User talk:Hoskir: Difference between revisions

| Line 221: | Line 221: | ||

---- | ---- | ||

Revision as of 10:12, 22 July 2025

REVISION REQUEST 4036

106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity

1. Chemical Analysis

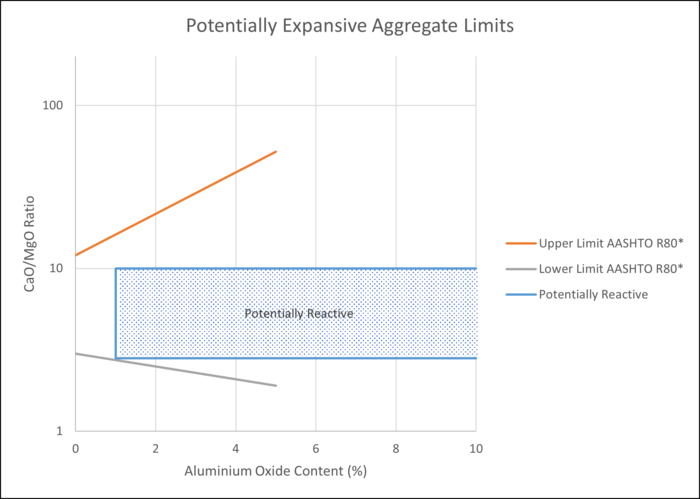

The chemical analysis of aggregate reactivity is an objective, quantifiable and repeatable test. MoDOT will perform the chemical analysis per the process identified in ASTM C 25 for determining the aggregate composition. The analysis determines the calcium oxide (CaO), magnesium oxide (MgO), and aluminum oxide (Al2O3) content of the aggregate. The chemical compositions are then plotted on a chart with the CaO/MgO ratio on the y-axis and Al2O3 percentage on the x-axis per Fig. 2 in AASHTO R 80. Aggregates are considered potentially reactive if the Al2O3 content is greater than or equal to 1.0% and the CaO/MgO ratio is either greater than or equal to 3.0 or less than or equal to 10.0 (see chart below). See flow charts in 106.3.2.93.2 for approval hierarchy. CaO, MgO and Al2O3 shall be analyzed by instrumental analysis only.

* MoDOT’s upper and lower limits of potentially reactive (shaded area) aggregates.

2. Petrographic Examination

A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum:

- Quarry name and ledge name; all ledges if used in combination

- MoDOT District quarry resides

- Date sample was obtained; date petrographic analysis was completed

- Name of petrographer and company/organization affiliated

- Lithographic descriptions with photographs of the sample(s) examined

- Microphotographs of aggregate indicating carbonate particles and/or other reactive materials

- Results of the examination

- All conclusions related to the examination

See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer.

3. Concrete Prism/Beam Test

ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy.

REVISION REQUEST 4060

902.5.43 Power Outages at Signalized Intersections

902.5.43.1 Temporary Stop Signs at Signalized Intersections

Support. Temporary Stop Signs (TSS) refer to stop signs that meet the MUTCD stop sign design requirements for regulatory signs and are temporarily installed at signalized intersections where the traffic signals cannot function due to damage and/or power outage. These temporary placements include but are not limited to roll-up stop signs, temporary mounts on the signal vertical upright, or stop signs mounted on other crash worthy devices.

Standard. If used, such signs shall remain at the intersection until power at the non-functioning signalized intersection has been restored (see EPG 902.5.43.1.4 Recovery).

902.5.43.1.1 Conditions For Use

Guidance. TSS may be erected at locations where a signalized intersection is non-functioning. A non-functioning signalized intersection is defined as an intersection that is equipped with a traffic signal that is damaged and/or without power which cannot display proper indications to control traffic.

