichever is critical to the proposed improvements. For battered walls, in order to allow for batter adjustments of the stepped level pad or variation of the top of the wall, the wall control line (baseline) is to be shown at a fixed elevation. For battered walls, the offset location and elevation of control line shall be indicated. All horizontal breaks in the wall shall be given station-offset points, and walls with curvature shall indicate the station-offsets to the PC and PT of the wall, and the radius, on the plans.

| |

|

| |

| * Any obstacles which could possibly interfere with the soil reinforcement shall be shown. Drainage structures, lighting, or truss pedestals and footings, etc. are to be shown, with station offset to centerline of the obstacle, with obstacle size. Skew angles are shown to indicate the angle between a wall and a pipe or box which runs through the wall.

| |

|

| |

| * Elevations at the top and bottom of the wall shall be shown at 25 ft. intervals and at any break points in the wall.

| |

|

| |

| * Curve data and/or offsets shall be shown at all changes in horizontal alignment. If battered wall systems are used on curved structures, show offsets at 10 ft. (max.) intervals from the baseline.

| |

|

| |

| * Details of any architectural finishes (formliners, concrete coloring, etc.).

| |

|

| |

| * Details of threaded rod connecting the top cap block.

| |

|

| |

| * Estimated quantities, total sq. ft. of mechanically stabilized earth systems.

| |

|

| |

| * Proposed grade and theoretical top of leveling pad elevation shall be shown in constant slope. Slope line shall be adjusted per project. Top of wall or coping elevation and stationing shall be shown in the developed elevation per project. If leveling pad is anticipated to encounter rock, then contact the Geotechnical Section for leveling pad minimum embedment requirements.

| |

|

| |

| '''MSE Wall Cross Sections'''

| |

|

| |

| * A typical wall section for general information is shown.

| |

|

| |

| * Additional sections are drawn for any special criteria. The front face of the wall is drawn vertical, regardless of the wall type.

| |

|

| |

| * Any fencing and barrier or railing are shown.

| |

|

| |

| * Barrier if needed are shown on the cross section. Barriers are attached to the roadway or shoulder pavement, not to the MSE wall. Standard barriers are placed along wall faces when traffic has access to the front face of the wall over shoulders of paved areas.

| |

|

| |

| <div id="Drainage at MSE Walls"></div>

| |

| '''Drainage at MSE Walls'''

| |

|

| |

| *'''Drainage Before MSE Wall'''

| |

|

| |

| :Drainage is not allowed to be discharged within 10 ft. from front of MSE wall in order to protect wall embedment, prevent erosion and foundation undermining, and maintain soil strength and stability.

| |

|

| |

| *'''Drainage Behind MSE Wall'''

| |

|

| |

| ::'''Internal (Subsurface) Drainage'''

| |

|

| |

| ::Groundwater and infiltrating surface waters are drained from behind the MSE wall through joints between the face panels or blocks (i.e. wall joints) and two-6 in. (min.) diameter pipes located at the base of the wall and at the basal interface between the reinforced backfill and the retained backfill.

| |

|

| |

| ::Excessive subsurface draining can lead to increased risk of backfill erosion/washout through the wall joints and erosion at the bottom of walls and at wall terminal ends. Excessive water build-up caused by inadequate drainage at the bottom of the wall can lead to decreased soil strength and wall instability. Bridge underdrainage (vertical drains at end bents and at approach slabs) can exacerbate the problem.

| |

|

| |

| ::Subsurface drainage pipes should be designed and sized appropriately to carry anticipated groundwater, incidental surface run-off that is not collected otherwise including possible effects of drainage created by an unexpected rupture of any roadway drainage conveyance or storage as an example.

| |

|

| |

| ::'''External (Surface) Drainage'''

| |

|

| |

| ::External drainage considerations deal with collecting water that could flow externally over and/or around the wall surface taxing the internal drainage and/or creating external erosion issues. It can also infiltrate the reinforced and retained backfill areas behind the MSE wall.

| |

|

| |

| ::Diverting water flow away from the reinforced soil structure is important. Roadway drainage should be collected in accordance with roadway drainage guidelines and bridge deck drainage should be collected similarly.

| |

|

| |

| *'''Guidance'''

| |

|

| |

| :ALL MSE WALLS

| |

|

| |

| :1. Appropriate measures to prevent surface water infiltration into MSE wall backfill should be included in the design and detail layout for all MSE walls and shown on the roadway plans.

| |

|

| |

| :2. Gutters behind MSE walls are required for flat or positive sloping backfills to prevent concentrated infiltration behind the wall facing regardless of when top of backfill is paved or unpaved. This avoids pocket erosion behind facing and protection of nearest-surface wall connections which are vulnerable to corrosion and deterioration. Drainage swales lined with concrete, paved or precast gutter can be used to collect and discharge surface water to an eventual point away from the wall. If rock is used, use impermeable geotextile under rock and align top of gutter to bottom of rock to drain. (For negative sloping backfills away from top of wall, use of gutters is not required.)

| |

|

| |

| :District Design Division shall verify the size of the two-6 in. (min.) diameter lower perforated MSE wall drain pipes and where piping will daylight at ends of MSE wall or increase the diameters accordingly. This should be part of the preliminary design of the MSE wall. (This shall include when lateral pipes are required and where lateral drain pipes will daylight/discharge).

| |

|

| |

| :BRIDGE ABUTMENTS WITH MSE WALLS

| |

|

| |

| :Areas of concern: bridge deck drainage, approach slab drainage, approach roadway drainage, bridge underdrainage: vertical drains at end bents and approach slab underdrainage, showing drainage details on the roadway and MSE wall plans

| |

|

| |

| :3. Bridge slab drain design shall be in accordance with [[751.10 General Superstructure#751.10.3 Bridge Deck Drainage - Slab Drains |EPG 751.10.3 Bridge Deck Drainage – Slab Drains]] unless as modified below.

| |

|

| |

| :4. Coordination is required between the Bridge Division and District Design Division on drainage design and details to be shown on the MSE wall and roadway plans.

| |

|

| |

| :5. Bridge deck, approach slab and roadway drainage shall not be allowed to be discharged to MSE wall backfill area or within 10 feet from front of MSE wall.

