751.31 Open Concrete Intermediate Bents: Difference between revisions

m →751.31.1.1 Material Properties: Per Bridge, corrected the usage of Class B and Class B-1 concrete for intermediate bents. |

m →751.31.2.4 Column Analysis: updated old math equations |

||

| (67 intermediate revisions by 3 users not shown) | |||

| Line 9: | Line 9: | ||

:''n'' = 10 | :''n'' = 10 | ||

:In special cases when stronger concrete is necessary for design, Class B-1 (''n'' = 8) may be considered for intermediate bents (caps, columns, tie beams, web beams, collision walls and/or footings). (Consult with the Structural Project Manager or Structural Liaison Engineer) | :In special cases when stronger concrete is necessary for design, Class B-1 (''n'' = 8) may be considered for intermediate bents (caps, columns, tie beams, web beams, collision walls and/or footings). (Consult with the Structural Project Manager or Structural Liaison Engineer.) | ||

| Line 25: | Line 25: | ||

Modulus of rupture, | |||

::::::<math> f_r \ = \ 0.24 \sqrt{f'_{c}}</math> LRFD 5.4.2.6 | |||

< | Where: | ||

:f'<sub>c</sub> is in ksi | |||

| Line 46: | Line 42: | ||

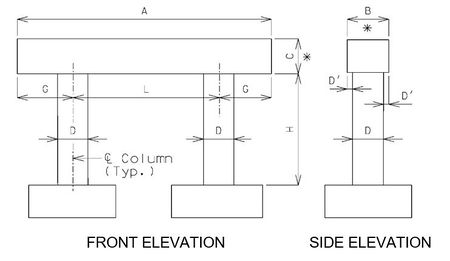

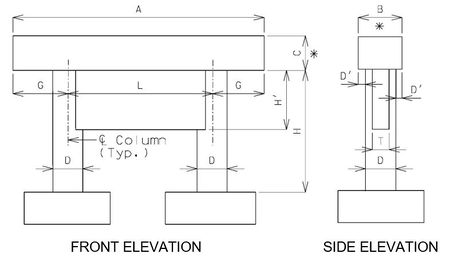

===751.31.1.2 Rigid Frame- No Tie or Web Beam=== | ===751.31.1.2 Rigid Frame- No Tie or Web Beam=== | ||

[[Image:751.31.1.2.jpg|center|450px]] | |||

Beam | Beam | ||

:A = Length to be determined by the superstructure requirements or the [[751. | :A = Length to be determined by the superstructure requirements or the [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, to the | ||

::nearest 1”. Use square ends. | ::nearest 1”. Use square ends. | ||

:B = Width to be determined by the minimum of: superstructure requirements, [[751. | :B = Width to be determined by the minimum of: superstructure requirements, [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, or | ||

::column diameter + 6”. (6” increments) (*) | ::column diameter + 6”. (6” increments) (*) | ||

:C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | :C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | ||

: | :'''*''' For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D ≤ C ≤ 1.25 D. SGS 8.13.5-1 | ||

Columns | Columns | ||

| Line 71: | Line 66: | ||

:::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | :::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | ||

::2) Beam width controlled by [[751. | ::2) Beam width controlled by [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria. | ||

:::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | :::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | ||

| Line 79: | Line 74: | ||

:H = Column height as required by grade and footing elevations. Use construction joint in column when H exceeds 35’-0”. | :H = Column height as required by grade and footing elevations. Use construction joint in column when H exceeds 35’-0”. | ||

:NOTE: Try to keep columns and beams the same size where possible for economy of construction. | :NOTE: Try to keep columns and beams the same size where possible for economy of construction. | ||

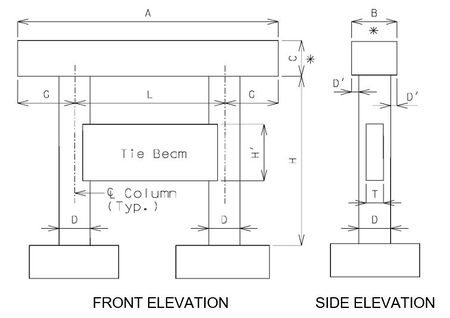

===751.31.1.3 Web Beam – Web Supporting Beam=== | ===751.31.1.3 Web Beam – Web Supporting Beam=== | ||

[[Image:751.31 | [[Image:751.31.1.3 2019.jpg|center|450px]] | ||

Beam | Beam | ||

:A = Length to be determined by the superstructure requirements or the [[751. | :A = Length to be determined by the superstructure requirements or the [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, to the | ||

::nearest 1”. Use square ends. | ::nearest 1”. Use square ends. | ||

:B = Width to be determined by the minimum of: superstructure requirements, [[751. | :B = Width to be determined by the minimum of: superstructure requirements, [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, or | ||

::column diameter + 6”. (6” increments) (*) | ::column diameter + 6”. (6” increments) (*) | ||

:C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | :C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | ||

: | :'''*''' For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D ≤ C ≤ 1.25 D. SGS 8.13.5-1 | ||

Columns | Columns | ||

| Line 109: | Line 102: | ||

:::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | :::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | ||

::2) Beam width controlled by [[751. | ::2) Beam width controlled by [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria. | ||

:::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | :::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | ||

| Line 121: | Line 114: | ||

:T = Web thickness. For a 3’-0” column diameter, use T = column diameter. For column diameters ≥ 3’-6”, use T = 0.5 x (column diameter). | :T = Web thickness. For a 3’-0” column diameter, use T = column diameter. For column diameters ≥ 3’-6”, use T = 0.5 x (column diameter). | ||

:H' = See bottom elevations of web given on the Design Layout. | :H' = See bottom elevations of web given on the Design Layout. | ||

:NOTE: Try to keep columns and beams the same size where possible for economy of construction. | :NOTE: Try to keep columns and beams the same size where possible for economy of construction. | ||

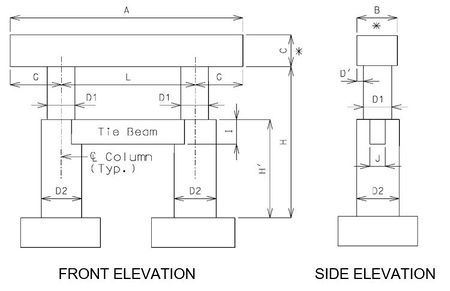

===751.31.1.4 Tie Beam=== | ===751.31.1.4 Tie Beam=== | ||

[[Image:751.31.1.4.jpg|center|450px]] | |||

Beam | Beam | ||

:A = Length to be determined by the superstructure requirements or the [[751. | :A = Length to be determined by the superstructure requirements or the [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, to the | ||

::nearest 1”. Use square ends. | ::nearest 1”. Use square ends. | ||

:B = Width to be determined by the minimum of: superstructure requirements, [[751. | :B = Width to be determined by the minimum of: superstructure requirements, [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, or | ||

::column diameter + 6”. (6” increments) (*) | ::column diameter + 6”. (6” increments) (*) | ||

:C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | :C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | ||

: | :'''*''' For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D ≤ C ≤ 1.25 D. SGS 8.13.5-1 | ||

Columns | Columns | ||

| Line 152: | Line 141: | ||

:::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | :::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | ||

::2) Beam width controlled by [[751. | ::2) Beam width controlled by [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria. | ||

:::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | :::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | ||

| Line 164: | Line 153: | ||

:T = Tie beam thickness. Minimum T = 0.5 x (column diameter). | :T = Tie beam thickness. Minimum T = 0.5 x (column diameter). | ||

:H' = See bottom elevations of tie beam given on the Design Layout. Minimum H' = 2 x T (round to the next foot higher). | :H' = See bottom elevations of tie beam given on the Design Layout. Minimum H' = 2 x T (round to the next foot higher). | ||

:NOTE: Try to keep columns and beams the same size where possible for economy of construction. | :NOTE: Try to keep columns and beams the same size where possible for economy of construction. | ||

===751.31.1.5 Tie Beam with Change in Column Diameter=== | ===751.31.1.5 Tie Beam with Change in Column Diameter=== | ||

[[Image:751.31 | [[Image:751.31.1.5.jpg|center|450px]] | ||

Beam | Beam | ||

:A = Length to be determined by the superstructure requirements or the [[751. | :A = Length to be determined by the superstructure requirements or the [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, to the | ||

::nearest 1”. Use square ends. | ::nearest 1”. Use square ends. | ||

:B = Width to be determined by the minimum of: superstructure requirements, [[751. | :B = Width to be determined by the minimum of: superstructure requirements, [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, or | ||

::column diameter + 6”. (6” increments) (*) | ::column diameter + 6”. (6” increments) (*) | ||

:C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | :C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*) | ||

: | :'''*''' For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D1 ≤ C ≤ 1.25 D1. SGS 8.13.5-1 | ||

Columns | Columns | ||

| Line 197: | Line 183: | ||

:::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | :::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | ||

::2) Beam width controlled by [[751. | ::2) Beam width controlled by [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria. | ||

:::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | :::<math>\, \Rightarrow</math>3” ≤ D' ≤ 15” | ||

| Line 212: | Line 198: | ||

:I = Depth as required by design. Minimum of 3’-0” (3” increments). | :I = Depth as required by design. Minimum of 3’-0” (3” increments). | ||

:J = Width as required by design. Minimum of (0.5 x D1). | :J = Width as required by design. Minimum of (0.5 x D1). | ||

:NOTE: Try to keep columns and beams the same size where possible for economy of construction. | :NOTE: Try to keep columns and beams the same size where possible for economy of construction. | ||

| Line 219: | Line 203: | ||

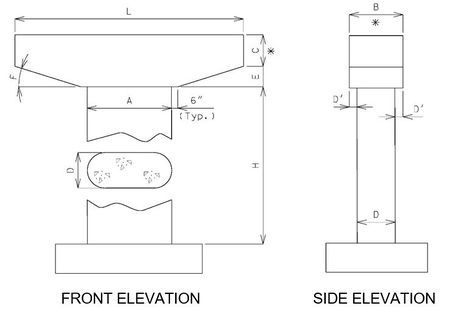

===751.31.1.6 Hammer Head Type=== | ===751.31.1.6 Hammer Head Type=== | ||

[[Image:751.31.1.6.jpg|center|450px]] | |||

[[Image:751.31 | |||

Beam | Beam | ||

:L = Length to be determined by the superstructure requirements or the [[751. | :L = Length to be determined by the superstructure requirements or the [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, to the | ||

:nearest 1”. Use square ends. | :nearest 1”. Use square ends. | ||

:B = Width to be determined by the minimum of: superstructure requirements, [[751. | :B = Width to be determined by the minimum of: superstructure requirements, [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria, or | ||

:column width + 6”. (6” increments) (*) | :column width + 6”. (6” increments) (*) | ||

| Line 236: | Line 218: | ||

:F = Angle as required by design (20° maximum) | :F = Angle as required by design (20° maximum) | ||

