User talk:Hoskir

REVISION REQUEST 4036

106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity

1. Chemical Analysis

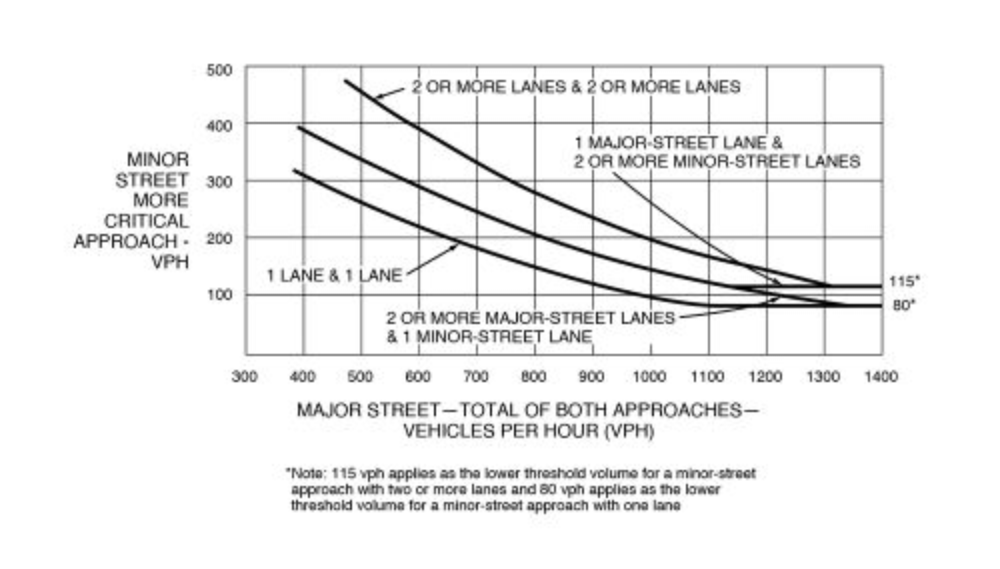

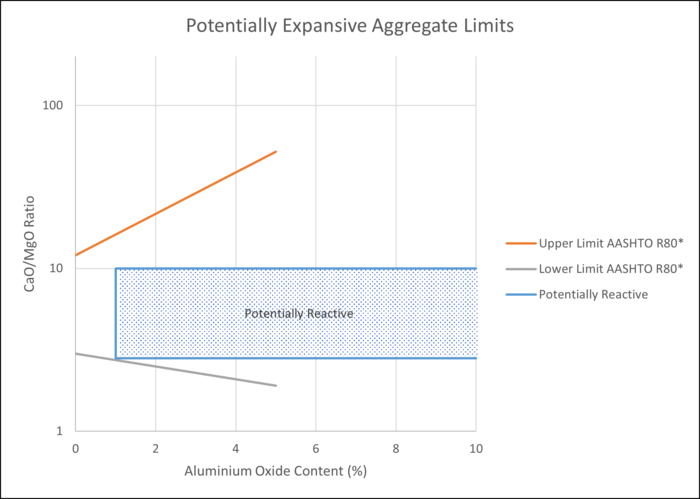

The chemical analysis of aggregate reactivity is an objective, quantifiable and repeatable test. MoDOT will perform the chemical analysis per the process identified in ASTM C 25 for determining the aggregate composition. The analysis determines the calcium oxide (CaO), magnesium oxide (MgO), and aluminum oxide (Al2O3) content of the aggregate. The chemical compositions are then plotted on a chart with the CaO/MgO ratio on the y-axis and Al2O3 percentage on the x-axis per Fig. 2 in AASHTO R 80. Aggregates are considered potentially reactive if the Al2O3 content is greater than or equal to 1.0% and the CaO/MgO ratio is either greater than or equal to 3.0 or less than or equal to 10.0 (see chart below). See flow charts in 106.3.2.93.2 for approval hierarchy. CaO, MgO and Al2O3 shall be analyzed by instrumental analysis only.

* MoDOT’s upper and lower limits of potentially reactive (shaded area) aggregates.

2. Petrographic Examination

A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum:

- Quarry name and ledge name; all ledges if used in combination

- MoDOT District quarry resides

- Date sample was obtained; date petrographic analysis was completed

- Name of petrographer and company/organization affiliated

- Lithographic descriptions with photographs of the sample(s) examined

- Microphotographs of aggregate indicating carbonate particles and/or other reactive materials

- Results of the examination

- All conclusions related to the examination

See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer.

3. Concrete Prism/Beam Test

ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy.

REVISION REQUEST 4060

902.5.43 Power Outages at Signalized Intersections

Guidance. Each District should plan for signalized intersection power outages by developing procedures for signalized intersections that include information about the installation, use, and recovery of Temporary Stop Signs (TSS) and, if used, the installation of battery backup systems. These subarticles provide information for these items.