| |

| ::*(Recommended) Use of a major bridge approach slab and approach pavement is ideal because bridge deck, approach slab and roadway drainage are directed using curbs and collected in drain basins for discharge that protect MSE wall backfill. For bridges not on a major roadway, consideration should be given to requiring a concrete bridge approach slab and pavement incorporating these same design elements (asphalt is permeable).

| |

|

| |

| ::*(Less Recommended) Use of conduit and gutters:

| |

|

| |

| :::* Conduit: Drain away from bridge and bury conduit daylighting to natural ground or roadway drainage ditch at an eventual point beyond the limits of the wall. Use expansion fittings to allow for bridge movement and consider placing conduit to front of MSE wall and discharging more than 10 feet from front of wall or using lower drain pipes to intercept slab drainage conduit running through backfill.

| |

|

| |

| :::* Conduit and Gutters: Drain away from bridge using conduit and 90° elbow (or 45° bend) for smoothly directing drainage flow into gutters and that may be attached to inside of gutters to continue along downward sloping gutters along back of MSE wall to discharge to sewer or to natural drainage system, or to eventual point beyond the limits of the wall. Allow for independent bridge and wall movements by using expansion fittings where needed. See [[751.10 General Superstructure#751.10.3.1 Type, Alignment and Spacing|EPG 751.10.3.1 Type, Alignment and Spacing]] and [[751.10 General Superstructure#751.10.3.3 General Requirements for Location of Slab Drains|EPG 751.10.3.3 General Requirements for Location of Slab Drains]].

| |

|

| |

| :6. Vertical drains at end bents and approach slab underdrainage should be intercepted to drain away from bridge end and MSE wall.

| |

|

| |

| :7. Discharging deck drainage using many slab drains would seem to reduce the volume of bridge end drainage over MSE walls.

| |

|

| |

| :8. Drain flumes at bridge abutments with MSE walls do not reduce infiltration at MSE wall backfill areas and are not recommended.

| |

|

| |

| :DISTRICT DESIGN DIVISION MSE WALLS

| |

|

| |

| :Areas of concern: roadway or pavement drainage, MSE wall drainage, showing drainage details on the roadway and MSE wall plans.

| |

|

| |

| :9. For long MSE walls, where lower perforated drain pipe slope become excessive, non-perforated lateral drain pipes, permitted by Standard Specifications, shall be designed to intercept them and go underneath the concrete leveling pad with a 2% minimum slope. Lateral drain pipes shall daylight/discharge at least 10 ft. from front of MSE wall. Screens should be installed and maintained on drain pipe outlets.

| |

|

| |

| :10. Roadway and pavement drainage shall not be allowed to be discharged to MSE wall backfill area or within 10 feet from front of MSE wall.

| |

|

| |

| :11. For district design MSE walls, use roadway or pavement drainage collection pipes to transport and discharge to an eventual point outside the limits of the wall.

| |

|

| |

| :Example: Showing drain pipe details on the MSE wall plans.

| |

|

| |

| <gallery mode=packed widths=300px heights=300px>

| |

| File:751.24.2.1_elev_drain_pipe-01.png| <big>'''ELEVATION SHOWING DRAIN PIPE'''</big>

| |

| File:751.24.2.1_elev_drain_pipe_alt-01.png| <big>'''Alternate option'''</big>

| |

| </gallery>

| |

| <gallery mode=packed widths=400px heights=400px>

| |

| File:751.24.2.1_sec_A-A-02.png| <big>'''Section A-A'''</big>

| |

| </gallery>

| |

| {| style="text-align: left; margin-left: auto; margin-right: auto;"

| |

| |

| |

| Notes:</br>

| |

| (1) To be designed by District Design Division.</br>

| |

| (2) To be designed by District Design Division if needed. Provide non-perforated lateral drain pipe under leveling pad at 2% minimum slope. (Show on plans).</br>

| |

| (3) Discharge to drainage system or daylight screened outlet at least 10 feet away from end of wall (typ.). (Skew in the direction of flow as appropriate).</br>

| |

| (4) Discharge to drainage system or daylight screened outlet at least 10 feet away from front face of wall (typ.). (Skew in the direction of flow as appropriate).</br>

| |

| (5) Minimum backfill cover = Max(15”, 1.5 x diameter of drain pipe).</br>

| |

| |}

| |

|

| |

| === E1. Excavation and Fill ===

| |

|

| |

| '''(E1.1) Use when specified on the Design Layout.'''

| |

| :Existing roadway fill under the ends of the bridge shall be removed as shown. Removal of existing roadway fill will be considered completely covered by the contract unit price for roadway excavation.

| |

|

| |

| '''Use one of the following two notes where MSE walls support abutment fill.'''

| |

|

| |

| '''(E1.2a) <font color="purple">[MS Cell]</font color="purple"> Use when pipe pile spacers are shown on plan details and bridge is 200 feet long or shorter. Add “See special provisions” to the pipe pile spacer callout and add table near the callout.'''

| |

|

| |

| See special provisions.

| |

|

| |

| <center>

| |

| {|border="1" style="text-align:center;" cellpadding="5" cellspacing="0"

| |

| |-

| |

| !style="background:#BEBEBE" width="200"| Pile Encasement !!style="background:#BEBEBE"|Option Used<br/>(√)

| |

| |-

| |

| |Pipe Pile Spacer ||

| |

| |-

| |

| |Pile Jacket ||

| |

| |}

| |

| </center>

| |

|

| |

| MoDOT Construction personnel will indicate the pile encasement used.

| |

|

| |

| '''(E1.2b) Use note when pipe pile spacers are shown on plan details for HP12, HP14, CIP 14” and CIP 16” piles and bridge is longer than 200 feet. For larger CIP pile size modify following note and use minimum 6” larger pipe pile spacer diameter than CIP pile.'''

| |

|

| |

| The pipe pile spacers shall have an inside diameter equal to <u>24</u> inches.

| |

|

| |

| '''(E1.4) Use for fill at pile cap end bents. Use the first underlined portion when MSE walls are present. Use <u>approach</u> for semi-deep abutments.'''

| |

| :Roadway fill<u>, exclusive of Select Granular Backfill for Structural Systems,</u> shall be completed to the final roadway section and up to the elevation of the bottom of the concrete <u>approach</u> beam within the limits of the structure and for not less than 25 feet in back of the fill face of the end bents before any piles are driven for any bents falling within the embankment section.

