|

|

| (225 intermediate revisions by the same user not shown) |

| Line 1: |

Line 1: |

| ='''REVISION REQUEST 3980'''= | | ='''REVISION REQUEST 4036'''= |

| | |

| ==620.2.16 Stop and Yield Lines (MUTCD Section 3B.16)==

| |

| '''Guidance.''' Stop lines should be used to indicate the point behind which vehicles are required to stop, in compliance with a traffic control signal.

| |

|

| |

| '''Option.''' Stop lines may be used to indicate the point behind which vehicles are required to stop in compliance with a STOP (R1-1) sign, a Stop Here For Pedestrians (R1-5b or R1-5c) sign, or some other traffic control device that requires vehicles to stop, except YIELD signs that are not associated with passive grade crossings.

| |

| | |

| Yield lines may be used to indicate the point behind which vehicles are required to yield in compliance with a YIELD (R1-2) sign or a Yield Here to Pedestrians (R1-5 or R1-5a) sign.

| |

| | |

| '''Standard.''' Except as provided in MUTCD Section 8B.28, stop lines shall not be used at locations where drivers are required to yield in compliance with a YIELD (R1-2) sign or a Yield Here To Pedestrians (R1-5 or R1-5a) sign or at locations on uncontrolled approaches where drivers are required by State law to yield to pedestrians.

| |

| | |

| Yield lines shall not be used at locations where drivers are required to stop in compliance with a STOP (R1-1) sign, a Stop Here For Pedestrians (R1-5b or R1-5c) sign, a traffic control signal, or some other traffic control device.

| |

| | |

| Stop lines shall consist of solid white lines extending across approach lanes to indicate the point at which the stop is intended or required.

| |

| | |

| Stop lines shall be used in advance of railroad crossings to indicate the appropriate location to stop.

| |

| | |

| When any crosswalk is installed where a permanent traffic control device is provided, such as a STOP sign or traffic signal, a stop line shall be installed in advance of the crosswalk.

| |

| | |

| Stop lines shall be 24 in. wide and shall extend across all lanes affected by the traffic control device.

| |

| | |

| Yield lines shall consist of a row of solid white isosceles triangles pointing toward approaching vehicles extending across approach lanes to indicate the point at which the yield is intended or required. The spacing of triangles in a yield line shall be consistent for that marking.

| |

| | |

| '''Guidance.''' Yield lines should be 24in. wide by 36in. long with 12 in. spacing between triangles, as shown on [https://www.modot.org/media/16896 Standard Plan 620.00]. Yield line triangles are paid for per each individual triangle. A yield line, for a lane that is 10 ft. or narrower, will consist of 4 individual triangles spaced accordingly.

| |

| | |

| Yield lines may be considered for those locations where a free right turn lane is developed but there is not an acceleration lane on the intersecting road. Yield lines may also be considered at on ramps with tapered acceleration lanes as shown in [[#Fig. 620.2.5.3|Fig. 620.2.5.3, Examples of Dotted Lined and Channelizing Line Applications for Entrance Ramp Markings]].

| |

| | |

| Yield lines may also be used where engineering judgment indicates a need.

| |

| | |

| '''Guidance.''' If used, stop and yield lines should be placed a minimum of 4 ft. in advance of the nearest crosswalk line at controlled intersections, except for yield lines at roundabouts as provided for in [https://epg.modot.org/index.php/620.3_Roundabout_Markings_(MUTCD_Chapter_3C)#620.3.4_Yield_Lines_for_Roundabouts_.28MUTCD_Section_3C.4.29 EPG 620.3.4 Yield Lines for Roundabouts] and at midblock crosswalks. In the absence of a marked crosswalk, the stop line or yield line should be placed at the desired stopping or yielding point, but should not be placed more than 30 ft. nor less than 4 ft. from the nearest edge of the intersecting traveled way. Stop lines should be placed to allow sufficient sight distance to all other approaches to an intersection.

| |

| | |

| When a stop line is used in conjunction with the STOP sign it should be placed adjacent to, or in line with, the STOP sign.

| |

| | |

| When a yield line is used in conjunction with the YIELD sign it should be placed adjacent to, or in line with, the YIELD sign.

| |

| | |

| Stop lines at midblock signalized locations should be placed at least 40 ft. in advance of the nearest signal indication.

| |

| | |

| If yield or stop lines are used at a crosswalk that crosses an uncontrolled multilane approach, the yield lines or stop lines should be placed 20 to 50 ft. in advance of the nearest crosswalk line, and parking should be prohibited in the area between the yield or stop line and the crosswalk (see Figure 620.2.17.1 Examples of Yield Lines at Unsignalized Midblock Crosswalks).

| |

| | |

| '''Standard.''' If yield (stop) lines are used at a crosswalk that crosses an uncontrolled multi-lane approach, [https://epg.modot.org/index.php/903.5_Regulatory_Signs#903.5.6_YIELD_HERE_TO_PEDESTRIANS_Signs_.28R1-5.2C_R1-5a.29_.28MUTCD_Section_2B.11.29 Yield Here To (Stop Here For) Pedestrians (R1-5 series)] signs (see [[#620.2.11 Raised Pavement Markers (MUTCD Section 3B.11)|EPG 620.2.11 Raised Pavement Markers]]) shall be used.

| |

| | |

| '''Guidance.''' Yield (stop) lines and Yield Here To (Stop Here For) Pedestrians signs should not be used in advance of crosswalks that cross an approach to or departure from a roundabout.

| |

| | |

| '''Support.''' Drivers yielding or stopping too close to crosswalks that cross uncontrolled multi-lane approaches place pedestrians at risk by blocking other drivers’ views of pedestrians and by blocking pedestrians’ view of vehicles approaching in the other lanes.

| |

| | |

| '''Option.''' Stop and yield lines may be staggered longitudinally on a lane-by-lane basis. Refer to [[#Fig. 620.2.8.2|"D" of Fig. 620.2.8.2]].

| |

| | |

| '''Support.''' Staggered stop lines and staggered yield lines can improve the driver's view of pedestrians, provide better sight distance for turning vehicles and increase the turning radius for left-turning vehicles.

| |

| | |

| [[620.2_Pavement_and_Curb_Markings_(MUTCD_Chapter_3B)#620.2.25_Stop_and_Yield_Lines_at_Highway-Rail_Grade_Crossings_(MUTCD_section_8B.28)|EPG 620.2.25 Stop and Yield Lines at Highway-Rail Grade Crossings]] contains information regarding the use of stop lines and yield lines at grade crossings.

| |

| | |

| | |

| ----

| |

| | |

| | |

| ==620.2.24 Pavement Markings for Highway-Rail Grade Crossings (MUTCD Section 8B.27)==

| |

| '''Standard.''' All grade crossing pavement markings shall be retroreflectorized white. All other markings shall be in accordance with [[:Category:620 Pavement Marking|EPG 620 Pavement Marking]].

| |

| | |

| On paved roadways, pavement markings in advance of a grade crossing shall consist of an X, the letters RR, a no-passing zone marking (on two-lane, two-way highways with centerline markings in compliance with [[#620.2.1 Yellow Centerline Pavement Markings and Warrants (MUTCD Section 3B.01)|EPG 620.2.1]]), and certain transverse lines as shown in Fig. 620.2.25.1, Example of Placement of Warning Signs and Pavement Markings at Grade Crossings and Fig. 620.2.25.2, Grade Crossing Pavement Markings.

| |

| | |

| Identical markings shall be placed in each approach lane on all paved approaches to grade crossings where signals or automatic gates are located, and at all other grade crossings where the posted or statutory highway speed is 40 mph or greater.

| |

| | |

| Pavement markings shall not be required at grade crossings where the posted or statutory highway speed is less than 40 mph if an engineering study indicates that other installed devices provide suitable warning and control. Pavement markings shall not be required at grade crossings in urban areas if an engineering study indicates that other installed devices provide suitable warning and control.

| |

| | |

| '''Guidance.''' When pavement markings are used, a portion of the X symbol should be directly opposite the Grade Crossing Advance Warning sign. The X symbol and letters should be elongated to allow for the low angle at which they will be viewed.

| |

| | |

| '''Option.''' When justified by engineering judgment, supplemental pavement marking symbol(s) may be placed between the Grade Crossing Advance Warning sign and the grade crossing.

| |

| | |

| | |

| ----

| |

| | |

| | |

| ==620.2.25 Stop and Yield Lines at Highway-Rail Grade Crossings (MUTCD section 8B.28)==

| |

| '''Standard.''' On paved roadways at grade crossings that are equipped with active control devices such as flashing-light signals, gates, or traffic control signals, a stop line (see [[#620.2.16 Stop and Yield Lines (MUTCD Section 3B.16)|EPG 620.2.16]]) shall be installed to indicate the point behind which highway vehicles are or might be required to stop.

