User talk:Hoskir

REVISION REQUEST 4036

106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity

1. Chemical Analysis

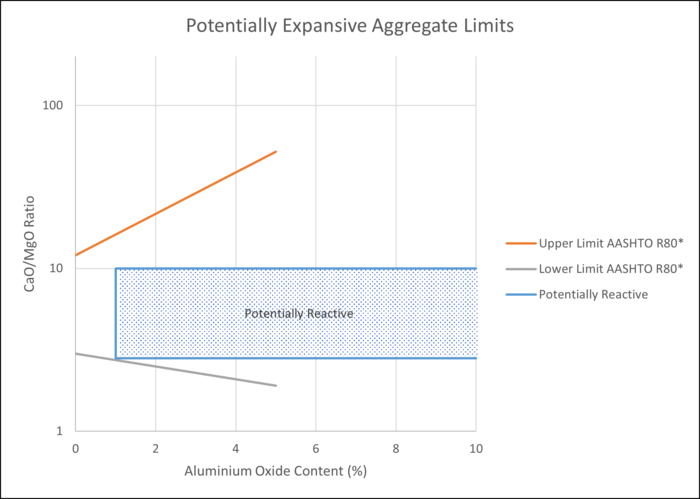

The chemical analysis of aggregate reactivity is an objective, quantifiable and repeatable test. MoDOT will perform the chemical analysis per the process identified in ASTM C 25 for determining the aggregate composition. The analysis determines the calcium oxide (CaO), magnesium oxide (MgO), and aluminum oxide (Al2O3) content of the aggregate. The chemical compositions are then plotted on a chart with the CaO/MgO ratio on the y-axis and Al2O3 percentage on the x-axis per Fig. 2 in AASHTO R 80. Aggregates are considered potentially reactive if the Al2O3 content is greater than or equal to 1.0% and the CaO/MgO ratio is either greater than or equal to 3.0 or less than or equal to 10.0 (see chart below). See flow charts in 106.3.2.93.2 for approval hierarchy. CaO, MgO and Al2O3 shall be analyzed by instrumental analysis only.

* MoDOT’s upper and lower limits of potentially reactive (shaded area) aggregates.

2. Petrographic Examination

A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum:

- Quarry name and ledge name; all ledges if used in combination

- MoDOT District quarry resides

- Date sample was obtained; date petrographic analysis was completed

- Name of petrographer and company/organization affiliated

- Lithographic descriptions with photographs of the sample(s) examined

- Microphotographs of aggregate indicating carbonate particles and/or other reactive materials

- Results of the examination

- All conclusions related to the examination

See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer.

3. Concrete Prism/Beam Test

ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy.

REVISION REQUEST 4060

902.5.43 Power Outages at Signalized Intersections

902.5.43.1 Temporary Stop Signs at Signalized Intersections

Support. Temporary Stop Signs (TSS) refer to stop signs that meet the MUTCD stop sign design requirements for regulatory signs and are temporarily installed at signalized intersections where the traffic signals cannot function due to damage and/or power outage. These temporary placements include but are not limited to roll-up stop signs, temporary mounts on the signal vertical upright, or stop signs mounted on other crash worthy devices.

Standard. If used, such signs shall remain at the intersection until power at the non-functioning signalized intersection has been restored (see EPG 902.5.43.1.4 Recovery).

902.5.43.1.1 Conditions For Use

Guidance. TSS may be erected at locations where a signalized intersection is non-functioning. A non-functioning signalized intersection is defined as an intersection that is equipped with a traffic signal that is damaged and/or without power which cannot display proper indications to control traffic.

After verifying that the signal is non-functioning, Districts should contact the appropriate utility company to notify them of the power outage, if applicable, and to determine if power will be restored in a reasonable amount of time (at the District’s discretion). If used, the TSS should be deployed as soon as practical depending on location of the signalized intersection and the stored TSS. Districts should also request police assistance for traffic control if they are not already present at the site or aware of the power outage. Outside of normal business hours, it might be necessary for the electrician or maintenance personnel to directly contact the highway patrol or local police and the power company. When a signalized intersection is non-functioning, then TSS may be installed when one of the following conditions is met:

- When the traffic signal is both damaged and without power, or

- When the traffic signal is without power and restoration of power using an alternate power source is not possible.

Standard. When TSS are utilized at a signalized intersection that is non-functioning, the District shall decide whether the power shall be disconnected or whether the signal should be switched to flash to avoid conflicts when power is restored. If switched to flash, the flash shall be red-red since TSS will be installed on all approaches, if used, at a signalized intersection without power (dark signals are to be treated like a 4-way stop according to the Missouri Driver’s Guide). The TSS shall not be displayed at the same time as any signal indication is displayed other than a flashing red.

A request shall be made of the nearest maintenance building, emergency responder, or external emergency responder (whomever stores the TSS) to bring stop signs to the intersection. Personnel or emergency responders instructed in signal operation shall disconnect the power or switch the signal to flash operation (external emergency responders will do this in the signal cabinet police door) before placing the TSS. Without this change in operation, the traffic signal could return to steady (stop-and-go) mode within seconds after the signal is repaired or power is restored, which would cause conflicts between the signal and the TSS (conflicting green or yellow indications with a stop sign for the same approach). The signal shall be visible to traffic on all approaches and all these approaches will flash upon restoration of power (see EPG 902.5.43.2 for more information regarding Startup from Dark).

Guidance. When law enforcement is present at a non-functioning signalized intersection to direct traffic, then the TSS that have been placed should be covered or removed to avoid conflicts (the law enforcements authority supersedes the TSS).

Option. If it has been determined that the power outage will last for an extended amount of time (at the district’s discretion) the signal heads may be covered to reduce the confusion of approaching motorists.

Guidance. If signal heads are covered, the appropriate enforcement agency should be advised and asked to occasionally monitor the intersection. Also, the power company should be advised and asked to notify proper personnel when the power is restored.

902.5.43.1.2 Location and Placement

Standard. The signalized intersection locations for installation of TSS shall meet the conditions of use in EPG 902.5.43.1.1 and shall be at the discretion of the district.

Guidance. The installation of TSS should be prioritized as follows (as applicable to each district):

- Signals with railroad preemption

- Signals with a speed limit greater than 50 mph

- Signals with a high accident rate

- Intersections difficult to flag or require multiple flaggers (non-routine roadway configurations/geometry, SPUIs, multi-lane approaches, etc.)

- Signals with high volumes (freeway type off-ramps, major roadways, etc.)

- Signals with frequent power outages

- Signals located at schools.

Standard. When used, TSS shall be placed in a location where they are visible to all lanes on all roadways. On two-way roadways, stop signs shall be erected on the right-hand side of all approaches. On divided highways, stop signs shall be erected on both the right and, if possible, on the left-hand side or at location for best visibility of all approaches.

Guidance. If the power outage is widespread, additional personnel should be requested to help with the placement of the signs.

902.5.43.1.3 Storage and Distribution

Standard. TSS shall be distributed by the district to the district’s maintenance personnel or emergency responders or external emergency responders on an as-needed basis. It shall be the responsibility of the district to develop a means of distribution.

902.5.43.1.4 Recovery

Standard. TSS shall remain at the intersection until power at the non-functioning signalized intersection has been restored. Power will remain disconnected or the signal will flash until TSS are removed. Immediately following TSS removal, personnel or emergency responders instructed in signal operation shall restore signal operation in accordance with the procedures set forth in EPG 902.5.43.2 Steady (stop-and-go) Mode for transition to steady (stop-and-go) mode.

The recovery of the TSS shall be accomplished by using the district’s maintenance personnel or emergency responders or external emergency responders by either of the following:

- Complete removal from each intersection.

- Stockpiling outside of the intersection to avoid conflicts with the signalized intersection (stockpiled signs shall not be faced towards the traveling public and stored not to damage sheeting) and stored in a location to not become a roadside hazard.

902.5.43.2 Start up from Dark at Signalized Intersections

Standard. When a signalized intersection has been damaged and/or is without power the district shall have either disconnected the power or switched the signal to flash to avoid conflicts when power is restored. If switched to flash, the flash shall be red-red since TSS will be installed on all approaches, if used, at a signalized intersection without power (dark signals are to be treated like a 4-way stop according to the Missouri Drive’s Guide). If TSS are in place, the power shall remain disconnected or the signal shall operate in flash mode until TSS are removed and personnel or emergency responders instructed in signal operation restore signal operation.