: | :'''*''' Ratio of beam width to beam depth, B/C, shall be ≤ 1.25 | ||

Columns | Columns | ||

| Line 249: | Line 231: | ||

:::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | :::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 6” | ||

::2) Beam width controlled by [[751. | ::2) Beam width controlled by [[751.9_Bridge_Seismic_Design|minimum support length]] required for earthquake criteria. | ||

:::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 15” | :::<math>\, \Rightarrow</math> 3” ≤ D' ≤ 15” | ||

| Line 257: | Line 239: | ||

===751.31.1.7 Collision Walls=== | ===751.31.1.7 Collision Walls=== | ||

[[Image:751.31 | [[Image:751.31.1.7.1.jpg|center|500px]] | ||

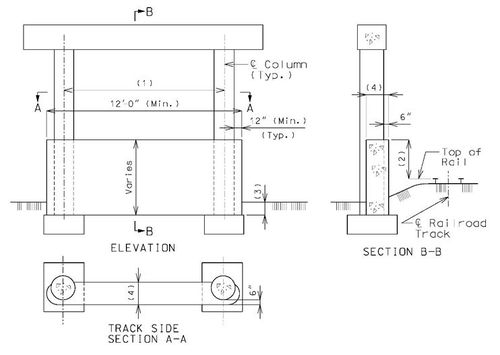

'''Structure Over Railroad, Track on One Side of Bent''' | '''Structure Over Railroad, Track on One Side of Bent''' | ||

| Line 268: | Line 250: | ||

{| | {| | ||

|- | |- | ||

|valign="top"|1 | |valign="top"|(1)||colspan=2|For column spacing over 25’-0”, see Structural Project Managers. | ||

|- | |- | ||

|valign="top"|2 | |valign="top"|(2)||colspan=2|6’-0” minimum for columns from 12’-0” to 25’-0” clear from the centerline of the track; 12’-0” minimum for columns less than 12’-0” clear from the centerline of the track. | ||

|- | |- | ||

|valign="top"|3 | |valign="top"|(3)||colspan=2|In general, the collision wall shall extend to at least 4’-0” below the lowest surrounding grade. For spread footing on rock, the collision wall may extend to less than 4’-0” below the lowest surrounding grade with railroad’s concurrence. Top of footing elevations should correspond with bottom of collision wall. | ||

|- | |- | ||

|4 | |(4) || | ||

{|border=1 cellspacing=1 cellpadding= 1 | {|border=1 cellspacing=1 cellpadding= 1 | ||

|- | |- | ||

| Line 285: | Line 267: | ||

|- | |- | ||

|} | |} | ||

'''*''' AREA–American Railway Engineering Association | |||

'''**''' To facilitate construction, match the back face of collision wall to the face of column. | |||

[[Image:751.31.1.7.2.jpg|center|500px]] | |||

[[Image:751.31 | |||

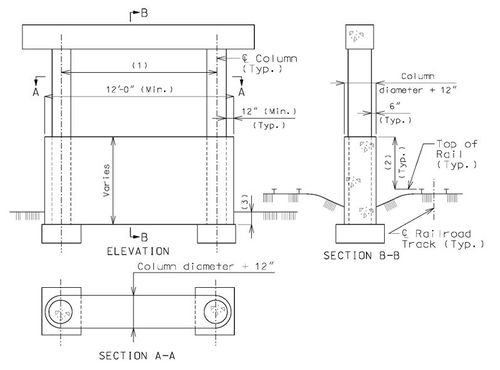

'''Structure Over Railroad, Track on Both Sides of Bent''' | '''Structure Over Railroad, Track on Both Sides of Bent''' | ||

| Line 301: | Line 281: | ||

{| | {| | ||

|- | |- | ||

|valign="top"|1 | |valign="top"|(1)||For column spacing over 25’-0”, see Structural Project Managers. | ||

|- | |- | ||

|valign="top"|2 | |valign="top"|(2)||6’-0” minimum for columns from 12’-0” to 25’-0” clear from the centerline of the track; 12’-0” minimum for columns less than 12’-0” clear from the centerline of the track. | ||

|- | |- | ||

|valign="top"|3 | |valign="top"|(3)||In general, the collision wall shall extend to at least 4’-0” below the lowest surrounding grade. For spread footing on rock, the collision wall may extend to less than 4’-0” below the lowest surrounding grade with railroad’s concurrence. Top of footing elevations should correspond with bottom of collision wall. | ||

|} | |} | ||

'''*''' AREA – American Railway Engineering Association | |||

[[Image:751.31.1.7.3.jpg|center|500px]] | |||

[[Image:751.31 | |||

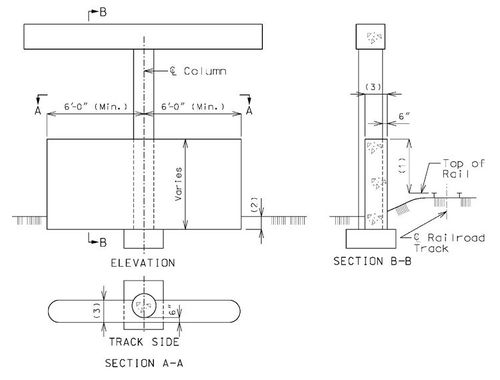

| Line 325: | Line 303: | ||

{| | {| | ||

|- | |- | ||

|valign="top"|1 | |valign="top"|(1)||6’-0” minimum for columns from 12’-0” to 25’-0” clear from the centerline of the track; 12’-0” minimum for columns less than 12’-0” clear from the centerline of the track. | ||

|- | |- | ||

|valign="top"|2 | |valign="top"|(2) ||In general, the collision wall shall extend to at least 4’-0” below the lowest surrounding grade. For spread footing on rock, the collision wall may extend to less than 4’-0” below the lowest surrounding grade with railroad’s concurrence. Top of footing elevations should correspond with bottom of collision wall. | ||

|- | |- | ||

|valign="top"|3 | |valign="top"|(3)|| | ||

{|border=1 cellpadding=1 cellspacing=1 | {|border=1 cellpadding=1 cellspacing=1 | ||

|- | |- | ||

| Line 338: | Line 316: | ||

|} | |} | ||

|} | |} | ||

'''*''' AREA – American Railway Engineering Association | |||

'''**''' To facilitate construction, match the back face of collision wall to the face of column. | |||

==751.31.2 Design== | ==751.31.2 Design== | ||

| Line 422: | Line 400: | ||

'''*''' A factor of 2.0 is applied to the moment to allow for the possibility of the column resisting earth pressure caused by the earth behind the column twice the column width. | |||

<center> | <center> | ||

| Line 433: | Line 411: | ||

:Collision walls are to be designed for the unequal horizontal forces from the earth pressure, if the condition exists (See Design Layout). The vertical force on the collision wall is the dead load weight of the wall (*). If a bent has three or more columns, design the steel in the top of the wall for negative moment. | :Collision walls are to be designed for the unequal horizontal forces from the earth pressure, if the condition exists (See Design Layout). The vertical force on the collision wall is the dead load weight of the wall (*). If a bent has three or more columns, design the steel in the top of the wall for negative moment. | ||

( | :(*) For footing design, the eccentric dead load moment due to an unsymmetrical collision wall shall be considered. | ||

:Columns shall be designed for collision loads as outlined in [[751.2 Loads#751.2.2.6 Other Loads|EPG 751.2.2.6 Other Loads]]. Collision shear reinforcement may be referenced from the table in [[#751.31.3.2 Column|EPG 751.31.3.2 Column]] or shear reinforcement may be determined by design. When collision design is required, flexural effects from collision forces shall be considered for the Extreme Event II limit state. For the collision loading the column may be assumed to act as fixed-pinned with no lateral movement at the top of the column for out-of-plane bending. | |||

''Seal Course'' | ''Seal Course'' | ||

| Line 443: | Line 423: | ||

[[Image:751.31 Open Concrete Int Bents and Piers- General Intermediate Bent Elevation.gif]] | [[Image:751.31 Open Concrete Int Bents and Piers- General Intermediate Bent Elevation.gif]] | ||

'''*''' Use only if specified on the Design Layout or as stated by the guidelines in this article. | |||

'''**''' For column spacings greater than 30'-0", tie beams are not to be used, unless the web supports the beam. | |||

| Line 459: | Line 439: | ||

:The joint between the column and footing is assumed to be “fixed”, unless foundation flexibility needs to be considered as required by the Structural Project Manager. | :The joint between the column and footing is assumed to be “fixed”, unless foundation flexibility needs to be considered as required by the Structural Project Manager. | ||

<div id="Beam"></div> | |||

''Beam'' | ''Beam'' | ||

| Line 469: | Line 450: | ||

:The minimum reinforcement shall be such that the factored flexural resistance, Mr, is greater than or equal to the lesser of: | :The minimum reinforcement shall be such that the factored flexural resistance, Mr, is greater than or equal to the lesser of: | ||

: | :Minimum Tensile Reinforcement | ||

: | |||

:The amount of tensile reinforcement shall be adequate to develop a factored flexural resistance, M<sub>r</sub>, at least equal to the lesser of either: | |||

::1) M<sub>cr</sub> = cracking moment LRFD Eq. 5.7.3.3.2-1 | |||

::2) 1.33 times the factored moment required by the applicable strength load combinations specified in LRFD Table 3.4.1-1. | |||

:Additional reinforcement is required in the sides of the beam. The following table gives adequate steel for both temperature and shrinkage (LRFD 5.10.8), and skin reinforcement (LRFD 5.7.3.4). | :Additional reinforcement is required in the sides of the beam. The following table gives adequate steel for both temperature and shrinkage (LRFD 5.10.8), and skin reinforcement (LRFD 5.7.3.4). | ||

<center> | |||

{|border=1 cellpadding=1 cellspacing= 1 style="text-align:center" | |||

|+'''Additional side reinforcement required for reinforced concrete beam caps (per face)''' | |+'''Additional side reinforcement required for reinforced concrete beam caps (per face)''' | ||

|Beam Height, H||Number – Bar Size | |width="300"|Beam Height, H||width="400"|Number – Bar Size | ||

|- | |- | ||

|H ≤ 36”||4 - #6 | |H ≤ 36”||4 - #6 | ||

| Line 488: | Line 473: | ||

|- | |- | ||

|} | |} | ||

</center> | |||

''Tie Beam'' | ''Tie Beam'' | ||

| Line 553: | Line 538: | ||

:The maximum reinforcement shall be limited by the following requirements: | :The maximum reinforcement shall be limited by the following requirements: | ||

<math>\, \ A_s \le 0.04A_g</math> SGS 8.8.1 | |||

:*Spacing limitations given in this article. | :*Spacing limitations given in this article. | ||

| Line 649: | Line 632: | ||

'''*''' Use a tie beam if specified on the Design Layout or if the design calls for one. | |||

'''**''' For column spacing > 30’, tie beams are not to be used unless the web supports the beam | |||