After verifying that the signal is non-functioning, Districts should contact the appropriate utility company to notify them of the power outage, if applicable, and to determine if power will be restored in a reasonable amount of time (at the District’s discretion). If used, the TSS should be deployed as soon as practical depending on location of the signalized intersection and the stored TSS. Districts should also request police assistance for traffic control if they are not already present at the site or aware of the power outage. Outside of normal business hours, it might be necessary for the electrician or maintenance personnel to directly contact the highway patrol or local police and the power company. When a signalized intersection is non-functioning, then TSS may be installed when one of the following conditions is met:

- When the traffic signal is both damaged and without power, or

- When the traffic signal is without power and restoration of power using an alternate power source is not possible.

Standard. When TSS are utilized at a signalized intersection that is non-functioning, the District shall decide whether the power shall be disconnected or whether the signal should be switched to flash to avoid conflicts when power is restored. If switched to flash, the flash shall be red-red since TSS will be installed on all approaches, if used, at a signalized intersection without power (dark signals are to be treated like a 4-way stop according to the Missouri Driver’s Guide). The TSS shall not be displayed at the same time as any signal indication is displayed other than a flashing red.

A request shall be made of the nearest maintenance building, emergency responder, or external emergency responder (whomever stores the TSS) to bring stop signs to the intersection. Personnel or emergency responders instructed in signal operation shall disconnect the power or switch the signal to flash operation (external emergency responders will do this in the signal cabinet police door) before placing the TSS. Without this change in operation, the traffic signal could return to steady (stop-and-go) mode within seconds after the signal is repaired or power is restored, which would cause conflicts between the signal and the TSS (conflicting green or yellow indications with a stop sign for the same approach). The signal shall be visible to traffic on all approaches and all these approaches will flash upon restoration of power (see EPG 902.5.43.2 for more information regarding Startup from Dark).

Guidance. When law enforcement is present at a non-functioning signalized intersection to direct traffic, then the TSS that have been placed should be covered or removed to avoid conflicts (the law enforcements authority supersedes the TSS).

Option. If it has been determined that the power outage will last for an extended amount of time (at the district’s discretion) the signal heads may be covered to reduce the confusion of approaching motorists.

Guidance. If signal heads are covered, the appropriate enforcement agency should be advised and asked to occasionally monitor the intersection. Also, the power company should be advised and asked to notify proper personnel when the power is restored.

902.5.43.1.2 Location and Placement

Standard. The signalized intersection locations for installation of TSS shall meet the conditions of use in EPG 902.5.43.1.1 and shall be at the discretion of the district.

Guidance. The installation of TSS should be prioritized as follows (as applicable to each district):

- Signals with railroad preemption

- Signals with a speed limit greater than 50 mph

- Signals with a high accident rate

- Intersections difficult to flag or require multiple flaggers (non-routine roadway configurations/geometry, SPUIs, multi-lane approaches, etc.)

- Signals with high volumes (freeway type off-ramps, major roadways, etc.)

- Signals with frequent power outages

- Signals located at schools.

Standard. When used, TSS shall be placed in a location where they are visible to all lanes on all roadways. On two-way roadways, stop signs shall be erected on the right-hand side of all approaches. On divided highways, stop signs shall be erected on both the right and, if possible, on the left-hand side or at location for best visibility of all approaches.

Guidance. If the power outage is widespread, additional personnel should be requested to help with the placement of the signs.

902.5.43.1.3 Storage and Distribution

Standard. TSS shall be distributed by the district to the district’s maintenance personnel or emergency responders or external emergency responders on an as-needed basis. It shall be the responsibility of the district to develop a means of distribution.

902.5.43.1.4 Recovery

Standard. TSS shall remain at the intersection until power at the non-functioning signalized intersection has been restored. Power will remain disconnected or the signal will flash until TSS are removed. Immediately following TSS removal, personnel or emergency responders instructed in signal operation shall restore signal operation in accordance with the procedures set forth in EPG 902.5.43.2 Steady (stop-and-go) Mode for transition to steady (stop-and-go) mode.

The recovery of the TSS shall be accomplished by using the district’s maintenance personnel or emergency responders or external emergency responders by either of the following:

- Complete removal from each intersection.