| |

| | |

| '''Guidance.''' On paved roadway approaches to passive grade crossings where a STOP sign is installed in conjunction with the Crossbuck sign, a stop line should be installed to indicate the point behind which highway vehicles are required to stop or as near to that point as practical.

| |

| | |

| If a stop line is used, it should be a transverse line at a right angle to the traveled way and should be placed approximately 8 ft. in advance of the gate (if present), but no closer than 15 ft. in advance of the nearest rail.

| |

| | |

| '''Option.''' On paved roadway approaches to passive grade crossings where a YIELD sign is installed in conjunction with the Crossbuck sign, a yield line (see [[#620.2.16 Stop and Yield Lines (MUTCD Section 3B.16)|EPG 620.2.16]]) or a stop line may be installed to indicate the point behind which highway vehicles are required to yield or stop or as near to that point as practical.

| |

| | |

| '''Guidance.''' If a yield line is used, it should be a transverse line at a right angle to the traveled way and should be placed no closer than 15 ft. in advance of the nearest rail (see Fig. 620.2.25.1, Example of Placement of Warning Signs and Pavement Markings at Grade Crossings).

| |

| | |

| [[Image:620.2.25.1 8B6 2020.jpg|thumb|center|780px|<center>'''Fig. 620.2.25.1, Example of Placement of Warning Signs and Pavement Markings at Grade Crossings (MUTCD 8B-6)'''</center>]]

| |

| | |

| [[Image:620.2.28.2 8B7.jpg|thumb|center|780px|<center>'''Fig. 620.2.25.2, Grade Crossing Pavement Markings (MUTCD 8B-7)'''</center><center>Note: Refer to Fig. 620.2.25.1 for placement.</center>]]

| |

| | |

| | |

| ='''REVISION REQUEST 3981'''=

| |

| | |

| | |

| ==620.2.18 Crosswalk Markings (MUTCD Section 3B.18)==

| |

| '''Support.''' Crosswalk markings provide guidance for pedestrians who are crossing roadways by defining and delineating paths on approaches to and within signalized intersections, and on approaches to other intersections where traffic stops.

| |

| | |

| In conjunction with signs and other measures, crosswalk markings help to alert road users of a designated pedestrian crossing point across roadways at locations that are not controlled by traffic control signals or STOP or YIELD signs.

| |

| | |

| At non-intersection locations, crosswalk markings legally establish the crosswalk.

| |

| | |

| '''Standard.''' When crosswalk lines are used, they shall consist of solid white lines that mark the crosswalk.

| |

| | |

| There are two styles of crosswalk markings: transverse and longitudinal (also known as continental). In most applications, the longitudinal markings are preferred and should be used to provide greater visibility, especially at midblock and uncontrolled crossings.

| |

| | |

| When used, longitudinal crosswalk markings shall be 24 inches wide and at least 6 feet in length, except that they shall be at least 8 feet in length at non-intersection crossings where the posted speed limit is 40 mph or greater.

| |

| | |

| If used, transverse crosswalk lines shall be no less than 6 inches wide and at least 6 feet apart

| |

| | |

| '''Guidance.''' Crosswalk lines, if used on both sides of the crosswalk, should extend across the full width of pavement or to the edge of the intersecting crosswalk to discourage diagonal walking between crosswalks.

| |

| | |

| At locations controlled by traffic control signals or on approaches controlled by STOP or YIELD signs, crosswalk lines should be installed where engineering judgment indicates they are needed to direct pedestrians to the proper crossing path(s).

| |

| | |

| Crosswalk lines should not be used indiscriminately. An engineering study should be performed before a marked crosswalk installed at a location away from a traffic control signal or STOP or YIELD signs. The engineering study should consider the number of lanes, the presence of a median, the distance from adjacent signalized intersections, the pedestrian volumes and delays, the average annual daily traffic (AADT), the posted or statutory speed limit or 85<sup>th</sup>-percentile speed, the geometry of the location, the possible consolidation of multiple crossing points, the availability of street lighting and other appropriate factors.

| |

| | |

| New marked crosswalks alone, without other measures designed to reduce traffic speeds, shorten crossing distances, enhance driver awareness of the crossing, and/or provide active warning of pedestrian presence, should not be installed across uncontrolled roadways where the speed limit exceeds 40 mph and either:

| |

| | |

| :A. The roadway has four or more lanes of travel without a raised median or pedestrian refuge island and an ADT of 12,000 vehicles per day or greater; or

| |

| | |

| :B. The roadway has four or more lanes of travel with a raised median or pedestrian refuge island and an ADT of 15,000 vehicles per day or greater.

| |

| | |

| '''Support.''' Chapter 4F of the MUTCD contains information on Pedestrian Hybrid Beacons. Section 4L.03 contains information regarding Warning Beacons to provide active warning of a pedestrian's presence. Section 4N.02 contains information regarding In-Roadway Warning Lights at crosswalks. Chapter 7D contains information regarding school crossing supervision.

| |

|

| |

| '''Guidance.''' Because non-intersection pedestrian crossings are generally unexpected by the road user, warning signs (see [[903.6 Warning Signs#903.6.41 Non-Vehicular Warning Signs (W11-2, W11-3, W11-4, W11-7, W11-32, W11-33, W16-9P) (MUTCD Section 2C.50)|Non-vehicular Sign (W11-2, W11-7)]]) should be installed and adequate visibility should be provided by parking prohibitions.

| |

| | |

| If used, the high-visibility longitudinal pedestrian crosswalk marking should consist of longitudinal bars 24 in. wide and spaced uniformly, centering one bar in each lane, and across each lane line, centerline, and edgeline ([https://www.modot.org/media/16896 see Standard Plan 620.00]).

| |

| | |

| When longitudinal bars are used to mark a crosswalk, the transverse crosswalk lines should be omitted. The marking design should avoid the wheel paths.

| |

| | |

| Existing 30 in. crosswalk bars should be replaced with 24 in. bars when the roadway is resurfaced.

| |

| | |

| '''Support.''' [[#620.2.16 Stop and Yield Lines (MUTCD Section 3B.16)|EPG 620.2.16]] contains information regarding placement of stop line markings near crosswalk markings.

| |

| | |

| '''Option.''' Where permanent traffic control devices are not provided, speeds are greater than 35 mph or the crosswalk is located in rural locations where they are unexpected, the width of the crosswalk line may be increased up to 24 inches.

| |

| | |

| Crosswalks may be located mid-block if this placement offers greater safety to the pedestrian than the normal placement at an intersection. In these cases, the longitudinal bar pedestrian crosswalk marking should be used for greater emphasis and visibility. This type of marking may also be used at locations where substantial numbers of pedestrians cross without any other traffic control device, at locations where physical conditions are such that added visibility of the crosswalk is desired, or at places where a pedestrian crosswalk might not be expected.

| |

| | |

| '''Standard.''' All school crosswalks authorized by an agreement between the Commission and the school and/or city shall be marked. Crosswalks for schools shall be maintained in a manner that will provide a clearly visible marking at all times.

| |

| | |

| All school crosswalks shall be marked using both the advance school crosswalk and the school crosswalk sign, refer to [[903.18 Signing for School Areas#903.18.8 School Sign (S1-1) and Plaques (S4-3p, W16-9P and W16-7P) (MUTCD Section 7B.08)|EPG 903.18.8 School Sign (S1-1) and Plaques]].

| |

| | |

| '''Option.''' When school crosswalks are located mid-block, the longitudinal bar pedestrian crosswalk marking should be used for greater emphasis and visibility.

| |

| | |

| '''Guidance.''' Crosswalk markings should be located so that the curb ramps are within the extension of the crosswalk markings.

| |

| | |

| '''Support.''' Detectable warning surfaces mark boundaries between pedestrian and vehicular ways where there is no raised curb. Detectable warning surfaces are required by 49 CFR, Part 37 and by the Americans with Disabilities Act (ADA) where curb ramps are constructed at the junction of sidewalks and the roadway, for marked and unmarked crosswalks. Detectable warning surfaces contrast visually with adjacent walking surfaces, either light-on-dark, or dark-on-light. The [https://www.access-board.gov/guidelines-and-standards/buildings-and-sites/about-the-ada-standards/background/adaag ''Americans with Disabilities Act Accessibility Guidelines for Buildings and Facilities (ADAAG)''] (see MUTCD Section 1A.11) contains specifications for design and placement of detectable warning surfaces.

