903.4 Overhead Sign Mounting

Contents

- 1 903.4.1 Overhead Sign Installations (MUTCD Section 2A.17)

- 2 903.4.2 Locating Support Structures

- 3 903.4.3 Lateral Offset

- 4 903.4.4 Vertical Clearances (MUTCD Section 2A.18)

- 5 903.4.5 Guardrail

- 6 903.4.6 Span, Cantilever and Butterfly Box Trusses

- 7 903.4.7 Tubular Steel Sign Supports

- 8 903.4.8 Bridge- and Wall-Mounted Signs

- 9 903.4.9 Bridge- and Wall-Mounted Structure Designs

- 10 903.4.10 Non-Standard Sign Support Structures

- 11 903.4.11 Sign Supports on Fill

- 12 903.4.12 Overhead Sign and Truss Inspection/Inventory

- 13 903.4.13 Structure Loading

903.4.1 Overhead Sign Installations (MUTCD Section 2A.17)

Guidance. Overhead guide signs are warranted at many important locations and should be used on freeways and expressways, at locations where some degree of lane-use control is desirable and where space is not available at the roadside. It is recommended that justification be provided when mounting signs overhead.

Support. The factors to be considered for the installation of overhead sign displays are not definable in specific numerical terms.

Option. Warrants are not specific, but the following conditions, listed in no particular priority, may be considered:

- Traffic volume at or near capacity

- Complex interchange design

- Three or more lanes in each direction

- Restricted sight distance

- Closely spaced interchanges

- Multilane exits

- Large percentage of trucks

- Background of street lighting and advertising signs

- High-speed traffic

| Additional Information |

| General Procedure for Overhead Span Box Truss Design |

- Consistency of sign message location through a series of interchanges

- Insufficient space for post-mounted signs

- Junction of two freeways

- Left exit ramps

- Reduction of basic lanes

- EXIT ONLY lane drops

Over-crossing structures may be used to support overhead signs.

Support. Under some circumstances, the use of over-crossing structures as sign supports might be the only practical solution that will provide adequate viewing distance. The use of such structures as sign supports might eliminate the need for the foundations and sign supports along the roadside.

Standard. Trusses in paved medians with concrete traffic barrier shall be located to allow for barrier transitions and field adjustments of the underground storm culvert, if necessary.

Bridge Division shall design all bridge and wall mounted truss pedestals.

Guidance. Supplemental guide signs for traffic generators should not to be mounted overhead for any highway system and should not to be considered when determining whether to mount all guide signs overhead.

If a mix of situations exists on a route, where some locations require overheads and others do not, then all guide signs on the project should be mounted overhead. Mixing ground mounted guide signs with overhead guide signs is discouraged.

Truss pedestals of any type are not to be placed in pavement gores or other exposed locations. Every attempt should be made to avoid special truss pedestal and column designs. Whenever possible, trusses are not to be mounted on bridges or walls, and should be placed in areas that may already require guardrail or traffic barrier due to other obstacles. Truss locations should be checked against existing and proposed underground drainage and utilities for potential conflicts.

To minimize glare and sign obstructions, trusses should be located so that signs do not face roadway lighting units and traffic signals. When limited geometrics require numerous traffic control devices within a given area, a 300 ft. minimum should be maintained between the sign face and the stop bar location. This includes trusses located before or after the stop bar. For lighting units, the minimum distance between the front of a sign and the luminaire should be 75 feet. Signals, lighting and sign trusses should be coordinated to achieve the best layout and remain within the standards indicated in EPG 902 Signals.

Roadway geometrics may cause sign glare at night from vehicle headlights on parallel outer roads, service roads or the mainline. Headlights from a mainline vertical crest curve located before overhead signs may create sign glare, and if possible trusses should be located to reduce or eliminate this glare.

Roadway curvature should be considered when placing overhead guide signs with down arrows (Type C). Down arrows on the outside of a curve may give the illusion of pointing to a lane other than intended. Down arrows on the inside of a curve may appear to point down at the shoulder or side slope. Consideration should be given to move overhead guide signs out of curves, or provide additional advance overhead signs on tangent sections of roadway.