'''Elevations for Intermediate Bent with Tie Beam''' | '''Elevations for Intermediate Bent with Tie Beam''' | ||

| Line 691: | Line 674: | ||

'''Transverse Reinforcement''' | '''Transverse Reinforcement''' | ||

''Seismic | ''Seismic Design Category (SDC) A'' | ||

:Columns shall be analyzed as “Tied Columns”. Unless excessive reinforcement is required, in which case spirals shall be used. | :Columns shall be analyzed as “Tied Columns”. Unless excessive reinforcement is required, in which case spirals shall be used. | ||

'''Bi-Axial Bending''' | '''Bi-Axial Bending''' | ||

Use the resultant of longitudinal and transverse moments. | Use the resultant of longitudinal and transverse moments. | ||

'''Slenderness effects in Columns''' | '''Slenderness effects in Columns''' | ||

| Line 705: | Line 686: | ||

<math>\, \ l_u \ge \frac {22r}{K}</math> | <math>\, \ l_u \ge \frac {22r}{K}</math> | ||

Where: | Where: | ||

| Line 714: | Line 694: | ||

<math>\, \ K</math> = effective length factor | <math>\, \ K</math> = effective length factor | ||

Effects should be investigated by using either the rigorous P-∆ analysis or the Moment Magnifier Method with consideration of bracing and non-bracing effects. Use of the moment magnifier method is limited to members with Kl<sub>u</sub>/r ≤ 100, or the diameter of a round column must be ≥ Kl<sub>u</sub>/25. A maximum value of 2.5 for moment magnifier is desirable for efficiency of design. Increase column diameter to reduce the magnifier, if necessary. | Effects should be investigated by using either the rigorous P-∆ analysis or the Moment Magnifier Method with consideration of bracing and non-bracing effects. Use of the moment magnifier method is limited to members with Kl<sub>u</sub>/r ≤ 100, or the diameter of a round column must be ≥ Kl<sub>u</sub>/25. A maximum value of 2.5 for moment magnifier is desirable for efficiency of design. Increase column diameter to reduce the magnifier, if necessary. | ||

When a compression member is subjected to bending in both principal directions, the effects of slenderness should be considered in each direction independently. Instead of calculating two moment magnifiers, | When a compression member is subjected to bending in both principal directions, the effects of slenderness should be considered in each direction independently. Instead of calculating two moment magnifiers, <math>\, \delta_b</math> and <math>\, \delta_s</math>, and performing two analyses for M<sub>2b</sub> and M<sub>2s</sub> as described in LRFD 4.5.3.2.2b, the following conservative, simplified moment magnification method in which only a moment magnifier due to sidesway, δ<sub>s</sub>, analysis is required: | ||

<center> | <center> | ||

[[Image:751.31 Open Concrete Int Bents and Piers- Typical Intermediate Bent.gif]] | [[Image:751.31 Open Concrete Int Bents and Piers- Typical Intermediate Bent.gif]] | ||

| Line 724: | Line 703: | ||

<center>'''Typical Intermediate Bent'''</center> | <center>'''Typical Intermediate Bent'''</center> | ||

''General Procedure for Bending in a Principal Direction'' | ''General Procedure for Bending in a Principal Direction'' | ||

::M<sub>c</sub> = δ<sub>s</sub>M<sub>2</sub> | ::M<sub>c</sub> = δ<sub>s</sub>M<sub>2</sub> | ||

::Where: | ::Where: | ||

| Line 738: | Line 717: | ||

::<math>\, =\cfrac{C_m}{1- \cfrac{\sum P_u }{\phi_k \sum P_e }} \ge 1.0; \ C_m = 1.0 </math> | ::<math>\, =\cfrac{C_m}{1- \cfrac{\sum P_u }{\phi_k \sum P_e }} \ge 1.0; \ C_m = 1.0 </math> | ||

Where: | Where: | ||

| Line 750: | Line 728: | ||

|- | |- | ||

|} | |} | ||

<math>\, =\sum {\frac{\pi^2 \ EI}{\left( \ Kl_u \right)^2}}</math> | <math>\, =\sum {\frac{\pi^2 \ EI}{\left( \ Kl_u \right)^2}}</math> | ||

| Line 757: | Line 733: | ||

Where: | Where: | ||

<math>\, \ K</math> = effective length factor = 1.2 min. (see | <math>\, \ K</math> = effective length factor = 1.2 min. (see the following figure showing boundary conditions for columns) | ||

<math>\, \ l_u</math> = unsupported length of column (in.) | |||

<math>\, \ EI = \cfrac{{E_cI_g}{/2.5}}{1+\beta_d}</math> | <math>\, \ EI = \cfrac{{E_cI_g}{/2.5}}{1+\beta_d}</math> | ||

| Line 772: | Line 746: | ||

<math>\, \beta_d</math>= ratio of maximum factored permanent load moments to maximum factored total load moment: always positive | <math>\, \beta_d</math>= ratio of maximum factored permanent load moments to maximum factored total load moment: always positive | ||

| Line 780: | Line 753: | ||

<math>l_{uy}</math>= top of footing to top of beam cap | <math>l_{uy}</math>= top of footing to top of beam cap | ||

| Line 789: | Line 761: | ||

<math>l_{uz}</math> = top of footing to bottom of beam cap or tie beam and/or top of tie beam to bottom of beam cap | <math>l_{uz}</math> = top of footing to bottom of beam cap or tie beam and/or top of tie beam to bottom of beam cap | ||

< | {| style="margin: auto;" | ||

|- | |||

| Out-of-plane bending<br>Non-integral Bent<sup>1</sup> || [[Image:751.31 Open Concrete Int Bents and Piers- Boundary Conditions for columns-Top Image.gif]] || Out-of-plane bending<br>Integral Bent | |||

|- | |||

| In-plane bending || [[Image:751.31 Open Concrete Int Bents and Piers- Boundary Conditions for columns-Bottom Image.gif]] || | |||

|- | |- | ||

| | | colspan="3" | '''Boundary Conditions for Columns''' | ||

|- | |- | ||

| | | colspan="3" | <sup>1</sup>A refined procedure may be used to determine a reduced effective length factor (less than 2.1) for<br>intermediate bents where the beam cap is doweled into a concrete superstructure diaphragm. The<br>procedure is outlined at the end of this section. | ||

|- | |- | ||

|} | |} | ||

For telescoping columns, the equivalent moment of inertia, <i>I</i>, and equivalent effective length factor, <i>K</i>, can be estimated as follows: | For telescoping columns, the equivalent moment of inertia, <i>I</i>, and equivalent effective length factor, <i>K</i>, can be estimated as follows: | ||

{| style="margin: auto; text-align: center" | |||

[[Image:751.31 Open Concrete Int Bents and Piers- Telescoping Columns.gif]] | |- | ||

| [[Image:751.31 Open Concrete Int Bents and Piers- Telescoping Columns.gif|center]] | |||

'''Telescoping Columns''' | |- | ||

| '''Telescoping Columns''' | |||

|- | |||

|} | |||

<math>\, \ I = \frac {\sum \left(l_n I_n \right)}{L}</math> | <math>\, \ I = \frac {\sum \left(l_n I_n \right)}{L}</math> | ||

Where: | Where: | ||

| Line 826: | Line 797: | ||

<math>\, \ K =\sqrt \frac{\pi^2EI}{P_cL^2}</math> | <math>\, \ K =\sqrt \frac{\pi^2EI}{P_cL^2}</math> | ||

Where: | Where: | ||

| Line 837: | Line 807: | ||

<math>\, P_c</math> =elastic buckling load solved from the equations given by the following boundary conditions: | <math>\, P_c</math> =elastic buckling load solved from the equations given by the following boundary conditions: | ||

Warning: The following equations were developed assuming equal column segment lengths. When the segment lengths become disproportionate other methods should be used to verify P<sub>c</sub>. | |||

<center> | <center> | ||

''Fixed- Fixed Condition'' | ''Fixed-Fixed Condition'' | ||

[[Image:751.31 Open Concrete Int Bents and Piers- Columns Fixed-Fixed Condition.gif]] | [[Image:751.31 Open Concrete Int Bents and Piers- Columns Fixed-Fixed Condition.gif]] | ||

| Line 845: | Line 818: | ||

<math>\, \left(a_1 + a_2 \right) \bigg[ \left(d_1 + d_2 \right) - P_c \Big( \frac{1}{l_1} + \frac{1}{l_2} \Big) \bigg]- \left(c_1 - c_2 \right)^2 = 0</math> | <math>\, \left(a_1 + a_2 \right) \bigg[ \left(d_1 + d_2 \right) - P_c \Big( \frac{1}{l_1} + \frac{1}{l_2} \Big) \bigg]- \left(c_1 - c_2 \right)^2 = 0</math> | ||

{| | {| | ||

| Line 857: | Line 828: | ||

|- | |- | ||

|} | |} | ||

''Hinged-Fixed Condition'' | ''Hinged-Fixed Condition'' | ||

[[Image:751.31 Open Concrete Int Bents and Piers- Columns Hinged-Fixed Condition.gif]] | [[Image:751.31 Open Concrete Int Bents and Piers- Columns Hinged-Fixed Condition.gif]] | ||

</center> | </center> | ||

{|align="center" | {|align="center" | ||

| Line 875: | Line 843: | ||

|<math>- \left(c_2 \right)^2 \left(a_2 + a_1 \right) = 0 </math> | |<math>- \left(c_2 \right)^2 \left(a_2 + a_1 \right) = 0 </math> | ||

|} | |} | ||

Where: | Where: | ||

| Line 888: | Line 855: | ||

<center> | <center> | ||

''Fixed-Fixed with Lateral Movement Condition'' | ''Fixed-Fixed with Lateral Movement Condition'' | ||

[[Image:751.31 Open Concrete Int Bents and Piers- Fixed-Fixed Lateral Movement Condition.gif]] | [[Image:751.31 Open Concrete Int Bents and Piers- Fixed-Fixed Lateral Movement Condition.gif]] | ||

</center> | </center> | ||

{|align="center" | {|align="center" | ||

| Line 910: | Line 874: | ||

<center> | <center> | ||

''Fixed-Free with Lateral Movement Condition'' | ''Fixed-Free with Lateral Movement Condition'' | ||

[[Image:751.31 Open Concrete Int Bents and Piers- Fixed-Free Lateral Movement Condition.gif]] | [[Image:751.31 Open Concrete Int Bents and Piers- Fixed-Free Lateral Movement Condition.gif]] | ||

</center> | </center> | ||

{|align="center" | {|align="center" | ||

| Line 923: | Line 884: | ||

|<math>\, - \Bigg[(-d_2) + \frac{P_c}{l_2} - \frac{A_2}{\beta} \Bigg]^2 = 0</math> | |<math>\, - \Bigg[(-d_2) + \frac{P_c}{l_2} - \frac{A_2}{\beta} \Bigg]^2 = 0</math> | ||

|} | |} | ||

Where: | Where: | ||

| Line 938: | Line 898: | ||

|- | |- | ||

|colspan="2"|<math>\, a_1, a_2, b_1, b_2, c_1, c_2, d_1,</math> and <math>\, d_2</math> are defined in the previous equations. | |colspan="2"|<math>\, a_1, a_2, b_1, b_2, c_1, c_2, d_1,</math> and <math>\, d_2</math> are defined in the previous equations. | ||

|} | |||

'''Refined Effective Length Factor for Out-of-plane Bending''' | |||

The following procedure may be used to reduce the effective length factor for column or pile bents where the beam cap is doweled into a concrete superstructure diaphragm. This procedure is applicable for out-of-plane bending only. The less stiff the substructure the larger the benefit expected from this procedure. | |||

