Category:1046 Pipe Liner

This article establishes procedures for inspecting, accepting and reporting of pipe liner. Refer to Sec 1046 for MoDOT’s specifications.

1046.1 Apparatus

(a) Rule with suitable graduations to accurately measure the material to be inspected.

1046.2 Procedure

Pipe liner is to be accepted for use on the basis of certification, identification marking and field inspection.

Manufacturers supplying polyethylene pipe liner in accordance with ASTM D 1248, Type III, Category 5, Class C, Grade P34, shall provide certification that their pipe liner meets the dimensional requirements of Table 1046.1. Those manufacturers that have submitted acceptable certification will be placed in 1046.5 Qualified Manufacturers. If a pipe liner does not meet the requirements of Table 1046.1, the manufacturers may submit their pipe liner dimensions, reasonable justification as to why the product should be accepted, and all pertinent supporting documentation and calculations. Upon approval, the manufacturer will be placed on the qualified list.

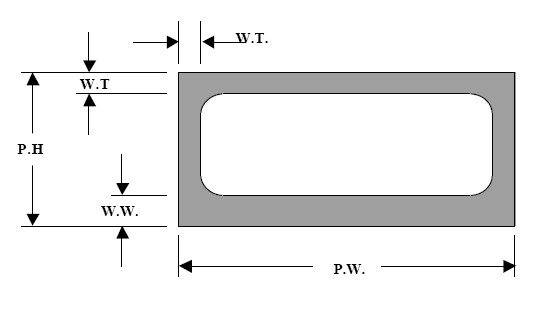

Table 1046.1, Type II Pipe Liner

| Nominal I.D. of PPPL, in. 1,2 | Average O.D., in. 1 | Average Profile Height (P.H.), in. 1 | Average Profile Width (P.W.), in. 1 | Minimum Waterway Wall (W.W.), in. | Minimum Wall Thickness (W.T.), in. |

|---|---|---|---|---|---|

| 10.000 | 11.200 | 0.600 | 0.740 | 0.070 | 0.060 |

| 12.000 | 13.470 | 0.740 | 0.920 | 0.080 | 0.070 |

| 13.500 | 15.360 | 0.930 | 1.160 | 0.090 | 0.080 |

| 15.000 | 16.850 | 0.930 | 1.160 | 0.090 | 0.080 |

| 18.000 | 20.240 | 1.120 | 1.400 | 0.110 | 0.100 |

| 21.000 | 23.650 | 1.330 | 1.660 | 0.130 | 0.110 |

| 24.000 | 27.060 | 1.530 | 1.910 | 0.140 | 0.120 |

| 27.000 | 30.340 | 1.720 | 2.150 | 0.160 | 0.140 |

| 30.000 | 33.820 | 1.910 | 2.390 | 0.180 | 0.150 |

| 36.000 | 40.650 | 2.330 | 2.910 | 0.210 | 0.180 |

| 40.000 | 45.200 | 2.600 | 3.250 | 0.230 | 0.200 |

| 42.000 | 47.470 | 2.740 | 3.420 | 0.240 | 0.210 |

| 1 These dimensions shall be determined by taking at least 3 measurements and averaging the results. | |||||

| 2 A tolerance of +/- 1 percent will be permitted on the nominal I.D. measurements. | |||||

1046.2.1 Manufacturer’s Certification

Prior to acceptance of pipe liner, the manufacturer shall submit a manufacturer’s certification stating that the material supplied conforms to all of the requirements of the specifications for the specific type of pipe liner provided.

1046.2.2 Identification Marking

Each pipe is to be clearly marked by the manufacturer and the marking is to contain the manufacturer’s name and the applicable ASTM designation.

1046.2.3 Field Inspection

Field inspection shall consist of reviewing the certification, checking the identification marking, checking dimensional requirements and randomly checking the length and workmanship.

1046.4 Report (Records)

Field inspection shall be recorded in SiteManager, as described in Automation Section 3510. The sample record shall include the brand name, manufacturer's name, size, and lengths. The sample record is to indicate acceptance or rejection. If the sample record indicates rejection, the reason for rejection shall be stated in the Free Form test.

If the sample record indicates acceptance, the basis of acceptance of the pipe liner shall be that the manufacturer’s certification and examination of the material indicates that the material conforms to all of the requirements of the specifications.

Completion of sample records for materials purchased under a MoDOT purchase order is to be as described in 1101 Materials Purchased by a Department Purchase Order.

1046.5 Qualified Manufacturers and Brand Names of ASTM D 1248, Type III, Category 5, Class C, Grade P34 HDPE Pipe Liner (1046PPLPET2..)

No manufacturers are currently qualified.

To become qualified, submit the required information in accordance with Sec 1046.2 and all supporting documentation to:

- Construction and Materials

- P.O. Box 270

- Jefferson City, MO 65102.