| |

| | |

| [[Image:620.2.18 3B19.jpg|thumb|center|780px|<center>'''Fig. 620.2.18, Examples of Crosswalk Markings (MUTCD Figs. 3B-19 and -20)'''</center>]]

| |

| | |

| | |

| ='''REVISION REQUEST 3997'''=

| |

| | |

| | |

| ===616.6.2.2 Flags and Advance Warning Rail System on Signs===

| |

| <div style="width:100%; overflow:auto;">

| |

| <div style="width:70%; float:left;">

| |

| Signs may be enhanced with flags, but only during daytime hours. Flags should not be used on signs at night, except that it is allowable to leave flags on signs when the work carries over from day to night.

| |

| | |

| '''Standard.''' When standard orange flags are used in conjunction with signs, they shall not block the sign face.

| |

| </div>

| |

| <div style="width:30%; float:left;"">

| |

| {|

| |

| | [[image:616.6.2.2_01.png|right|210px|thumb|<center>'''Example of flag assembly on a sign'''</center>]] || [[image:616.2.9 flag assembly.jpg|right|210px|thumb|<center>'''Example of flag assembly, viewed from behind the temporary sign'''</center>]]

| |

| |}

| |

| </div>

| |

| </div>

| |

| | |

| | |

| | |

| | |

| | |

| ==616.23.1 Definitions==

| |

| {|style="border:10px solid #ff9933;" width="775px" align="center"

| |

| |-

| |

| |[[image:616.23.1.jpg|center|750px]]

| |

| |}

| |

| | |

| '''Activity Area''' - Area of a temporary traffic control zone where work activity takes place. It is comprised of the work, traffic and buffer spaces.

| |

| | |

| '''Advance Warning Area''' - Area of a temporary traffic control zone where traffic is informed of the upcoming temporary traffic control zone.

| |

| | |

| '''Area Lighting''' - Lighting used at night to guide traffic through the temporary traffic control zone.

| |

| | |

| '''Annual Average Daily Traffic (AADT) ''' - Volume of vehicular traffic using a section of highway on an average day.

| |

| | |

| '''Barricade''' - Temporary traffic control device consisting of one or three appropriately marked rails used to close, restrict or delineate all or a portion of the right of way.

| |

| | |

| '''Barrier-Mounted Sign''' - Sign mounted on a temporary or permanent traffic barrier.

| |

| | |

| '''Buffer Space''' - Area within the activity area free of equipment, material, and personnel used to provide lateral and/or longitudinal separation of traffic from the workspace or an unsafe condition.

| |

| | |

| '''Channelizer''' - Temporary traffic control device used to guide traffic or delineate an unsafe condition.

| |

| [[image:616.23.1 daytime.jpg|right|200px]]

| |

| '''Crash Cushion''' - Temporary traffic control device used at fixed object and other desirable locations to reduce crash severity.

| |

| | |

| '''Daytime/Daylight''' - Period of time from one-half hour after sunrise to one-half hour before sunset.

| |

| | |

| '''Detour''' - Temporary rerouting of traffic onto an existing facility to avoid a temporary traffic control zone.

| |

| | |

| '''Diversion''' - Rerouting of traffic around an activity area using a temporary roadway or portions of an existing parallel roadway.

| |

| | |

| '''Divided Highway''' - Highway with physical separation of traffic in opposite directions.

| |

| | |

| '''Downstream Taper''' - Visual cue to traffic that access back into a closed lane is available.

| |

| | |

| '''Emergency Operation''' - Work involving the initial response to and repair/removal of safety concerns including Response Priority 1 items.

| |

| | |

| '''Fine Sign''' - Regulatory sign indicating the applicability of additional fines in a temporary traffic control zone.

| |

| | |

| '''Flag System''' – A flag bracket and two flag assemblies. Flags are used to enhance signs.

| |

| | |

| '''Flagger''' - Person who provides temporary traffic control by assigning right of way.

| |

| | |

| '''Flashing Arrow Panel''' - Temporary traffic control device with a pattern of elements capable of flashing displays (i.e. left/right arrow, double arrow, caution mode) used to provide warning or guidance to traffic.

| |

| [[image:616.23.1 fleet warning light.jpg|right|200px|thumb|<center>'''Fleet Lighting'''</center>]]

| |

| '''Fleet Lighting''' - Rotating or flashing lights used to increase the visibility of work-related vehicles and equipment in the temporary traffic control zone.

| |

| | |

| '''Guide Sign''' - Sign showing route designations, destinations, directions, distances, services, points of interest or other geographical, recreational or cultural information.

| |

| | |

| '''High Speed''' - Posted speed of 50 mph and above.

| |

| | |

| '''Highway''' - Any facility constructed for the purposes of moving traffic.

| |

| | |

| '''Incident Area''' - Temporary traffic control zone where temporary traffic control devices are deployed in response to a traffic incident, natural disaster, special event, etc.

| |

| | |

| '''Intermediate-Term Stationary Operation''' - Daytime work occupying a location from more than one daylight period up to 3 days or nighttime work occupying a location more than 60 minutes.

| |

| | |

| '''Lane Taper''' - Temporary traffic control measure used to merge or shift traffic either left or right out of a closed lane.

| |

| | |

| '''Lateral Buffer Space''' - Obstacle-free area adjacent to the workspace or an unsafe condition that provides room for recovery of an errant vehicle.

| |

| | |

| '''Lighting Device''' - Temporary traffic control device illuminating a portion of the roadway or supplementing other traffic control devices.

| |

| | |

| '''Long-Term Stationary Operation''' - Work occupying a location longer than 3 days.

| |

| | |

| '''Longitudinal Buffer Space''' - Obstacle-free area in advance of the work space or an unsafe condition that provides room for recovery of an errant vehicle.

| |

| | |

| '''Low Speed''' - Posted speed of 45 mph and below.

| |

| | |

| '''Low Volume''' - 500 or less AADT. The rule of thumb is to count the number of vehicles passing a single reference point over a five-minute period. If not more than three vehicles pass the reference point in that period, then the road can be considered low volume for the purpose of installing work zone traffic control.

| |

| | |

| '''May''' - Indicates a permitted practice and carries no requirement or recommendation.

| |

| | |

| '''Mobile Operation''' - Work on the roadway that moves intermittently or continuously.

| |

| | |

| '''Motorized Traffic''' - Movement of vehicles and equipment on the roadway.

| |

| | |

| '''Multilane Highway''' - Highway with two or more driving lanes in the same direction of travel.

| |

| | |

| '''Nighttime''' - Period of time from one-half hour before sunset to one-half hour after sunrise.

| |

| [[image:616.23.1 non-motorize 2013.jpg|right|300px]]

| |

| '''Non-Motorized Traffic''' - Movement of pedestrians, bicycles, horse-drawn vehicles, etc. on roadway or within the right of way.

| |

| | |

| '''One-Lane, Two-Way Taper''' - Temporary traffic control measure used to channelize traffic through an activity area occupying one lane of an undivided, two-lane roadway.

| |

| | |

| '''[[:Category:620 Pavement Marking|Pavement Marking]]''' - Lines, markers, words and symbols affixed to the pavement surface to channelize and guide traffic.

| |

| | |

| '''Pilot Car''' - Vehicle used to guide a queue of vehicles through the temporary traffic control zone.

| |

| | |

| '''[[616.6 Temporary Traffic Control Zone Devices (MUTCD 6F)#616.6.60 Portable Changeable Message Signs (MUTCD 6F.60)|

| |

| Portable Changeable Message Signs (CMS)]]''' - Temporary traffic control device capable of displaying a variety of messages to traffic.

| |

| | |

| '''Portable Sign''' - Sign mounted on temporary supports (e.g. self-driving post, easels, foldup stands, barricades, etc.).

| |

| | |

| '''Post-Mounted Sign''' - Sign mounted on a non-portable post (e.g. perforated square steel tube, u-channel, wood, etc.).

| |

| | |

| '''Protective Vehicle''' - Vehicle used to protect workers or work equipment from errant vehicles (e.g. pick up, dump truck, loader, etc.).

| |

| | |

| [[903.5 Regulatory Signs|'''Regulatory Sign''']] - Sign giving notice of traffic laws or regulations.

| |

| | |

| '''Roadway''' - Portion of highway, including shoulders, intended for use by motorized traffic.

| |

| | |

| [[941.3 Urban/Rural Designations|'''Rural''']] - Area generally characterized by lower volumes, higher speeds and fewer turning conflicts and conflicts with pedestrians. Includes unincorporated areas designated by community boards.

| |

| | |

| [[616.18 Construction Inspection Guidelines for Sec 616# Safety Requirements (for Sec 616.3)| '''Safety Apparel''']] - [http://sharepoint/safety/csp/SitePages/PPE.aspx Personal protective equipment] worn by a worker to improve visibility (e.g. vests, hats, etc.).