- Stockpiling outside of the intersection to avoid conflicts with the signalized intersection (stockpiled signs shall not be faced towards the traveling public and stored not to damage sheeting) and stored in a location to not become a roadside hazard.

902.5.43.2 Start up from Dark at Signalized Intersections

Standard. When a signalized intersection has been damaged and/or is without power the district shall have either disconnected the power or switched the signal to flash to avoid conflicts when power is restored. If switched to flash, the flash shall be red-red since TSS will be installed on all approaches, if used, at a signalized intersection without power (dark signals are to be treated like a 4-way stop according to the Missouri Drive’s Guide). If TSS are in place, the power shall remain disconnected or the signal shall operate in flash mode until TSS are removed and personnel or emergency responders instructed in signal operation restore signal operation.

Steady (stop-and-go) Mode

Standard. When power is reconnected or when the signal is switched from flash to steady (stop-and-go) mode, the controllers shall be programmed for startup from flash. The signal shall flash red-red for 7 seconds and then change to steady red clearance for 6 seconds followed by beginning of major-street green interval or if there is no common major-street green interval, at the beginning of the green interval for the major traffic movement on the major street.

902.5.43.3 Battery Backup Systems at Signalized Intersections

902.5.43.3.1 Installation/Placement

Guidance. The installation of Battery Backup Systems(BBS) should be prioritized as follows (as applicable to each district):

- Signals with railroad preemption

- Signals with a speed limit greater than 50 mph

- Signals with a high accident rate

- Intersections difficult to flag or require multiple flaggers (non-routine roadway configurations/geometry, SPUIs, multi-lane approaches, etc.)

- Signals with high volumes (freeway type off-ramps, major roadways, etc.)

- Signals with frequent power outages

- Signals located at schools.

902.5.43.3.2 Duration

Standard. BBS shall be capable of operating at a minimum of 2 hours in steady (stop-and-go) mode and a minimum of 2 hours in flash operation.

Guidance. Any signalized intersection with BBS should have a generator socket for extended operation.

REVISION REQUEST 4066

751.50 Standard Detailing Notes

Delete Notes B3.5 and B3.6

(B3.5) Use for CIP pile in all bridges except for continuous concrete slab bridges. All reinforcement in cast-in-place pile at non-integral end bents and intermediate bents is included in the substructure quantities. (B3.6) Use for CIP pile in continuous concrete slab bridges. All reinforcement in cast-in-place pile at end bents and pile cap intermediate bents is included in the superstructure quantities and all reinforcement in cast-in-place pile at open concrete intermediates bents is included in the substructure quantities.

G5. CIP Concrete Piles (Notes for Bridge Standard Drawings)

G5a Closed Ended Cast-in Place (CECIP) Concrete Pile

(G5a1)

- Welded or seamless steel shell (pipe) shall be ASTM A252 Modified Grade 3 (fy = 50,000 psi) with physical and chemical requirements that meet ASTM A572 Grade 50. Pipe certification and source material certification shall be required.

(G5a2)

- Concrete for cast-in-place pile shall be Class B-1.

(G5a3)

- Steel for closure plate shall be ASTM A709 Grade 50.

(G5a4)

- Steel for cruciform pile point reinforcement shall be ASTM A709 Grade 50.

(G5a5)

- Steel casting for conical pile point reinforcement shall be ASTM A148 Grade 90-60.

(G5a6)

- The minimum wall thickness of any spot or local area of any type shall not be more than 12.5% under the specified nominal wall thickness.

(G5a7)

- Closure plate shall not project beyond the outside diameter of the pipe pile. Satisfactory weldments may be made by beveling tip end of pipe or by use of inside backing rings. In either case, proper gaps shall be used to obtain weld penetration full thickness of pipe. Payment for furnishing and installing closure plate will be considered completely covered by the contract unit price for Galvanized Cast-In-Place Concrete Piles.

(G5a8)

- Splices of pipe for cast-in-place concrete pile shall be made watertight and to the full strength of the pipe above and below the splice to permit hard driving without damage. Pipe damaged during driving shall be replaced without cost to the state. Pipe sections used for splicing shall be at least 5 feet in length.