| |

|

| |

| ----

| |

|

| |

|

| |

| ='''REVISION REQUEST 4034'''=

| |

|

| |

| <big><big>'''<font color= red>!!! Only replace first part of 751.9.1 up to 751.9.1.1 !!!</font color>'''</big></big>

| |

|

| |

| ==751.9.1 Seismic Analysis and Design Specifications==

| |

| <div style="float: left; margin-top: 5px; margin: 15px; width:255px; background-color: #f8f9fa; padding: 0.3em; border: 1px solid #a2a9b1; text-align:left;">

| |

| '''<u><center>Additional Information</center></u>'''

| |

| * [https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Design_Flowchart.pdf Bridge Seismic Design Flowchart]

| |

| </div>

| |

| All new or replacement bridges on the state system shall include seismic design and/or detailing to resist an expected seismic event per the [https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Design_Flowchart.pdf Bridge Seismic Design Flowchart]. For example, for a bridge in Seismic Design Categories A, B, C or D, complete seismic analysis or seismic detailing only may be determined as per “[https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Design_Flowchart.pdf Bridge Seismic Design Flowchart]”.

| |

|

| |

| Missouri is divided into four Seismic Design Categories. Most of the state is SDC A which requires minimal seismic design and/or detailing in accordance with SGS (Seismic Zone 1 of LRFD) and “[https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Design_Flowchart.pdf Bridge Seismic Design Flowchart]”. The other seismic design categories will require a greater amount of seismic design and/or detailing.

| |

|

| |

| For seismic detailing only:

| |

|

| |

| When A<sub>S</sub> is greater than 0.75 then use A<sub>S</sub> = 0.75 for abutment design where required per “[https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Design_Flowchart.pdf Bridge Seismic Design Flowchart]” and [https://www.modot.org/media/47036 SEG 24-01]

| |

|

| |

| For complete seismic analysis:

| |

|

| |

| When A<sub>S</sub> is greater than 0.75 then use A<sub>S</sub> = 0.75 at zero second for seismic analysis and response spectrum curve. See [https://epg.modot.org/forms/general_files/BR/Example-1_SDC_Response_Spectra.docx Example 1_SDC_Response_Spectra]. The other data points on the response spectrum curve shall not be modified.

| |

|

| |

| <div style="float: left; margin-top: 5px; margin: 15px; width:255px; background-color: #f8f9fa; padding: 0.3em; border: 1px solid #a2a9b1; text-align:left;">

| |

| '''<u><center>Additional Information</center></u>'''

| |

| * [https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Retrofit_Flowchart.pdf Bridge Seismic Retrofit Flowchart]

| |

| </div>

| |

|

| |

| When existing bridges are identified as needing repairs or maintenance, a decision on whether to include seismic retrofitting in the scope of the project shall be determined per the “[https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Retrofit_Flowchart.pdf Bridge Seismic Retrofit Flowchart]”, the extent of the rehabilitation work and the expected life of the bridge after the work. For example, if the bridge needs painting or deck patching, no retrofitting is recommended. However, redecking or widening the bridge indicates that MoDOT is planning to keep the bridge in the state system with an expected life of at least 30 more years. In these instances, the project core team should consider cost effective methods of retrofitting the existing bridge. Superstructure replacement requires a good substructure and the core team shall decide whether there is sufficient seismic capacity. Follow the design procedures for new or replacement bridges in forming logical comparisons and assessing risk in a rational determination of the scope of a superstructure replacement project specific to the substructure. For example, based on SPC and route, retrofit of the substructure could include seismic detailing only or a complete seismic analysis may be required determine sufficient seismic capacity. Economic analysis should be considered as part of the decision to re-use and retrofit, or re-build. Where practical, make end bents integral and eliminate expansion joints. Seismic isolation systems shall conform to AASHTO Guide Specifications for Seismic Isolation Design 4th Ed. 2023.

| |

|

| |

| Bridge seismic retrofit for widenings shall be in accordance with [https://epg.modot.org/forms/general_files/BR/Bridge_Seismic_Retrofit_Flowchart.pdf Bridge Seismic Retrofit Flowchart]. Seismic details should only be considered for widenings where they can be practically implemented and where they can be uniformly implemented as not to create significant stress redistribution in the structure. When a complete seismic analysis is required for widenings the existing structure shall be retrofitted and the new structural elements shall be detailed to resist seismic demand.

| |

|

| |

| * '''Seismic Details for Widening (one side):''' When widening the bridge in one direction there is not a significant benefit, and it could be detrimental, to strengthen a new wing or column while ignoring the existing structure. It may be practical to use FRP wrap to retrofit the existing columns to provide a similar level of service to a new column with seismic details, but this will likely require design computations to verify (see below). For SDC C and D, seismic details typically require a T-joint detail in the beam cap and footing, but t-joint details shall be ignored if the existing beam cap is not retrofitted. For abutments it is not practical to dig up an existing wing solely to match the new wing design so the abutment need not be designed for mass inertial forces. SPM, SLE or owner’s representative approval is required to determine the appropriate level of seismic detail implementation.

| |

| * '''Seismic Details for Widening (both sides):''' When widening in both directions the wings shall be designed to resist the mass inertial forces. Seismic details shall be added to the new columns in SDC B only if the existing columns can be retrofitted with FRP wrap to provide a similar level of service as discussed below. SDC C and D bridges may be detailed and retrofitted similar to SDC B since retrofitting the beam cap or footing is likely not practical.

| |

| * '''Seismic Details for Widening (FRP wrap)''': Carbon or glass fiber reinforced polymer (FRP) composite wrap should be considered to strengthen the factored axial resistance of existing columns. There are limitations to the existing and achievable column factored axial resistance with FRP wrap. The goal of the FRP wrap is to increase the factored axial resistance of the existing column to be not less than the factored axial resistance of the new column with seismic details. If an existing column cannot be retrofitted with FRP wrap to match the factored axial resistance of a new column with seismic details at the same bent then seismic details shall be ignored for all columns in the bridge substructure. See AASHTO Guide Spec for Design of Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements, March 2023, 2nd Ed., Appendix A, Example 6 for an example for increasing column factored axial resistance with FRP wrap. Use [[751.50_Standard_Detailing_Notes#I5._Fiber_Reinforced_Polymer_(FRP)_Wrap_–_Intermediate_Bent_Column_Strengthening_for_Seismic_Details_for_Widening._Report_following_notes_on_Intermediate_bent_plan_details.|EPG 751.50 Standard Detailing Notes I5]] on plans to report factored axial resistance of existing column and new column. The flexural resistance of the column is also increased with FRP wrap, but it may not be practical to match the flexural resistance of a new column using existing longitudinal steel. For additional references, see [[751.40_LFD_Widening_and_Repair#751.40.3.2_Bent_Cap_Shear_Strengthening_using_FRP_Wrap|EPG 751.40.3.2 Bent Cap Shear Strengthening using FRP Wrap]].