| |

| | |

| '''Shall''' - Indicates a required, mandatory, or specifically prohibitive practice. Shall statements are not to be modified or compromised based on engineering judgement or engineering study.

| |

| | |

| '''Short Duration Operation''' - Daytime or nighttime work occupying a location up to 60 minutes.

| |

| | |

| '''Short-Term Stationary Operation''' - Daytime work occupying a location more than 60 minutes, but less than 12 hours.

| |

| | |

| '''Should''' - Indicates a recommended, but not mandatory, practice in typical situations. Deviations are allowed if engineering judgement or engineering study indicates the deviation to be appropriate.

| |

| | |

| '''Shoulder Taper''' - Temporary traffic control measure used to close the shoulder.

| |

| | |

| '''Sign''' - Traffic control device conveying a static message to traffic through words or symbols.

| |

| | |

| '''Speed Limit''' - Maximum speed applicable to a section of highway as established by law.

| |

| | |

| '''Stop Bar''' - Solid white pavement marking extending across an approach lane to indicate the point where traffic is to stop.

| |

| | |

| '''Supplemental Warning Methods''' - Temporary traffic control enhancements used to increase the effectiveness of select temporary traffic control devices or the awareness of the entire temporary traffic control zone.

| |

| | |

| '''Taper''' - Series of channelizers and/or pavement markings used to move traffic into the intended path.

| |

| | |

| '''Temporary Traffic Barrier''' - Temporary traffic control device used to create a physical separation between traffic and the workspace, an unsafe condition, or non-motorized traffic.

| |

| | |

| '''Temporary Traffic Control Device''' - Item used to regulate, warn or guide traffic through a temporary traffic control zone.

| |

| | |

| '''Temporary Traffic Control Plan''' - Describes temporary traffic control measures to be used for moving traffic through a temporary traffic control zone.

| |

| | |

| '''Temporary Traffic Control Signal''' - Temporary traffic control device used to assign right of way through automatic means.

| |

| | |

| '''Temporary Traffic Control Zone''' - Section of highway where traffic conditions are changed due to a work zone or an incident area through the use of temporary traffic control devices, [[616.16 Law Enforcement Services|law enforcement]] or other authorized officials. It extends from the first warning sign or rotating/strobe lights on a vehicle to the last temporary traffic control device.

| |

| | |

| '''Termination Area''' - Area of a temporary traffic control zone returning traffic to the normal path.

| |

| | |

| '''Traffic''' - Highway user.

| |

| | |

| '''Traffic Space''' - Area within the activity area in which traffic is routed through the activity area.

| |

| | |

| '''Transition Area''' - Area of a temporary traffic control zone where traffic is redirected out of the normal path and into the traffic space.

| |

| | |

| '''Traveled Way''' - Portion of roadway intended for the movement of motorized traffic.

| |

| | |

| [[:Category:612 Impact Attenuators#612.1.1 Truck- and Trailer-Mounted Attenuators|'''Truck-Mounted Attenuator (TMA) ''']] - Device designed to attach to the rear of protective vehicles to absorb the impact of an errant vehicle or inattentive driver.

| |

| | |

| '''Undivided Highway''' - Highway with no physical separation of traffic in opposite directions.

| |

| | |

| '''Urban''' - Area within the limits of incorporated towns and cities where the posted speed is 60 mph or less.

| |

| | |

| '''Vehicle-Mounted Sign''' - Sign mounted on a protective vehicle used in short duration and mobile operations or on a pilot car.

| |

| | |

| '''Warning Sign''' - Sign giving notice of a situation or condition that might not be readily apparent.

| |

| | |

| '''Work Duration''' - Length of time an operation occupies a location.

| |

| | |

| '''Work Lighting''' - Lighting used at night to perform activities within the workspace.

| |

| | |

| '''Work Location''' - Portion of right of way in which work is performed.

| |

| | |

| '''Workspace''' - Area within the activity area closed to traffic and set aside for workers, equipment, materials and a protective vehicle, if one is used upstream. Channelizers usually delineate workspaces.

| |

| | |

| '''Work Vehicle''' - Any vehicle by which work is performed.

| |

| | |

| '''Work Zone''' - Temporary traffic control zone where temporary traffic control devices are deployed for construction, maintenance or utility- related work activities.

| |

| | |

| '''Work Zone Length''' - Distance from last sign in the advance warning area to the last temporary traffic control device in the same direction or the last sign in the advance warning area in the opposing direction, whichever is longest.

| |

| | |

| Refer to [[902.18 Glossary|EPG 902.18 Glossary]] for definitions of interchange, intersection and right of way.

| |

| | |

| | |

| | |

| | |

| | |

| =====616.23.2.5.1.1 [[616.6_Temporary_Traffic_Control_Zone_Devices_(MUTCD_6F)#616.6.2.2_Flags|Flags]]=====

| |

| Guidance is located in [[616.6 Temporary Traffic Control Zone Devices (MUTCD 6F)#616.6.2.2 Flags|EPG 616.6.2.2 Flags]].

| |

|

| |

|

| | ==106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity== |

|

| |

|

| | '''1. Chemical Analysis''' |

|

| |

|

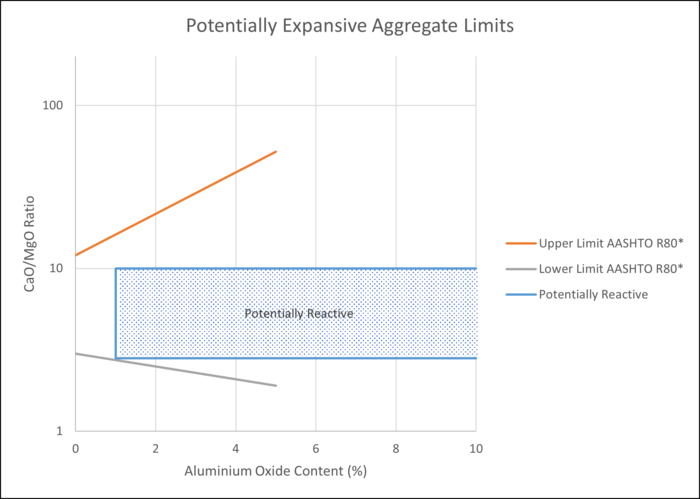

| | The chemical analysis of aggregate reactivity is an objective, quantifiable and repeatable test. MoDOT will perform the chemical analysis per the process identified in ASTM C 25 for determining the aggregate composition. The analysis determines the calcium oxide (CaO), magnesium oxide (MgO), and aluminum oxide (Al<sub>2</sub>O<sub>3</sub>) content of the aggregate. The chemical compositions are then plotted on a chart with the CaO/MgO ratio on the y-axis and Al<sub>2</sub>O<sub>3</sub> percentage on the x-axis per Fig. 2 in AASHTO R 80. Aggregates are considered potentially reactive if the Al<sub>2</sub>O<sub>3</sub> content is greater than or equal to 1.0% and the CaO/MgO ratio is either greater than or equal to 3.0 or less than or equal to 10.0 (see chart below). See flow charts in 106.3.2.93.2 for approval hierarchy. CaO, MgO and Al2O3 shall be analyzed by instrumental analysis only. |

|

| |

|

| | [[File:106.3.2.93.1_Potentially_Expansive_Aggregate_Limits-01.png|700px]] |

|

| |

|

| =====616.23.2.5.1.3 [[616.6 Temporary Traffic Control Zone Devices (MUTCD 6F)#616.6.2.3 Sign Dimension|Sign Design]]=====

| | <nowiki>*</nowiki> MoDOT’s upper and lower limits of potentially reactive (shaded area) aggregates. |

| Details, descriptions, and ordering information for signs used for temporary traffic control are specified in [[616.6 Temporary Traffic Control Zone Devices (MUTCD 6F)|EPG 616.6 Temporary Traffic Control Zone Devices]].

| |

|

| |

|

| These signs may have a rigid or flexible substrate. Additional information is located in [[616.6 Temporary Traffic Control Zone Devices (MUTCD 6F)#616.6.2.3 Sign Dimension|EPG 616.6.2.3 Sign Dimension]] and [[616.6 Temporary Traffic Control Zone Devices (MUTCD 6F)#616.6.3 Sign Placement (MUTCD 6F.03)|EPG 616.6.3 Sign Placement]].

| | '''2. Petrographic Examination''' |

|

| |

|

| Flags may be used to supplement these signs provided they do not block the sign face. Additional information located in [[616.6 Temporary Traffic Control Zone Devices (MUTCD 6F)#616.6.2.2 Flags|EPG 616.6.2.2 Flags]].