Steady (stop-and-go) Mode

Standard. When power is reconnected or when the signal is switched from flash to steady (stop-and-go) mode, the controllers shall be programmed for startup from flash. The signal shall flash red-red for 7 seconds and then change to steady red clearance for 6 seconds followed by beginning of major-street green interval or if there is no common major-street green interval, at the beginning of the green interval for the major traffic movement on the major street.

902.5.43.3 Battery Backup Systems at Signalized Intersections

902.5.43.3.1 Installation/Placement

Guidance. The installation of Battery Backup Systems(BBS) should be prioritized as follows (as applicable to each district):

- Signals with railroad preemption

- Signals with a speed limit greater than 50 mph

- Signals with a high accident rate

- Intersections difficult to flag or require multiple flaggers (non-routine roadway configurations/geometry, SPUIs, multi-lane approaches, etc.)

- Signals with high volumes (freeway type off-ramps, major roadways, etc.)

- Signals with frequent power outages

- Signals located at schools.

902.5.43.3.2 Duration

Standard. BBS shall be capable of operating at a minimum of 2 hours in steady (stop-and-go) mode and a minimum of 2 hours in flash operation.

Guidance. Any signalized intersection with BBS should have a generator socket for extended operation.

REVISION REQUEST 4066

751.50 Standard Detailing Notes

Delete Notes B3.5 and B3.6

(B3.5) Use for CIP pile in all bridges except for continuous concrete slab bridges. All reinforcement in cast-in-place pile at non-integral end bents and intermediate bents is included in the substructure quantities. (B3.6) Use for CIP pile in continuous concrete slab bridges. All reinforcement in cast-in-place pile at end bents and pile cap intermediate bents is included in the superstructure quantities and all reinforcement in cast-in-place pile at open concrete intermediates bents is included in the substructure quantities.

G5. CIP Concrete Piles (Notes for Bridge Standard Drawings)

G5a Closed Ended Cast-in Place (CECIP) Concrete Pile

(G5a1)

- Welded or seamless steel shell (pipe) shall be ASTM A252 Modified Grade 3 (fy = 50,000 psi) with physical and chemical requirements that meet ASTM A572 Grade 50. Pipe certification and source material certification shall be required.

(G5a2)

- Concrete for cast-in-place pile shall be Class B-1.

(G5a3)

- Steel for closure plate shall be ASTM A709 Grade 50.

(G5a4)

- Steel for cruciform pile point reinforcement shall be ASTM A709 Grade 50.

(G5a5)

- Steel casting for conical pile point reinforcement shall be ASTM A148 Grade 90-60.

(G5a6)

- The minimum wall thickness of any spot or local area of any type shall not be more than 12.5% under the specified nominal wall thickness.

(G5a7)

- Closure plate shall not project beyond the outside diameter of the pipe pile. Satisfactory weldments may be made by beveling tip end of pipe or by use of inside backing rings. In either case, proper gaps shall be used to obtain weld penetration full thickness of pipe. Payment for furnishing and installing closure plate will be considered completely covered by the contract unit price for Galvanized Cast-In-Place Concrete Piles.

(G5a8)

- Splices of pipe for cast-in-place concrete pile shall be made watertight and to the full strength of the pipe above and below the splice to permit hard driving without damage. Pipe damaged during driving shall be replaced without cost to the state. Pipe sections used for splicing shall be at least 5 feet in length.

(G5a9a) Use the following note for seismic category A

- At the contractor's option, the hooks of vertical bars embedded in the beam cap may be oriented inward or outward.

(G5a9b) Use the following note for seismic category B, C or D

- The hooks of vertical bars embedded in the beam cap should not be turned outward, away from the pile core.

(G5a10)

- The hooks of vertical bars embedded in the pile cap footing should be oriented outward for all seismic categories.

(G5a11)

- Closure plate need not be galvanized.

(G5a12)

- Reinforcing steel for cast-in-place pile is included in the Bill of Reinforcing Steel.

(G5a13) Use for CIP pile on all bridges except for continuous concrete slab bridges. Remove underlined portion for non-integral end bents.

- All reinforcement for cast-in-place pile at end bents is included in the Estimated Quantities for Slab on _____. Reinforcement for cast-in-place pile at intermediate bents is included in the substructure quantity tables.

(G5a14) Use for CIP pile on continuous concrete slab bridges. The first underlined portion is included for pile cap intermediate bents. The second underlined portion is included for intermediate bents with pile footings.

- All reinforcement in cast-in-place pile at end bents and intermediate bents is included in the superstructure quantities and all reinforcement in cast-in-place pile at intermediates bents is included in the substructure quantity tables.

(G5a15)

- The contractor shall determine the pile wall thickness required to avoid damage from all driving activities, but wall thickness shall not be less than the minimum specified. No additional payment will be made for furnishing a thicker pile wall than specified on the plans.

G5b Open Ended Cast-in Place (OECIP) Concrete Pile

(G5b1)

- Welded or seamless steel shell (pipe) shall be ASTM A252 Modified Grade 3 (fy = 50,000 psi) with physical and chemical requirements that meet ASTM A572 Grade 50. Pipe certification and source material certification shall be required.

(G5b2)

- Open ended pile shall be augered out to the minimum pile cleanout penetration elevation and filled with Class B-1 concrete.

(G5b3)

- Concrete for cast-in-place pile shall be Class B-1.

(G5b4)

- Steel casting for open ended cutting shoe pile point reinforcement shall be ASTM A148 Grade 90-60.

(G5b5)

- The minimum wall thickness of any spot or local area of any type shall not be more than 12.5% under the specified nominal wall thickness.

(G5b6)

- Splices of pipe for cast-in-place pipe pile shall be made watertight and to the full strength of the pipe above and below the splice to permit hard driving without damage. Pipe damaged during driving shall be replaced without cost to the state. Pipe sections used for splicing shall be at least 5 feet in length.

(G5b7a) Use the following note for seismic category A

- At the contractor's option, the hooks of vertical bars embedded in the beam cap may be oriented inward or outward.

(G5b7b) Use the following note for seismic category B, C or D

- The hooks of vertical bars embedded in the beam cap should not be turned outward, away from the pile core.

(G5b8)

- The hooks of vertical bars embedded in the pile cap footing should be oriented outward for all seismic categories.

(G5b9)

- Reinforcing steel for cast-in-place pile is included in the Bill of Reinforcing Steel.

(G5b10) Use for CIP pile on all bridges except for continuous concrete slab bridges. Remove underlined portion for non-integral end bents.

- All reinforcement for cast-in-place pile at end bents is included in the Estimated Quantities for Slab on _____. Reinforcement for cast-in-place pile at intermediate bents is included in the substructure quantity tables.

(G5b11) Use for CIP pile on continuous concrete slab bridges. The first underlined portion is included for pile cap intermediate bents. The second underlined portion is included for intermediate bents with pile footings.

- All reinforcement in cast-in-place pile at end bents and intermediate bents is included in the superstructure quantities and all reinforcement in cast-in-place pile at intermediates bents is included in the substructure quantity tables.

(G5b12)

- The contractor shall determine the pile wall thickness required to avoid damage from all driving activities, but wall thickness shall not be less than the minimum specified. No additional payment will be made for furnishing a thicker pile wall than specified on the plans.

REVISION REQUEST 4071

751.1.2.9.2 Steel Girder Options

When considering steel structures, the preliminary designer must decide if the girders should be painted or fabricated from weathering steel. If site-specific conditions allow, the use of unpainted weathering steel (ASTM A709 Grades 50W and HPS70W) should be considered and is MoDOT’s preferred system for routine steel I-girder type bridges due to its performance, economic and environmental benefits. Cost savings are realized because of the elimination of the initial paint system as well as the need for periodic renewal of the paint system over the life of the structure.

Weathering steels provide significant environmental and worker safety benefits as well. Since they do not require initial and periodic repainting of the whole bridge, emissions of volatile organic compounds (VOC) are reduced. Also, they generally do not require coating removal or disposal of contaminated blast debris over the service life of the structure. By eliminating the need for periodic repainting, the closing of traffic lanes can be prevented as well as the associated hazards to painters, maintenance workers, and the travelling public.