| |

|

| |

|

| |

|

| |

|

| |

|

| |

| ===751.40.3.2 Bent Cap Shear Strengthening using FRP Wrap===

| |

|

| |

| {| class="wikitable" style="margin: 0 auto; text-align: center"

| |

| |+

| |

| | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]'''

| |

| |-

| |

| | Rehabilitation, Surfacing & Widening; Fiber Reinf. Polymer (FRP) Wrap for Bent Cap Strengthening [RHB08]

| |

| |}

| |

|

| |

| Fiber Reinforced Polymer (FRP) wrap may be used for Bent Cap Shear Strengthening. FRP wrap may also be used for seismic retrofit of existing columns, but that procedure is not discussed herein (see [[751.9_Bridge_Seismic_Design#751.9.1_Seismic_Analysis_and_Design_Specifications|EPG 751.9.1 Seismic Analysis and Design Specifications]]).

| |

|

| |

| '''When to strengthen:''' When increased shear loading on an existing bent cap is required and a structural analysis shows insufficient bent cap shear resistance, bent cap shear strengthening is an option. An example of when strengthening a bent cap may be required: removing existing girder hinges and making girders continuous will draw significantly more force to the adjacent bent. An example of when strengthening a bent cap is not required: redecking a bridge where analysis shows that the existing bent cap cannot meet capacity for an HS20 truck loading, and the new deck is similar to the old deck and the existing beam is in good shape.

| |

|

| |

| '''How to strengthen:''' Using FRP systems for shear strengthening follows from the guidelines set forth in ''NCHRP Report 678, Design of FRP System for Strengthening Concrete Girders in Shear''. The method of strengthening, using either discrete strips or continuous sheets, is made optional for the contractor in accordance with ''NCHRP Report 678''. A Bridge Standard Drawing and Bridge Special Provision have been prepared for including this work on jobs. They can be revised to specify a preferred method of strengthening if desired, strips or continuous sheet.

| |

|

| |

| '''What condition of existing bent cap required for strengthening:''' If a cap is in poor shape where replacement should be considered, FRP should not be used. Otherwise, the cap beam can be repaired before applying FRP. Perform a minimum load check using (1.1DL + 0.75(LL+I))'''*''' on the existing cap beam to prevent catastrophic failure of the beam if the FRP fails (''ACI 440.2R, Guide for the Design and Construction of Externally Bonded FRP, Sections 9.2 and 9.3.3''). If the factored shear resistance of the cap beam is insufficient for meeting the factored minimum load check, then FRP strengthening should not be used.

| |

|

| |

| :: '''*''' ACI 440.2R: ''Guide for the Design and Construction of Externally Bonded FRP''

| |

|

| |

| '''Design force (net shear strength loading):''' Strengthening a bent cap requires determining the net factored shear loading that the cap beam must carry in excess of its unstrengthened factored shear capacity, or resistance. The FRP system is then designed by the manufacturer to meet this net factored shear load, or design force. The design force for a bent cap strengthening is calculated considering AASHTO LFD where the factored load is the standard Load Factor Group I load case. To determine design force that the FRP must carry alone, the factored strength of the bent cap, which is 0.85 x nominal strength according to LFD design, is subtracted out to give the net factored shear load that the FRP must resist by itself. ''NCHRP Report 678'' is referenced in the special provisions as guidelines for the contractor and the manufacturer to follow. The report and its examples use AASHTO LRFD. <u>Regardless, the load factor case is given and it is left to the manufacturer to provide for a satisfactory factor of safety based on their FRP system.</u>

| |

|

| |

| Other References:

| |

| :: '''*''' ACI 201.1R: ''Guide for Making a Condition Survey of Concrete in Service''

| |

| :: '''*''' ACI 224.1R: ''Causes, Evaluation, and Repair of Cracks in Concrete''

| |

| :: '''*''' ACI 364.1R-94: ''Guide for Evaluation of Concrete Structures Prior to Rehabilitation''

| |

| :: '''*''' ACI 440.2R-08: ''Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures''

| |

| :: '''*''' ACI 503R: ''Use of Epoxy Compounds with Concrete''

| |

| :: '''*''' ACI 546R: ''Concrete Repair Guide''

| |

| :: '''*''' International Concrete Repair Institute (ICI) ICI 03730: ''Guide for Surface Preparation for the Repair of Deteriorated Concrete Resulting from Reinforcing Steel Corrosion''

| |

| :: '''*''' International Concrete Repair Institute (ICI) ICI 03733: ''Guide for Selecting and Specifying Materials for Repairs of Concrete Surfaces''

| |

| :: '''*''' NCHRP Report 609: ''Recommended Construction Specifications Process Control Manual for Repair and Retrofit of Concrete Structures Using Bonded FRP Composites''

| |

| :: '''*''' AASHTO Guide Spec for Design of Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements, March 2023, 2nd Ed.

| |

|

| |

|

| |

|

| |

|

| |

|

| |

| ===I5. Fiber Reinforced Polymer (FRP) Wrap – Intermediate Bent Column Strengthening for Seismic Details for Widening. Report following notes on Intermediate bent plan details.===

| |

|

| |

| '''(I5.1)'''

| |

| :Factored axial resistance of new columns = _____ kip and factored axial resistance of existing columns = _____ kip. The factored axial resistance of the existing column with FRP wrap shall not be less than the factored axial resistance of the new columns.

| |

|

| |

| '''(I5.2)'''

| |

| :See special provisions.