The equation for rotational stiffness assumes the dowel bars are fully bonded in the superstructure and beam. To utilize this procedure the dowel bars shall be developed l<sub>d</sub> min into diaphragm and beam but shall not extend into slab and shall clear bottom of beam by 3 inches minimum. Dowel bars shall not be hooked to meet development requirements. | |||

{| style="margin: auto; text-align: center" | |||

|- | |||

| [[image:751.31.2.4_09-2025.png|200px|center]] | |||

|- | |||

| SECTION THRU KEY | |||

|- | |||

|} | |||

The following procedure is developed for the most common substructure type (columns on drilled shafts). This procedure is greatly simplified for non-telescoping column bents and pile bents. | |||

'''Step 1''' – Determine the rotational stiffness at top of bent per ft length of diaphragm, <math>R_{ki}</math> | |||

:: <math>R_{ki}</math> = -12500 + 300A<sub>d</sub> + 600D<sub>W</sub> – 150 x θ | |||

Where: | |||

{| | |||

|- | |||

| style="text-align: right" | <math>R_{ki}</math> || = rotational stiffness at top of bent per ft length of diaphragm (k-ft/rad per ft) | |||

|- | |||

| style="text-align: right" | <math>A_{d}</math> || = total area of dowel bars (in2) | |||

|- | |||

| style="text-align: right" | <math>D_{W}</math> || = diaphragm width between girders and normal to bent (in) | |||

|- | |||

| style="text-align: right" | <math>\theta</math> || = skew angle of bent (deg.) | |||

|- | |||

|} | |||

'''Step 2''' – Determine the rotational stiffness at top of column, <math>R_{kb}</math> | |||

To determine the rotational stiffness at top of column, the rotational stiffness at top of bent, <math>R_{ki}</math>, shall be multiplied by the beam cap length and divided by the number of columns. The beam cap length is substituted for the diaphragm length to simplify the calculations and has a marginal affect on the final result. | |||

:: <math>R_{kb}\, =\, \frac{R_{ki}\, (\text{beam cap length})}{(\text{No. Columns})}</math> | |||

'''Step 3''' – Determine the buckling load assuming no rotational stiffness at top, <math>P_{co}</math> | |||

''For a non-telescoping column on footing or pile with in-ground point of fixity:'' | |||

Note: this step is not required for a non-telescoping column or pile bent but shown here for completeness. | |||

:: <math>P_{co}\, =\, \frac{\pi^2EI}{4L^2}\, \, \, \text{... Note: assumes K= 2.0}</math> | |||

Where: | |||

{| | |||

|- | |||

| style="text-align: right" | <math>P_{co}</math> || = initial buckling load assuming no rotational stiffness at top of bent (k) | |||

|- | |||

| style="text-align: right" | <math>E</math> || = modulus of elasticity of column or pile (ksi) | |||

|- | |||

| style="text-align: right" | <math>I</math> || = moment of inertia of column or pile for out-of-plane bending (in4) | |||

|- | |||

| style="text-align: right" | <math>L</math> || = length between point of fixity and top of beam cap (in) | |||

|- | |||

|} | |||

''For a telescoping column:'' | |||

As noted above the equations provided for determining the buckling load of telescoping columns are not accurate for diverging segment lengths. The following equation is provided and may be used for the fixed-free with lateral movement condition. | |||

:: <math>P_{co}\, =\, \frac{\pi^2EI_2}{4L^2}\, \frac{1}{\frac{l_2}{L} + \frac{l_1 I_2}{LI_1} - \frac{1}{\pi} \left ( \frac{I_2}{I_1} - 1 \right ) sin \frac{\pi l_2}{L}} \, \text{... fixed-free with lateral movement}</math> | |||

Where: | |||

{| | |||

|- | |||

| <math>E = \frac{\sum(l_n E_n)}{L}</math> | |||

|- | |||

| <math>l_1, l_2, I_1, I_2</math> and <math>L</math> are shown in the figures above. | |||

|- | |||

|} | |||

'''Step 4''' – Determine the equivalent moment of inertia for a non-telescoping column using <math>P_{co}</math> | |||

:: <math>I_{eq}\, =\, \frac{P_{co} 4 L^2}{E\pi^2}\, \, \, \text{... Note: assumes K= 2.0}</math> | |||

Note: This step is only required for telescoping columns. | |||

'''Step 5''' – Determine ideal k | |||

A bilinear approximation is used to determine the ideal effective length factor for out-of-plane bending, <math>k</math>. | |||

:: <math> | |||

k = | |||

\begin{cases} | |||

2.000 - 0.3135 \left ( \frac{R_{kb}L}{EI_{eq}} \right ) for\, \frac{R_{kb}L}{EI_{eq}} < 2\\ | |||

1.428 - 0.0275 \left ( \frac{R_{kb}L}{EI_{eq}} \right ) for\, \frac{R_{kb}L}{EI_{eq}} < 2 | |||

\end{cases} | |||

</math> | |||

Note: <math>I_{eq} = I</math> for non-telescoping columns or piles | |||

[[image:751.31.2.4_10-2025.png|400px|center]] | |||

<center>'''Graphical Approximation of k-factor'''</center> | |||

'''Step 6''' – Adjust <math>k</math> for design | |||

The effective length factor for out-of-plane bending requires an adjustment for design conditions. | |||

:: <math>K\, =\, \frac{2.1k}{2.0}</math> | |||

'''Step 7''' – Determine refined buckling load | |||

The buckling load can be calculated using the equivalent non-telescoping column moment of inertia. | |||

:: <math>P_{c}\, =\, \frac{\pi^2EI_{eq}}{(KL)^2}</math> | |||

===751.31.2.5 Column Charts=== | ===751.31.2.5 Column Charts=== | ||

| Line 991: | Line 1,063: | ||

==751.31.3 Reinforcement== | ==751.31.3 Reinforcement== | ||

For Seismic detail requirements for seismic design category, SDC B, C and D, See [[751.9_Bridge_Seismic_Design#751.9.1.2_LRFD_Seismic_Details|EPG 751.9.1.2 LRFD Seismic Details]]. | |||

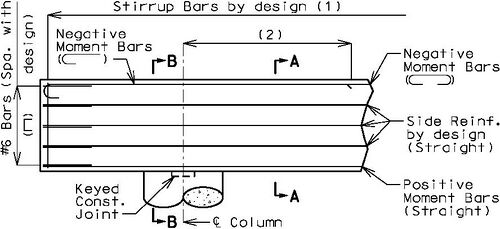

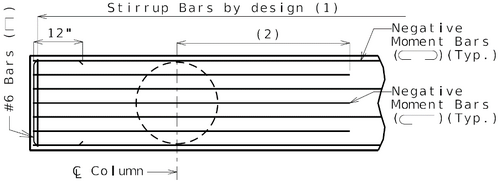

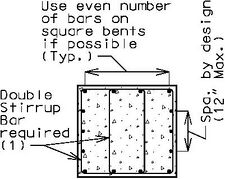

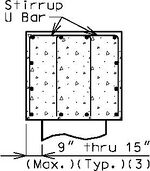

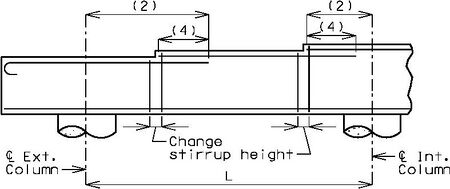

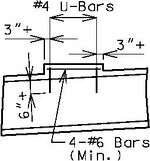

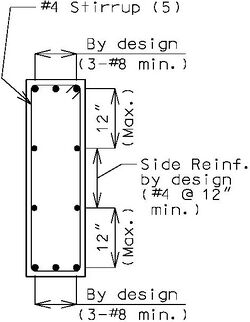

===751.31.3.1 Beam Cap=== | ===751.31.3.1 Beam Cap=== | ||

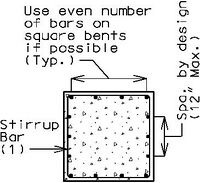

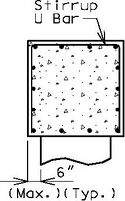

{| cellpadding="10" style="text-align:center; margin:auto" | |||

{|style="text-align:center | |||

|- | |- | ||

|[[Image:751.31 | | colspan="2" | [[Image:751.31.3.1_01-2025.jpg|center|500px]] || [[Image:751.31.3.1_02-2025.jpg|center|200px]] || [[Image:751.31.3.1_03-2025.jpg|center|125px]] | ||

|- | |- | ||

| colspan="2" | '''PART ELEVATION''' || '''SECTION A-A''' || '''SECTION B-B''' | |||

|- | |- | ||

|colspan="2"|( | | colspan="2" | || colspan="2" | '''(Single Stirrups)''' | ||

|- | |- | ||

|colspan="2"| | | colspan="2" | [[Image:751.31.3.1_04-2025.png|center|500px]] || [[Image:751.31.3.1_05-2025.jpg|center|225px]] || [[Image:751.31.3.1_06-2025.jpg|center|150px]] | ||

|- | |- | ||

|colspan="2"| | | colspan="2" | '''PART PLAN''' || '''SECTION A-A''' || '''SECTION B-B''' | ||

|- | |- | ||

| colspan="2" | || colspan="2" | '''(Double Stirrups)''' | |||

|- | |- | ||

|[[Image:751.31 | | colspan="2" | [[Image:751.31.3.1_07-2025.jpg|center|450px]] || colspan="2" | [[Image:751.31.3.1_08-2025.jpg|center|150px]] | ||

|- | |- | ||

| colspan="2" | '''TRANSVERSE BEAM STEPS OVER 3 INCHES'''<br>(Also, steps accumulating over 3 inches) || colspan="2" | '''SLOPED BEAMS'''<br>(Steps over 3 inches on high side) | |||

|- | |- | ||

| | | [[Image:751.31.3.1_09-2025.jpg|center|230px]] || [[Image:751.31.3.1_10-2025.jpg|center|250px]] || rowspan="5" colspan="2" style="text-align:left; vertical-align:top;" | | ||

(1) #4 @ 12” cts. (Min.)<br> | |||

#6 (Dbl.) @ 6” cts. (Max.)<br> | |||

Minimum spacing of 5” for single stirrups and 6” for double stirrups<br> | |||

Maximum spacing of 12”<br> | |||

All stirrups in the beam shall be the same bar size.<br> | |||

(2) L/4 + d, but not less than theoretical cut-off plus development length, where d equals<br> the distance from compression face to centroid of tension steel.<br> | |||