Partial coating of weathering steel is required near expansion joints. See EPG 751.14.5.8. Periodic recoating or overcoating will be required, however, on a much smaller scale than the whole bridge with the effect that lane closures and associated hazards are greatly reduced compared to painted steel.

Although weathering steel is MoDOT’s preferred system for routine I-girder bridges with proper detailing, it should not be used for box girders, trusses or other structure types where details may tend to trap moisture or debris. There are also some situations where the use of weathering steel may not be advisable due to unique environmental circumstances of the site. Generally, these types of structures would receive high deposits of salt along with humidity, or long-term wet conditions and individually each circumstance could be considered critical.

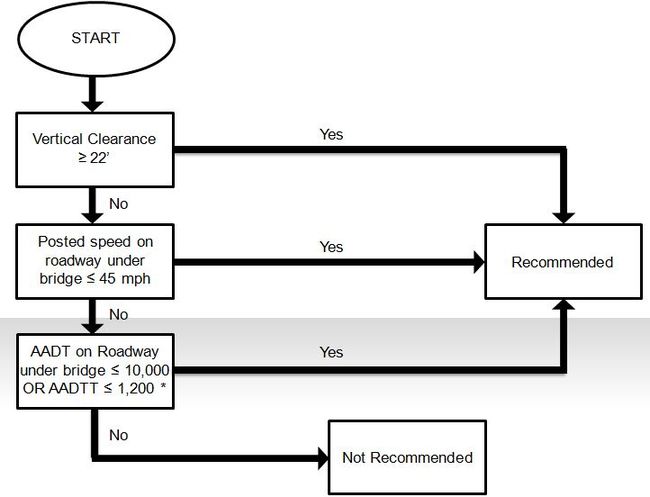

The FHWA Technical Advisory T5140.22 October 1989 should be used as guidance when determining the acceptability of weathering steel. Due to the large amounts of deicing salts used on our highways which ultimately causes salt spray on bridge girders, the flowchart below should be used as guidance for grade separations. The flowchart, Fig. 751.1.2.9, below, is general guidance but is not all inclusive. There may be cases based on the circumstances of the bridge site where the use of weathering steel is acceptable even though the flowchart may indicate otherwise. In these cases, follow MoDOT’s design exception process.

Weathering steel may be used for stream crossings where 1) the base flood elevation is lower than the bottom of girder elevation and 2) the difference between the ordinary high water and bottom of girder elevations is greater than 10 ft. for stagnant and 8 ft. for moving bodies of water. Where the difference in elevations is less than noted, weathering steel may be used upon approval of the Assistant State Bridge Engineer.

Additional documents that can be referenced to aid in identifying the site-specific locations and details that should be avoided when the use of weathering steel is being considered include:

- 1. Transportation Research Board. (1989). Guidelines for the use of Weathering Steel in Bridges, (NCHRP Report 314). Washington, DC: Albrecht, et al.

- 2. American Iron and Steel Institute. (1995). Performance of Weathering Steel in Highway Bridges, Third Phase Report. Nickerson, R.L.

- 3. American Institute of Steel Construction. (2022). Uncoated Weathering Steel Reference Guide. NSBA

- 4. MoDOT. (1996). Missouri Highway and Transportation Department Task Force Report on Weathering Steel for Bridges. Jefferson City, MO: Porter, P., et al.

The final brown rust appearance could be an aesthetic concern. When determining the use of weathering steel, aesthetics and other concerns should be discussed by the Core Team members, with input from Bridge Division and Maintenance Division.

If weathering steel cannot be used, the girders should be painted gray (Federal Standard #26373). If the district doesn’t want gray, they can choose brown (Federal Standard #30045). If the district or the local municipality wants a color other than gray or brown, they must meet the requirements of EPG 1045.5 Policy on Color of Structural Steel Paint. See EPG 751.6.2.11, EPG 751.6.2.12 and EPG 751.14.5.8 for further guidance on paint systems.

751.6.1 Index of Quantities

| Sec 712 – Structural Steel Construction | |||

| 712-09.00 | 1 | linear foot | Expansion Device (Finger Plate) |

| 712-09.15 | 1 | linear foot | Expansion Device (Flat Plate) |

| 712-10.00 | 10 | pound | Fabricated Structural Carbon Steel (Misc.) |

| 712-10.10 | 10 | pound | Fabricated Structural Carbon Steel (I-Beam) |

| 712-10.20 | 10 | pound | Fabricated Structural Carbon Steel (Plate Girder) |

| 712-10.30 | 10 | pound | Fabricated Structural Carbon Steel (Trusses) |

| 712-10.40 | 10 | pound | Fabricated Structural Carbon Steel (Concrete) |

| 712-10.50 | 10 | pound | Fabricated Structural Carbon Steel (Box Girder) |

| 712-10.60 | 1 | lump sum | Fabricated Sign Support Brackets |

| 712-11.00 | 10 | pound | Fabricated Structural Low Alloy Steel (Misc.) |

| 712-11.11 | 10 | pound | Fabricated Structural Low Alloy Steel (I-Beam) A709, Grade 50 |

| 712-11.13 | 10 | pound | Fabricated Structural Low Alloy Steel (I-Beam) A709, Grade 50W |

| 712-11.21 | 10 | pound | Fabricated Structural Low Alloy Steel (Plate Girder) A709, Grade 50 |

| 712-11.22 | 10 | pound | Fabricated Structural Low Alloy Steel (Plate Girder) A709, Grade 50W |

| 712-11.23 | 10 | pound | Fabricated Structural Low Alloy Steel (Plate Girder) A709 Grade HPS70W |

| 712-11.24 | 10 | pound | Fabricated Structural Low Alloy Steel (Plate Girder) A709 Grade HPS50W |

| 712-11.30 | 10 | pound | Fabricated Structural Low Alloy Steel (Trusses) |

| 712-11.40 | 10 | pound | Fabricated Structural Low Alloy Steel (Concrete) |

| 712-11.51 | 10 | pound | Fabricated Structural Low Alloy Steel (Box Girder) A709, Grade 50 |

| 712-11.52 | 10 | pound | Fabricated Structural Low Alloy Steel (Box Girder) A709, Grade 50W |

| 712-11.59 | 1 | each | Shear Connectors |

| 712-11.60 | 1 | sq. foot | Steel Grid Floor (Half Concrete Filled) |

| 712-11.61 | 1 | sq. foot | Steel Grid Floor (Concrete Filled) |

| 712-12.50 | 1 | lump sum | Strengthening Existing Beams |

| 712-12.51 | 1 | each | Hinge Modification |

| 712-13.00 | 10 | pound | Fabricated Structural Steel Bearings |

| 712-20.00 | 10 | pound | Carbon Steel Castings |

| 712-22.00 | 10 | pound | Gray Iron Castings |

| 712-23.00 | 1 | linear foot | Bridge Rail (Two Tube Structural Steel) |

| 712-30.00 | 1 | each | Steel Bar Dam |

| 712-31.00 | 1 | each | Cleaning and Coating Existing Bearings |

| 712-31.10 | 1 | each | Bearing Removal for Inspection |

| 712-31.15 | 1 | each | Surface Finishing Bearing Rocker |

| 712-31.20 | 1 | each | Cleaning, Lubricating and Coating Bearing |

| 712-31.30 | 1 | each | Rehabilitate Bearing |

| 712-31.40 | 10 | pound | New Bearing Materials |

| 712-31.50 | 1 | each | Anchor Bolt Replacement |

| 712-32.00 | 1 | each | Removing, Coating and Reinstalling Light Standards (Bridges) |

| 712-32.10 | 1 | each | Earthquake Restrainer Assemblies |

| 712-32.50 | 1 | each | Rivet Removal and Replacement |

| 712-33.00 | 1 | lump sum | Existing Diaphragm Connections to Flange |

| 712-33.01 | 1 | each | Steel Intermediate Diaphragm for P/S Concrete Girders |

| 712-35.00 | 1 | linear foot | Railing for Steps |

| 712-36.10 | 1 | each | Slab Drain |

| 712-36.11 | 1 | each | Slab Drain with Grate |

| 712-36.20 | 1 | lump sum | Drainage System (On Structure) |

| 712-51.00 | 1 | lump sum | Surface Preparation for Recoating Structural Steel |