| |

|

| |

| ----

| |

|

| |

|

| |

| ='''REVISION REQUEST 4036'''= | | ='''REVISION REQUEST 4036'''= |

|

| |

|

| |

|

| |

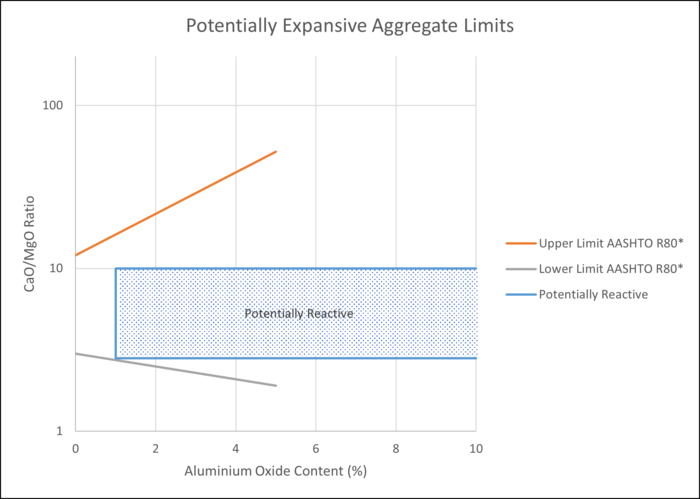

|

| ==106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity== | | ==106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity== |

| Line 426: |

Line 15: |

| A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum: | | A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum: |

|

| |

|

| :* Quarry name and ledge name; all ledges if used in combination

| | * Quarry name and ledge name; all ledges if used in combination |

| :* MoDOT District quarry resides

| | * MoDOT District quarry resides |

| :* Date sample was obtained; date petrographic analysis was completed

| | * Date sample was obtained; date petrographic analysis was completed |

| :* Name of petrographer and company/organization affiliated

| | * Name of petrographer and company/organization affiliated |

| :* Lithographic descriptions with photographs of the sample(s) examined

| | * Lithographic descriptions with photographs of the sample(s) examined |

| :* Microphotographs of aggregate indicating carbonate particles and/or other reactive materials

| | * Microphotographs of aggregate indicating carbonate particles and/or other reactive materials |

| :* Results of the examination

| | * Results of the examination |

| :* All conclusions related to the examination

| | * All conclusions related to the examination |

|

| |

|

| See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer. | | See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer. |

| Line 441: |

Line 30: |

| ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy. | | ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy. |

|

| |

|

| ----

| |

|

| |

|

| |

| ='''REVISION REQUEST 4038'''=

| |

|

| |

| ==1018.5 Laboratory Procedures for Sec 1018==

| |

| ===1018.5.1 Sample Preparation===

| |

| Prior to testing, the sample should be thoroughly mixed, passed through a No.20 [850 mm] sieve, and brought to room temperature. All foreign matter and lumps that do not pulverize easily in the fingers must be discarded.

| |

|

| |

| ===1018.5.2 Procedure===

| |

| Chemical analysis is to be conducted according to ASTM C114 and MoDOT Test Methods T46 and T91. Original test data and calculations are to be recorded in Laboratory workbooks. Test results are to be recorded through AWP and retained on file in the Laboratory.

| |

|

| |

| Physical tests on the following are to be conducted in accordance with ASTM C311.

| |

| :(a) Fineness, 325 (45 mm) sieve analysis ASTM C430

| |

| :(b) Pozzolanic Activity Index (7 day) ASTM C311

| |

| :(c) Water requirement ASTM C311

| |

| :(d) Soundness, autoclave ASTM C311

| |

| :(e) Specific Gravity ASTM C311

| |

| Original test data and calculations are to be recorded in Laboratory workbooks. Test results are to be recorded through AWP and retained on file in the Laboratory.

| |

|

| |

| ===1018.5.3 Source Acceptance===

| |

| Samples are to be taken by the manufacturer in accordance with ASTM C311 from the conveyor, after exiting the precipitator collector and prior to entry into the designated storage silo, or where designated by the engineer.

| |

|

| |

| Ash, that is manually sampled and tested every 400 tons, is to be held until the required tests have been run and the results are properly certified and are available for pick up by MoDOT personnel prior to shipment.

| |

|

| |

| Ash, that is continually sampled and tested at a frequency and duration acceptable to the engineer, can be continuously shipped direct from a generating station silo, provided the following minimum criteria are met:

| |

| :a. The storage silo has a minimum capacity of two days production or 1000 tons, whichever is the largest.

| |

| :b. The storage silo is full, and certified test results on the entire contents are available prior to the first shipment.

| |

| :c. The ash quantity in the silo is never less than 400 tons.

| |

| :d. A continual inventory of the quantity of ash in silos is maintained within one shift of being correct.

| |

| :e. The engineer has free access to station facilities and records necessary to conduct inspection and sampling.

| |

| :f. All ash conveyance lines to the designated silo or silos will be sampled after precipitator collector and prior to entry into the designated silo(s) where designated by the engineer.

| |

| :g. The generating station personnel handle and expedite all documents required to ship by MoDOT Certification.

| |

|

| |

| ===1018.5.4 Plant Inspection===

| |

| Qualified fly ash manufacturers and terminals shipping material by certification to Department projects shall be inspected on a regular basis by a representative of the Laboratory. This inspection shall include a review of plant facilities for producing a quality product; plant testing procedures; frequency of tests; plant records of daily test results and shipping information; company certification procedures of silos, bins, and/or shipments; and a discussion of items of mutual interest between the plant and the Department. The Laboratory representative shall coordinate test results and test procedures between the Laboratory and the respective plant laboratory, and investigate associated problems.

| |

|

| |

| All silo or bin certifications and results of complete physical and chemical tests received in the Laboratory are to be checked for specification compliance and to determine if the required certifications have been furnished.

| |

|

| |

| ===1018.5.5 Sample Record===

| |

| The sample record shall be completed in AASHTOWARE Project (AWP) in accordance with [[:Category:101 Standard Forms #Sample Record, General|AWP MA Sample Record, General]], and shall indicate acceptance, qualified acceptance, or rejection. Appropriate remarks, as described in [[106.20 Reporting|EPG 106.20 Reporting]], are to be included in the remarks to clarify conditions of acceptance or rejections. Test results shall be reported on the appropriate templates under the Tests tab.