| | A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum: |

|

| |

|

| | * Quarry name and ledge name; all ledges if used in combination |

| | * MoDOT District quarry resides |

| | * Date sample was obtained; date petrographic analysis was completed |

| | * Name of petrographer and company/organization affiliated |

| | * Lithographic descriptions with photographs of the sample(s) examined |

| | * Microphotographs of aggregate indicating carbonate particles and/or other reactive materials |

| | * Results of the examination |

| | * All conclusions related to the examination |

|

| |

|

| | | See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer. |

| | |

| <BIG><BIG><BIG><BIG>UPLOAD NEW IMAGES</BIG></BIG></BIG></BIG>

| |

| | | |

| | '''3. Concrete Prism/Beam Test''' |

|

| |

|

| ===616.19.2.2.2 Sign and Flag Quality===

| | ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy. |

| <gallery widths=250px heights=250px position="right" style="text-align:center; font-weight:bold; margin-left:0em" caption="Acceptable Examples">

| |

| File:616.19.2.2.2_01.jpg|(1)

| |

| File:616.19.2.2.2_02.jpg|(2)

| |

| File:616.19.2.2.2_03.jpg|(3)

| |

| </gallery>

| |

| The signs in '''Pictures 1, 2 and 3''' are considered in good quality. Supplemental devices such as flags and/or a cone may be placed next to a sign. Picture 2 is an example of the proper placement of a FLAGGER (WO20-7) sign, with the optional flags, in advance of the hill versus after the hill. In urban areas with barrier walls and narrow shoulders, a truncated sign may be used as shown in Picture 3.

| |

|

| |

|

| ::Note: TTCDs may be highly visible during the day but may not be at night due to inadequate retroreflectivity. MoDOT and Contractor representatives should drive through the work zone at night to check nighttime visibility.

| |

|

| |

|

| <gallery widths=250px heights=250px position="right" style="text-align:center; font-weight:bold; margin-left:0em" caption="Unacceptable Examples">

| |

| File:616.19.2.2.2_04.jpg|(4)

| |

| File:616.19.2.2.2_05.jpg|(5)

| |

| File:616.19.2.2.2_06.jpg|(6)

| |

| File:616.19.2.2.2_07.jpg|(7)

| |

| File:616.19.2.2.2_08.jpg|(8)

| |

| File:616.19.2.2.2_09.jpg|(9)

| |

| </gallery>

| |

| '''Pictures 4-7''' are in unacceptable condition. Dirty or damaged signs should be cleaned, repaired, or replaced before being installed. When cleaning, follow manufacturer’s recommendations, so the daytime and nighttime visibility of the sign is not adversely impacted. The MEN WORKING sign ('''Picture 8''') should be replaced with worker symbol sign or WORKERS sign (WO-21-1 or 1a) to meet current standards. '''Picture 9''' shows unacceptable flags, if used, deteriorated flags should be replaced.

| |

|

| |

|

| <gallery widths=250px heights=250px position="right" style="text-align:center; font-weight:bold; margin-left:0em" caption="Unacceptable Examples">

| | ='''REVISION REQUEST 4143'''= |

| File:616.19.2.2.2_10.jpg|(10)

| | ==751.36.5 Design Procedure== |

| File:616.19.2.2.2_11.jpg|(11)

| | *Structural Analysis |

| File:616.19.2.2.2_12.jpg|(12)

| | *Geotechnical Analysis |

| File:616.19.2.2.2_13.jpg|(13)

| | *Drivability Analysis |

| </gallery>

| |

| '''Pictures 10 - 13''' are examples of unacceptable nighttime visibility. Proper storing, transporting, and covering signs is crucial to minimizing deficiencies.

| |

|

| |

|

| | ===751.36.5.1 Design Procedure Outline=== |

| | *Determine foundation load effects from the superstructure and substructure for Service, Strength and Extreme Event Limit States. |

| | *If applicable, determine scour depths, liquefaction information and pile design unbraced length information. |

| | *Determine if downdrag loadings should be considered. |

| | *Select preliminary pile size and pile layout. |

| | *Perform a Static Pile Soil Interaction Analysis. Estimate Pile Length and pile capacity. |

| | *Based on pile type and material, determine Resistance Factors for Structural Strength (<math>\, \phi_c</math> and <math>\, \phi_f</math>). |

| | *Determine: |

| | **Maximum axial load effects at toe of a single pile |

| | **Maximum combined axial & flexural load effects of a single pile |

| | **Maximum shear load effect for a single pile |

| | **Uplift pile reactions |

| | *Determine Nominal and Factored Structural Resistance for single pile |

| | **Determine Structural Axial Compression Resistance |

| | **Determine Structural Flexural Resistance |

| | **Determine Structural Combined Axial & Flexural Resistance |

| | **Determine Structural Shear Resistance |

| | *Determine method for pile driving acceptance criteria |

| | *Determine Resistance Factor for Geotechnical Resistance (<math>\, \phi_{stat}</math>) and Driving Resistance (<math>\, \phi_{dyn}</math>). |

| | *If other than end bearing pile on rock or shale, determine Nominal Axial Geotechnical Resistance for pile. |

| | *Determine Factored Axial Geotechnical Resistance for single pile. |

| | *Determine Nominal pullout resistance if pile uplift reactions exist. |

| | *Check for pile group effects. |

| | *Resistance of Pile Groups in Compression |

| | *Check Drivability of all pile (bearing and friction pile) using the Wave equation analysis. |

| | *Review Static Pile Soil Interaction Analysis and pile lengths for friction pile. |

| | *Show proper Pile Data on Plan Sheets ([https://epg.modot.org/index.php/751.50_Standard_Detailing_Notes#E2._Foundation_Data_Table Foundation Data Table]). |

|

| |

|

| ='''REVISION REQUEST 4008'''= | | ===751.36.5.2 Structural Resistance Factor (ϕ<sub>c</sub> and ϕ<sub>f</sub>) for Strength Limit State=== |

| | | {| style="margin: 1em auto 1em auto" |

| | |

| ===403.1.5 Mixture Production Specification Limits (Sec 403.5)=== | |

| Intentional deviations from the JMF will not be permitted, except under the conditions set forth in Sec 403.11. The plant shall be operated in such a manner that the mix is produced as shown on the JMF. The specification tolerances are developed in an attempt to keep the mix as consistent as possible and to allow for some variation during production. However, these tolerances are not production limits. For example, if the target binder content is 5.0%, the binder content of the mix can range from 4.7% to 5.3% when the tolerances are applied. The contractor will not be allowed to produce the mix at 4.7% to save money.

| |

| | |

| Operating out of the specifications may reduce the contractor's pay and/or the pavement service life. When QC tests, either random or informational, are out of specification tolerances, the contractor should adjust the production to bring the mix back in. When QA tests are out of specification tolerances, the contractor should be notified immediately. The contractor is responsible for deciding when adjustments are made to control the mix. Some test properties may be allowed to deviate beyond specification limits occasionally, provided that adjustments are made and the following tests show that production is back within limits.

| |

| | |

| Production may be required to cease if the random QC or QA test results are either out of specifications far enough to indicate that the mix may be subject to failure or beyond the specification removal limits. Production should cease until verification that the problem has been corrected. An order record should be written, on the same day or the next day if paving occurs at night, describing the deficiency and the location and amount of mix affected. The contractor may elect to continue production in order to run more tests. If so, the order record should state that any mix produced after the order record was issued is at the contractor’s risk. Final disposition of the mix can then be made based on all tests and observations and may consist of acceptance at a reduced price or removal and replacement of unacceptable material.

| |

| | |

| Both QC and QA will use the following procedures to determine volumetrics of the mix and compliance with Standard Specification Sections 403.5.3 through 403.5.5. These procedures are discussed in greater detail in the Levels 1 and 2 Bituminous Training.

| |

| | |

| In situations where a retained sample must be tested, the following procedure should be used to reheat the sample. Heat the sample in an oven until the mix is workable. Take the mix out of the sample container (box, bucket, etc.) and spread it in a large pan or several smaller pans. Using this procedure, the mix will reach the molding temperature much quicker than it would if it were left in a mass in the sample container. Also, less aging of the mix occurs since the mix is in the oven for a shorter period of time. Once the mix has reached an acceptable temperature, quarter split the mix. The split portions to be used for making gyratory specimens shall then be heated to the compaction temperature. The entire suite of tests must be performed on a retained sample.

