751.34 Concrete Pile Cap Non-Integral End Bents: Difference between revisions

Change minimum distance from 9" to 8" from outside edge of pile to face of beam on concrete pile cap integral and non-integral end bents, intermediate pile cap bents, semi-deep abutment beam caps. |

m Typographical correction. |

||

| Line 225: | Line 225: | ||

!width="50%"|Expansion Device||width="50%"|No Expansion Device | !width="50%"|Expansion Device||width="50%"|No Expansion Device | ||

|- | |- | ||

|colspan="2"|Note: Provide a minimum of 8" | |colspan="2"|Note: Provide a minimum of 8" cl. from outside edge of pile to face of beam. | ||

|} | |} | ||

{|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | {|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | ||

| Line 235: | Line 235: | ||

{|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | {|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | ||

|- | |- | ||

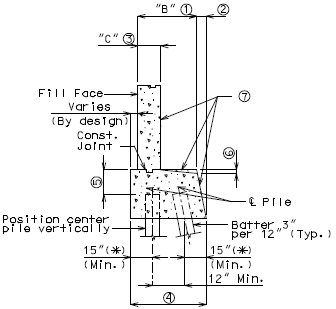

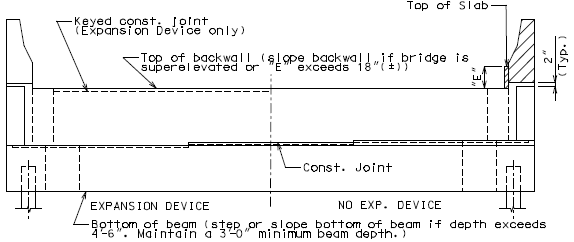

|valign="top" align="right"|*||align="left" width="500pt"|When the total length of a beam and backwall exceeds 60'-0", use a keyed construction joint at or near CL bent as shown, preferably located at 1/4 point between piles. Maximum key length equals 18". For multiple keys make total key length equal to H/3 or d/3. | |valign="top" align="right"|(*)||align="left" width="500pt"|When the total length of a beam and backwall exceeds 60'-0", use a keyed construction joint at or near CL bent as shown, preferably located at 1/4 point between piles. Maximum key length equals 18". For multiple keys make total key length equal to H/3 or d/3. | ||

|rowspan=" | |rowspan="4" valign="bottom"|[[Image:751.34 part section thru 16in barrier curb.gif]] | ||

|- | |- | ||

|valign="top" align="right"|**||align="left" width="500pt" |Slope top of beam 1" when using expansion devices. | |valign="top" align="right"|(**)||align="left" width="500pt" |Slope top of beam 1" when using expansion devices. | ||

|- | |- | ||

|valign="top" align="right"|***||align="left" width="500pt"|Wing layout length shall be rounded to the next higher foot. See the profile sheet for length of wing to fill face. | |valign="top" align="right"|(***)||align="left" width="500pt"|Wing layout length shall be rounded to the next higher foot. See the profile sheet for length of wing to fill face. | ||

|- | |- | ||

|valign="top" align="right"|****||align="left" width="500pt" valign="top"|See Design Layout for maximum slope of spill fill. | |valign="top" align="right"|(****)||align="left" width="500pt" valign="top"|See Design Layout for maximum slope of spill fill. | ||

|- | |||

|valign="top" align="right"|[[Image:751.34 circled 1.gif]]||align="left" width="500pt" valign="top" | Provide a minimum of 8" cl. from outside edge of pile to face of beam. | |||

!rowspan="2" valign="top" valign="top"|Part Section Thru<br/>16" Barrier Curb | !rowspan="2" valign="top" valign="top"|Part Section Thru<br/>16" Barrier Curb | ||

|} | |} | ||

| Line 306: | Line 308: | ||

{|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | {|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | ||

|- | |- | ||

|valign="top" align="right"|[[Image:751.34 circled 1.gif]]||align="left" width="400pt" |3'-6" min. (1" Increments). | |valign="top" align="right"|[[Image:751.34 circled 1.gif]]||align="left" width="400pt" |3'-6" min. (1" Increments). | ||

| Line 356: | Line 356: | ||

{|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | {|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | ||

|- | |- | ||

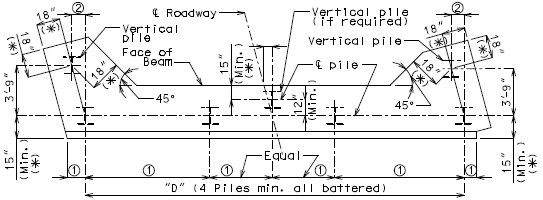

|valign="top" align="right"|[[Image:751.34 circled 1.gif]]||align="left" width="400pt" |End pile edge distance is to be 18". Max. pile spacing = 12'-0". Pile spacing increments to be dimensioned as computed (1" increment). | |valign="top" align="right"|[[Image:751.34 circled 1.gif]]||align="left" width="400pt" |End pile edge distance is to be 18". Max. pile spacing = 12'-0". Pile spacing increments to be dimensioned as computed (1" increment). Provide a minimum of 8" clear from outside edge of pile to outside face of beam. | ||