902.5.43.1 Temporary Stop Signs at Signalized Intersections

Support. Temporary Stop Signs (TSS) refer to stop signs that meet the MUTCD stop sign design requirements for regulatory signs and are temporarily installed at signalized intersections where the traffic signals cannot function due to damage and/or power outage. These temporary placements include but are not limited to roll-up stop signs, temporary mounts on the signal vertical upright, or stop signs mounted on other crash worthy devices.

Standard. Utilities or other non-MoDOT parties doing planned permitted work that will cause a power outage leading to a non-functioning signalized intersection(s) shall be responsible for providing the necessary TSS or generator(s) to power the signalized intersection(s) until power at the non-functioning signalized intersection(s) has been restored.

902.5.43.1.1 Conditions For Use

Option. TSS may be erected at locations where a signalized intersection is non-functioning. A non-functioning signalized intersection is defined as an intersection that is equipped with a traffic signal that is damaged and/or without power which cannot display proper indications to control traffic. When a signalized intersection is non-functioning, then TSS may be installed when one of the following conditions is met:

- When the traffic signal is both damaged and without power, or

- When the traffic signal is without power and restoration of power using an alternate power source is not possible.

Guidance. After verifying that the signal is non-functioning, Districts should contact the appropriate utility company to notify them of the power outage, if applicable, and to determine if power will be restored in a reasonable amount of time (at the District’s discretion). If used, the TSS should be deployed as soon as practical depending on location of the signalized intersection and the stored TSS. Districts should also request police assistance for traffic control if they are not already present at the site or aware of the power outage. Outside of normal business hours, it might be necessary for the electrician or maintenance personnel to directly contact the highway patrol or local police and the power company.

Standard. When TSS are utilized at a signalized intersection that is non-functioning, the District shall decide whether the power shall be disconnected or whether the signal should be switched to flash to avoid conflicts when power is restored. If switched to flash, the flash shall be red-red since TSS will be installed on all approaches, if used, at a signalized intersection without power (dark signals are to be treated like a 4-way stop according to the Missouri Driver’s Guide). The TSS shall not be displayed at the same time as any signal indication is displayed other than a flashing red.

A request shall be made of the nearest maintenance building, emergency responder, or external emergency responder (whomever stores the TSS) to bring stop signs to the intersection. Personnel or emergency responders instructed in signal operation shall disconnect the power or switch the signal to flash operation (external emergency responders will do this in the signal cabinet police door) before placing the TSS. Without this change in operation, the traffic signal could return to steady (stop-and-go) mode within seconds after the signal is repaired or power is restored, which would cause conflicts between the signal and the TSS (conflicting green or yellow indications with a stop sign for the same approach). The signal shall be visible to traffic on all approaches and all these approaches will flash upon restoration of power (see EPG 902.5.43.2 for more information regarding Startup from Dark).

If used, TSS signs shall remain at the intersection until power at the non-functioning signalized intersection has been restored (see EPG 902.5.43.1.4 Recovery).

Guidance. When law enforcement is present at a non-functioning signalized intersection to direct traffic, then the TSS that have been placed should be covered or removed to avoid conflicts (the law enforcements authority supersedes the TSS).

Option. If it has been determined that the power outage will last for an extended amount of time (at the District’s discretion) the signal heads may be covered to reduce the confusion of approaching motorists.

Guidance. If signal heads are covered, the appropriate enforcement agency should be advised and asked to occasionally monitor the intersection. Also, the power company should be advised and asked to notify proper personnel when the power is restored.

902.5.43.1.2 Location and Placement

Standard. The signalized intersection locations for installation of TSS shall meet the conditions of use in EPG 902.5.43.1.1 and shall be at the discretion of the District.

Option Each District may develop a list of signalized intersections to establish a priority for TSS installation.

Guidance. The installation of TSS should be prioritized as follows (as applicable to each district) or, if a list is developed, should begin at the identified intersections:

- Signals with railroad preemption

- Signals with a speed limit greater than 50 mph

- Signals with a high accident rate

- Intersections difficult to flag or require multiple flaggers (non-routine roadway configurations/geometry, SPUIs, multi-lane approaches, etc.)

- Signals with high volumes (freeway type off-ramps, major roadways, etc.)

- Signals with frequent power outages

- Signals located at schools.

If battery backup systems are installed (see EPG 902.5.43.3 Battery Backup Systems at Signalized Intersections) at signalized intersections, Districts should re-evaluate their list of prioritized intersections, if developed, for the installation of TSS.

Standard. When used, TSS shall be placed in a location where they are visible to all lanes on all roadways. On two-way roadways, stop signs shall be erected on the right-hand side of all approaches. On divided highways, stop signs shall be erected on both the right and, if possible, on the left-hand side or at location for best visibility of all approaches.

Guidance. If the power outage is widespread, additional personnel should be requested to help with the placement of the signs.

902.5.43.1.3 Storage and Distribution

Guidance. Each District should store enough TSS to be deployed at high priority signalized intersections.