(3) Beam width controlled by minimum support length required for earthquake criteria.<br> | |||

(4) Location 1 Class B lap splice.<br> | |||

(5) 6” (Max.), add #6 bars as needed.<br> | |||

(6) 9” (Max.), add #6 bars at each face as needed.<br> | |||

(7) Location 2 development length, f'c = 3 ksi: 20”(uncoated), 30”(epoxy coated)<br> | |||

See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.8_Development_and_Lap_Splices EPG 751.5.9.2.8] for development and lap splice lengths not given or lengths for<br>scenarios other than those shown. Provide standard hooks if required. | |||

See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.2_Epoxy_Coated_Reinforcement_Requirements EPG 751.5.9.2.2] for epoxy coated reinforcement requirements. | |||

See [https://epg.modot.org/index.php/751.13_Expansion_Devices#751.13.1.4_Details_of_Substructure_Protection EPG 751.13.1.4] for details of protective coating and sloping top of beam to drain<br>when below an expansion device. | |||

|- | |||

| '''Over 3 Inches Thru 12 Inches''' || '''Over 12 Inches''' | |||

|- | |||

< | | colspan="2" | '''LONGITUDINAL BEAM STEPS''' | ||

''' | |||

|- | |- | ||

|[[Image:751.31 | | colspan="2" | [[Image:751.31.3.1_11-2025.jpg|center|475px]] | ||

|- | |- | ||

| colspan="2" | '''REINFORCEMENT UNDER BEARINGS''' | |||

|- | |- | ||

|} | |} | ||

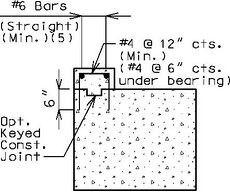

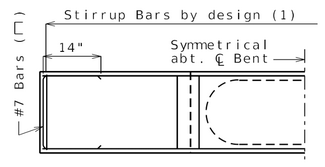

===751.31.3.2 Column=== | ===751.31.3.2 Column=== | ||

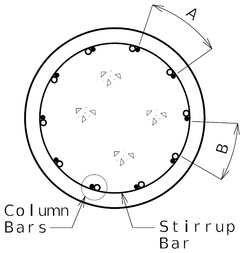

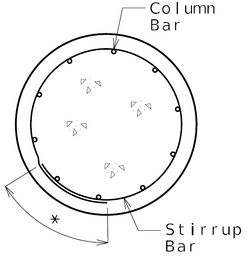

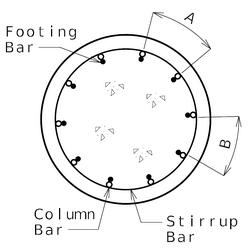

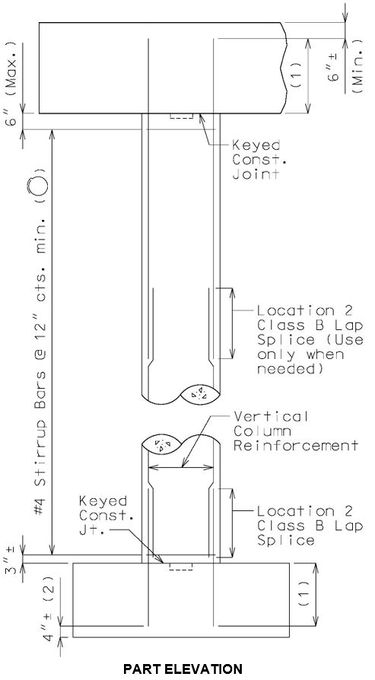

{| | {| style="text-align:center; margin:auto" | ||

|- | |||

| colspan="2" | [[image:751.31.3.2_01-2025.png|center|250px]] || [[image:751.31.3.2_02-2025.png|center|250px]] | |||

|- | |||

| colspan="2" | '''MINIMUM SPACING AT LAP SPLICES''' || '''ALTERNATE DOWEL PLACEMENT''' | |||

|- | |||

| style="width:25px; text-align:right;" | * || colspan="2" style="text-align:left;" | Use alternate detail only with approval of Structural Project Manager and then design column reinforcement using the smaller ring diameter. | |||

|- | |||

| style="width:25px; text-align:right;" | || colspan="2" style="text-align:left;" | Include 1/2-inch buffer for mechanical bar splice. | |||

|- | |||

| style="width:25px; text-align:right;" | A = || colspan="2" style="text-align:left;" | 4 1/2” (5") minimum spacing center-to-center. | |||

|- | |||

| style="width:25px; text-align:right;" | B = || colspan="2" style="text-align:left;" | 2” (2 1/2") clear spacing for bar sizes thru #10. | |||

|- | |||

| style="width:25px; text-align:right;" | || colspan="2" style="text-align:left;" | 2 1/2” (3") clear spacing for bar sizes #11 and #14. | |||

|- | |||

| style="width:25px; text-align:right;" | || colspan="2" style="text-align:left;" | 3 1/2” (4") clear spacing for bar size #18. | |||

|- | |||

| colspan="3" | [[image:751.31.3.2_03-2025.png|center|250px]] | |||

|- | |||

| colspan="3" | '''STIRRUP LAP DETAIL AND STAGGER NOTE''' | |||

|- | |||

| colspan="3" | * X” Minimum lap (Stagger adjacent bar splices) | |||

|- | |||

| colspan="3" style="text-align:left;" | Lap splices for closed circular ties shall be provided and staggered in accordance with LRFD 5.10.6.3. | |||

|- | |- | ||

|( | | colspan="3" style="text-align:left;" | Lap length of 1.3 '''l'''<sub>d</sub> (or Class B) for closed stirrup/ties shall be provided in accordance with LRFD 5.11.2.6.4. | ||

|- | |- | ||

| | | colspan="3" style="text-align:left;" | Lap length for #4 stirrup bars (4” min. spacing, f’c = 3 ksi, and clear cover = 1½”) equals 24” for uncoated<br>bars and 28” for epoxy coated bars. | ||

|- | |- | ||

| | | colspan="3" style="text-align:left;" | For lap length for other scenarios, see [[751.5 Structural Detailing Guidelines#751.5.9.2.8 Development and Lap Splices|EPG 751.5.9.2.8 Development and Lap Splices]]. | ||

|- | |- | ||

|} | |} | ||

{| class="wikitable" cellpadding="10" style="text-align:center; margin:auto" | |||

''' | |+'''Collision Shear Reinforcement<sup>1</sup>''' | ||

|- | |||

! rowspan="2" | Column Diameter !! rowspan="2" | Minimum Reinforcement<sup>2,3</sup> !! colspan="2" | Minimum Lap Splice | |||

|- | |- | ||

! Uncoated<br>(f’c = 3ksi)<br>(Cl. = 1½”) !! Epoxy Coated<br>(f’c = 3ksi)<br>(Cl. = 1½”) | |||

|- | |- | ||

|3’-0”|| | | 3’-0” || By Design || NA || NA | ||

|- | |- | ||

|3’-6”|| | | 3’-6” || By Design || NA || NA | ||

|- | |- | ||

|4’-0”||# | | 4’-0” || #6 @ 5” || 47” || 61” | ||

|- | |- | ||

|4’-6”||# | | 4’-6” || #5 @ 5” || 34” || 44” | ||

|- | |- | ||

|5’-0”||#4 @ | | 5’-0” || #4 @ 5” || 24” || 28” | ||

|- | |- | ||

|5’-6”||#4 @ | | 5’-6” || #4 @ 10” || 24” || 28” | ||

|- | |- | ||

|6’-0”||#4 @ 12” | | 6’-0” || #4 @ 12” || 24” || 28” | ||

|- | |- | ||

| colspan="4" style="text-align:left;" | | |||

'''<sup>1</sup>''' See [[751.2 Loads#751.2.2.6 Other Loads|EPG 751.2.2.6 Other Loads]] to determine if a pier requires design for collision loads.<br/> | |||

'''<sup>2</sup>''' Design assumptions:<br/> | |||

* Vu = 600 k, Pu = 0 k, Mu = 0 k-ft<br/> | |||

* f’c = 3 ksi, fy = 60 ksi, 1.5” clear cover<br/> | |||

* Shear resistance factor = 1.0<br/> | |||

* Minimum longitudinal reinforcement per [[#751.31.2.3 General Design Assumptions|EPG 751.31.2.3 General Design Assumptions]]<br/> | |||

'''<sup>3</sup>''' The shear reinforcement tabulated is adequate for collision but may not be adequate for other design<br>checks. For example, columns greater than 5’-0” require more stirrups to meet min reinforcement. Lesser<br>reinforcement values may be used by design. Design is required for 3’-0” and 3’-6” columns because the<br>design criteria used for the table requires double stirrups which is not common practice. | |||

|} | |} | ||

::Columns shall be reinforced using stirrup ties, unless excessive reinforcement is required, in which case spirals shall be used. | |||

::Show spiral details of [[751.9_Bridge_Seismic_Design#751.9.1.2.1.2|Fig. 751.9.1.2.1.2]] on the bridge plans if spirals are used for bridge in non-seismic area. Anchorage of spiral reinforcement shall be provided by 1 ½ extra turns of spiral reinforcement at each end of the spiral unit. | |||

::For Seismic detail requirements for seismic design category, SDC B, C and D, See [[751.9_Bridge_Seismic_Design#751.9.1.2_LRFD_Seismic_Details|EPG 751.9.1.2 LRFD Seismic Details]]. | |||

{| style="margin: 1em auto 1em auto" | |||

|- | |||

[[Image:751.31 | |[[Image:751.31.3.2.3 part elev.jpg|left|375px]]||valign="center"|(1) Location 2 development length.<br/><br/>(2) Check clearance to concrete piles.<br/><br/>See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.8_Development_and_Lap_Splices EPG 751.5.9.2.8] for development and lap splice lengths not given or lengths for scenarios other than those shown. Provide standard hooks if required.<br/><br/>See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.2_Epoxy_Coated_Reinforcement_Requirements EPG 751.5.9.2.2] for epoxy coated reinforcement requirements. | ||

|} | |||

( | |||

( | |||

</ | |||

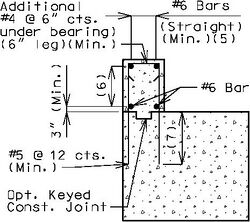

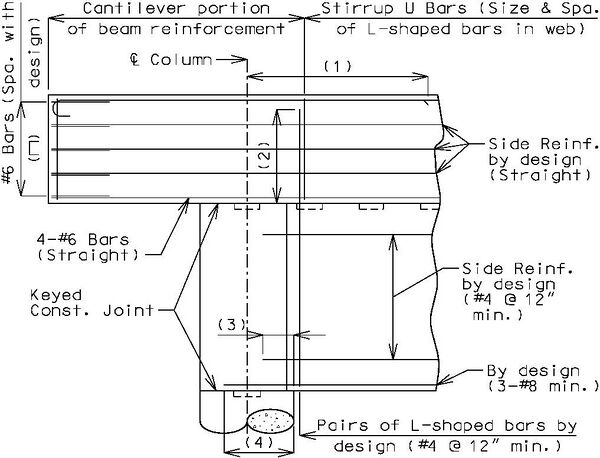

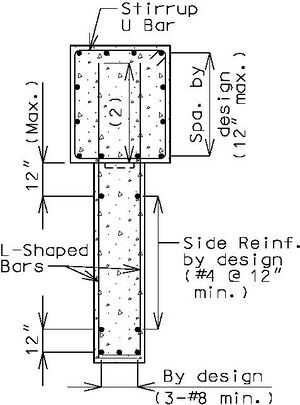

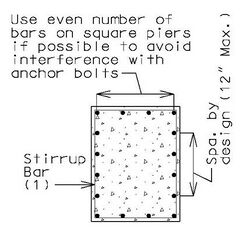

===751.31.3.3 Web Beam=== | ===751.31.3.3 Web Beam=== | ||

{| cellpadding="10" style="text-align:center; margin:auto" | |||

[[ | |- | ||

| colspan="2" | [[image:751.31.3.3_01-2025.jpg|center|600px]] || [[image:751.31.3.3_02-2025.jpg|center|300px]] | |||

|- | |- | ||

| | | colspan="2" | '''PART ELEVATION''' || '''SECTION THRU WEB BEAM''' | ||

|- | |- | ||

| | | [[image:751.31.3.3_03-2025.jpg|center|275px]] || colspan="2" rowspan="2" style="text-align:left; | | ||