The pedestal location should be outside the clear zone. Normally, this may only be accomplished with span trusses. When this clearance is not economically feasible, the minimum horizontal clearance to the nearest part of the overhead sign support pedestal should be designed with an appropriate barrier according to the standard plans and the AASHTO Roadside Design Guide. Cantilever trusses with appropriate guardrail design should be used to mount single guide signs at the exit gore location.

Type A guardrail designed according to the standard plans and the AASHTO Roadside Design Guide should be used to shield traffic from truss pedestals. Type E guardrail should be used only when necessary for areas with limited horizontal clearance, and installed within the guidelines as shown in the standard plans. Trusses should be designed to eliminate the need for Type E guardrail.

Aluminum and steel span, combination span-cantilever, butterfly and cantilever box trusses should be used when the required span exceeds the 90 ft. maximum span of standard tubular supports, or when sign height, sign design area or sign spread exceeds the limits of tubular support designs.

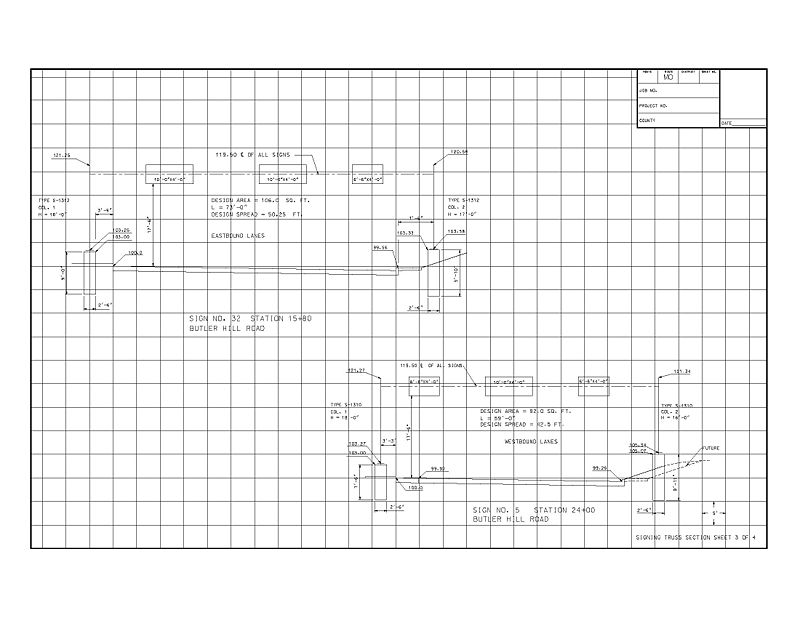

Column height "H" for box trusses should be shown to the nearest inch on the truss cross-section sheet. Pedestal heights should be designed as shown in the standard plans. Use an assumed elevation of 100 ft. at the highest point of the roadway create the truss cross-section, and the scale is 1 in. = 5 ft. (1:60). An assumed elevation will allow the movement of a truss over an area with the same template without adjusting all the elevations. Elevations to be shown (referenced to the assumed elevation) on the cross-section is to include: top of pedestal, top of footing, bottom of base plate and the centerline elevations of truss, signs and bottom chord. A 0.2 ft. elevation difference should be assumed between the bottom of base plate and top of pedestal for placement of expansive grout. The truss cross-section is to contain, at a minimum, the following information: truss number, station, roadway, column types, sign design area, overall truss length, pedestal and footing information, sign locations, guardrail and any signs to be strapped to the truss column. Columns should be numbered from left to right. Different column types are allowed for each column. Truss sections should be drawn as the driver views the main sign(s). If applicable, signs should be indicated as near and far side, the far side sign being shown with dashed lines. Lighting is not to be provided for any overhead sign. Provision should be made for hand holes and pedestal conduit, as shown in the standard plans.

Required information on cross-sections is similar to box truss cross-sections. For two-arm spans between 40 and 75 ft., post lengths should be in 3 in. increments. Post lengths for other designs should be in 1 ft. increments. The footing height above the ultimate ground line should be designed as shown in the standard plans. The footing height plus the post length provides the minimum vertical clearance of 17 ft. 6 in. and is to meet the minimum post length requirements.