Standard. TSS shall be distributed by the District to the District’s maintenance personnel or emergency responders or external emergency responders on an as-needed basis. It shall be the responsibility of the District to develop a means of distribution.

902.5.43.1.4 Recovery

Standard. TSS shall remain at the intersection until power at the non-functioning signalized intersection has been restored. Power will remain disconnected or the signal will flash until TSS are removed. Immediately following TSS removal, personnel or emergency responders instructed in signal operation shall restore signal operation in accordance with the procedures set forth in EPG 902.5.43.2 Steady (stop-and-go) Mode for transition to steady (stop-and-go) mode.

The recovery of the TSS shall be accomplished by using the District’s maintenance personnel or emergency responders or external emergency responders by either of the following:

- Complete removal from each intersection.

- Stockpiling outside of the intersection to avoid conflicts with the signalized intersection (stockpiled signs shall not be faced towards the traveling public and stored not to damage sheeting) and stored in a location to not become a roadside hazard.

Option. Detailed recovery procedures for each intersection with TSS may be developed by each District at their discretion.

902.5.43.2 Start up from Dark at Signalized Intersections

Standard. When a signalized intersection has been damaged and/or is without power the District shall have either disconnected the power or switched the signal to flash to avoid conflicts when power is restored. If switched to flash, the flash shall be red-red since TSS will be installed on all approaches, if used, at a signalized intersection without power (dark signals are to be treated like a 4-way stop according to the Missouri Drive’s Guide). If TSS are in place, the power shall remain disconnected or the signal shall operate in flash mode until TSS are removed and personnel or emergency responders instructed in signal operation restore signal operation.

Steady (stop-and-go) Mode

Standard. When power is reconnected or when the signal is switched from flash to steady (stop-and-go) mode, the controllers shall be programmed for startup from flash. The signal shall flash red-red for 7 seconds and then change to steady red clearance for 6 seconds followed by beginning of major-street green interval or if there is no common major-street green interval, at the beginning of the green interval for the major traffic movement on the major street.

902.5.43.3 Battery Backup Systems at Signalized Intersections

902.5.43.3.1 Installation/Placement

Option. Battery Backup Systems (BBS) may be installed at signalized intersections at the District’s discretion. Each District may develop a list of signalized intersections to establish a priority for the installation of BBS.

Guidance. The installation of BBS should be prioritized as follows (as applicable to each District) or, if a list is developed, should begin at the identified intersections:

- Signals with railroad preemption

- Signals with a speed limit greater than 50 mph

- Signals with a high accident rate

- Intersections difficult to flag or require multiple flaggers (non-routine roadway configurations/geometry, SPUIs, multi-lane approaches, etc.)

- Signals with high volumes (freeway type off-ramps, major roadways, etc.)

- Signals with frequent power outages

- Signals located at schools.

If developed, each District’s prioritized installation list for BBS should be based on their traffic conditions and needs. The prioritized TSS installation list, if developed, will need to be reevaluated as BBS are installed.

902.5.43.3.2 Duration

Standard. BBS shall be capable of operating at a minimum of 2 hours in steady (stop-and-go) mode and a minimum of 2 hours in flash operation.

Guidance. Any signalized intersection with BBS should have a generator socket for extended operation.

REVISION REQUEST 4088

902.6.6 Pedestrian Intervals and Signal Phases (MUTCD Section 4E.06)

Support. At times, it can be difficult to time for pedestrians. On one side is the duty to consider the time needed to allow pedestrians of all travel speeds to cross wide roadways. On the other side is the responsibility to operate busy arterials to their peak capacity by minimizing stops and delay for the vehicles. These two goals are usually in conflict if every green interval must be timed long enough to accommodate pedestrians.

The walk interval is intended for pedestrians to start their crossing. The pedestrian clearance time is intended to allow pedestrians who started crossing during the walk interval to complete their crossing. Confusion is common among pedestrians as to the meaning of the indications. This can result in a pedestrian turning back once the WALK time expires and not using the flashing DON'T WALK to cross. Every effort is to be made to educate the public to the meanings of these indications instead of lengthening the WALK time, since the flashing DON'T WALK time is the critical time. Countdown pedestrian indications can help confusion issues see EPG 902.6.7 Countdown Pedestrian Signals.

Standard. At intersections equipped with pedestrian signal heads, the pedestrian signal indications shall be displayed except when the vehicular traffic control signal is being operated in the flashing mode. At those times, the pedestrian signal indications shall not be displayed.

When the pedestrian signal heads associated with a crosswalk are displaying either a steady WALKING PERSON (symbolizing WALK) or a flashing UPRAISED HAND (symbolizing DONT WALK) signal indication, a steady red signal indication shall be shown to any conflicting vehicular movement that is approaching the intersection or midblock location perpendicular or nearly perpendicular to the crosswalk.