(1) L/4 + d, but not less than theoretical cut-off + development length. | |||

: L = span between columns | |||

: d = distance from compression face to centroid of tension steel | |||

(2) Location 2 development length, 4” to 12” spacing, 1½” clear, f'c = 3 ksi: | |||

: 14" (uncoated #4), 17" (epoxy coated #4) | |||

: 18" (uncoated #5), 27" (epoxy coated #5) | |||

(3) Location 1 development length, f'c = 3 ksi: | |||

: 18" (uncoated #4), 22" (epoxy coated #4) | |||

: 23" (uncoated #5), 27" (epoxy coated #5) | |||

(4) Location 2 development length. | |||

(5) Location 2 Class B lap splice. | |||

( | (6) Maximum spacing shall be 6" or 1/5 development length for noncontact lap splice. | ||

See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.8_Development_and_Lap_Splices EPG 751.5.9.2.8] for development and lap splice lengths<br>not given or for lengths for scenarios other than those shown. Provide standard hooks if required. | |||

[ | See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.2_Epoxy_Coated_Reinforcement_Requirements EPG 751.5.9.2.2] for epoxy coated reinforcement requirements. | ||

|- | |||

'''VARIABLE DIAMETER COLUMN | | '''VARIABLE DIAMETER COLUMN'''<BR>(Without Seismic Detailing) | ||

|- | |- | ||

|} | |} | ||

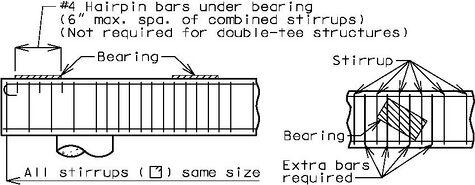

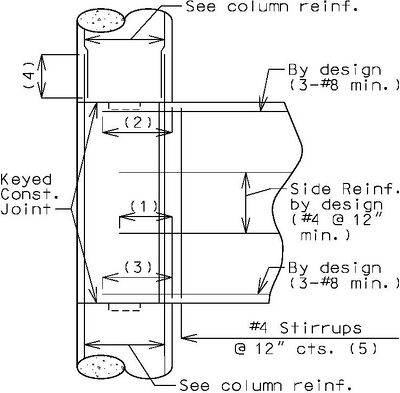

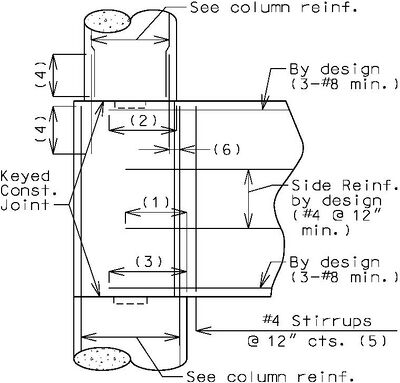

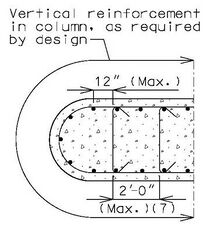

===751.31.3.4 Tie Beam=== | ===751.31.3.4 Tie Beam=== | ||

{| cellpadding="10" style="text-align:center; margin:auto" | |||

{| | |||

|- | |- | ||

|[[ | | colspan="2" | [[image:751.31.3.4_01-2025.jpg|center|400px]] || [[image:751.31.3.4_02-2025.jpg|center|400px]] | ||

|- | |- | ||

| | | colspan="2" | '''CONSTANT COLUMN DIAMETER''' || '''CHANGE IN COLUMN DIAMETER''' | ||

|- | |- | ||

| | | colspan="3" | '''PART ELEVATION AT TIE BEAM AND COLUMN''' | ||

|PART ELEVATION | |||

|- | |- | ||

| | | [[image:751.31.3.4_03-2025.jpg|center|250px]] || colspan="2" rowspan="2" style="text-align:left; | | ||

</ | (1) Location 1 development length, f'c = 3 ksi:<br/> | ||

18" (uncoated #4), 22" (epoxy coated #4)<br> | |||

23" (uncoated #5), 27" (epoxy coated #5)<br> | |||

(2) Location 1 development length.<br> | |||

(3) Location 2 development length.<br> | |||

(4) Location 2 Class B lap splice.<br> | |||

(5) If depth of tie beam exceeds 1/2 column spacing, use pairs of U-shaped bars.<br> | |||

(6) Maximum spacing shall be 6" or 1/5 development length for noncontact lap splice. | |||

See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.8_Development_and_Lap_Splices EPG 751.5.9.2.8] for development and lap splice lengths not given or for lengths<br>for scenarios other than those shown. Provide standard hooks if required. | |||

See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.2_Epoxy_Coated_Reinforcement_Requirements EPG 751.5.9.2.2] for epoxy coated reinforcement requirements. | |||

|- | |- | ||

| | | '''SECTION THRU TIE BEAM''' | ||

|- | |- | ||

|} | |} | ||

{| | ===751.31.3.5 Hammer Head Type=== | ||

{| cellpadding="10" style="text-align:center; margin:auto;" | |||

|- | |||

| style=" vertical-align: bottom;" | [[image:751.31.3.5_01-2025.png|center|325px]] || style=" vertical-align: bottom;" | [[Image:751.31.3.5_02-2025.jpg|center|250px]] | |||

|- | |- | ||

| | | '''PART PLAN''' || '''SECTION A-A''' | ||

|- | |- | ||

| | | style=" vertical-align: bottom;" | [[Image:751.31.3.5_03-2025.jpg|center|350px]] || style=" vertical-align: bottom;" | [[Image:751.31.3.5_04-2025.jpg|center|210px]] | ||

|- | |- | ||

| | | '''PART ELEVATION''' || '''SECTION B-B''' | ||

|- | |- | ||

| | | colspan="2" style="text-align:left;" | | ||

(1) #4 @ 12” cts. (Min.) | |||

: #6 (Dbl.) @ 6” cts. (Max.) | |||

:Minimum spacing of 5” for single stirrups and 6” for double stirrups | |||

:Maximum spacing of 12” | |||

:All stirrups in the beam shall be the same bar size. | |||

:Locate #4 bars (Π) under bearings if required (not required for P/S double-tee girders). | |||

(2) Hook bars if cantilever is less than the required Location 1 development length. | |||

(3) Location 2 development length. | |||

(4) Location 2 Class B lap splice, f'c = 3 ksi: | |||

::34" (uncoated #7), 51" (epoxy coated #7) | |||

(5) Location 1 Class B lap splice, f'c = 3 ksi: | |||

::24" (uncoated #4), 28" (epoxy coated #4) | |||

(6) See EPG 751.2.2.6 and 751.31.2.2 for collision requirements. | |||

(7) See LRFD 5.10.6.3 for tie requirements. | |||

See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.8_Development_and_Lap_Splices EPG 751.5.9.2.8] for development and lap splice lengths not given or for lengths<br>for scenarios other than those shown. Provide standard hooks if required. | |||

See [https://epg.modot.org/index.php/751.5_Structural_Detailing_Guidelines#751.5.9.2.2_Epoxy_Coated_Reinforcement_Requirements EPG 751.5.9.2.2] for epoxy coated reinforcement requirements. | |||

|- | |- | ||

|} | |} | ||

===751.31.3.6 Collision Wall=== | ===751.31.3.6 Collision Wall=== | ||

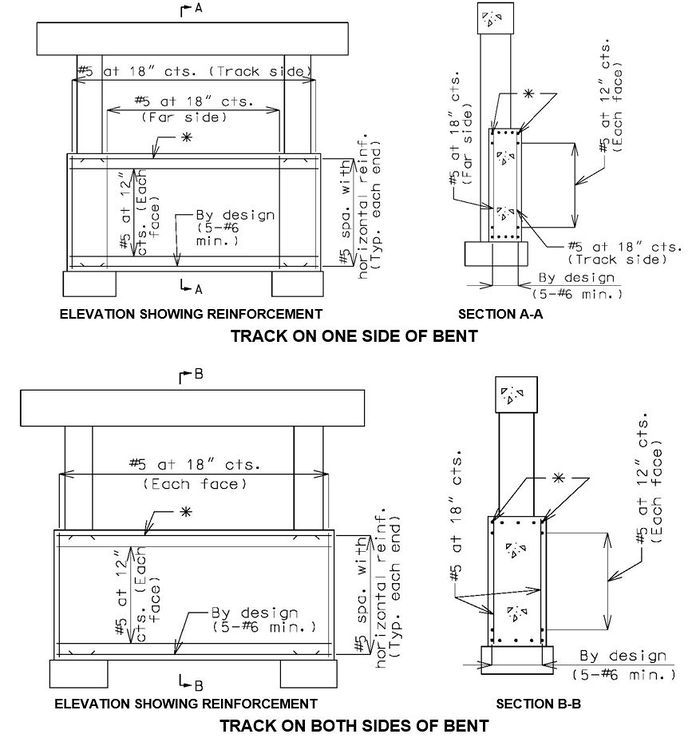

[[Image:751.31.3.5.6.jpg|center|700px]] | |||

See [[751.5 Structural Detailing Guidelines#751.5.9.2.2 Epoxy Coated Reinforcement Requirements|EPG 751.5.9.2.2 Epoxy Coated Reinforcement Requirements]]. | |||

'''*''' Design and use negative moment reinforcement for bents with three or more columns (5-#6 bars minimum). | |||