| |

|

| |

|

| |

|

| |

| ----

| |

|

| |

| ='''REVISION REQUEST 4041'''=

| |

|

| |

|

| |

| ===751.31.2.4 Column Analysis===

| |

|

| |

| Refer to this article to check slenderness effects in column and the moment magnifier method of column design. See Structural Project Manager for use of P Delta Analysis.

| |

|

| |

|

| |

| '''Transverse Reinforcement'''

| |

|

| |

|

| ''Seismic Design Category (SDC) A''

| |

| :Columns shall be analyzed as “Tied Columns”. Unless excessive reinforcement is required, in which case spirals shall be used.

| |

|

| |

|

| '''Bi-Axial Bending''' | | ='''REVISION REQUEST 4143'''= |

| | ==751.36.5 Design Procedure== |

| | *Structural Analysis |

| | *Geotechnical Analysis |

| | *Drivability Analysis |

|

| |

|

| Use the resultant of longitudinal and transverse moments.

| | ===751.36.5.1 Design Procedure Outline=== |

| | *Determine foundation load effects from the superstructure and substructure for Service, Strength and Extreme Event Limit States. |

| | *If applicable, determine scour depths, liquefaction information and pile design unbraced length information. |

| | *Determine if downdrag loadings should be considered. |

| | *Select preliminary pile size and pile layout. |

| | *Perform a Static Pile Soil Interaction Analysis. Estimate Pile Length and pile capacity. |

| | *Based on pile type and material, determine Resistance Factors for Structural Strength (<math>\, \phi_c</math> and <math>\, \phi_f</math>). |

| | *Determine: |

| | **Maximum axial load effects at toe of a single pile |

| | **Maximum combined axial & flexural load effects of a single pile |

| | **Maximum shear load effect for a single pile |

| | **Uplift pile reactions |

| | *Determine Nominal and Factored Structural Resistance for single pile |

| | **Determine Structural Axial Compression Resistance |

| | **Determine Structural Flexural Resistance |

| | **Determine Structural Combined Axial & Flexural Resistance |

| | **Determine Structural Shear Resistance |

| | *Determine method for pile driving acceptance criteria |

| | *Determine Resistance Factor for Geotechnical Resistance (<math>\, \phi_{stat}</math>) and Driving Resistance (<math>\, \phi_{dyn}</math>). |

| | *If other than end bearing pile on rock or shale, determine Nominal Axial Geotechnical Resistance for pile. |

| | *Determine Factored Axial Geotechnical Resistance for single pile. |

| | *Determine Nominal pullout resistance if pile uplift reactions exist. |

| | *Check for pile group effects. |

| | *Resistance of Pile Groups in Compression |

| | *Check Drivability of all pile (bearing and friction pile) using the Wave equation analysis. |

| | *Review Static Pile Soil Interaction Analysis and pile lengths for friction pile. |

| | *Show proper Pile Data on Plan Sheets ([https://epg.modot.org/index.php/751.50_Standard_Detailing_Notes#E2._Foundation_Data_Table Foundation Data Table]). |

|

| |

|

| '''Slenderness effects in Columns'''

| | ===751.36.5.2 Structural Resistance Factor (ϕ<sub>c</sub> and ϕ<sub>f</sub>) for Strength Limit State=== |

| | | {| style="margin: 1em auto 1em auto" |

| The slenderness effects shall be considered when:

| |

| | |

| <math>\, \ l_u \ge \frac {22r}{K}</math>

| |

| | |

| Where:

| |

|

| |

| <math>\, \ l_u</math> = unsupported length of column

| |

| | |

| <math>\, \ r</math> = radius of gyration of column cross section

| |

| | |

| <math>\, \ K</math> = effective length factor

| |

| | |

| Effects should be investigated by using either the rigorous P-∆ analysis or the Moment Magnifier Method with consideration of bracing and non-bracing effects. Use of the moment magnifier method is limited to members with Kl<sub>u</sub>/r ≤ 100, or the diameter of a round column must be ≥ Kl<sub>u</sub>/25. A maximum value of 2.5 for moment magnifier is desirable for efficiency of design. Increase column diameter to reduce the magnifier, if necessary.

| |

| | |

| When a compression member is subjected to bending in both principal directions, the effects of slenderness should be considered in each direction independently. Instead of calculating two moment magnifiers, <math>\, \delta_b</math> and <math>\, \delta_s</math>, and performing two analyses for M<sub>2b</sub> and M<sub>2s</sub> as described in LRFD 4.5.3.2.2b, the following conservative, simplified moment magnification method in which only a moment magnifier due to sidesway, δ<sub>s</sub>, analysis is required:

| |

| <center>

| |

| [[Image:751.31 Open Concrete Int Bents and Piers- Typical Intermediate Bent.gif]]

| |

| </center>

| |

| | |

| <center>'''Typical Intermediate Bent'''</center>

| |

| | |

| | |

| ''General Procedure for Bending in a Principal Direction''

| |

| | |

| ::M<sub>c</sub> = δ<sub>s</sub>M<sub>2</sub>

| |

| | |

| ::Where:

| |

| ::M<sub>c</sub> = Magnified column moment about the axis under investigation.

| |

| | |

| ::M<sub>2</sub> = value of larger column moment about the axis under investigation due to LRFD Load Combinations.

| |

| | |

| ::δ<sub>s</sub> = moment magnification factor for sidesway about the axis under investigation

| |

| | |

| ::<math>\, =\cfrac{C_m}{1- \cfrac{\sum P_u }{\phi_k \sum P_e }} \ge 1.0; \ C_m = 1.0 </math>

| |

| | |

| Where:

| |

| {|style="text-align:left" | |

| |-

| |

| |<math>\, \sum P_u</math> ||=||summation of individual column factored axial loads for a specific Load Combination (kip)

| |

| |-

| |

| |<math>\, \phi_K</math> ||=||stiffness reduction factor for concrete = 0.75

| |

| |-

| |

| |<math>\, \sum P_e</math>|| =||summation of individual column Euler buckling loads

| |

| |- | | |- |

| | |align="right" width="850"|'''LRFD 6.5.4.2''' |

| |} | | |} |

|

| |

|

| <math>\, =\sum {\frac{\pi^2 \ EI}{\left( \ Kl_u \right)^2}}</math>

| | '''For integral end bent simple pile design,''' use Φ<sub>c</sub> = 0.35 for CIP steel pipe piles and HP piles. See [[751.35 Concrete Pile Cap Integral End Bents#751.35.2.4.2 Pile Design|Figure 751.35.2.4.2]]. |

| | |

| Where:

| |

| | |

| <math>\, \ K</math> = effective length factor = 1.2 min. (see the following figure showing boundary conditions for columns)

| |

| | |

| <math>\, \ l_u</math> = unsupported length of column (in.)