| 712-51.01 | 1 | lump sum | Surface Preparation for Overcoating Structural Steel (System G) |

| 712-51.02 | 1 | lump sum | Surface Preparation for Applying Epoxy-Mastic Primer |

| 712-51.09 | 1 | lump sum | Field Application of Organic Zinc Primer |

| 712-51.10 | 1 | lump sum | Field Application of Inorganic Zinc Primer |

| 712-51.11 | 1 | lump sum | Intermediate Field Coat (System G) |

| 712-51.12 | 1 | lump sum | Finish Field Coat (System G) |

| 712-51.13 | 1 | lump sum | Intermediate Field Coat (System H) |

| 712-51.14 | 1 | lump sum | Finish Field Coat (System H) |

| 712-51.15 | 1 | lump sum | Finish Field Coat (System I) |

| 712-51.16 | 1 | lump sum | Finish Field Coat (System L) |

| 712-52.00 | 100 | sq. foot | Surface Preparation for Recoating Structural Steel |

| 712-52.01 | 100 | sq. foot | Surface Preparation for Overcoating Structural Steel (System G) |

| 712-52.09 | 100 | sq. foot | Field Application of Organic Zinc Primer |

| 712-52.10 | 100 | sq. foot | Field Application of Inorganic Zinc Primer |

| 712-53.15A | 0.1 | ton | Intermediate Field Coat (System G) |

| 712-53.20A | 0.1 | ton | Finish Field Coat (System G) |

| 712-53.35A | 0.1 | ton | Intermediate Field Coat (System H) |

| 712-53.40A | 0.1 | ton | Finish Field Coat (System H) |

| 712-53.46 | 0.1 | ton | Finish Field Coat (System I) |

| 712-53.47 | 0.1 | ton | Finish Field Coat (System L) |

| 712-53.65A | 100 | sq. foot | Intermediate Field Coat (System G) |

| 712-53.70A | 100 | sq. foot | Finish Field Coat (System G) |

| 712-53.85A | 100 | sq. foot | Intermediate Field Coat (System H) |

| 712-53.90A | 100 | sq. foot | Finish Field Coat (System H) |

| 712-53.96 | 100 | sq. foot | Finish Field Coat (System I) |

| 712-53.97 | 100 | sq. foot | Finish Field Coat (System L) |

| 712-59.60 | 1 | lump sum | Aluminum Epoxy-Mastic Primer |

| 712-59.61 | 1 | lump sum | Gray Epoxy-Mastic Primer |

| 712-60.00 | 1 | linear foot | Non-Destructive Testing |

| 712-99.01 | 1 | lump sum | Galvanizing Structural Steel |

| 712-99.02 | 1 | each | Misc. |

| 712-99.03 | 1 | linear foot | Misc. |

| 712-99.04 | 1 | sq. foot | Misc. |

| 712-99.05 | 1 | sq. yard | Misc. |

| 712-99.10 | 0.1 | ton | Misc. |

| 712-99.11 | 10 | pound | Misc. |

751.6.2.11 Structural Steel Protective Coatings (Non-weathering Steel)

The protective coating, as specified on the Design Layout, shall be System G, H, I or L with the color being gray or brown. The coating color shall be specified on the Design Layout. The following gives pay item guidelines for most bridges.

Note: The figures in this section are provided to aid in interpretation of the specifications and do not intend to represent a preference for any particular system.

Coating New Multi-Girder/Beam Bridges

Intermediate Field Coat and Finish Field Coat (System G, H, I or L) (Gray or Brown) - The quantity shall be computed to the nearest one hundred square foot of structural steel to be field coated. The area computations do not include bearings, diaphragms, stiffeners and all other miscellaneous steel within the limits of the field coatings.

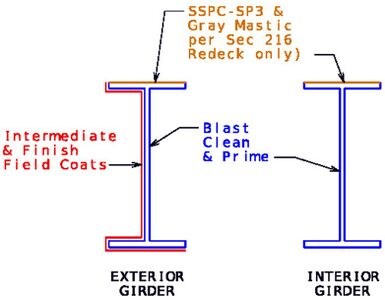

1. Bridges over Roadways (does not include over Railroads)

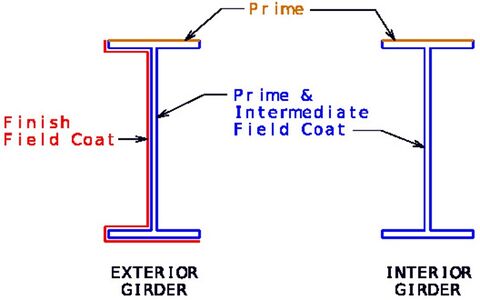

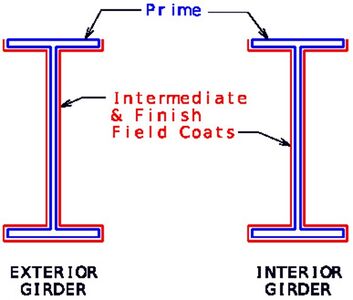

The intermediate field coat for System G and H and the finish field coat for System L for beam and girder spans shall be applied to the surfaces of all structural steel except those surfaces to be in contact with concrete. The field coat shall also be applied to the bearings, except where bearings will be encased in concrete.

The finish field coat for System G or H for beam and girder spans shall include the facia girders or beams. The limits of the facia girders or beams shall include the bottom of the top exterior flanges, the top of the bottom exterior flanges, the exterior web area, the exterior face of the top and bottom flanges, and the bottom of the bottom flange. Areas of steel to be in contact with concrete shall not receive the finish coat. The finish coat shall also be applied to the exterior bearings, except where bearings will be encased in concrete.

The surfaces of all structural steel located under expansion joints of beam and girder spans shall be field coated with intermediate and finish coats for a distance of one and a half times the girder depth, but not less than 10 feet from the center line of the joint. Within this limit, the items to be field coated shall include all surfaces of beams, girders, bearings, diaphragms, stiffeners and miscellaneous structural steel items. Areas of steel to be in contact with concrete shall not receive the field coats.

When System I finish field coat is specified on the plans with System G intermediate coat, System I finish field coat quantity will be figured the same as above for the finish field coat for System G or H. System G intermediate coat with System I finish field coat will be as above for the intermediate field coat except that the area of the System I finish field coat will not be included in the System G intermediate field coat area. When the plans state System I finish field coat shall be substituted for System G intermediate coat, System I finish field coat quantity will be figured for all girder surfaces as discussed above for finish field coat area for System L.

| New Non-Weathering Bridge Over Roadway | ||

|

| |

| Typical Coating for System G | Coating Near Deck Joints (System G) | |

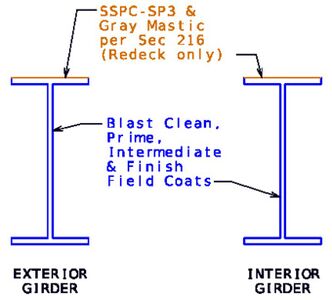

2. Bridges over Streams and Bridges over Railroads

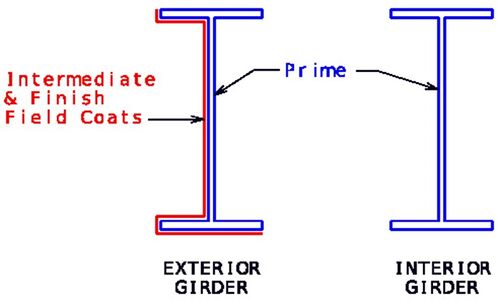

The field coatings (including intermediate and finish coats) for beam and girder spans shall include the facia girders or beams. The limits of the facia girders or beams shall include the bottom of the top exterior flanges, the top of the bottom exterior flanges, the exterior web area, the exterior face of the top and bottom flanges, and the bottom of the bottom flange. Areas of steel to be in contact with concrete shall not receive the field coats. The field coatings shall also be applied to the exterior bearings, except where bearings will be encased in concrete. The interior beams or girders shall only have the prime coat applied with no other field coatings required.