Bridges should be utilized wherever possible to mount guide signs. This concept removes a potential roadside obstacle and any need for guardrail or concrete traffic barrier, and is generally more economical. The district should request Bridge to prepare details for bridge-mount sign support brackets after preliminary sign location approval. Bridge prepares plans that are included in the appropriate bridge details. Bridge is responsible for pay items and design of bridge- and wall-mounted sign support brackets on new bridges. When retrofitting an existing bridge with a new bracket, Bridge designs the bracket and submits the plan to the district for inclusion into the roadway plans.

The sign and sign brackets are designed to provide a clear distance of 2 ft. from the outside edge of the bridge to the edge of the sign. The sign is to have a maximum skew angle of 5 degrees to the roadway for which it is provided. The sign bracket is designed so that the sign is visible to traffic at least 1,000 ft. ahead of the installation.

For wall- and bridge-mounts, the district prepares and submits a truss cross-section to Bridge for their concurrence of location, column type and height. The sign dimensions and location over the roadway should be included with the request. The district coordinates design details with Bridge so that footing and pedestal details are included in the bridge or wall plans. Bridge is responsible for pay items and design of pedestals for bridge- and wall-mounted trusses. The district is responsible for the truss and column design and pay items.

When retrofitting an existing structure with a new truss, the preferred truss location and existing bridge- or wall-number should be submitted to Bridge along with the same data as required for a new bridge mounted truss. The incorporation of pay items is similar to new bridge-mounted trusses.

Option. Box span trusses may also support a cantilever support beyond one or both columns. This may help eliminate the need for a truss for the opposing traffic direction. Guide signs may be placed over the left hand lanes to utilize a span-cantilever design.

Signs may be raised above the standard vertical clearance to improve visibility and avoid other obstructions such as signal equipment.

Consideration may be given to placing guardrail at the edge of the clear zone to protect traffic from pedestals placed outside the clear zone.

Column height "H" for box trusses may be adjusted up 6 in. or down 3 in. during construction to meet field conditions. This will avoid any change in design height "H" of the prefabricated steel columns.

Columns for overhead sign trusses shorter than 10 ft. or taller than 30 ft. are nonstandard and require a special design. Column type may not be extrapolated from Figure 903.4.1.4 or Figure 903.4.1.5. Nonstandard columns shall be identified on the plans and details of special design shall be shown. (Do not identify a nonstandard column with a column type number from standard plans. Use a different number or call-out to identify column in order to avoid confusion.)

During construction the footing height may be adjusted up 6 in. or down 3 in. to match actual field conditions. This will avoid changes in the prefabricated post lengths and accommodate actual field conditions.