| |

| | |

| <math>\, \ EI = \cfrac{{E_cI_g}{/2.5}}{1+\beta_d}</math>

| |

| | |

| Where:

| |

| | |

| <math>\, \ E_c</math>= concrete modulus of elasticity as defined in [[751.31 Open Concrete Intermediate Bents#751.31.1.1 Material Properties|EPG 751.31.1.1]] (ksi)

| |

| | |

| <math>\, \ I_g</math>= moment of inertia of gross concrete section about the axis under investigation <math>\, (in^4)</math>

| |

| | |

| <math>\, \beta_d</math>= ratio of maximum factored permanent load moments to maximum factored total load moment: always positive

| |

| | |

| | |

| ''Column Moment Parallel to Bent In-Plane Direction''

| |

|

| |

|

| <math>M_{cy}= \delta_{sy}M_{2y}</math>

| | '''For pile at all locations where integral end bent simple pile design is not applicable,''' use the following: |

|

| |

|

| <math>l_{uy}</math>= top of footing to top of beam cap | | :The structural resistance factor for axial resistance in compression is dependent upon the expected driving conditions. When the pile is subject to damage due to severe driving conditions where use of pile point reinforcement is necessary: |

| | ::Steel Shells (Pipe): <math> \phi_c </math>= 0.60 |

| | ::HP Piles: <math> \phi_c </math>= 0.50 |

| | :When the pile is subject to good driving conditions where use of pile point reinforcement is not necessary: |

| | ::Steel Shells (Pipe) Piles: <math> \phi_c </math>= 0.70 |

| | ::HP Piles: <math> \phi_c </math>= 0.60 |

| | :For HP piles, pile point reinforcement is always required when HP piles are anticipated to be driven to rock and proofed. Driving HP piles to rock is considered severe driving conditions for determination of structural resistance factor. However, driving HP piles through overburden not likely to impede driving to deep rock or preboring to rock for setting piles are two situations that could be considered as less than severe. Further, driving any steel pile through soil without rubble, boulders, cobbles or very dense gravel could be considered good driving conditions for determination of structural resistance factor. Consult the Structural Project Manager or Structural Liaison Engineer. |

| | :The structural resistance factor for combined axial and flexural resistance of undamaged piles: |

| | ::Axial resistance factor for HP Piles: <math> \phi_c </math>= 0.70 |

| | ::Axial resistance for Steel Shells (Pipe): <math> \phi_c </math>= 0.80 |

| | ::Flexural resistance factor for HP Piles or Steel Shells: <math> \phi_f </math>= 1.00 |

| | :For Extreme Event Limit States, see LRFD 10.5.5.3. |

| | <div id="751.36.5.3 Geotechnical Resistance"></div> |

|

| |

|

| | ===751.36.5.3 Geotechnical Resistance Factor (ϕ<sub>stat</sub>) and Driving Resistance Factor (ϕ<sub>dyn</sub>)=== |

| | The factors for Geotechnical Resistance (<math> \phi_{stat}</math>) and Driving Resistance (<math> \phi_{dyn}</math>) may be different because of the reliability of the different methods used to determine the nominal bearing resistance. Caution should be used if the difference in factors for Geotechnical Resistance and Driving Resistance are great as it can lead to issues with pile overruns. Also see [[#751.36.5.9 Estimate Pile Length and Check Pile Capacity|EPG 751.36.5.9]]. |

|

| |

|

| ''Column Moment Normal to Bent In-Plane Direction'' | | '''Geotechnical Resistance Factor, ϕ<sub>stat</sub>:''' |

|

| |

|

| <math>M_{cz}= \delta_{sz}M_{2z}</math>

| | The Geotechnical Resistance factor is based on the static method used by the designer in determining the nominal bearing resistance. Unlike the Driving Resistance factor the Geotechnical Resistance factor can vary with the soil layers. If Geotechnical Resistance factors are not provided by the Geotechnical Engineer, the static method and resistance factors shall be selected from the table below. The values provided in LRFD Table 10.5.5.2.3-1 are only applicable if the end of drive criteria is based off the total pile penetration which is not recommended. For Extreme Event Limit States see LRFD 10.5.5.3. |

|

| |

|

| <math>l_{uz}</math> = top of footing to bottom of beam cap or tie beam and/or top of tie beam to bottom of beam cap

| | {|border="1" style="text-align:center; width: 750px" cellpadding="5" align="center" cellspacing="0" |

| | | |+ '''Table - Static Analysis Resistance Factors used for Pile Length Estimates''' |

| {| style="margin: auto;"

| | ! Pile Type !! Soil Type !! Static Analysis Method !! Side Friction<sup>1</sup><br><math> \phi_{stat}</math> !! End Bearing<br><math> \phi_{stat}</math> |

| |- | |

| | Out-of-plane bending<br>Non-integral Bent<sup>1</sup> || [[Image:751.31 Open Concrete Int Bents and Piers- Boundary Conditions for columns-Top Image.gif]] || Out-of-plane bending<br>Integral Bent

| |

| |- | | |- |

| | In-plane bending || [[Image:751.31 Open Concrete Int Bents and Piers- Boundary Conditions for columns-Bottom Image.gif]] || | | | rowspan="4" | '''CIP Piles - Steel Pipe Shells''' || Clay || Alpha - Tomlinson || <math> \phi_{dyn}</math><sup>2</sup> || <math> \phi_{dyn}</math><sup>2</sup> |

| |- | | |- |

| | colspan="3" | '''Boundary Conditions for Columns''' | | | rowspan="3" | Sand || Nordlund<sup>3</sup> || 0.45 - Gates<br>0.45 - WEAP<br>0.55 - PDA || 0.45 - Gates<br>0.45 - WEAP<br>0.55 - PDA |