The surfaces of all structural steel located under expansion joints of beam and girder spans shall be field coated with intermediate and finish coats for a distance of one and a half times the girder depth, but not less than 10 feet from the center line of the joint. Within the limit, the items to be field coated shall include all surfaces of beams, girders, bearings, diaphragms, stiffeners and miscellaneous structural steel items. Areas of steel to be in contact with concrete shall not receive the field coats.

When System I or L is specified, the intermediate field coat will not be required.

| New Non-Weathering Bridge Over Stream or Railroad | ||

|

| |

| Typical Coating for System G | Coating Near Deck Joints (System G) | |

Coating New Truss Bridges or Other Unusual Structures

Intermediate Field Coat and Finish Field Coat (System G, H, I or L) (Gray or Brown) - The quantity shall be computed as a lump sum quantity.

All structural steel for truss or steel box girder spans shall be field coated with intermediate and finish coats, except the area of steel to be in contact with concrete. Intermediate field coat is not required when System I or L is specified.

Recoating Existing Multi-Girder/Beam Bridges

Quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or coated. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings.

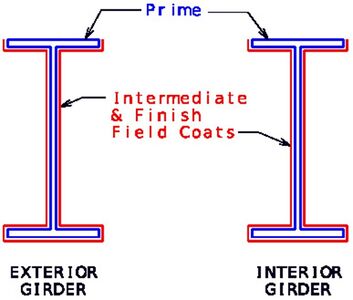

1. Surface Preparation for Recoating Structural Steel - Preparation shall include the surfaces of all structural steel except areas to be in contact with concrete.

2. Field Application of Inorganic or Organic Zinc Primer - Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel.

3. Intermediate Field Coat (System G or H) (Gray or Brown) - Coverage shall meet the same requirements as new multi-girder/beam bridges.

4. Finish Field Coat (System G, H, I or L) (Gray or Brown) - Coverage shall meet the same requirements as new multi-girder/beam bridges.

| Existing Non-Weathering Bridge | ||

|

| |

| Typical Recoating Over Roadway for System G or H | Typical Recoating Over Stream or Railroad for System G or H | |

| ||

| Recoating Near Deck Joints (System G or H) | ||

Recoating Existing Truss Bridges or other Unusual Structures

Quantities shall be computed as lump sum quantities. The approximate weight of steel shall be shown to the nearest ton in the contract documents.

1. Surface Preparation for Recoating Structural Steel - Preparation shall include the surfaces of all structural steel except areas to be in contact with concrete.

2. Field Application of Inorganic or Organic Zinc Primer – Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel.

3. Intermediate Field Coat (System G or H) (Gray or Brown) – Coverage shall meet the same requirements as new truss bridges.

4. Finish Field Coat (System G, H, I or L) (Gray or Brown) – Coverage shall meet the same requirements as new truss bridges.

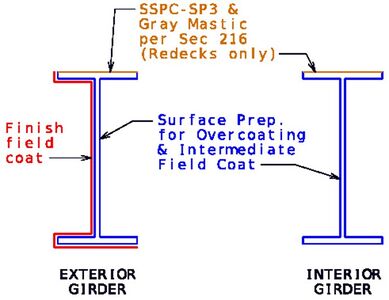

Overcoating Existing Multi-Girder/Beam Bridges

Quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or overcoated except as noted below. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. Partial overcoating of steel structures is allowed and the areas of partial overcoating should be clearly indicated on the plans.

1. Surface Preparation for Overcoating Structural Steel (System G) - Preparation shall include the surfaces of all structural steel except areas to be in contact with concrete.

2. Intermediate Field Coat (System G) - Coverage shall meet the same requirements as Surface Preparation for Overcoating Structural Steel (System G).

3. Finish Field Coat (System G) - Coverage shall meet the same requirements as new bridges.

| ||

| Overcoating Existing Non-Weathering Bridge (System G) |

Limits of Paint Overlap

Refer to EPG 751.50 Note A4a1.24. The figure below with note is available in a CADD cell. Detail should be modified as necessary for paint systems other than System G.

751.6.2.12 Structural Steel Protective Coatings (Weathering Steel)

Coating New Multi-Girder/Beam Bridges, Truss Bridges or other Unusual Structures

There will not be a quantity item for coating weathering steel. The cost of coating weathering steel structures will be considered completely covered by the contract unit price for the Fabricated Structural Steel.

Recoating Existing Multi-Girder/Beam Bridges, Truss Bridges or other Unusual Structures

Recoating weathering steel when performing joint repair/replacement may be included on the contract plans. Other areas may be recoated depending upon inspection of the condition of weathering steel and the future deterioration expectations of same by Bridge Maintenance. See Structural Project Manager or Structural Liaison Engineer.

For existing multi-girder/beam bridges, quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or recoated. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. For truss bridges or other unusual structures, quantities shall be computed as lump sum quantities.

1. Surface Preparation for Recoating Structural Steel - Preparation shall be on a case-by-case basis except areas to be in contact with concrete.

2. Field Application of Inorganic or Organic Zinc Primer - Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel.

3. Intermediate Field Coat (System G) (Brown) - Coverage shall be on a case-by-case basis.

4. Finish Field Coat (System G, I or L) (Brown) - Coverage shall be on a case-by-case basis.

751.14.5.8 Protective Coating Requirements

Coating requirements for new steel girder bridge shall be in accordance with Sec 1080 and Sec 1081. See EPG 751.1.2.9.2, EPG 751.6.2.11 and EPG 751.6.2.12 for additional guidance.

System G (three-coat system) may be used for non-weathering steel and weathering steel structures (Sec 1081). System G typically is not preferred when overlapping an existing vinyl coating but may be allowed if the existing coating is determined to be in good condition. System G uses a solvent based finish coat which may cause issues when overlapping an existing solvent-based vinyl coating system (System C) because it may re-wet the existing coating and cause delamination of the base coat. If the existing coating is in good condition as determined by paint pull-off tests the intermediate epoxy coating will provide a reliable barrier between the solvent-based coatings. Consult the structural project manager or structural liaison engineer before using System G near existing vinyl coatings.

System G has replaced calcium sulfonate as the preferred overcoating system. To ensure sufficient bond of the existing coating, adhesion pull-off tests shall be performed in accordance with ASTM D4541. If the adhesion test fails, as determined by the engineer of record, then overcoating shall not be allowed and recoating should be considered.

System H (three-coat system) is typically used when the bond for System G is considered questionable where recoating operations will take place near an existing vinyl coating system (System C). System H uses a waterborne acrylic for the intermediate and finish field coats that does not tend to interfere with the solvent-based vinyl coating.

System I (two-coat system) may be used for non-weathering and weathering steel and should be based on the following guidance:

- (a) System I should be considered in areas where the aesthetics of a coating system over the long term is critical. While System G, L and I provide long term protection, System I has excellent gloss retention and UV resistance. System I is a context sensitive design (CSD) solution. CSD follows from project scoping and is subject to the project core team protocols.

- (1) Consider for locations where the structure is more visible or the public has leisurely time for more than just a casual glance, for example structures near a ballpark or a pedestrian bridge. Using same rationale, bridges that are tall or have wide girder spacing or a low number of girders where more of the superstructure is visible could also be candidates.

- (2) Consider the image consciousness of the surroundings in conjunction with rather than solely the protection of the structure which is equally provided by systems G and I. Maintenance of either System G or I should be considered the same. Reduced maintenance is an expectation for System L.

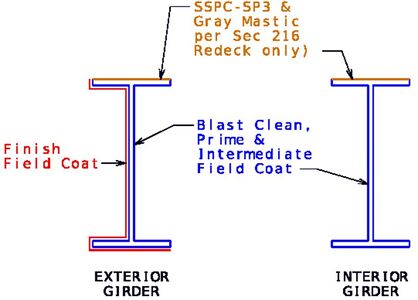

- (b) System I is a polysiloxane finish coat that is normally applied directly over an inorganic or organic zinc primer with no intermediate coating. Since the system is a two-coat system, it may be applied in less time which can influence critical path scheduling and impacts to the driving public. For example, it may be possible for a contractor to get in and out quicker than if they were to use a three-coat system. MoDOT coating policy as described in Standard Specification Section 1081 requires different field coating requirements based on the type of bridge crossing. For roadway grade separations, it is required that interior girders have only a single field coat in order to satisfy that all girders on a roadway grade separation bridge have at least two coatings for protection. In the case of System I, the Standard Specifications require that a System G epoxy intermediate field coat be applied to all interior girders and the interior of fascia girders and that the System I polysiloxane finish coating be applied to the exterior of the facia girders only. This is based on a system I polysiloxane coating cost being greater than a system G epoxy coating on a per-gallon cost basis. It also requires that the contractor be given the option to substitute the System I finish coat in place of a System G intermediate coat. If CSD determines that the polysiloxane should be applied to all girders, then the general notes for coatings and the quantities on the contract plans will need to reflect the revised coating requirements.