When pedestrian signal heads are used, a WALKING PERSON (symbolizing WALK) signal indication shall be displayed only when pedestrians are permitted to leave the curb or shoulder.

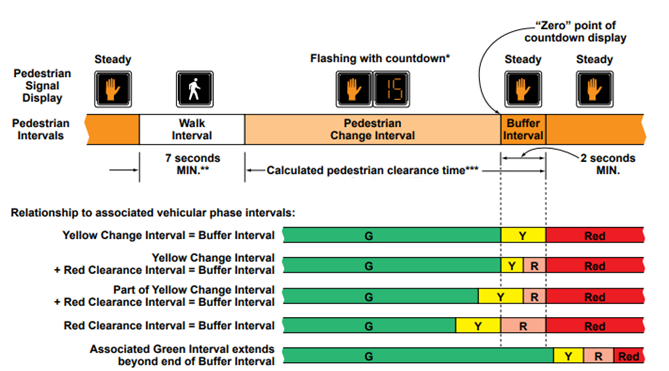

A pedestrian change interval consisting of a flashing UPRAISED HAND (symbolizing DONT WALK) signal indication shall begin immediately following the WALKING PERSON (symbolizing WALK) signal indication. Following the pedestrian change interval, a buffer interval consisting of a steady UPRAISED HAND (symbolizing DONT WALK) signal indication shall be displayed for at least 2 seconds prior to the release of any conflicting vehicular movement. The sum of the time of the pedestrian change interval and the buffer interval shall not be less than the calculated pedestrian clearance time (see below). The buffer interval shall not begin later than the beginning of the red clearance interval.

Option. During the yellow change interval, the UPRAISED HAND (symbolizing DON’T WALK) signal indication may be displayed as either a flashing indication, a steady indication, or a flashing indication for an initial portion of the yellow change interval and a steady indication for the remainder of the interval.

Support. Fig. 902.6.6 illustrates the pedestrian intervals and their possible relationships with associated vehicular signal phase intervals.

| LEGEND | |||

| * The countdown display is optional for Pedestrian Change intervals of 7 seconds or less. ** The Walk Interval may be reduced under some conditions (see EPG 902.6.6). *** The Buffer Interval, which shall always be provided and displayed, may be used to help satisfy the calculated pedestrian clearance time, or may begin after the calculated pedestrian clearance time has ended (see EPG 902.6.6) | G = | Green Interval | |

| Y = | Yellow Change Interval (of at least 3 seconds) | ||

| R = | Red Clearance Interval | ||

| Red = | Red because conflicting traffic has been released | ||

Guidance. The pedestrian clearance time should be sufficient to allow a pedestrian crossing in the crosswalk who left the curb or shoulder at the end of the WALKING PERSON (symbolizing WALK) signal indication to travel at a walking speed of 3.5 ft. per second to at least the far side of the traveled way or to a median of sufficient width for pedestrians to wait.

Option. If pedestrian and/or other unusual characteristics exist and documented engineering judgment supports the use, a walking speed of 4 ft. per second may be considered.

Guidance. Where pedestrians who walk slower than 3.5 ft. per second, or pedestrians who use wheelchairs, routinely use the crosswalk, a walking speed of less than 3.5 ft. per second should be considered in determining the pedestrian clearance time.

Except as provided in the next Option, the walk interval should be at least 7 seconds in length so that pedestrians will have adequate opportunity to leave the curb or shoulder before the pedestrian clearance time begins.

Option. If pedestrian volumes and characteristics do not require a 7-second walk interval, walk intervals as short as 4 seconds may be used.

If pedestrian volumes and characteristics indicate that a longer walk interval is needed then the walk interval may be lengthened. Longer walk intervals are often used when the duration of the vehicular green phase associated with the pedestrian crossing is long enough to allow it.

Guidance. The total of the walk interval and pedestrian clearance time should be sufficient to allow a pedestrian crossing in the crosswalk who left the pedestrian detector (or, if no pedestrian detector is present, a location 6 ft. from the face of the curb or from the edge of the pavement) at the beginning of the WALKING PERSON (symbolizing WALK) signal indication to travel at a walking speed of 3 ft. per second to the far side of the traveled way being crossed or to the median if a two-stage pedestrian crossing sequence is used. Any additional time that is required to satisfy the conditions of this paragraph should be added to the walk interval.

If a pedestrian signal head is used that does not have a concurrent vehicular phase (exclusive pedestrian movement), the pedestrian change interval (flashing UPRAISED HAND) should be set to be approximately 4 seconds less than the required pedestrian clearance time and an additional clearance interval (during which a steady UPRAISED HAND is displayed) should be provided prior to the start of the conflicting vehicular phase. See Fig. 902.6.6.