| |

| | |

| '''Gradation''' (Sec 403.5.1)

| |

| | |

| See Sieve Analysis in [[460.3 Plant Inspection|Plant Inspection]]. The gradation of the mix

| |

| is not a pay factor item. However, it does have a significant influence on the volumetrics of the mix. Samples may be taken from the hot bins at a batch plant or from the combined cold feed at a drum plant. It is acceptable to determine gradation from the binder ignition sample according to AASHTO Standard Test Method T 308. Contractors should be allowed the option provided that the chosen method is spelled out in the Quality Control Plan. Gradations of extracted samples would be satisfactory as well. QC is required to sample the aggregate and perform a sieve analysis twice per lot. QA is required to independently sample the aggregate and perform a sieve analysis once per lot. These testing requirements are minimums and should be increased as necessary. Minor deviations outside the tolerances given in Standard Specification Sections 403.5.1.1 or 403.5.1.2, whichever is applicable, may be allowed if the test results indicate that the binder content, volumetrics, and density of the mix are satisfactory. If the test results are unsatisfactory, adjustments of the JMF, in accordance with Standard Specification Section 403.11, are necessary.

| |

| | |

| '''Stone Matrix Asphalt Tolerances''' (Sec 403.5.1.1)

| |

| | |

| The tolerances from the JMF for SMA mixes are given in Standard Specification Section 403.5.1.1.

| |

| | |

| '''Mixture Tolerance''' (Sec 403.5.1.2)

| |

| | |

| During production, the combined aggregate gradation must be within the following limits:

| |

| | |

| {| class="wikitable" style="margin: 1em auto 1em auto" | |

| |-

| |

| ! Colspan="4" style="background:#BEBEBE" | Percent Passing by Weight

| |

| |- | | |- |

| !style="background:#BEBEBE"|Sieve Size||style="background:#BEBEBE"|SP250||style="background:#BEBEBE"|SP190||style="background:#BEBEBE"|SP125

| | |align="right" width="850"|'''LRFD 6.5.4.2''' |

| |-

| |

| | 1 ½ in. || 100 || -- || --

| |

| |-

| |

| |1 in.|| 90-100 || 100 || --

| |

| |-

| |

| |¾ in.|| 92 Max. || 90-100 || 100

| |

| |-

| |

| |½ in.|| -- || 92 Max. || 90-100

| |

| |-

| |

| |3/8 in.|| -- || -- || 92 Max.

| |

| |-

| |

| |#4||--||--||--

| |

| |-

| |

| |#8||17-47||21-51||26-60

| |

| |-

| |

| |#16||--||--||--

| |

| |-

| |

| |#30||--||--||--

| |

| |-

| |

| |#50||--||--||--

| |

| |-

| |

| |#100||--||--||--

| |

| |-

| |

| |#200||1-7||2-8||2-10

| |

| |} | | |} |

|

| |

|

| '''Density''' (Sec 403.5.2) | | '''For integral end bent simple pile design,''' use Φ<sub>c</sub> = 0.35 for CIP steel pipe piles and HP piles. See [[751.35 Concrete Pile Cap Integral End Bents#751.35.2.4.2 Pile Design|Figure 751.35.2.4.2]]. |

| | |

| See also Density in [[460.3 Plant Inspection|Plant Inspection]] Density Samples in [[460.6 Paving Operations|Paving Operations]]. One sample per sublot will be taken for QC testing. QA will randomly test one of the samples from each lot to verify that a favorable comparison is obtained. These testing requirements are minimums and should be increased as necessary. SMA mixes shall have a minimum density of 94.0% with no upper limit. All other mixes shall have a density of 94.0 ±2.0%. | |

| | |

| '''Shoulder Density''' (Sec 403.5.2.1) and '''Integral Shoulder''' (Sec 403.5.2.2)

| |

| | |

| If the shoulders and the traveled way are placed in the same pass (integrally), the cores will be taken on the traveled way. No cores will be taken on the shoulder. For example, if the paving width is 16’ with a 12’ travel lane and a 4’ shoulder, the shoulder will not be subject to density testing.

| |

|

| |

|

| '''Asphalt Content''' (Sec 403.5.3) | | '''For pile at all locations where integral end bent simple pile design is not applicable,''' use the following: |

|

| |

|

| QC is required to sample and test the mix for the binder content once per sublot and QA is

| | :The structural resistance factor for axial resistance in compression is dependent upon the expected driving conditions. When the pile is subject to damage due to severe driving conditions where use of pile point reinforcement is necessary: |

| required to independently sample and test the mix once per lot. These testing requirements are | | ::Steel Shells (Pipe): <math> \phi_c </math>= 0.60 |

| minimums and should be increased as necessary. During production, the binder content of the

| | ::HP Piles: <math> \phi_c </math>= 0.50 |

| mix, as determined by sampling and testing, shall be within ±0.3% of the target listed on the JMF.

| | :When the pile is subject to good driving conditions where use of pile point reinforcement is not necessary: |

| | ::Steel Shells (Pipe) Piles: <math> \phi_c </math>= 0.70 |

| | ::HP Piles: <math> \phi_c </math>= 0.60 |

| | :For HP piles, pile point reinforcement is always required when HP piles are anticipated to be driven to rock and proofed. Driving HP piles to rock is considered severe driving conditions for determination of structural resistance factor. However, driving HP piles through overburden not likely to impede driving to deep rock or preboring to rock for setting piles are two situations that could be considered as less than severe. Further, driving any steel pile through soil without rubble, boulders, cobbles or very dense gravel could be considered good driving conditions for determination of structural resistance factor. Consult the Structural Project Manager or Structural Liaison Engineer. |

| | :The structural resistance factor for combined axial and flexural resistance of undamaged piles: |

| | ::Axial resistance factor for HP Piles: <math> \phi_c </math>= 0.70 |

| | ::Axial resistance for Steel Shells (Pipe): <math> \phi_c </math>= 0.80 |

| | ::Flexural resistance factor for HP Piles or Steel Shells: <math> \phi_f </math>= 1.00 |

| | :For Extreme Event Limit States, see LRFD 10.5.5.3. |

| | <div id="751.36.5.3 Geotechnical Resistance"></div> |

|

| |

|

| <div id="Voids in the Mineral Aggregate (VMA) (Sec 403.5.4)"></div>

| | ===751.36.5.3 Geotechnical Resistance Factor (ϕ<sub>stat</sub>) and Driving Resistance Factor (ϕ<sub>dyn</sub>)=== |

| '''Voids in the Mineral Aggregate (VMA)''' (Sec 403.5.4)

| | The factors for Geotechnical Resistance (<math> \phi_{stat}</math>) and Driving Resistance (<math> \phi_{dyn}</math>) may be different because of the reliability of the different methods used to determine the nominal bearing resistance. Caution should be used if the difference in factors for Geotechnical Resistance and Driving Resistance are great as it can lead to issues with pile overruns. Also see [[#751.36.5.9 Estimate Pile Length and Check Pile Capacity|EPG 751.36.5.9]]. |

|

| |

|

| QC is required to sample and test the mix for the VMA once per sublot and QA is required

| | '''Geotechnical Resistance Factor, ϕ<sub>stat</sub>:''' |

| to independently sample and test the mix once per lot. These testing requirements are minimums

| |

| and should be increased as necessary. The VMA of the mix shall be within –0.5% and +2.0% of

| |

| the minimum required for the corresponding mix type (see Standard Specification Section 403.4.6.2).

| |

|

| |

|

| The following table gives the ranges for each mix type: | | The Geotechnical Resistance factor is based on the static method used by the designer in determining the nominal bearing resistance. Unlike the Driving Resistance factor the Geotechnical Resistance factor can vary with the soil layers. If Geotechnical Resistance factors are not provided by the Geotechnical Engineer, the static method and resistance factors shall be selected from the table below. The values provided in LRFD Table 10.5.5.2.3-1 are only applicable if the end of drive criteria is based off the total pile penetration which is not recommended. For Extreme Event Limit States see LRFD 10.5.5.3. |

|

| |

|

| {| border="1" class="wikitable" style="margin: 1em auto 1em auto" | | {|border="1" style="text-align:center; width: 750px" cellpadding="5" align="center" cellspacing="0" |

| | |+ '''Table - Static Analysis Resistance Factors used for Pile Length Estimates''' |

| | ! Pile Type !! Soil Type !! Static Analysis Method !! Side Friction<sup>1</sup><br><math> \phi_{stat}</math> !! End Bearing<br><math> \phi_{stat}</math> |

| |- | | |- |

| !style="background:#BEBEBE"|Mix Type||style="background:#BEBEBE"|VMA Limits (percent)

| | | rowspan="4" | '''CIP Piles - Steel Pipe Shells''' || Clay || Alpha - Tomlinson || <math> \phi_{dyn}</math><sup>2</sup> || <math> \phi_{dyn}</math><sup>2</sup> |

| |- | | |- |

| |align="center"| SP250 ||align="center"| 11.5-14.0 | | | rowspan="3" | Sand || Nordlund<sup>3</sup> || 0.45 - Gates<br>0.45 - WEAP<br>0.55 - PDA || 0.45 - Gates<br>0.45 - WEAP<br>0.55 - PDA |

| |- | | |- |

| |align="center"|SP190||align="center"| 12.5-15.0 | | | LCPC<sup>4</sup> || 0.70 || 0.45 |

| |- | | |- |

| |align="center"|SP125||align="center"| 13.5-16.0 | | | Schmertmann<sup>5</sup> || 0.50 || 0.50 |

| |-

| |

| |align="center"|SP095||align="center"|14.5-17.0

| |

| |- | |

| |align="center"|SP048||align="center"| 15.5-18.0 | |

| |-

| |

| |align="center"|SMA||align="center"| 16.5-19.0

| |

| |} | | |} |

|

| |

|

| '''Air Voids (V<sub>a</sub>)''' (Sec 403.5.5)

| | {|border="0" style="text-align:left; width: 750px" align="center" cellspacing="0" |

| | |

| QC is required to sample and test the mix for the air voids once per sublot and QA is

| |

| required to independently sample and test the mix once per lot. These testing requirements are

| |

| minimums and should be increased as necessary. The V<sub>a</sub> for all mixes shall be 4.0 ±1.0%.