- (c) System I is approved for use on state highway projects beginning February 2011. Alternate bidding is encouraged if guideline (a) is not required to be met and with approval of the Structural Project Manager or Structural Liaison Engineer and the project core team.

System L (two-coat system) may be used for non-weathering steel and weathering steel structures. System L requires an inorganic zinc primer so organic zinc shall not be substituted. Testing indicates that System L is expected to outlast System G, H or I coatings when properly applied. Since the system is a two-coat system, it may be applied in less time which can influence critical path scheduling and impacts to the driving public. Similarly, the expectation for reduced maintenance should be considered for areas where access is limited or impactful (e.g., over railroads and interstates).

Inorganic zinc primer shall be used for new steel fabrication with System G, I or L coatings. For recoating operations with System G, H or I, where closure time has severe impacts on cost or safety, organic zinc primer should be considered as a direct replacement for the inorganic zinc required in the specifications. Organic zinc primers require a lower level of surface preparation (SSPC-SP6: commercial blast cleaning vs SSPC-SP10: near white blast cleaning) and are generally easier to apply in the field than inorganic zinc primers. Only organic zinc primers that can provide a Class B slip coefficient are allowed for use in recoating operations.

See EPG 751.50 A4. Protective Coatings for standard detailing notes and guidance on how they are used.

Epoxy-mastic primers may be used for overcoating lead-based coatings if the existing coating is determined to be in good condition, but this is considered a short-term solution in comparison to System G overcoating. Consult the structural project manager or structural liaison engineer before using epoxy-mastics near existing lead-based coatings.

Galvanized non-weathering structural steel beams, girders, bracing and diaphragms may be used as required or allowed by alternate, on a case-by-case basis, with approval of the Structural Project Manager or Structural Liaison Engineer and the project core team.

When galvanized structural steel is required, place note EPG 751.50 (A4a1.8.2a) on the plans. Do not use notes EPG 751.50 (A4a1.1 – A4a1.7). When galvanized structural steel is bid as an alternate, place notes EPG 751.50 (A4a1.8.1a, A4a1.8.1b, and A4a1.8.1c) on the plans under the applicable coating new steel notes EPG 751.50 (A4a1.1-A4a1.7).

A4. Protective Coatings

A4a. Structural Steel Protective Coatings

In "General Notes:" section of plans, place the following notes under the heading "Structural Steel Protective Coatings:".

A4a1. Steel Structures-Nonweathering Steel

Coating New Steel (Notes A4a1.1 – A4a1.7)

(A4a1.1) Use the 2nd underlined option for grade separations where System I finish field coat is only required on the fascia surfaces per Sec 1081. “System I” may be used for water crossings or where note A4a1.3 is used.

- Protective Coating: System G System I Prime Coat with System I Finish Field Coat and System G Intermediate Field Coat System I System L in accordance with Sec 1081.

(A4a1.2)

- Prime Coat: The cost of the inorganic zinc prime coat will be considered completely covered by the contract unit price for the fabricated structural steel.

(A4a1.3) For grade separations where System I is preferred for all girder surfaces and not just the fascia surfaces.

- System I finish coat shall be substituted for System G intermediate coat in Sec 1081.10.3.4.1.5.

(A4a1.4) The coating color shall be as specified on the Design Layout. When System L or note (A4a1.3) is used, omit the 2nd sentence.

- Field Coat(s): The color of the field coat(s) shall be Gray (Federal Standard #26373) Brown (Federal Standard #30045) Black (Federal Standard #17038) Dark Blue (Federal Standard #25052) Bright Blue (Federal Standard #25095). The cost of the intermediate field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Intermediate Field Coat (System G). The cost of the finish field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Finish Field Coat (System G I L) .

(A4a1.5) When System L is specified, System I is specified for water crossings or when note (A4a1.3) is used, omit the underlined part.

- At the option of the contractor, the intermediate field coat and finish field coat may be applied in the shop. The contractor shall exercise extreme care during all phases of loading, hauling, handling, erection and pouring of the slab to minimize damage and shall be fully responsible for all repairs and cleaning of the coating systems as required by the engineer.

(A4a1.6) Use for structures with Access Doors

- Structural steel access doors shall be cleaned and coated in the shop or field with a minimum of two coats of inorganic zinc primer to provide a total dry film thickness of 4 mils minimum, 6 mils maximum. In lieu of coating, the access doors may be galvanized in accordance with ASTM A123 and AASHTO M 232 (ASTM A153), Class C. The cost of coating or galvanizing doors will be considered completely covered by the contract unit price for other items.

(A4a1.7) Use for structures with Access Doors and when a fabricated structural steel pay item is not included.

- Payment for furnishing, coating or galvanizing and installing access doors and frames will be considered completely covered by the contract unit price for other items.

(A4a1.8.1) Place the following notes on the plans when alternate galvanized structural steel protective coating is approved by SPM.

- (A4a1.8.1a) Place the following note under the notes for “Structural Steel Protective Coatings”.

- Alternate A Structural Steel Protective Coating:

- Structural steel shall be galvanized in accordance with ASTM A123 and Sec 1081.

- (A4a1.8.1b) In "General Notes:" section place the following note under the heading "Miscellaneous:”

- Alternate bids for structural steel coating shall be completed.

- (A4a1.8.1c) Place following information at bottom part of “Estimated Quantities” table. (At least four (4) blank rows should be left at bottom of table to allow for additional entries in the field.)

| Estimated Quantities | |||

|---|---|---|---|

| Item | Substr. | Superstr. | Total |

| Last Pay Item | |||

| Blank | |||

| ADD ALTERNATE A: | |||

| Galvanizing Structural Steel lump sum | 1 | ||

| Blank | |||

| Blank | |||

| Blank | |||

| Blank | |||

(A4a1.8.2) Place the following note instead of notes A4a1.1 – A4a1.7 on the plans when galvanized structural steel protective coating is approved by SPM.

- (A4a1.8.2a)

- Structural steel shall be galvanized in accordance with ASTM A123 and Sec 1081.

Recoating Existing Steel (Notes A4a1.9 - A4a1.13)

(A4a1.9) Use the 2nd underlined option for grade separations where System I finish field coat is only required on the fascia surfaces per Sec 1081. “System I” may be used for water crossings or where note A4a1.13 is used.

- Protective Coating: System G System I Prime Coat with System I Finished Field Coat and System G Intermediate Field Coat System I System L in accordance with Sec 1081.

(A4a1.10) Use primer specified on the Design Memorandum. System L must be used with inorganic zinc primer only.

- Surface Preparation: Surface preparation of the existing steel shall be in accordance with Sec 1081 for Recoating of Structural Steel (System G, H, I or L) with organic inorganic zinc primer. The cost of surface preparation will be considered completely covered by the contract lump sum unit price per sq. foot for Surface Preparation for Recoating Structural Steel.

(A4a1.11)

- Prime Coat: The cost of the prime coat will be considered completely covered by the contract lump sum unit price per sq. foot for Field Application of Inorganic Organic Zinc Primer.

(A4a1.12) The coating color shall be as specified on the Design Layout. When System L or note (A4a1.13) is used, omit the 2nd sentence.

- Field Coat(s): The color of the field coat(s) shall be Gray (Federal Standard #26373) Brown (Federal Standard #30045) Black (Federal Standard #17038) Dark Blue (Federal Standard #25052) Bright Blue (Federal Standard #25095). The cost of the intermediate field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Intermediate Field Coat (System G). The cost of the finish field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Finish Field Coat (System G I L).

(A4a1.13) For grade separations where System I is preferred for all girder surfaces and not just the fascia surfaces.

- System I finish coat shall be substituted for System G intermediate coat in Sec 1081.10.3.4.1.5.