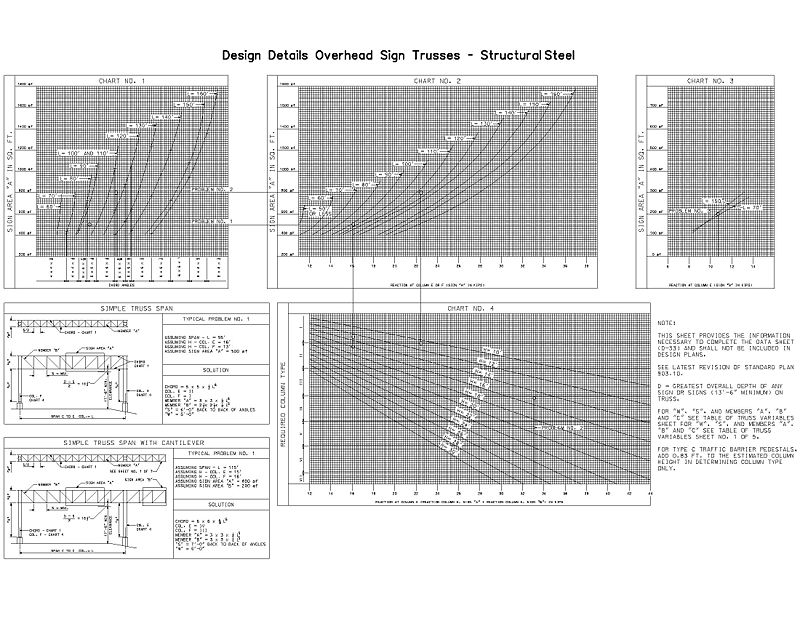

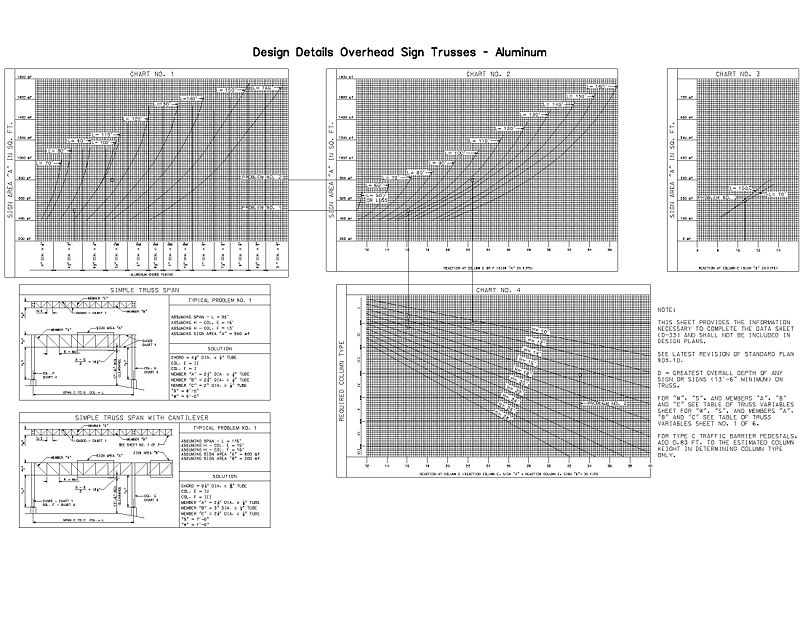

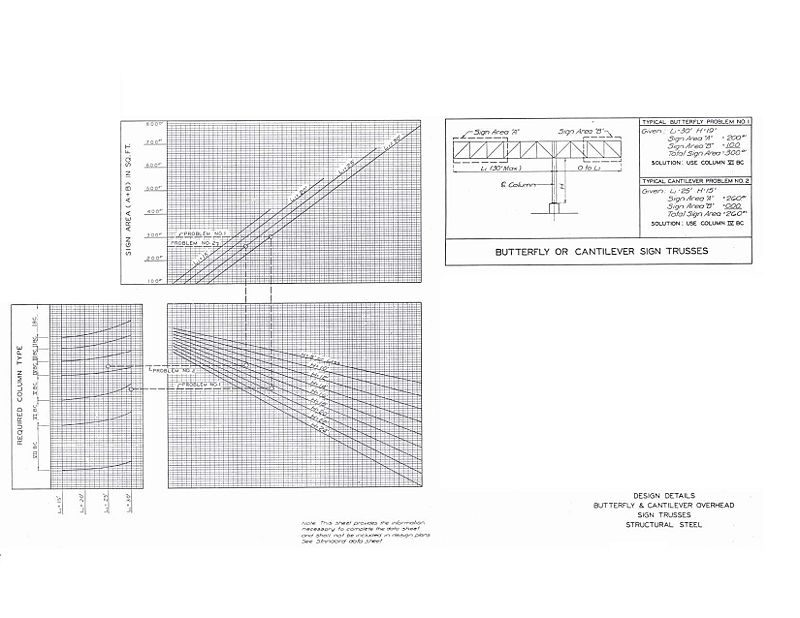

Support. Aluminum and steel span, combination span-cantilever, butterfly and cantilever box trusses are shown on the standard plans. Details necessary to complete truss data sheets for overhead trusses are obtained from Fig. 903.4.1.3 and 903.4.1.5. Design data for both aluminum and steel span box trusses are shown on Forms D-32 and D-33. The contractor has the option to use steel or aluminum for span designs. Steel box trusses are used without option for all types of bridge-mounted trusses and for all butterfly and cantilever trusses.

Truss designs for spans exceeding 160 ft., bridge-, wall- and any special mounting conditions are requested from Bridge. See other areas in this article for truss design procedures involving Bridge.

See Fig. 903.4.1.1 and General Procedure for Overhead Span Box Truss Design for examples of span, cantilever and butterfly box truss cross-sections.