|- | |- | ||

|valign="top" align="right"|[[Image:751.34 circled 2.gif]]||align="left" width="400pt" |Show on plans. For exceptions to these dimensions, see the Structural Project Manager. | |valign="top" align="right"|[[Image:751.34 circled 2.gif]]||align="left" width="400pt" |Show on plans. For exceptions to these dimensions, see the Structural Project Manager. | ||

|- | |- | ||

|valign="top" align="right"|(*)||Provide a minimum of 8" cl. from outside edge of | |valign="top" align="right"|(*)||Provide a minimum of 8" cl. from outside edge of pile to outside face of beam. | ||

|- | |- | ||

|colspan="2" align="left"|Steel piles shown, CIP piles similar. | |colspan="2" align="left"|Steel piles shown, CIP piles similar. | ||

| Line 398: | Line 398: | ||

|- | |- | ||

| | | | ||

|- | |||

|See [[751.10 General Superstructure#751.10.1.8 Epoxy Coated Reinforcement|751.10.1.8 Epoxy Coated Reinforcement]] | |||

|- | |- | ||

|[[Image:751.34 construction joints and keys-part section a-a.gif]] | |[[Image:751.34 construction joints and keys-part section a-a.gif]] | ||

Revision as of 13:16, 30 September 2009

751.34.1 General

751.34.1.1 Material Properties

| Concrete | ||

|---|---|---|

| Class B Concrete (Substructure) | = 3.0 ksi | |

| = 10 | ||

Class B-1 Concrete (Substructure) may also be used in special cases (See Project Manager). The following equations shall apply to both concrete classes:

| Concrete modulus of elasticity, |

Where: = unit weight of non-reinforced concrete = 0.145 kcf = correction factor for source of aggregate = 1.0

| Modulus of rupture: | For minimum reinforcement, | |

| For all other calculations, | ||

| is in units of ksi |

| Reinforcing Steel | ||

|---|---|---|

| Minimum yield strength, | = 60.0 ksi | |

| Steel modulus of elasticity, | = 29000 ksi | |

751.34.2 Design

751.34.2.1 Limit States and Factors

In general, each component shall satisfy the following equation:

Where:

| = Total factored force effect | |

| = Force effect | |

| = Load modifier | |

| = Load factor | |

| = Resistance factor | |

| = Nominal resistance | |

| = Factored resistance |

Limit States

The following limit states shall be considered for abutment design:

- STRENGTH – I

- STRENGTH – III

- STRENGTH – IV

- STRENGTH – V

- SERVICE – I

- FATIGUE

See LRFD Table 3.4.1-1 and LRFD 3.4.2 for Loads and Load Factors applied at each given limit state.

Resistance factors

- STRENGTH limit states, see LRFD 6.5.4.2 and LRFD 5.5.4.2

- For all other limit states, = 1.00

751.34.2.2 Loads

Dead Loads

Loads from stringers, girders, etc. shall be applied as concentrated loads applied at the centerline of bearing. Loads from concrete slab spans shall be applied as uniformly distributed loads.

Live Loads

Loads from stringers, girders, etc. shall be applied as concentrated loads applied at the centerline of bearing. Dynamic load allowance (impact) should be included for the design of the beam. No dynamic load allowance should be included for foundation design.

For wings with detached wing walls, no portion of the bridge live load shall be distributed to the detached wall. The detached wing wall shall be designed as a retaining wall. The weight of the safety barrier curb on top of the wall shall be included in the dead load.

Collision

Collision shall be designed if abutments are located within a distance of 30.0 feet to the edge of roadway, or within a distance of 50.0 feet to the centerline of a railway track and conditions do not qualify for exemptions given in Section 751.2.2.5. If designed for, the collision force shall be a static force of 400 kips assumed to act in any direction in a horizontal plane, at a distance of 4.0 feet above ground.

Temperature

The force due to expansion or contraction applied at bearing pads are not used for stability or pile bearing computations. However, the movement due to temperature should be considered in the bearing pad design and expansion device design.