| |- | | |- |

| | colspan="3" | <sup>1</sup>A refined procedure may be used to determine a reduced effective length factor (less than 2.1) for<br>intermediate bents where the beam cap is doweled into a concrete superstructure diaphragm. The<br>procedure is outlined at the end of this section. | | | LCPC<sup>4</sup> || 0.70 || 0.45 |

| |- | | |- |

| | | Schmertmann<sup>5</sup> || 0.50 || 0.50 |

| |} | | |} |

|

| |

|

| For telescoping columns, the equivalent moment of inertia, <i>I</i>, and equivalent effective length factor, <i>K</i>, can be estimated as follows:

| | {|border="0" style="text-align:left; width: 750px" align="center" cellspacing="0" |

| | |

| {| style="margin: auto; text-align: center" | |

| |- | | |- |

| | [[Image:751.31 Open Concrete Int Bents and Piers- Telescoping Columns.gif|center]] | | | <sup>1</sup> For mixed soil profiles the lowest applicable resistance factor for clay or sand may be used to simplify the analysis. |

| |-

| |

| | '''Telescoping Columns'''

| |

| |- | | |- |

| |} | | | <sup>2</sup> ϕ<sub>dyn</sub> = see following section. |

| | |

| <math>\, \ I = \frac {\sum \left(l_n I_n \right)}{L}</math> | |

| | |

| Where:

| |

| | |

| <math>\, l_n</math>= length of column segment <math>\, n</math>

| |

| | |

| <math>\, I_n</math>= moment of inertia of column segment <math>\, n</math>

| |

| | |

| <math>\, L</math>= total length of telescoping column

| |

| | |

| | |

| '''Equivalent Effective Length Factor'''

| |

| | |

| <math>\, \ K =\sqrt \frac{\pi^2EI}{P_cL^2}</math>

| |

| | |

| Where:

| |

| | |

| <math>\, E</math> = modulus of elasticity of column | |

| | |

| <math>\, I</math> = equivalent moment of inertia of column

| |

| | |

| <math>\,L</math> = total length of telescoping column

| |

| | |

| <math>\, P_c</math> =elastic buckling load solved from the equations given by the following boundary conditions:

| |

| | |

| Warning: The following equations were developed assuming equal column segment lengths. When the segment lengths become disproportionate other methods should be used to verify P<sub>c</sub>.

| |

| | |

| | |

| <center>

| |

| ''Fixed-Fixed Condition''

| |

| | |

| [[Image:751.31 Open Concrete Int Bents and Piers- Columns Fixed-Fixed Condition.gif]]

| |

| | |

| | |

| <math>\, \left(a_1 + a_2 \right) \bigg[ \left(d_1 + d_2 \right) - P_c \Big( \frac{1}{l_1} + \frac{1}{l_2} \Big) \bigg]- \left(c_1 - c_2 \right)^2 = 0</math>

| |

| | |

| {|

| |

| |- | | |- |

| |<math>\, a_1</math>||<math>\, = \frac{4EI_1}{l_1}</math>||width="100"| ||<math>\, a_2</math>||<math>\, =\frac{4EI_2}{l_2}</math> | | | <sup>3</sup>The Nordlund method is recommended for sand layers in mixed soil profiles where CPT data is not available. |

| |- | | |- |

| |<math>\, c_1</math>||<math>\, = \frac{6EI_1}{{l_1}^2}</math>|| ||<math>\, c_2</math>||<math>\, =\frac{6EI_2}{{l_2}^2}</math> | | | <sup>4</sup>The resistance factors associated with the LCPC method are not statistically calibrated for reliability, but studies have shown this method to be one of the most reliable methods for predicting soil behavior from CPT data. |

| |- | | |- |

| |<math>\, d_1</math>||<math>\, = \frac{12EI_1}{{l_1}^3}</math>|| ||<math>\, d_2</math>||<math>\, = \frac{12EI_2}{{l_2}^3}</math> | | | <sup>5</sup>Per LRFD 10.7.3.8.6g the Schmertmann method shall only be used for sands and nonplastic silts with CPT data. |

| |- | | |- |

| | | For more detailed guidance see [https://www.modot.org/media/54989 SEG 25-001 New Policy for Friction Pile]. |

| |} | | |} |

|

| |

|

| | '''Driving Resistance Factor, ϕ<sub>dyn</sub>:''' |

|

| |

|

| ''Hinged-Fixed Condition''

| | The Driving Resistance factor shall be selected from LRFD Table 10.5.5.2.3-1 based on the method to be used in the field during construction to verify nominal axial compressive resistance. |

| | |

| [[Image:751.31 Open Concrete Int Bents and Piers- Columns Hinged-Fixed Condition.gif]]

| |

| </center>

| |

|

| |

|

| {|align="center" | | {|border="1" style="text-align:center;" cellpadding="5" align="center" cellspacing="0" |

| |-

| | ! Pile Driving Verification Method !! Resistance Factor,<br/><math> \phi_{dyn}</math> |

| |<math>\, \left(a_2 \right) \left(a_1 + a_2 \right) \bigg[ \left(d_1 + d_2 \right) - P_c \Big( \frac{1}{l_1} + \frac{1}{l_2} \Big) \bigg]- \left(2b_2c_2 \right) \left(c_2 - c_1 \right) </math>

| |

| |- | | |- |

| |<math>- \left(b_2 \right)^2 \bigg[ \left(d_1 + d_2 \right) - P_c \Big( \frac{1}{l_1} + \frac{1}{l_2} \Big) \bigg]- \left(a_2 \right) \left(c_2 - c_1 \right)^2</math> | | | FHWA-modified Gates Dynamic Pile Formula<br/>(End of Drive condition only) || 0.40 |

| |- | | |- |

| |<math>- \left(c_2 \right)^2 \left(a_2 + a_1 \right) = 0 </math> | | | Wave Equation Analysis (WEAP) || 0.50 |

| |} | |

| | |

| Where:

| |

| {|

| |

| |- | | |- |

| |<math>\, b_1</math>||<math>\, = \frac{2EI_1}{l_1}</math>||width="100"| ||<math>\, b_2</math>||<math>\, =\frac{2EI_2}{l_2}</math> | | | Dynamic Testing (PDA) on 1 to 10% piles || 0.65 |