Combination span-cantilever truss cross-sections require similar information. Tubular span, cantilever and butterfly sign supports are shown on the standard plans. Details necessary to complete Form D-34 are shown on various drawings on the standard plans. These structures have limiting design factors including sign height, total sign area and sign spread, as noted on each drawing. When any one of these limits is exceeded, box type trusses are used.

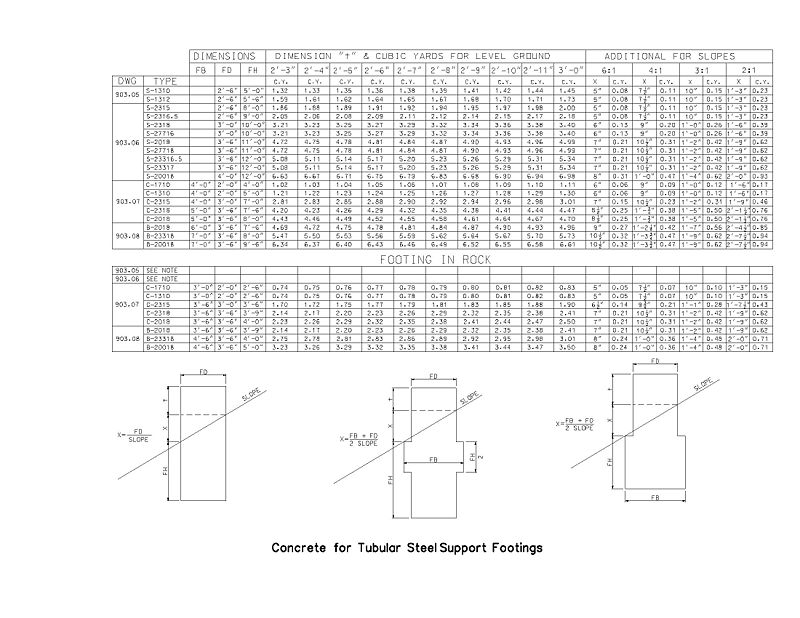

Quantities for concrete footings and various bolt-down heights and types of pedestals are shown in Fig. 903.4.1.4 and in the standard plans.

See Fig. 903.4.1.2 for an example of a one-arm span tubular truss cross-section. Other types of tubular designs require similar information as shown on this figure.

Special design details are required on spans greater than 160 feet. A truss cross-section is submitted to Bridge as required for any new truss. The district receives recommendations from the Bridge Division for special footing, pedestal, truss and column information. Unless otherwise noted, the district is responsible for including the information in the final plans.

903.4.2 Locating Support Structures

Support. Foundations of any type are not placed in pavement gores or other exposed locations. Every attempt is made to avoid special structure designs. Whenever possible, sign support structures are not mounted on bridges or walls, and are placed in areas which may already require guardrail or traffic barrier due to other obstacles.

Box span trusses (refer to Standard Plans 903.10 or 903.60) may also support a cantilever support beyond one or both columns. This may help eliminate the need for a structure for the opposing traffic direction. Guide signs may be placed over the left hand lanes to utilize a span-cantilever design.

Structure locations should be checked against existing and proposed underground drainage and utilities for potential conflicts. Structures in paved medians with concrete traffic barrier shall be located at a minimum of 150 ft. from median inlets to allow for barrier transitions and field adjustments of the underground storm culvert, if necessary.

903.4.3 Lateral Offset

Support. The preferred location of the exposed foundation is outside the clear zone. Normally, this may only be accomplished with span structures. When this clearance is not economically feasible, the minimum lateral offset to the nearest part of the exposed foundation is designed with an appropriate barrier according to the standard plans and the AASHTO Roadside Design Guide. Cantilever structures with appropriate guardrail design are used to mount single guide signs at the exit gore location.

Standard. For overhead sign supports, the minimum lateral offset from the edge of the shoulder (or if no shoulder exists, from the edge of the pavement) to the near edge of overhead sign supports (cantilever or sign bridges) shall be 6 feet. Overhead sign supports shall have a barrier or crash cushion to shield them if they are within the clear zone.

Guidance. Overhead sign supports should not intrude into the usable width of a sidewalk or other pedestrian facility.