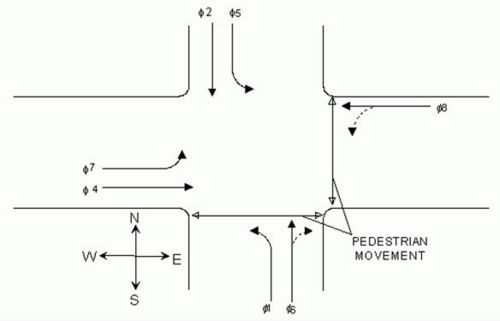

Every effort is to be made to display the WALK indications with a green phase or interval. This "phase-associated" pedestrian operation lessens the overall delay to drivers. Using a fully actuated intersection as shown:

The pedestrian WALK and flashing DON'T WALK indications for northbound-southbound on the east side of the intersection would be displayed only during phase 6. Likewise, the indications for eastbound-westbound on the south side would be displayed only during phase 4.

Standard. Under no circumstance will a pedestrian WALK or flashing DON'T WALK indication be active during a phase or interval which leads vehicles into the crosswalk.

Guidance. Using the previous example, the pedestrian indications for northbound-southbound cannot be active during phase 5, or any phase for the east-west direction of travel. Pedestrian indications are allowed in conjunction with the phase 6 right turn (using the permissive indication) and/or the phase 5 southbound yielding left turn, if allowed, since the pedestrian movement has legal right-of-way over the northbound right turn or southbound yielding left turn.

Under rare circumstances, an exclusive movement might be needed for the pedestrian indications.

Other options should be considered prior to the installation of an exclusive pedestrian movement.

Option. On a street with a median of sufficient width for pedestrians to wait, a pedestrian clearance time that allows the pedestrian to cross only from the curb or shoulder to the median may be provided.

Standard. Where the pedestrian clearance time is sufficient only for crossing from the curb or shoulder to a median of sufficient width for pedestrians to wait, median-mounted pedestrian signals (with pedestrian detectors if actuated operation is used) shall be provided (see EPG 902.6.7 and EPG 902.6.8) and signing such as the R10-3d sign (see EPG 903.5.30) shall be provided to notify pedestrians to cross only to the median to await the next WALKING PERSON (symbolizing WALK) signal indication.

Guidance. Where median-mounted pedestrian signals and detectors are provided, the use of accessible pedestrian signals (see EPG 902.6.9) should be considered.

Option. During the transition into preemption, the walk interval and the pedestrian change interval may be shortened or omitted as described in EPG 902.5.38 Preemption and Priority Control of Traffic Control Signals.

At intersections with high pedestrian volumes and high conflicting turning vehicle volumes, a brief leading pedestrian interval, during which an advance WALKING PERSON (symbolizing WALK) indication is displayed for the crosswalk while red indications continue to be displayed to parallel through and/or turning traffic, may be used to reduce conflicts between pedestrians and turning vehicles.

Guidance. If a leading pedestrian interval is used, the use of accessible pedestrian signals (see EPG 902.6.9) should be considered.

Support. If a leading pedestrian interval is used without accessible features, pedestrians who are visually impaired can be expected to begin crossing at the onset of the vehicular movement when drivers are not expecting them to begin crossing.

Guidance. If a leading pedestrian interval is used, it should be at least 3 seconds in duration and should be timed to allow pedestrians to cross at least one lane of traffic or, in the case of a large corner radius, to travel far enough for pedestrians to establish their position ahead of the turning traffic before the turning traffic is released.

If a leading pedestrian interval is used, consideration should be given to prohibiting turns across the crosswalk during the leading pedestrian interval.

Support. At intersections with pedestrian volumes that are so high that drivers have difficulty finding an opportunity to turn across the crosswalk, the duration of the green interval for a parallel concurrent vehicular movement is sometimes intentionally set to extend beyond the pedestrian clearance time to provide turning drivers additional green time to make their turns while the pedestrian signal head is displaying a steady UPRAISED HAND (symbolizing DONT WALK) signal indication after pedestrians have had time to complete their crossings.

REVISION REQUEST 4093 106.3.2.96 TM-96, Standard Test Method for Chemical Analysis of Concrete Cores by Extraction and Solubility

106.3.2.96.1 Scope

This method evaluates concrete cores by concentrating on three phases (aggregate, paste, and voids) to assist and/or verify the reason(s) for the failure.

106.3.2.96.2 Summary of Method

Aggregate and paste samples are meticulously extracted from the concrete core sample. The aggregate and paste samples are analyzed under a stereoscope for any contamination of paste on the aggregate and aggregate in the paste. The samples are crushed and sieved through a #40 sieve. The minus 40 material is evaluated by instrumental analysis for chemical tracers (indicators) potentially associated with the concrete failure. The remaining portions of the concrete core sample(s) are submerged in distilled water and boiled on a hot plate. A semi-quantitative analysis is performed on the extract for water-soluble elements (tracers) that could be potentially associated with the failure.