| |

| | |

| <div id="Tensile Strength Ratio (TSR) (Sec 403.5.6)"></div>

| |

| '''Tensile Strength Ratio (TSR)''' (Sec 403.5.6)

| |

| | |

| The TSR is used to evaluate the impact that water saturation and freeze-thaw cycles have on the strength of an asphalt mix. It can also be used to predict the susceptibility of the mix to

| |

| stripping.

| |

| | |

| During production, loose mix samples will be taken and quartered as described in [[#403.1.5 Mixture Production Specification Limits (Sec 403.5)|Mixture Production Specification Limits]]. TSR samples need to be taken from random locations. However, they should be taken whenever it is convenient to production, such as during a big gap between QC volumetric tests. By specification, sampling locations are from the roadway behind the paver, however, should the MoDOT inspector deem this an unsafe or impractical location, the sample may be taken from the plant. The QA sample(s) should be taken from the same point as the QC sample(s). If QC takes their sample from the plant, QA should take their sample from the plant also. This does not mean that QA should be taking their samples at the same time as QC. Two opposite quarters will be retained and the remaining two quarters will be mixed together and tested in accordance with AASHTO T283.

| |

| | |

| QC should obtain enough mix to retain a sample. QC will sample and test each mix at a minimum of once every 10,000 tons, or fraction thereof. QA will independently sample and test each mix at a minimum of once every 50,000 tons. The TSR sampling requirements are best described with an example. Suppose that 112,960 tons of SP190 are to be placed on a project. By specification, QC is required to take twelve samples and QA is required to take three samples. There are two possible scenarios for sampling this mix. QC may take eleven samples representing 10,000 tons each and a twelfth sample that represents the remaining 2,960 tons. Or QC may take ten samples that represent 10,000 tons each and two samples that represent the remaining 12,960 tons (6,480 tons each). Either scenario is acceptable. Likewise, QA may take two samples representing 50,000 tons each and a third sample that represents the remaining 12,960 tons. Or QA may take one sample that represents 50,000 tons and two samples that represent the remaining 62,960 tons (31,480 tons each). The contract quantity may be used to approximate sample 1 locations.

| |

| | |

| MoDOT should collect at least 250 pounds of asphalt mix for the QA sample, 125 pounds is retained by the RE and the other 125 pounds is sent to the Central Laboratory (typically) in 4 – 13” x 13” x 4.5” boxes for QA testing. Each box must be labeled on one side with the AASHTOWARE Project (AWP) ID, Mix Type, VMA Limits (percent) number and the mix number. An AWP record must be created for each sample, which must include all required information, the mix number, sample date, and the represented tonnage. The represented tonnage is explained in the example in the preceding paragraph. It is recommended to include the lot and sublot to the AWP record as additional information.

| |

| | |

| Additional information that may be included in the AWP record is the G<sub>mm</sub> from the sublot that the sample was taken in (QC or QA) and the specimen weight that QC has been using. The specimen weight may be different from that shown on the JMF because of bin percent changes, etc. This information is helpful because it results in less trial-and-error for the Central Laboratory.

| |

| | |

| In the laboratory, a minimum of six specimens are compacted to a height of approximately 95 mm. The air voids of the specimens are calculated. For all mixes other than SMA, the air voids must be within 7.0 ±0.5%. For SMA mixes, the air voids must be within 6.0 ±0.5%. Half of these specimens are saturated, frozen, and thawed. These are the conditioned specimens. The degree of saturation of the conditioned specimens is also calculated. The remaining specimens are unconditioned. Then, the indirect-tensile strength of all of the specimens is determined. Therefore, the TSR is the ratio of the average tensile strength of the conditioned specimens to the average tensile strength of the unconditioned specimens.

| |

| <div id="A favorable comparison will be obtained"></div>

| |

| | |

| A favorable comparison will be obtained if the QC and QA test results are within 10% of each other. The contractor’s pay will be adjusted in accordance with Standard Specification Section 403.23.5 based on the QC test results. For example, if the QC TSR is 95% and the QA TSR is 93%, a favorable comparison has been obtained and the contractor will receive a 3% bonus. However, if the difference is greater than 10%, the field office should be consulted. The field office will evaluate the air voids and saturation levels. The raw data should be collected from QC and forwarded to the field office for comparison in order to determine whether it will be necessary to proceed with 3<sup>rd</sup> party testing. QC and QA retained samples should be kept for an extended period of time so that they may be used during dispute resolution, if necessary.

| |

| | |

| The QC data should be reported in AWP (Test - SAA402AB). Contractors may report their own test results using the TSR Contractor Reporting Excel to Oracle Spreadsheet available on the MoDOT [http://www.modot.org/business/contractor_resources/Quality_Management/ Quality Management] website. Furthermore, this information is quarried regularly and, provided that a favorable comparison is reached, used to signal the appropriate time for disposal of the remaining TSR sample at the Central Lab.

| |

|

| |

| <div id="Aggregate Properties"></div>

| |

| | |

| '''Aggregate Properties''' (Sec 403.5.7)

| |

| | |

| The aggregate consensus tests (Fine and Coarse Aggregate Angularity, Clay Content, and Thin, Elongated Particles) are performed on the blended aggregate. The aggregate will be sampled from the combined cold feed whether dealing with a drum-mix plant or a batch plant. Aggregate samples should be taken in accordance with AASHTO R 90.

| |

| | |

| For each mix that is produced, QC shall sample the aggregate and perform the consensus tests once every 10,000 tons with a minimum of one per mix per project. QA will independently sample the aggregate and perform the consensus tests once per project. QA should also test a minimum of one QC retained sample per project. For large projects, enough QC retained samples should be tested to ensure that QC is performing the tests correctly. These testing requirements are minimums and should be increased as necessary. During production, the following tolerances are applied (see Standard Specification Sections 403.2.1 through 403.2.5 and [[media:403 Figure Consensus Testing.pdf|Consensus Testing]]).

| |

| | |

| {| border="1" class="wikitable" style="margin: 1em auto 1em auto" | |

| |-

| |

| !style="background:#BEBEBE"|Property||style="background:#BEBEBE"|Tolerance

| |

| |- | | |- |

| | FAA || 2% below the minimum | | | <sup>1</sup> For mixed soil profiles the lowest applicable resistance factor for clay or sand may be used to simplify the analysis. |

| |- | | |- |

| | CAA || 5% below the minimum | | | <sup>2</sup> ϕ<sub>dyn</sub> = see following section. |

| |- | | |- |

| | Clay Content|| 5% below the minimum

| | | <sup>3</sup>The Nordlund method is recommended for sand layers in mixed soil profiles where CPT data is not available. |

| |-

| |

| |Thin, Elongated Particles|| 2% above the maximum

| |

| |}

| |

| | |

| '''Moisture Content''' (Sec 403.5.9)

| |

| | |

| See also Asphalt Binder Content in [[460.3 Plant Inspection|Plant Inspection]].

| |

| | |

| '''Contamination''' (Sec 403.5.10)

| |

| | |

| See Material Acceptance in [[460.6 Paving Operations|Paving Operations]].

| |

| | |

| | |

| | |

| | |

| ===403.1.17 Quality Control (Sec 403.17)===

| |

| | |

| Under QC/QA, the contractor performs quality control (QC) testing. The contractor is paid based on the results of the randomly located QC tests for Superpave mixes. Beyond random QC tests, quality control by the contractor consists of constantly monitoring materials integrity, mix production and laydown operations to ensure overall acceptability.