903.4.4 Vertical Clearances (MUTCD Section 2A.18)

Standard. The provisions of this article shall apply unless specifically stated otherwise for a particular sign elsewhere in the EPG.

Overhead signs shall provide a vertical clearance of not less than 17 ft. 6 in. from the highest point of pavement or shoulder (including mountable curbs located within the shoulder limits) to the lowest point of the sign, light fixture or sign bridge over the entire width of the pavement and shoulders except where the structure on which the overhead signs are to be mounted or other structures along the roadway near the sign structure have a lesser vertical clearance. This applies to all types of overhead structures.

Option. Signs may be raised above the standard vertical clearance to improve visibility and avoid other obstructions such as signal equipment.

If the vertical clearance of other structures along the roadway near the sign structure is less than 16 ft., the vertical clearance to an overhead sign structure or support may be as low as 1 ft. higher than the vertical clearance of the other structures in order to improve the visibility of the overhead signs.

In special cases it may be necessary to reduce the clearance to overhead signs because of substandard dimensions in tunnels and other major structures such as double-deck bridges.

Support. Bridge-mounted signs are no lower than the bridge, or 17 ft. 6 in., whichever clearance is lower.

Figure 903.2.26.1 illustrates some examples of the mounting height requirements contained in this portion of the article.

903.4.5 Guardrail

Support. Type A guardrail designed according to the standard plans and the AASHTO Roadside Design Guide is used to shield traffic from structure foundations. Type E guardrail is used only when necessary for areas with limited horizontal clearance, and installed within the guidelines as shown in the standard plans. Structures are designed to eliminate the need for Type E guardrail.

Consideration may be given to placing guardrail at the edge of the clear zone to protect traffic from pedestals placed outside the clear zone.

903.4.6 Span, Cantilever and Butterfly Box Trusses

Support. Aluminum and steel span, combination span-cantilever, butterfly and cantilever box trusses are shown on Standard Plans 903.10, 903.12 and 903.60. These types are used when the required span exceeds the 90 ft. maximum span of standard tubular supports, or when sign height, sign design area, or sign spread exceeds the limits of tubular support designs. Necessary information to complete truss data sheets for overhead trusses include:

Design data for both aluminum and steel span box trusses are shown on Forms D-32 and D-33. The contractor has the option to use steel or aluminum for span designs. Steel box trusses are used without option for all types of bridge-mounted trusses, and for all butterfly and cantilever trusses.

The standard foundation design in standard plans is a drilled shaft. A spread footing foundation design may also be used. Savings may be realized by basing the foundation design on actual sign area rather than maximum and also using site specific geotechnical information. Upon request, Bridge will determine the most cost effective design. Note that ample time must be allowed for this determination. See Guidelines for the Design of Miscellaneous Foundations in Bridge Reports and Layouts for the proper procedure.

Truss designs for spans exceeding 160 ft., bridge, wall and any special mounting conditions are requested from Bridge. See other areas in this section for truss design procedures involving the Bridge Division.

Column height, "H", for box trusses is shown to the nearest inch on the truss cross-section sheet. Exposed foundation heights are designed as shown in the standard plans. This height may be adjusted up 6 in. or down 3 in. during construction to meet field conditions. This will avoid any change in design height "H" of the prefabricated steel columns. An assumed elevation of 100 ft. at the highest point of the roadway is used to create the truss cross-section, and the scale is 1 in. = 5 ft. (1:60). An assumed elevation will allow the movement of a truss over an area with the same template without adjusting all the elevations. Elevations to be shown (referenced to the assumed elevation) on the cross-section include: top of foundation, top of footing (as applicable), bottom of base plate, the centerline elevations of truss and signs, the top of the top chord and the bottom of the bottom chord. The elevation difference between the bottom of base plate and top of pedestal for placement of expansive grout is approximately equal to the anchor bolt diameter + 1/2 inch. Refer to the standard plans for anchor bolt diameters. The truss cross-section contains, at a minimum, the following information: truss number, station, roadway, column types, sign design area, overall truss length, foundation information, sign locations, guardrail, and any signs to be strapped to the truss column. Columns are numbered from left to right. Different column types are allowed for each column. Truss sections are drawn as the driver views the main sign(s). If applicable, signs are indicated as near and far side, the far side sign being shown with dashed lines. Lighting is not provided for any overhead sign. Provisions are made for hand holes and foundation conduit, as shown in the standard plans, in case lighting is needed in the future.