106.3.2.96.3 Equipment and Reagents

- Glass beaker, 2000-ml; Nitric Acid (HNO3), Certified ACS grade

- Distilled water

- Mortar and pestle

- Hammer

- No. 40 sieve, conforming to ASTM E-11 specification

- Hook/Straight Fork tip, 5 ½ in. in length

- Brown waxed paper, for sample collection

- Graphite crucible, 8-ml capacity

- Clear plastic (polypropylene) beakers, 400-ml capacity

- Magnetic stirring bars, length of bars should be ½” less than the inside diameter of the beaker

- Lithium metaborate (LiBO2), reagent grade, anhydrous

- Yttrium Stock Solution, 1000 ppm (mg/l)

- Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES), capable of internal standard correction

- Filter paper, rapid filtering, #41 or equivalent

- Filter funnel

- Semi-quantitative standards, traceable to NIST, 10 ppm

- Muffle furnace, 1000 C capability

- Polypropylene digestion vessel with cap, 70-ml capacity

- Porcelain crucible, 15-ml capacity

106.3.2.96.4 Procedure

Place brown wax paper on floor and set the concrete core sample in the middle of the paper. Strike the sample with a hammer to expose the inside of the core. Examine the sample and choose section(s) to extract aggregate and paste from the concrete core. Sample a minimum of 5 large pieces of aggregate and paste to retain separately for further evaluation. Using a Hook Fork tip tool, chip off excess paste off the extracted aggregate and use a stereoscope to verify aggregate is not contaminated and retain. For extracted paster, use mortar and pestle to gently agitate paste to isolate any aggregate and sand in the paste. View under a stereoscope, remove aggregate and sand from the paste, if present, and retain. Use mortar and pestle to break each individual sample into a fine consistency and sieve through a #40 sieve. Repeat, if necessary, and retain for further testing. Determine the moisture content on the paste and aggregate separately in a 105 C drying oven for 2 hours on a 1 +/- 0.0005-gram sample in a porcelain crucible. Cool, weigh, record, and calculate.

Determine the % Loss on Ignition (LOI) on the moisture free aggregate and paste samples at 950 C in a muffle furnace for 2 hours. Cool, weigh, record, and calculate. Use the % LOI result to calculate corrected weight from 0.25 +/- .0005 grams. As an example, if the % LOI is 35%, take (100% - 35%) = %65%. From there, take 0.25 +/- .0005 grams * 0.65 = 0.1625 grams. This is the corrected weight and is used to fuse with LiBO2. For fusion of aggregate and paste, add ¼ teaspoon of LiBO2 to 2 graphite crucibles and use a test tube with the same inner diameter of the crucible, press down on the LiBO2 to make a bed. Use the % LOI of the aggregate and paste, and determine corrected weight, as described above, to weigh into the bed of LiBO2 in the crucibles. Once weighed up, add another ¼ teaspoon of LiBO2 over the sample in the crucibles. Load crucibles into a 1000C muffle furnace for a minimum of 15 minutes, use tongs to remove crucibles, swirl bead in crucible, and carefully drop fused pellet into a clear plastic beaker containing 200-ml of 1:24 HNO3. Place beaker(s) on a stir plate and stir for at least 10 minutes until dissolved. Filter through a #41 filter paper into a 250-ml volumetric flask. Dilute to volume and analyze on ICP-OES using prescribed test template set up for aggregate analysis. 1-ml of Yttrium can be added initially to the 250-volumetric flask prior to filtration of adjusted accordingly based off elemental analysis and volume.

Take remaining pieces of the concrete core sample, after extraction of aggregate and paste, and place in a 2000-ml beaker. Cover the sample with distilled water, cover with suitable watch glass, and boil on hot plate for at least 30 minutes. Take beaker off hot plate, and cool to room temperature. Pour water extract into at least 3 70-ml polypropylene digestion vessels and cap. Analyze water extract on ICP-OES with blank (1:24 HNO3) and 10 ppm semi-quantitative standards. Dilute, if needed, and print report.

The main analytes to evaluate on aggregates are calcium (CaO), magnesium (MgO), and aluminum (Al2O3). Measure CaO/MgO ratio versus Al2O3 concentration to validate if aggregate is reactive based off MoDOT TM-93 graph.

The paste analysis measures moisture availability and total alkali content, which are variables associated with reactive aggregates. The paste is tested for LOI, CO2, Na2O, and K2O. Total alkali content can be calculated by the following equation:

Na2O + 0.658*K2O

High alkali and moisture contents are indicators of tendencies for reaction to occur.

Chemical analysis by solubility is the last step of the concrete core analysis. This method is done to flush out any chemical tracers (indicators) that assist in pinpointing the cause of pavement distress. A semi-quantitative analysis measures the water extract from the core (entrapped and entrained air) and looks at over 60 analytes. The intensity values are displayed based on the concentration of the analytes present in the water extract.

In addition, chemical analysis of chloride (Cl-), Sulfur (SO3), and Ferric oxide (Fe2O3) should be noted as indicators and can be included in the paste analysis.

The chemical analysis of all three phases can assist in identifying the factors leading to the pavement distress.