Reinforcement shown is in addition to column reinforcement. | Reinforcement shown is in addition to column reinforcement. | ||

| Line 1,231: | Line 1,314: | ||

</center> | </center> | ||

'''*''' Optional Construction Joints in bearing beam and tie beam:<br>When the total length of bearing beam exceeds 60'-0", show a keyed construction joint at or near a 1/4 point between columns in the bearing beam and tie beam. Unless required by design or stage construction, this construction joint shall be shown as optional on the plans and may be eliminated at the contractor's discretion. | |||

For column height greater than 35'-0" with no tie beam or collision wall, place the construction joint at approximately the mid-point of the column height. | For column height greater than 35'-0" with no tie beam or collision wall, place the construction joint at approximately the mid-point of the column height. | ||

| Line 1,275: | Line 1,358: | ||

At the contractor’s option, the details shown in Optional Section A-A may be used for Column-Web Beam or Tie Beam at Intermediate Bent No._. No addtional payment will be made for this substitution. | At the contractor’s option, the details shown in Optional Section A-A may be used for Column-Web Beam or Tie Beam at Intermediate Bent No._. No addtional payment will be made for this substitution. | ||

'''*''' Bent with two columns is shown, bents with three or more columns are similar. | |||

===751.31.4.3 Substructure Beam Overhang=== | ===751.31.4.3 Substructure Beam Overhang=== | ||

| Line 1,286: | Line 1,369: | ||

</center> | </center> | ||

'''*''' Slope 1/8" per foot for drainage. | |||

'''**''' When substructure beam extends beyond the slab as shown, slope end of beam to drain water. | |||

===751.31.4.4 Closed Concrete Intermediate Diaphragms=== | |||

See [[751.22 P/S Concrete I Girders#751.22.3.7.4 Bent Details|EPG 751.22.3.7.4 Bent Details]] for intermediate bent details required for closed concrete intermediate diaphragms. | |||

Latest revision as of 14:57, 15 January 2026

751.31.1 General

751.31.1.1 Material Properties

Concrete

Intermediate bents on pile cap footings, spread footings or drilled shafts, or pile cap intermediate bents shall consist of:

- Class B Concrete (Substructure) f'c = 3.0 ksi

- n = 10

- In special cases when stronger concrete is necessary for design, Class B-1 (n = 8) may be considered for intermediate bents (caps, columns, tie beams, web beams, collision walls and/or footings). (Consult with the Structural Project Manager or Structural Liaison Engineer.)

The following equations shall apply to both concrete classes:

Modulus of elasticity,

Where:

- f'c in ksi

- wc = unit weight of nonreinforced concrete = 0.145 kcf

- K1 = correction factor for source of aggregate

- = 1.0 unless determined by physical testing

Modulus of rupture,

- LRFD 5.4.2.6

Where:

- f'c is in ksi

Reinforcing Steel

| Minimum yield strength, | 60.0 ksi |

| Steel modulus of elasticity, | 29000 ksi |

751.31.1.2 Rigid Frame- No Tie or Web Beam

Beam

- A = Length to be determined by the superstructure requirements or the minimum support length required for earthquake criteria, to the

- nearest 1”. Use square ends.

- B = Width to be determined by the minimum of: superstructure requirements, minimum support length required for earthquake criteria, or

- column diameter + 6”. (6” increments) (*)

- C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*)

- * For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D ≤ C ≤ 1.25 D. SGS 8.13.5-1

Columns

- D = Column diameter. 2’-6” minimum. Use 3’-0” minimum when the beam depth exceeds 3’-6”. (6” increments)

- D' = Beam width overhang. Controlled by one of the following:

- 1) Beam width controlled by superstructure requirements

- 3” ≤ D' ≤ 6”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- 3” ≤ D' ≤ 15”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- L = Spacing as determined by design, with no limit. (1” increments)

- G = Overhang as determined by design, with no limits.

- H = Column height as required by grade and footing elevations. Use construction joint in column when H exceeds 35’-0”.

- NOTE: Try to keep columns and beams the same size where possible for economy of construction.

751.31.1.3 Web Beam – Web Supporting Beam

Beam

- A = Length to be determined by the superstructure requirements or the minimum support length required for earthquake criteria, to the

- nearest 1”. Use square ends.

- B = Width to be determined by the minimum of: superstructure requirements, minimum support length required for earthquake criteria, or

- column diameter + 6”. (6” increments) (*)

- C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*)

- * For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D ≤ C ≤ 1.25 D. SGS 8.13.5-1

Columns

- D = Column diameter. 3’-0” minimum. (6” increments)

- D' = Beam width overhang. Controlled by one of the following:

- 1) Beam width controlled by superstructure requirements

- 3” ≤ D' ≤ 6”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- 3” ≤ D' ≤ 15”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- L = Spacing as determined by design, with 35'-0" maximum. (1” increments)

- G = Overhang as determined by design, with no limits.

- H = Column height as required by grade and footing elevations.

Webs

- T = Web thickness. For a 3’-0” column diameter, use T = column diameter. For column diameters ≥ 3’-6”, use T = 0.5 x (column diameter).

- H' = See bottom elevations of web given on the Design Layout.

- NOTE: Try to keep columns and beams the same size where possible for economy of construction.

751.31.1.4 Tie Beam

Beam

- A = Length to be determined by the superstructure requirements or the minimum support length required for earthquake criteria, to the

- nearest 1”. Use square ends.

- B = Width to be determined by the minimum of: superstructure requirements, minimum support length required for earthquake criteria, or

- column diameter + 6”. (6” increments) (*)

- C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*)

- * For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D ≤ C ≤ 1.25 D. SGS 8.13.5-1

Columns

- D = Column diameter. 3’-0” minimum. (6” increments)

- D' = Beam width overhang. Controlled by one of the following:

- 1) Beam width controlled by superstructure requirements

- 3” ≤ D' ≤ 6”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- 3” ≤ D' ≤ 15”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- L = Spacing as determined by design, with 30'-0" maximum. (1” increments)

- G = Overhang as determined by design, with no limits.

- H = Column height as required by grade and footing elevations.

Tie Beam

- T = Tie beam thickness. Minimum T = 0.5 x (column diameter).

- H' = See bottom elevations of tie beam given on the Design Layout. Minimum H' = 2 x T (round to the next foot higher).

- NOTE: Try to keep columns and beams the same size where possible for economy of construction.

751.31.1.5 Tie Beam with Change in Column Diameter

Beam

- A = Length to be determined by the superstructure requirements or the minimum support length required for earthquake criteria, to the

- nearest 1”. Use square ends.

- B = Width to be determined by the minimum of: superstructure requirements, minimum support length required for earthquake criteria, or

- column diameter + 6”. (6” increments) (*)

- C = Depth as required by design. 2’-6” minimum and no less than the column diameter. (3” increments) (*)

- * For SDC A ratio of beam width to beam depth, B/C, shall be ≤ 1.25. For SDC B, C and D, beam depth shall be proportioned to D1 ≤ C ≤ 1.25 D1. SGS 8.13.5-1

Columns

- D1 = Column diameter. 3’-0” minimum. (6” increments)

- D2 = Column diameter, Minimum of (D1 + 6”). Check lap of vertical reinforcement required. See Structural Project Manager.

- D' = Beam width overhang. Controlled by one of the following:

- 1) Beam width controlled by superstructure requirements

- 3” ≤ D' ≤ 6”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- 3” ≤ D' ≤ 15”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- L = Spacing as determined by design, with a 30’-0” maximum with tie beams and no limit without tie beams. (1” increments)

- G = Overhang as determined by design, with no limits.

- H = Column height as required by grade and footing elevations.

- H' = Approximately 0.5 x H. Top of tie beam should be at the same elevation as the top of the larger diameter columns in order to

- minimize the number of construction joints. Top of tie beam may be located on the Design Layout.

Tie Beam

- I = Depth as required by design. Minimum of 3’-0” (3” increments).

- J = Width as required by design. Minimum of (0.5 x D1).

- NOTE: Try to keep columns and beams the same size where possible for economy of construction.

751.31.1.6 Hammer Head Type

Beam

- L = Length to be determined by the superstructure requirements or the minimum support length required for earthquake criteria, to the

- nearest 1”. Use square ends.

- B = Width to be determined by the minimum of: superstructure requirements, minimum support length required for earthquake criteria, or

- column width + 6”. (6” increments) (*)

- C = Depth as required by design. 2’-6” minimum and no less than the column width. (3” increments) (*)

- E = Depth as required by design (see “F”)

- F = Angle as required by design (20° maximum)

- * Ratio of beam width to beam depth, B/C, shall be ≤ 1.25

Columns

- A = Length as required by design, approximately L/3. Use round ends for column.

- D = Width as required by design with a minimum of 2’-6”. (6” increments)

- D' = Beam width overhang. Controlled by one of the following:

- 1) Beam width controlled by superstructure requirements

- 3” ≤ D' ≤ 6”

- 1) Beam width controlled by superstructure requirements

- 2) Beam width controlled by minimum support length required for earthquake criteria.

- 3” ≤ D' ≤ 15”

- 2) Beam width controlled by minimum support length required for earthquake criteria.

NOTE: Try to keep columns and beams the same size where possible for economy of construction.

751.31.1.7 Collision Walls

Structure Over Railroad, Track on One Side of Bent

These details are typical for bents with two or more columns.

Column faces located within 25’-0” of the centerline of track shall meet standards specified in part 2 or Chapter 8 of the AREA Manual (*) except as modified in this article. Certain railroads have specific requirements that also must be complied with. Check the Preliminary Design Layout data.

| (1) | For column spacing over 25’-0”, see Structural Project Managers. | |||||||||

| (2) | 6’-0” minimum for columns from 12’-0” to 25’-0” clear from the centerline of the track; 12’-0” minimum for columns less than 12’-0” clear from the centerline of the track. | |||||||||

| (3) | In general, the collision wall shall extend to at least 4’-0” below the lowest surrounding grade. For spread footing on rock, the collision wall may extend to less than 4’-0” below the lowest surrounding grade with railroad’s concurrence. Top of footing elevations should correspond with bottom of collision wall. | |||||||||

| (4) |

|

|||||||||

* AREA–American Railway Engineering Association

** To facilitate construction, match the back face of collision wall to the face of column.

Structure Over Railroad, Track on Both Sides of Bent

These details are typical for bents with two or more columns.

Column faces located within 25’-0” of the centerline of track shall meet standards specified in part 2 or Chapter 8 of the AREA Manual (*) except as modified in this article. Certain railroads have specific requirements that also must be complied with. Check the Preliminary Design Layout data.

| (1) | For column spacing over 25’-0”, see Structural Project Managers. |

| (2) | 6’-0” minimum for columns from 12’-0” to 25’-0” clear from the centerline of the track; 12’-0” minimum for columns less than 12’-0” clear from the centerline of the track. |

| (3) | In general, the collision wall shall extend to at least 4’-0” below the lowest surrounding grade. For spread footing on rock, the collision wall may extend to less than 4’-0” below the lowest surrounding grade with railroad’s concurrence. Top of footing elevations should correspond with bottom of collision wall. |

* AREA – American Railway Engineering Association

Structure Over Railroad, Track on One Side of Single Column Bent

These details are typical for bents with one column.