Examples of cross-sections for cantilever, butterflyand span box trusses are available. Combination span-cantilever truss cross-sections require similar information.

903.4.7 Tubular Steel Sign Supports

Support. Tubular steel span, cantilever and butterfly sign supports are shown on Standard Plans 903.05, 903.06, 903.07 and 903.08. Details necessary to complete Form D-34 are shown on the standard plans. These structures have limiting design factors including sign height, total sign area, and sign spread, as noted on each drawing. When any one of these limits is exceeded, box type trusses are used.

Required information on cross-sections is similar to box truss cross-sections. For two arm spans between 40 and 75 ft., post lengths are in 3 in. increments. Post lengths for other designs are in 1 ft. increments. The foundation height above the ultimate ground line is designed as shown in the standard plans. During construction the foundation height may be adjusted up 6 in. or down 3 in. to match actual field conditions. This will avoid changes in the prefabricated post lengths and accommodate actual field conditions. The quantities of concrete for tubular steel support footings have been tabulated and are also shown in the standard plans (see Fig. 903.4.1.2).

Fig. 903.4.1.1 shows an example of a one-arm span tubular structure cross-section. Other types of tubular steel structure designs require similar information as shown on this figure.

903.4.8 Bridge- and Wall-Mounted Signs

Support. Bridges are utilized wherever possible to mount guide signs and, possibly, sign trusses. This concept removes a potential roadside obstacle and any need for guardrail or concrete traffic barrier, and is generally more economical. The district requests Bridge to prepare details for bridge-mount sign support brackets after preliminary sign location approval. Bridge prepares plans that are included in the appropriate bridge details. Bridge is responsible for bid items and design of bridge and wall-mounted sign support brackets on new bridges. When retrofitting an existing bridge with a new bracket, Bridge designs the bracket and submits the plan to the district for inclusion into the roadway plans.

The sign and sign brackets are designed to provide a clear distance of 2 ft. from the outside edge of the bridge to the edge of the sign. The sign has a maximum skew angle of 5 degrees to the roadway for which it is provided. The sign bracket is designed so the sign is visible to traffic at least 600 ft. ahead of the installation.

903.4.9 Bridge- and Wall-Mounted Structure Designs

Support. The Bridge Division designs all bridge- and wall-mounted structure pedestals.

For wall- and bridge-mounts, the district prepares and submits a sign support structure cross-section to Bridge for their concurrence of location, column type and height. The sign dimensions and location over the roadway are included with the request. The district coordinates design details with Bridge so pedestal details are included in the bridge or wall plans. Bridge is responsible for design of pedestals for bridge- and wall-mounted structures and related pay items. The district is responsible for the design of the structure above the pedestal and related bid items.

When retrofitting an existing bridge or wall with a new sign support structure, the preferred location and existing bridge or wall number is submitted to Bridge, along with the same data as required for a new bridge-mounted sign support structure. The incorporation of bid items is similar to new bridge-mounted sign support structures.

903.4.10 Non-Standard Sign Support Structures

Support. Special design details are required on spans greater than 160 ft. and other situations not covered by the Standard Plans. A truss cross-section is submitted to Bridge as required for any new truss. The district receives recommendations from Bridge for special foundation, truss, and column information. Design of non-standard structures should be in accordance with the latest version and latest interims of the AASHTO Standard Specifications for Structural Supports for Highway Signs, Luminaires and Traffic Signals. Unless otherwise noted, the district is responsible for including the information in the final plans.

903.4.11 Sign Supports on Fill

Support. The pole’s design height for overhead sign supports placed on elevated roadway fill is to include the height of the fill. Consult Bridge if the pole’s design height exceeds the values shown in the standard plans.

903.4.12 Overhead Sign and Truss Inspection/Inventory

Option. Sign truss inspection may be made by consultant as determined by Bridge Division.

Standard. Bridge Division shall determine the frequency of inspection for all sign trusses and shall maintain the sign truss inventory.

903.4.13 Structure Loading

Support. There is a maximum signage area allowed for each structure. For changes in signing call Traffic for assistance and review.