REVISION REQUEST 4094

941.6.3.6 Deposit Requirements

Deposits are not routinely required for applicants constructing Type I (private residential/farm) entrances, however unusual conditions or construction may warrant a deposit. Deposits may be required for Type II (side street/road), Type III, Type IV, and Type V (commercial/industrial) entrances if the applicant is not a government agency. Details regarding entrance types, refer to the standard plans.

In order to maintain consistent deposit requirements for entrance permits, the cost of curbing required is used as a guide. If other circumstances or construction dictate the need to increase the deposit above the amount required to build the curbing, this increased amount is added to the deposit.

If the deposit is a cashier’s check, a minimum amount of $500 and a maximum of $50,000 will be required. If deposit requirements exceed $50,000, a performance bond will be required. There is no maximum limit for a performance bond. The performance bond or cashier's check shall be made payable to Director of Revenue - Credit State Road Fund.

All deposit checks shall be transmitted to Financial Services using the following procedure:

- Forward deposit as received to Financial Services by attaching the Receipt - Transmittal of Money form. It is imperative to furnish the remitter’s correct name and address.

- Upon satisfactory completion of the permit, the district advises Financial Services by email or other written communication to refund a check to the remitter.

- Financial Services will transmit the check directly to the remitter and also notify the district by email that the check has been processed. The warrant request is attached to the file copy of the permit.

- If the work is not completed as described in the permit, refer to Default of Permit Requirements.

Performance bonds for permits to work on Missouri Highways and Transportation Commission right of way will cover all permitted work for a five (5) year period beginning from the bond execution date. Bonds will be cancelled after all permit work covered by the bond is successfully completed and the permit is released by MoDOT. Any new permit work will require a new executed bond. Bonds can be cancelled by the principal or surety when there is no active work being completed. MoDOT reserves the right to cancel or hold a bond at their discretion.

Performance bonds for permits to work on Missouri Highways and Transportation Commission (MHTC) right of way should use the table below to determine minimum performance bond amounts for statewide consistency. All bond amounts should be discussed with a MoDOT representative. MoDOT reserves the right to adjust any performance bond amount at any time.

| Number of Permits per Year | Minimum Bond Amount |

|---|---|

| less than 24 | Based on work to be performed |

| 24 | $120,000.00 |

| 40 | $200,000.00 |

| 60 | $300,000.00 |

| 100 | $500,000.00 |

REVISION REQUEST 4107

108.16.1 Informational Dates

Informational dates are defined by each agency using AWP (AASHTOWARE Project) and may be used for any purpose. MoDOT has decided to use these dates for tracking significant contract events and to facilitate the final plans process.

The person(s) responsible for entering the Informational dates and their definitions follow:

- 1. Letting Date (LETD) - The date on which bids for the project are accepted and opened publicly by MoDOT. Date passes through AWP during the transition from Preconstruction to Construction modules.

- 2. Award Date (AWRD-DT) - The date of action of the Commission accepting the bid of the lowest responsible bidder for the work, subject to the execution and approval of a satisfactory contract therefore and bond to secure the performance thereof, and to such other conditions as may be specified or as required by law. The date passes into AWP during contract transition from Preconstruction to Construction modules.

- 3. Execution Date (EXEC) - The date that the contract has been signed by all parties and approved by the Chief Counsel's Office. The contractor has 15 days from award to return an executed contract for execution by the commission. The execution date can be more or less than 15 days after award based on the time the contractor takes to return the contract and the time for review and execution by the commission. The date for this record is entered at time of contract activation by CM-Division.

- 4. Notice to Proceed Date (NTP) - The date on which prosecution of the work may begin. This date is specified in the contract and is generally about 45 days after letting unless modified by JSP. Date is entered into AWP during contract activation from CM-Division.

- 5. Work Begin Date (WKBG-DT) - This is the date the contractor begins work and is used by AWP as the start date for the count of contract time. This date is entered by the Project Office.

- 6. Open to Traffic Date (OPTF) - Leave this field blank except for special program projects that are designated by the Division to have the “opening” date documented. When required, this date serves as a measure of progress towards completion of the special program. Smooth Road Initiative and Focus on Bridges are examples of past programs that required tracking of the Open to Traffic date. The Division will let the REs know what programs require tracking and what parameters constitute the project as being “Open to Traffic”.

- 7. Date of Final Inspection - See Sec 105.10.7 and EPG 105.15.1.4 Acceptance for Maintenance (Final Inspection) for detail on the Final Inspection. This is the date of the Final Inspection, which is when all corrections and exceptions are complete on the last remaining project to be finally inspected in the contract. This date will be pulled from AWP by Cognos and listed on the Final Acceptance form. (See QRG AWP CO Contract Times). The Final Inspection Date is entered into AWP by the Project Office.