Distribution of Loads

Wing with Detached Wing Wall

When Wing Length, L, is greater than 22'-0", use maximum of 22'-0" rectangular wing wall combined with a detached wing wall.

| (*) | Detached wing wall shown is for illustration purpose only. Design detached wing wall as a retaining wall. |

| (*) | Detached wing wall shown is for illustration purpose only. Design detached wing wall as a retaining wall. |

| (**) | Use retaining wall design. |

751.34.2.3 Design Assumptions

| (1) | Beam |

| The beam shall be assumed continuous over supports at centerline of piles. One half of the dead load of the approach slab shall be included in the beam design. |

| (2) | Wing and Backwall | |

| (a) | Vertical Loads | |

| The minimum steel placed horizontally in wings shall be #6 bars at 8" centers, each face. These bars should be adequate to support the wing. See figure below. | ||

| Note: | The minimum steel (horizontally) in the corner haunch at the junction of the wing and backwall shall be #6 bars at 8" cts. " |

| (b) | Horizontal Loads |

751.34.3 Details

751.34.3.1 Front Sheet

| Notes: | The following are details and dimensions for the plan view on the Front Sheets. |

| Details for unsymmetrical roadways will require dimensions tying Centerline Lane to Centerline Structure. | |

| Pile arrangement shown is for illustrating dimensions and should not be considered as a recommended pile arrangement. |

751.34.3.2 Wide Flange Beams, Plate Girders and Prestressed Girders

| |

| Expansion Device | No Expansion Device |

|---|---|

| Note: Provide a minimum of 8" cl. from outside edge of pile to face of beam. | |

|

|

| Part Section at Centerline | Elevation of Safety Barrier Curb |

|---|

| |

| Expansion Device | No Expansion Device |

|---|---|

| Elevation | |

| |

| Expansion Device | No Expansion Device |

| Plan (Square) | |

| |

| Expansion Device | No Expansion Device |

| Plan (Skewed) | |

|

| Square |

|---|

|

| Skews Thru 15° - Left Advance Shown |

|

| Skews Thru 15° - Right Advance Shown |

| (*) | When total length of beam and backwall exceeds 60'-0", show a keyed construction joint at or near the centerline of bent as shown, preferably located at the 1/4 point between piles. Unless required by design or stage construction, this construction joint shall be shown as optional on the plans and may be eliminated at the contractor's discretion. |

|

| Two Rows of Piles |

| Section Thru Bents |

|---|

| Note: | Pile arrangements shown is for illustrating minimum dimensions only and should not be considered recommended arrangements. |

|

| Plan of Footing (Square) |

|---|

|

| Plan of Footing (Skews Thru 15° - Left Advance) |

|

| Plan of Footing (Skews Over 15° - Left Advance) |

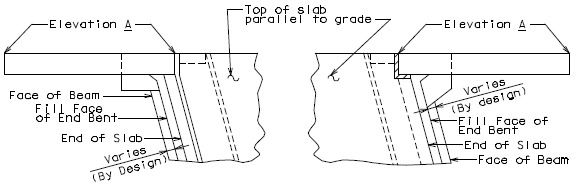

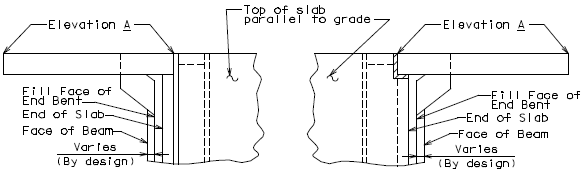

| |

| Expansion Device | No Expansion Device |

|---|---|

| Bridges on Grade and Skew or Superelevated (With or Without Expansion Device | |

| |

| Expansion Device | No Expansion Device |

|

| Bridges With Expansion Devices |

|---|

| |

| Typical View of Beam | |

|---|---|

| See 751.10.1.8 Epoxy Coated Reinforcement | |

|

|

| Part Section A-A | Part Elevation |

| |

| Detail of Keyed Const. Joint | |

| Top of curtain wall shall not obstruct bottom of slab. If necessary slope top of curtain wall. | |

| Elevation A - | Wing elevation is determined at this point for bridges on grade. |

751.34.3.3 Wing Brace Details

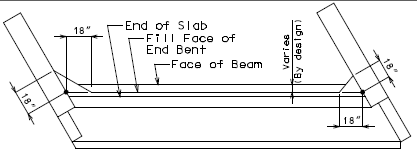

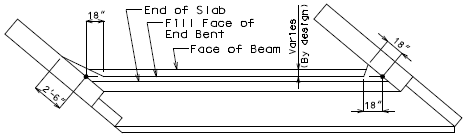

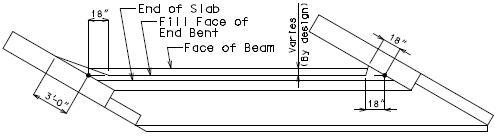

The wing brace dimensions will only vary on the wing with obtuse angle. Wing brace dimensions shown are minimum dimensions. The wing with the acute angle will always be 18" minimum.

|

| Skews 0° thru 45° |

|---|

|

| Skews 45°00'01" thru 55° |

|

| Skews 55°00'01" and Over |

| Note: | Left advance shown, right advance similar. |

751.34.3.4 Exploded View of the End Bent

| Note: | Exploded view above is for information only. |