Column face located within 25’-0” of the centerline of track shall meet standards specified in part 2 or Chapter 8 of the AREA Manual (*) except as modified in this article. Certain railroads have specific requirements that also must be complied with. Check the Preliminary Design Layout data.

| (1) | 6’-0” minimum for columns from 12’-0” to 25’-0” clear from the centerline of the track; 12’-0” minimum for columns less than 12’-0” clear from the centerline of the track. | ||||||||

| (2) | In general, the collision wall shall extend to at least 4’-0” below the lowest surrounding grade. For spread footing on rock, the collision wall may extend to less than 4’-0” below the lowest surrounding grade with railroad’s concurrence. Top of footing elevations should correspond with bottom of collision wall. | ||||||||

| (3) |

|

* AREA – American Railway Engineering Association

** To facilitate construction, match the back face of collision wall to the face of column.

751.31.2 Design

751.31.2.1 Limit States and Factors

In general, each component shall satisfy the following equation:

Where:

| = Total factored force effect | |

| = Force effect | |

| = Load modifier | |

| = Load factor | |

| = Resistance factor | |

| = Nominal resistance | |

| = Factored resistance |

Limit States

The following limit states shall be considered for bent design:

- STRENGTH – I

- STRENGTH – III

- STRENGTH – IV

- STRENGTH – V

- SERVICE – I

- EXTREME EVENT– II

See LRFD Table 3.4.1-1 and LRFD 3.4.2 for Loads and Load Factors applied at each given limit state. The minimum load factor for TU should be used in the application of temperature forces. Maximum load factor for TU is used in calculating deformations only.

Service dead loads only are required for the beam cap rupture check. See EPG 751.31.2.3.

Resistance factors

- STRENGTH limit states, see LRFD 5.5.4.2

- For all other limit states, Ø = 1.00

751.31.2.2 Loads

Dead Loads

- Loads from stringers, girders, etc. shall be applied as concentrated loads applied at the centerline of bearing. Loads from concrete slab spans shall be applied as uniformly distributed loads.

Live Loads

- Loads from stringers, girders, etc. shall be applied as concentrated loads applied at the centerline of bearing. Dynamic load allowance (impact) should be included for the design of the beam, web supporting beam and top of columns. No dynamic load allowance should be included for bottom of column, tie beams or footing design.

Temperature and Shrinkage

- The effect of temperature and shrinkage from the superstructure shall be considered. Columns and footings shall be analyzed for moments normal to the bent due to the horizontal deflection of the top of the bent due to bearings with high friction coefficients.

- The effect of temperature should be applied at the top of the substructure beam.

Buoyancy

- The effect of buoyancy should be analyzed when specified on the Design Layout or by the Structural Project Manager.

Earth Pressure

- Moments due to the equivalent fluid pressure of earth on columns and webs shall be analyzed where the ground line at the time of construction or potential changes in the ground line indicate.

- Vertical earth loads on tie beams shall be applied as uniform loads for a column of earth equal to 3 times the width of the beam. The weight of earth for footing design shall be that directly above the footing, excluding that occupied by the column.

- The earth load above seal course shall be considered in computing pile loads. Refer to the Pile Footings portion of the guidelines for design and dimensions of pile.

- For horizontal earth loads the following shall be used:

* A factor of 2.0 is applied to the moment to allow for the possibility of the column resisting earth pressure caused by the earth behind the column twice the column width.

Horizontal Earth Load Distributed To Columns

Collision

- Collision walls are to be designed for the unequal horizontal forces from the earth pressure, if the condition exists (See Design Layout). The vertical force on the collision wall is the dead load weight of the wall (*). If a bent has three or more columns, design the steel in the top of the wall for negative moment.

- (*) For footing design, the eccentric dead load moment due to an unsymmetrical collision wall shall be considered.

- Columns shall be designed for collision loads as outlined in EPG 751.2.2.6 Other Loads. Collision shear reinforcement may be referenced from the table in EPG 751.31.3.2 Column or shear reinforcement may be determined by design. When collision design is required, flexural effects from collision forces shall be considered for the Extreme Event II limit state. For the collision loading the column may be assumed to act as fixed-pinned with no lateral movement at the top of the column for out-of-plane bending.

Seal Course

- The weight of the seal course shall not be considered as contributing to the pile loads, except for unusual cases (See Structural Project Manager).

751.31.2.3 General Design Assumptions

* Use only if specified on the Design Layout or as stated by the guidelines in this article.

** For column spacings greater than 30'-0", tie beams are not to be used, unless the web supports the beam.

Elevations for General Intermediate Bent

General

- The following are general design guidelines for the design of intermediate bents.

- Rigid frame design is to be used for designing Intermediate Bents and Piers.

- The joint between the beam and column, and web or tie beam and column, shall be assumed to be integral for all phases of design and must be analyzed for reinforcement requirements as a “Rigid Frame”.

- The joint between the column and footing is assumed to be “fixed”, unless foundation flexibility needs to be considered as required by the Structural Project Manager.

Beam

- Beams shall be designed for vertical loads, including a dynamic load allowance (impact) and components of horizontal forces.

- The gross concrete section, without contribution from reinforcement, shall not rupture under service dead loads. In addition, longitudinal reinforcement shall be distributed to control cracking at the Service-I limit state.

- Fatigue design should not control the size of reinforcement in the beam. LRFD 5.5.3.2 may be ignored for open concrete intermediate bents.

- The minimum reinforcement shall be such that the factored flexural resistance, Mr, is greater than or equal to the lesser of:

- Minimum Tensile Reinforcement

- The amount of tensile reinforcement shall be adequate to develop a factored flexural resistance, Mr, at least equal to the lesser of either:

- 1) Mcr = cracking moment LRFD Eq. 5.7.3.3.2-1

- 2) 1.33 times the factored moment required by the applicable strength load combinations specified in LRFD Table 3.4.1-1.

- Additional reinforcement is required in the sides of the beam. The following table gives adequate steel for both temperature and shrinkage (LRFD 5.10.8), and skin reinforcement (LRFD 5.7.3.4).

| Beam Height, H | Number – Bar Size |

| H ≤ 36” | 4 - #6 |

| 36” < H < 54” | 5 - #6 |

| 54” ≤ H ≤ 72” | 6 - #6 |

| H > 72” | By Design (LRFD 5.7.3.4) |

Tie Beam

- Use a tie beam when specified on the Design Layout or by the Structural Project Manager or when the unsupported height exceeds 30 feet, except as noted

- Do not use tie beams on grade separations.

- Do not use tie beams when column spacing exceeds 30 feet. For this situation, use a minimum column diameter of in lieu of a tie beam.

- Additional side reinforcement shall be designed for temperature and shrinkage (LRFD 5.10.8), and skin reinforcement (LRFD 5.7.3.4).

Unsupported Height

- The unsupported height is the distance from the bottom of the beam to the top of the footing. If the distance from the ground line to the top of footing is 10 feet, the unsupported height and the fixed point may be measured from the bottom of the beam to the ground line plus 1/2 the distance from the ground line to the top of the footing.

- For single column intermediate bents, the column shall be considered “fixed” at the top of footing for all conditions.

Columns

- Use round columns for all bridges, unless otherwise specified on the Design Layout.

- Tops of column shall be designed for vertical loads with consideration of dynamic load allowance (impact) and maximum components of horizontal forces. Bottom of columns do not require impact forces to be included.

- The minimum area of reinforcement, As, shall be taken as the greater of:

- LRFD 5.7.4.2

- Where:

- = gross area of section. (in.²)

- For typical columns with f’c = 3 ksi, the 1% of column gross area will control. MoDOT prefers to follow ACI 10.9 and recognize LRFD 5.7.4.2 when it would control. (The minimum area of reinforcement based on LRFD is significantly less than ACI for f’c = 3 ksi).

Minimum Allowable Bars for Column Reinforcement Design Column Diameter Vertical Reinforcement

(Assuming 1% of Column Gross Area)2’-6” 9 - #8 3’-0” 13 - #8 3’-6” 18 - #8 4’-0” 23 - #8 4’-6” 29 - #8 5’-0” 29 - #9 5’-6” 35 - #9 6’-0” 41 - #9

- The maximum reinforcement shall be limited by the following requirements:

SGS 8.8.1

- Spacing limitations given in this article.

Maximum Allowable Number of Bars for the Given Bar Sizes Column Diameter Maximum Number of Bars #8 #9 #10 #11 2’-6” 18 18 17 15 3’-0” 22 22 21 18 3’-6” 26 26 26 22 4’-0” 30 30 30 25 4’-6” 34 34 34 29 5’-0” 38 38 32 5’-6” 43 42 36 6’-0” 47 46 40

- Above table is applicable for standard dowel bar arrangments, see EPG 751.31.3.2.

- A preliminary economic analysis should be conducted before determining the number of columns and column spacing. For the analysis, assume the rates for Concrete, Class 1 and Class 2 Excavation, and Piles. Omit reinforcing bars in the cost analysis.

Column Spacing

- Columns, with the exception of web supporting beam type bents, shall be spaced, to the nearest 1”, in which balanced positive and negative beam moments are produced. A positive beam moment up to 10% larger than the negative beam moment is acceptable. Strength Limit State Load Combinations shall be used to determine column spacing.

- To estimate centerline-to-centerline spacing for a two column bent, use 72% of the distance from centerline of outside girder to centerline of outside girder. For a three column bent, use 44% of the centerline-to-centerline distance of outside girders.

Footings

- Footings shall be designed for vertical loads and maximum normal and parallel components of the horizontal forces.

Elevations for Intermediate Bent with Web Beam

Web Supporting Beam

- In analysis, web beams shall be modeled as plate elements. If the ability to model a web beam as a plate element is unavailable, the following may be considered:

Simplified Model

- The web itself is made up of several tie beams (typically 4 tie beams). The moment of inertia of an individual tie beam is equal to the moment of inertia of the web in the bent’s out-of-plane direction divided by the total number of tie beams.

- Any column segment which is connected to the web is treated as a prismatic member with moment of inertia in the bent’s out-of-plane direction equal to the actual column moment of inertia in that direction, and with the moment of inertia in the bent’s in-plane direction equal to the total moment of inertia of web in the bent’s in-plane direction divided by the total number of columns plus the moment of inertia of the column itself. The equivalent column diameter is assumed to be .

Section Views for an Intermediate Bent with Web Beam

In the above example, the moment of inertia of the column in the bent’s in-plane and out-of-plane directions can be calculated as:

| Out-of-plane-> | |

| In-plane-> |

The equivalent column diameter is then assumed to be .

Thus, the column can be treated as a telescoping column and then the moment magnifier or P-δ slenderness effects can be calculated.

Since the web is made up of 4 tie beams, the moment of inertia of the tie beams in the bent’s out-of-plane direction is:

Reinforcement

- Additional side reinforcement shall be designed for temperature and shrinkage (LRFD 5.10.8), and skin reinforcement (LRFD 5.7.3.4).

Column Spacing