- 8. Acceptance Date (ACCEPT-DT) - This is the Final Acceptance date as confirmed and documented by the District Construction & Materials Engineer (DCE) on the Final Acceptance Report (C-239). Reference EPG 105.15.2 Final Acceptance. The DCE makes Final Acceptance after receiving the Final Inspection notice from the RE and confirming that all requirements listed in Sec 105.15.2 have been met. Final Acceptance should be made as soon as possible after receiving the final documentation from the contractor, but no later than the 30 day maximum allowed per Sec 105.10.7. The Final Acceptance date is entered by the District Final Plans and Reports Processor.

- 9. 030 Project Data ready for Matls Summary (MCF) - The date is entered by the project office when the last change order is approved or when it is determined that the current contract quantities are final. The date is used to notify district materials personnel that the materials summary may be completed.

- 10. 040 Date Final Plans Recvd at District (FPR) - After the project office completes the as built plans, the RE shall notify the DFP&RP by email that the project is complete and ready for review by the district. After confirming all final documents are present in eProjects, the DFP&RP shall enter the date as built plans were received by the district.

- 11. 080 Materials Summary Submitted to HQ (SSH) - This date is entered by District Materials when the materials summary is completed, uploaded to eProjects and available for review by the CM-Division.

- 12. 095 Materials Summary Approved by HQ (SAH) - The date is entered by the CM-Division after the materials summary is approved.

- 13. 050 Date Final Plans Received at HQ (DFPR) - After the district check of the as built plans is complete, the DFP&RP shall notify the Final Plans Reviewer by email that the project is ready for final review and processing. After confirming that all needed documents are present in eProjects, the Final Plans Reviewer will enter the date into this record to indicate the plans have been received by CM-Division.

- 14. 100 Date Sent to DBE (SDBE) - The Final Plans Reviewer enters this date when the as built plans are sent to Business Development and Compliance (BDC) for their review.

- 15. 105 – Date Approved by DBE (ADBE) - The date the BDC approved the final DBE participation of the project. The date is populated by the BDC.

- 16. 110 Date Received from DBE (RDBE) - The Final Plans Reviewer enters this date when the as built plans are received from BDC after their review.

- 17. Contract Closed for CRLMS Date (CRLMS-DT) - This date represents the review and approval of the final DBE participation for a contract. Entry of this date is necessary for the project data to be reported on the DBE Uniform Report. The date is populated by BDC.

- 18. 060 Date Final Plans Check is Complete (FPC) - The Final Plans Reviewer will enter this date after completing the review of the as built plans and approving the final estimate as the second level of approval.

- 19. Contract Items Complete Date (CICM) - This will be the same date as the date of the Final Payment letter (Surety Letter) from the Financial Services office, which occurs after the FS Controller approves the final estimate as the third and final level of approval. The date is entered by the Final Plans Reviewer.

- Average Working Days per Month for Six Major Item Types of Work

- Contract Time Determination

- 2017 Production Rates

Contract time is to be set to encourage contractors to continuously and diligently prosecute the work in a reasonable fashion while causing the least disruption to traffic. Calculate contract time using the typical working days available during a construction season and anticipated production rates for the items of work , such as average working days per month for six major item types of work. Great care is to be taken in preparing a working day study for a project. Incorrect contract time can be the most significant factor in the bid prices on a project, as well as a primary cause of claims, particularly where other constraints such as tight working conditions, heavy traffic, multiple traffic shifts, complex staging or weather-dependent items are included. When preparing the working day study], review the standard specifications for construction restrictions and approval requirements, and consult with Bridge and district construction and materials personnel to determine probable order of work and time involved to receive material and mix design approvals. Consideration is to be given, but not limited to:

- Restrictions on construction of individual items of work (e.g. thickness of lifts allowed)

- Time allowed for asphalt mix design approval process (particularly on Superpave projects)

- Concrete curing time

- 120 calendar days are to be added to the working days in computation of the project completion date for fabrication and delivery of signal posts and lighting poles, when signals or lighting are a significant portion of the project

- Other materials fabrication or delivery time (including aggregate, steel, and other specialty items such as signal controllers)

When asphalt paving, a temperature-sensitive project activity, is a part of the project, the designer is to try to coordinate working days so paving activities can be completed during favorable weather conditions. If paving activities are to extend beyond one construction season, working days are to reflect a milestone around October 1 so plan thickness is constructed for all pavements to be opened to traffic over the winter season.

Design will assign the Notice to Proceed date for the contractor to receive a Notice to Proceed for the contract 45 days from the award of the contract. The district is to coordinate with Design when determining a delayed Notice to Proceed. An early notice to proceed should not be granted without approval from the Bidding and Contract Services Engineer and the Construction Liaison Engineer. For early or delayed Notice’s to Proceed, a JSP stating the date of the Notice to Proceed is to be included in the final plans submittal.

A Contract Time Determination report is available for further information on developing working day studies. This report contains the most current data available for production rates. Core team members and Central Office personnel are good resources to use for assisting in establishing contract time.

image test