(G5a9a) Use the following note for seismic category A

- At the contractor's option, the hooks of vertical bars embedded in the beam cap may be oriented inward or outward.

(G5a9b) Use the following note for seismic category B, C or D

- The hooks of vertical bars embedded in the beam cap should not be turned outward, away from the pile core.

(G5a10)

- The hooks of vertical bars embedded in the pile cap footing should be oriented outward for all seismic categories.

(G5a11)

- Closure plate need not be galvanized.

(G5a12)

- Reinforcing steel for cast-in-place pile is included in the Bill of Reinforcing Steel.

(G5a13) Use for CIP pile on all bridges except for continuous concrete slab bridges. Remove underlined portion for non-integral end bents.

- All reinforcement for cast-in-place pile at end bents is included in the Estimated Quantities for Slab on _____. Reinforcement for cast-in-place pile at intermediate bents is included in the substructure quantity tables.

(G5a14) Use for CIP pile on continuous concrete slab bridges. The first underlined portion is included for pile cap intermediate bents. The second underlined portion is included for intermediate bents with pile footings.

- All reinforcement in cast-in-place pile at end bents and intermediate bents is included in the superstructure quantities and all reinforcement in cast-in-place pile at intermediates bents is included in the substructure quantity tables.

(G5a15)

- The contractor shall determine the pile wall thickness required to avoid damage from all driving activities, but wall thickness shall not be less than the minimum specified. No additional payment will be made for furnishing a thicker pile wall than specified on the plans.

G5b Open Ended Cast-in Place (OECIP) Concrete Pile

(G5b1)

- Welded or seamless steel shell (pipe) shall be ASTM A252 Modified Grade 3 (fy = 50,000 psi) with physical and chemical requirements that meet ASTM A572 Grade 50. Pipe certification and source material certification shall be required.

(G5b2)

- Open ended pile shall be augered out to the minimum pile cleanout penetration elevation and filled with Class B-1 concrete.

(G5b3)

- Concrete for cast-in-place pile shall be Class B-1.

(G5b4)

- Steel casting for open ended cutting shoe pile point reinforcement shall be ASTM A148 Grade 90-60.

(G5b5)

- The minimum wall thickness of any spot or local area of any type shall not be more than 12.5% under the specified nominal wall thickness.

(G5b6)

- Splices of pipe for cast-in-place pipe pile shall be made watertight and to the full strength of the pipe above and below the splice to permit hard driving without damage. Pipe damaged during driving shall be replaced without cost to the state. Pipe sections used for splicing shall be at least 5 feet in length.

(G5b7a) Use the following note for seismic category A

- At the contractor's option, the hooks of vertical bars embedded in the beam cap may be oriented inward or outward.

(G5b7b) Use the following note for seismic category B, C or D

- The hooks of vertical bars embedded in the beam cap should not be turned outward, away from the pile core.

(G5b8)

- The hooks of vertical bars embedded in the pile cap footing should be oriented outward for all seismic categories.

(G5b9)

- Reinforcing steel for cast-in-place pile is included in the Bill of Reinforcing Steel.

(G5b10) Use for CIP pile on all bridges except for continuous concrete slab bridges. Remove underlined portion for non-integral end bents.

- All reinforcement for cast-in-place pile at end bents is included in the Estimated Quantities for Slab on _____. Reinforcement for cast-in-place pile at intermediate bents is included in the substructure quantity tables.

(G5b11) Use for CIP pile on continuous concrete slab bridges. The first underlined portion is included for pile cap intermediate bents. The second underlined portion is included for intermediate bents with pile footings.

- All reinforcement in cast-in-place pile at end bents and intermediate bents is included in the superstructure quantities and all reinforcement in cast-in-place pile at intermediates bents is included in the substructure quantity tables.

(G5b12)

- The contractor shall determine the pile wall thickness required to avoid damage from all driving activities, but wall thickness shall not be less than the minimum specified. No additional payment will be made for furnishing a thicker pile wall than specified on the plans.