(A4a1.14) Use for recoating truss bridges.

| The length of span that is permissible to drape is to be determined by the designer and given in the note. Typically, ¼ span length is used but greater lengths have been used in the past based on calculations. See Structural Project Manager or Structural Liaison Engineer. |

- For the duration of cleaning and recoating the truss spans, the truss span superstructure in any span shall not be draped with an impermeable surface subject to wind loads for a length any longer than 1/4 the span length at any one time regardless of height of coverage. Simultaneous work in adjacent spans is permissible using the specified limits in each span.

Overcoating Existing Steel (Notes A4a1.21 – A4a1.27)

(A4a1.21) Include underlined portion when overcoating an existing vinyl coating (System C).

- Protective Coating: System G in accordance with Sec 1081 except thinners are not permitted.

(A4a1.22)

- Surface Preparation: Surface preparation of the existing steel shall be in accordance with Sec 1081 for Overcoating of Structural Steel. The cost of surface preparation will be considered completely covered by the contract lump sum unit price per sq. foot for Surface Preparation for Overcoating Structural Steel (System G).

(A4a1.23) The 2nd underlined portion in the first sentence is applicable only for bridges over streams and railroads.

- Field Coat(s): The color of the field overcoat shall be Gray (Federal Standard #26373) Brown (Federal Standard #30045) Black (Federal Standard #17038) Dark Blue (Federal Standard #25052) Bright Blue (Federal Standard #25095) and shall be applied in accordance with Sec 1081.10.3.4, except that all structural steel shall have the intermediate field coat applied in accordance with Sec 1081.10.3.4.1.1. The cost of the intermediate field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Intermediate Field Coat (System G). The cost of the finish field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Finish Field Coat (System G).

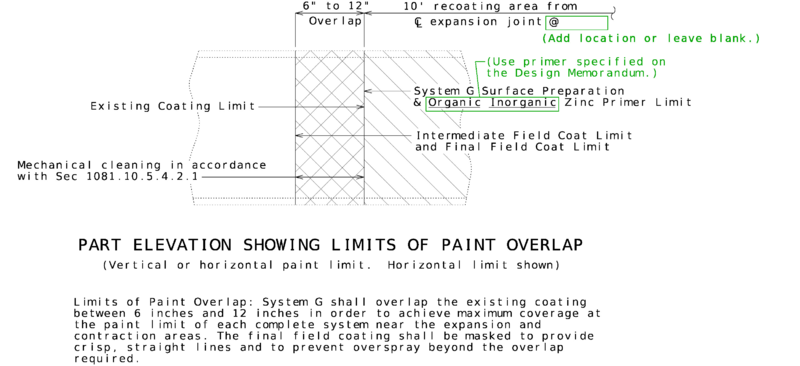

(A4a1.24) Use when new coating system overlaps existing coating system. Show detail on plans.

- Limits of Paint Overlap: System G shall overlap the existing coating between 6 inches and 12 inches in order to achieve maximum coverage at the paint limit of each complete system near the expansion and contraction areas. The final field coating shall be masked to provide crisp, straight lines and to prevent overspray beyond the overlap required.

A4a2. Steel Structures- Weathering Steel

Coating New Steel (Notes A4a2.1 - A4a2.3)

(A4a2.1)

- Protective Coating: System G I L in accordance with Sec 1080.

- Prime Coat: The cost of the inorganic zinc prime coat will be considered completely covered by the contract unit price for the fabricated structural steel.

(A4a2.2)

- Field Coats: The color of the field coats shall be Brown (Federal Standard #30045). The cost of the intermediate and finish field coats will be considered completely covered by the contract unit price for the fabricated structural steel.

(A4a2.3)

- At the option of the contractor, the intermediate and finish field coats may be applied in the shop. The contractor shall exercise extreme care during all phases of loading, hauling, handling, erection and pouring of the slab to minimize damage and shall be fully responsible for all repairs and cleaning of the coating systems as required by the engineer.

Recoating Existing Steel (A4a2.10 – A4a2.13)

(A4a2.10)

- Protective Coating: System G I L in accordance with Sec 1080.

(A4a2.11) Use primer specified on Design Memorandum. System L must be used with inorganic zinc primer only.

- Surface Preparation: Surface preparation of the existing steel shall be in accordance with Sec 1080 and Sec 1081 for Recoating of Structural Steel (System G, H or I) with inorganic organic zinc primer. The cost of surface preparation will be considered completely covered by the contract lump sum unit price per sq. foot for Surface Preparation for Recoating Structural Steel.

(A4a2.12)

- Prime Coat: The cost of the prime coat will be considered completely covered by the contract lump sum unit price per sq. foot for Field Application of Inorganic Organic Zinc Primer.

(A4a2.13) The coating color shall be as specified on the Design Layout. When System L or I is specified, omit the 2nd sentence.

- Field Coats: The color of the field coats shall be Brown (Federal Standard #30045). The cost of the intermediate field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Intermediate Field Coat (System G). The cost of the finish field coat will be considered completely covered by the contract lump sum unit price per sq. foot for Finish Field Coat (System G I).

A4a3. Miscellaneous

(A4a3.1) Use for weathering steel or concrete structures with girder chairs and when a coating pay item is not included.

- Structural steel for the girder beam chairs shall be coated with not less than 2 mils of inorganic zinc primer. Scratched or damaged surfaces are to be touched up in the field before concrete is poured. In lieu of coating, the girder beam chairs may be galvanized in accordance with ASTM A123. The cost of coating or galvanizing the girder beam chairs will be considered completely covered by the contract unit price for other items.

(A4a3.2) Use when recoating existing exposed piles. (Guidance: "Aluminum" is preferred because it acts as both a barrier and corrosion protection where "Gray" only acts as a barrier. If for any reason coated pile is embedded in fresh concrete, "Aluminum" shall not be used.)

- All exposed surfaces of the existing structural steel piles and sway bracing shall be recoated with one 6-mil thickness of aluminum gray epoxy-mastic primer applied over an SSPC-SP3 surface preparation in accordance with Sec 1081. The bituminous coating shall be applied one foot above and below the existing ground line and in accordance with Sec 702. These protective coatings will not be required below the normal low water line. The cost of surface preparation will be considered completely covered by the contract lump sum price for Surface Preparation for Applying Epoxy-Mastic Primer. The cost of the aluminum gray epoxy-mastic primer and bituminous coating will be considered completely covered by the contract lump sum price for Aluminum Gray Epoxy-Mastic Primer.

A4b. Concrete Protective Coatings

A4b1. Concrete Protective Coatings

In "General Notes:" section of plans, place the following notes under the heading "Concrete Protective Coatings:".

(A4b1.1) Use note with weathering steel structures.

- Temporary coating for concrete bents and piers (weathering steel) shall be applied on all concrete surfaces above the ground line or low water elevation on all abutments and intermediate bents in accordance with Sec 711.

(A4b1.2) Use note with coating for concrete bents and piers either urethane or epoxy.

- Protective coating for concrete bents and piers (Urethane) (Epoxy) shall be applied as shown on the bridge plans and in accordance with Sec 711.

(A4b1.3) Use note when specified on Design Layout.

- Concrete and masonry protective coating shall be applied on all exposed concrete and stone areas in accordance with Sec 711.

(A4b1.4) Use note when specified on Design Layout.

- Sacrificial graffiti protective coating shall be applied on all exposed concrete and stone areas in accordance with Sec 711.

1045 Paint for Structural Steel

This article establishes procedures for inspecting, sampling and reporting paint and paint constituents. Refer to Sec 1045 for MoDOT’s specifications.

Discussions on non-standard colors of structural steel paint and color of structural steel paint policies are available.

For Laboratory testing and sample reporting procedures, refer to EPG 1045.6 Laboratory Testing Guidelines for Sec 1045.

1045.1 Apparatus

All sample containers and equipment used in sampling paint and paint constituents shall be clean and free of all contaminants. The apparatus required shall consist of:

(a) Appropriate size and type of sample container as given in the following subsections for the type of paint to be sampled.

(b) Appropriate thief or sampling device to obtain a representative sample.

(c) Packaging and labeling materials as described in EPG 106.3.1.2.2 Transportation of Samples and EPG 106.3.1.3 Sampling Supplies.