| |

| | |

| <div id="Asphalt Test Results (Sec 403.17.1.1)">

| |

| '''Asphalt Test Results''' (Sec 403.17.1.1)

| |

| | |

| A copy of all random QC test results shall be furnished to the QA inspector no later than the beginning of the day after testing has been performed. All raw data and printouts must be included with the testing records. Raw data consists of all weights, measurements, etc. used to arrive at the final test results. Printouts include the gyration/height data from the gyratory compactor and the asphalt content ticket from the binder ignition oven or nuclear gauge. The QC testing records must be made available to the QA inspector at all times.

| |

| | |

| It is QC’s responsibility to take appropriate action if unsatisfactory mix is being produced. This may include making adjustments to the plant to bring the mix back into specification, sampling the mix from the roadway and performing informational testing, removing mix from the roadway, etc.

| |

| | |

| '''Informational Tests'''

| |

| | |

| An informational test is a test that QC may perform between random testing to determine whether or not the mix is within specifications. Informational testing is not required and may be performed at any time and at any frequency. Generally, informational testing will be performed early in the production period. The informational test may not be completed in full. For example, QC may only compact the gyratory specimens. Doing so will yield specimen heights and the contractor may or may not make production adjustments based on these heights. Informational test samples must be clearly marked as such if they are tested and stored in the field laboratory.

| |

| | |

| QC is not required to provide the QA inspector with informational test results, since informational tests cannot be used in the QC process to determine pay factors, The timing of random number locations being given to the contractor, typically 100 to 150 tons in advance, is meant to protect the integrity of the statistical sampling process. QA always has the option of taking its own informational samples.

| |

| | |

| Informational test data may be used to determine asphalt removal limits if it is adequately documented. It should not be used for QLA under any circumstances. To be considered adequately documented the following criteria should be met:

| |

| | |

| *The gyratory pucks should be clearly identified and labeled and made available for verification.

| |

| *The gyratory printout should be available.

| |

| *The printout from the AC test should be available.

| |

| | |

| If the preceding conditions are met and the gyratory specimens are used to troubleshoot the placement, the specimens can then be weighed and bulked to determine the volumetric properties. Data from informational tests is approximate. Its only legitimate use to the QA inspector is to help determine the point on the roadway where the mixture transitioned either above or below the removal limits. We don’t want to remove acceptable mix or leave unacceptable mix in place.

| |

| | |

| '''Removal Limits'''

| |

| | |

| As an example of how informational tests may be used to designate removal limits of failing QC samples, the following situation is provided. The random QC sample shown in the diagram below fell late in sublot ‘a’ and test results indicated that voids were below the limits for removal. By specification sublot ‘a’ should be removed. By the time the test results were available and corrective action was taken, the contractor had crossed into sublot ‘b’. Assuming that mix properties were acceptable at the beginning of sublot ‘a’, the actual limits of unacceptable material are indicated by the dashed lines.

| |

| | |

| Adhering strictly to the specification, it is likely that acceptable material early in sublot ‘a’ will be removed, and it is also likely that unacceptable material early in sublot ‘b’ will be left in place. An adequately documented informational test may be used to zero in on the transitions out of, and back into, acceptable mix. It doesn’t matter that the data is approximate, only that it is above the limit for removal.

| |

| | |

| Random tests within removal limits are to be replaced by an equal number of random QC test locations, regardless of tonnage. For example, if 750 tons replace an area covered by two random tests, the new tests would be randomly chosen in each 375 ton portion of the replaced mixture.

| |

| | |

| The resident engineer has the option to determine removal limits based on puck height, provided that the informational test data is consistent with previous production.

| |

| | |

| [[image:403_removal_limits.png|950px|center|thumb|<center>]]

| |

| | |

| When the random QC density core is below or above the removal limits, additional cores may be cut using the following procedure to determine the area of removal. Locations 250’ parallel to the centerline, ahead and back of the failing QC location, will be determined by the engineer. Cores will be cut in these locations and tested. If both sets of cores are not below or above the removal limits, the 500’ section will be removed and replaced with acceptable material and a new random QC core will be cut with-in the new pavement. If either set of the cores are below or above the removal limits, the whole sublot or the area in which the density core represents is subject to removal.

| |

| | |

| Any sublot of material with air voids in the compacted specimens less than 2.5 percent shall be evaluated with Hamburg testing and removed and replaced with acceptable material by the contractor if the rut depth is greater than 14.0 mm.

| |

| | |

| <div id="level of service (LOS)"></div>

| |

| '''Inertial Profiler Test Results''' (Sec 610)

| |

|

| |

| Surface of the pavement should be thoroughly tested with an inertial profiler or straightedge as required by [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=9 Sec 610]. The procedures for testing with an inertial profiler and analyzing the results with the ProVAL software program are set forth in [[106.3.2.59 TM-59, Determination of the International Roughness Index|EPG 106.3.2.59 TM-59, Determination of the International Roughness Index]].

| |

| | |

| '''Bituminous Quality Control Plan''' (Sec 403.17.2)

| |

| | |

| The contractor documents the QC method with a quality control plan (QC Plan*). The QC plan for Superpave mixes shall include the contact information of the contractor’s QC representative, lot and sublot sizes and how they will be designated, the test method for determining asphalt binder content, the number of cores to be cut for density determination, and the independent third party for dispute resolution. The QC plan is approved by MoDOT Construction and Materials and used as a contract document during mix production. Contractor technicians who perform materials testing shall be certified through the MoDOT Technician Certification Program (TCP).

| |

| | |

| *Note*: A QC Plan is not required for bituminous base (BB) and pavement (BP) mixes.

| |

| | |

| Up to 3 cores are allowed at each random location, but only if spelled out in the QC plan. In the drawing below, the cylinder represents the station and offset of the random location. Best management practice is for QA to mark that location on the pavement. The first density core should have that marking on it. Any additional cores should be taken along a straight line, parallel to the centerline, within 1 foot either side of the random location.

| |

| | |

| [[image:403_2foot.png|350px|center|thumb|<center>]]

| |

| | |

| '''Plant Calibration''' (Sec 403.17.2.2)

| |

| | |

| See [[:Category:404 Bituminous Mixing Plants|Bituminous Mixing Plants]].

| |

| | |

| '''Retained Samples''' (Sec 403.17.2.3)

| |

| | |

| QC must retain the portion of each sample that is not tested after the sample has been reduced to testing size. This includes gradation, consensus, TSR, and volumetrics samples. The retained samples must be clearly identified in accordance with Standard Specification Section 403.17.2.3 and stored in the field laboratory for a minimum of 7 days. Also, all cores must be retained for a minimum of 7 days. Notwithstanding the 7 day minimum, retained samples should not be discarded until all comparison issues with the lot are resolved. If space at the field lab is an issue, the sample should be stored at the project office.

| |

| | |

| There is no legitimate reason for unidentified samples to be in the field laboratory. The QA inspector should insist that all test specimens in the field laboratory be marked as soon as they are cool enough. The identifying mark should be permanent, unique, and indicate what the sample is.

| |

| | |

| When running a QC split sample, the comparisons should be within the tolerances shown in the following table:

| |

| | |

| {| border="1" class="wikitable" style="margin: 1em auto 1em auto"

| |

| |-

| |

| !style="background:#BEBEBE"|Loose Mix Property||style="background:#BEBEBE"|Tolerance

| |

| |-

| |

| |align="center"| G<sub>mb</sub> ||align="center"| 0.010

| |

| |-

| |

| |align="center"|G<sub>mm</sub>||align="center"| 0.010

| |

| |-

| |

| |align="center"|AC %||align="center"| 0.1%

| |

| |}

| |

| | |

| '''Gradation Sample''' (Sec 403.17.2.3.1)

| |

| | |

| QC will retain the portion of their gradation sample that is not tested. This includes the sample of the combined cold feed from a drum plant and all hot bin samples from a batch plant. Aggregate samples should be taken in accordance with AASHTO R 90.

| |

| | |

| '''Loose Mix Sample''' (Sec 403.17.2.3.2)

| |

| | |

| A loose mix sample consisting of roughly 100 lbs. will be taken from the roadway behind the paver, in accordance with AASHTO T168, at the required frequency. The sample will be thoroughly mixed and quartered in accordance with AASHTO R47, or with an approved splitting/quartering device. Two opposite quarters will be retained for testing during the dispute resolution process, if necessary. The remaining two quarters will be mixed together and quartered again.

| |

| | |

| The required weight of mix, as listed on the JMF, will be taken from one quarter and used to compact a specimen in accordance with AASHTO T312. The mix will be compacted to Ndes gyrations while the mix temperature is within the molding range listed on the JMF. Using the opposite quarter, follow the same procedure for the second specimen. The Gmb of each specimen will be determined and the average will be used to calculate the air voids Va and the voids in the mineral aggregate (VMA). By specification, a minimum of two compacted specimens must be used to calculate these properties.

| |

| | |