1045.2 Procedure

Samples shall be taken by, or under the direct supervision of, the inspector, using all possible caution, skill and judgment to ensure that a representative sample is obtained.

When sampling paint and paint constituents, take precautions to ensure that the samples are not contaminated or altered by any material not representative of the lot being sampled. Some paints or liquid constituents exhibit a tendency to settle or separate upon standing. Because of this, it is important to ensure that containers to be sampled, no matter the size container, is uniform prior to obtaining a sample. Mark all sample containers with the type of material, lot number, and the inspector's identification number. It is essential that samples of constituents be marked with the chemical names as called for in the given specification. Unless specifically requested, obtain only one random sample from each lot, batch, day's pack or other unit of production. In cases where several small lots are uniformly mixed in a larger mixer or tank, the mixed material shall be considered as one lot.

Whenever possible, obtain samples from original, unopened containers for all types of materials. When constituent containers have no markings distinguishing between units of production, take samples from different containers or storage units in the ratio of two samples for each 10,000 pounds (4500 kg) or portion thereof and blended in equal quantities to form a composite sample. Submit constituent samples only when requested by the Laboratory.

Packaging must comply with the applicable requirements of Sec 1045.

1045.2.1 Vehicle Constituents

When samples are requested by the Laboratory, ensure that the contents of the container or tank to be sampled has been thoroughly mixed. Fill the sample container, leaving approximately one inch (25 mm) space for expansion. Secure friction top lids with clips or other fastening devices before shipment. Observe shipping regulations when preparing samples for shipment.

1045.2.2 Pigments

When the Laboratory requests samples, open the package or storage container and take a sample at random from the contents.

1045.2.3 Mixed Paints

Sample containers are one quart (1 L), friction top cans and should be filled, leaving approximately one inch (25 mm) space for expansion. The inspector may mark and submit an original, unopened container of paint to the Laboratory in cases where the containers are small, such as quarts (L) or gallons (L). When an original container of paint cannot be sent to the Laboratory and there are no facilities for mixing or shaking the material mechanically, the inspector must ensure a representative sample by the following steps:

(a) Pour off the top liquid into a clean, suitable container having a volume equal to or larger than the one being sampled.

(b) Stir the settled portion of the paint with a paddle, gradually reincorporating the poured off liquid in small quantities until all has been returned.

(c) Mix the paint by pouring it back and forth between the two containers several times.

(d) Obtain a sample promptly so that settling does not occur before the sample is obtained.

NOTE: This process is referred to as “boxing” the material.

When samples are taken during the filling of containers, obtain a composite sample by combining samples taken at the beginning, middle, and near the end of the operation.

Mechanically mix paint in holding tanks or 55 gallon (208 L) drums to ensure uniformity and sample promptly after mixing.

1045.2.4 Submission of Samples

Paint and some paint constituents require special handling. See EPG 106.3.1.2.2 Transportation of Samples and EPG 106.3.1.3 Sampling Supplies for packaging, labeling and marking instructions. Enter a Basic Sample Data report into AASHTOWARE Project (AWP) (see AWP MA Sample Record, General) for each sample of material submitted to the Laboratory. Include all pertinent information necessary to the sample, such as: kind of paint or constituent, batch or lot number, project number, purchase order or "general construction" for warehouse stock, inspector, source, quantity, intended use, contractor, destination, manufacturer's name and address.

1045.2.5 High Solids Inorganic Zinc Silicate Coating

Refer to the applicable requirements of Sec 1045 for requirements pertaining to prequalification. The list of paints that are qualified by manufacturer and brand name appears as Qualified High Solids Inorganic Zinc Silicate Paints. Sample each batch or lot of each component. A sample consists of one pint (500 mL) of inorganic silicate vehicle, one pint (500 mL) of metallic zinc powder and four ounces (120 mL) of activator component. Note that the activator is not to be sampled in metal containers and will be required only when sampling 3-component, high-solids primer. Submit the samples to the Laboratory through AWP, including the brand name, the batch or lot number of each component and the net weight (mass) shown on the container of each component.

1045.2.6 Polyurethane System G Final Coating

Refer to the applicable requirements of Sec 1045 for requirements pertaining to prequalification. The list of paints that are qualified by manufacturer and brand name appears as Qualified Epoxy\Polyurethane Paints. Sample each batch or lot of each component. A sample consists of each component in the approximate volume proportions recommended by the manufacturer so that the mixed sample will consist of at least one quart (1 L). Submit the samples to the Laboratory through an AWP record, including the brand name, the batch or lot number of each component, and the net weight (mass) shown on the container of each component.

1045.2.7 High Solids Epoxy Intermediate Coat

Refer to the applicable requirements of Sec 1045 for requirements pertaining to prequalification. The list of paints that are qualified by manufacturer and brand name appears as Qualified Epoxy\Polyurethane Paints. Sample each batch or lot of each component. A sample consists of one pint (500 mL) of each component. Submit the samples to the Laboratory using an AWP record, including the brand name, batch or lot number of each component, and the net weight (mass) as shown on the container of each component.

1045.2.8 Waterborne Acrylic System H Intermediate and Finish Coating

Refer to the applicable requirements of Sec 1045 for requirements pertaining to prequalification. The list of paints that are qualified by manufacturer and brand name appears as Qualified Waterborne Acrylic Paints. Sample each batch or lot of each intermediate or finish coat. A sample consists of one quart (1 L) in a friction top can. Submit the sample to the Laboratory through an AWP record, including the brand name, the batch or lot number of each component, and the net weight (mass) shown on the container.

1045.2.9 Aluminum Epoxy Mastic Primer

Refer to Sec 1045 for requirements pertaining to prequalification. Aluminum epoxy mastic primer is not suitable for use in contact with freshly poured concrete. Brands that have been qualified are listed in Qualified Aluminum Epoxy Mastic Paint. Sample each batch or lot submitted for use. A sample consists of one pint (500 mL) of each component in friction top cans. Submit the sample to the Laboratory through an AWP record, including the brand name, batch or lot number(s) of each component, and the weight (mass) shown on each container.

1045.2.10 Gray Epoxy Mastic Primer

Refer to Sec 1045 for requirements pertaining to prequalification. Gray epoxy mastic primer may be used in lieu of aluminum epoxy mastic. The list of paints that have been qualified by manufacturer and brand name are listed in Sec 1045. Each batch or lot submitted for use shall be sampled. A sample consists of one pint (500 mL) of each component in friction top cans. Submit the sample to the Laboratory through an AWP record, including the brand name, batch or lot number(s) of each component, and the weight (mass) shown on each container.

1045.2.11 Organic Zinc-Rich Coating

Refer to the applicable requirements of Sec 1045 for requirements pertaining to prequalification. The list of paints that are qualified by manufacturer and brand name appears as Qualified Organic Zinc Paints. Sample each batch or lot of each component. A sample consists of one pint (500 mL) of organic vehicle, one pint (500 mL) of metallic zinc powder and four ounces (120 mL) of activator component. Note that the activator is not to be sampled in metal containers and will be required only when sampling 3-component, high-solids primer. Submit the samples to the Laboratory through AWP, including the brand name, the batch or lot number of each component and the net weight (mass) shown on the container of each component.

1045.2.12 High Solids Inorganic Ethyl Silicate Coating

Refer to the applicable requirements of Sec 1045 for requirements pertaining to prequalification. The list of paints that are qualified by manufacturer and brand name appears as Qualified High Solids Inorganic Ethyl Silicate Paints. Sample each batch or lot submitted for use. A sample consists of one pint (500 mL) in a friction top can. Submit the sample to the Laboratory through an AWP record, including the brand name, the batch or lot number of each component, and the net weight (mass) shown on the container of each component.

1045.3 Acceptance

Confirm that the paint is on the current approved list and that the paint is within its shelf life. Obtain a certification specific to the batch of paint, with lot or batch numbers, date of manufacture and quantity represented by the certification. Confirm that the lot or batch of paint has been sampled and approved by the Laboratory. If not, sample the paint and submit it for approval prior to use.

1045.4 Sample Record

The Laboratory will issue the reports for samples submitted to the Laboratory. Sample records indicating acceptance for project use will typically state “Prior Approval or Acceptance”, and will include the information provided in the certification, and where the certification is filed.