606.1 Guardrail

606.1.1 Types of Guardrail

Type A Guardrail - single W beam rail with 6 ft. 3 in. post spacing.

Type B Guardrail - double W beam rail (single beam on each side of post) with 6 ft. 3in. post spacing, generally for use in median.

Type D Guardrail - single W beam rail with 12 ft. 6 in. post spacing for use at end of road or street.

Type E Guardrail - single thrie beam rail with 3 ft. 1 ½ in. post spacing.

606.1.2 Guardrail Terms

End Anchor - a guardrail end device without a buffer end to develop the full strength of the rail system.

Embedded End Anchor - an end anchorage system for guardrail whereby the rail is embedded in a concrete block and buried in the backslope.

Rock Face End Anchor - an end anchorage system for guardrail whereby the rail is bolted to a rock face.

Blockout - spacer block to separate the guardrail beam from the post used on all types of guardrail.

| Warrant for Median Barriers |

| These are very short video clips of guardrail crash tests conducted at the Midwest Roadside Safety Facility in Lincoln, Nebraska. The video image is very small (and typically located on the lower left of your screen) unless you click the video's enlarge button. |

| A successful pickup test |

| A successful pickup test, slow motion |

| Another successful pickup test |

| Another successful pickup test, rear view |

| A successful car test |

| An unsuccessful pickup test |

| MoDOT cooperates with other states in the Midwest State's Regional Pooled Fund Program to develop and improve new and innovative safety devices. |

Bullnose Guardrail System – an enclosed guardrail design that wraps a semi-rigid guardrail around a hazard.

606.1.3 Applications

606.1.3.1 3R/4R Projects

The necessity of guardrail modifications as a part of a 3R/4R project must be evaluated when work is performed on any state-maintained roadway. As used here, "work" is defined as projects that involve raising the elevation of the travelway through resurfacing which requires height adjustment of the guardrail (as outlined below) or requiring any other adjustment of the guardrail, but does not include surface maintenance activities (i.e. patching, full depth repair, microsurfacing, seal coating, ultrathin bonded wearing surface, 1 ¾" thin lift overlay, and Recycled Asphaltic Pavement (RAP)).

- On dual lane facilities, guardrail end terminals are to be upgraded with an approved crashworthy end terminal in both directions even if the project covers only rehabilitation of the roadway in one direction. Median pier protection is to be installed in both directions on expressways and freeways when applicable.

- Guardrail or concrete barrier blunt ends located on either side of a two-way roadway or on the guardrail approach end of dual lane facilities must be replaced with an approved crashworthy end terminal even if the project covers only rehabilitation of the roadway in one direction.

- All guardrail turned-down ends, concrete height transitions and Breakaway Cable Terminals (BCT) must be replaced with an approved crashworthy end terminal.

- When crashworthy end terminals are installed, the guardrail is to be extended to provide the proper length of need to protect the roadside safety hazard based on current policy. The proper flat recovery area required for the end terminal, as recommended by the manufacturer, is to also be provided for on the plans.

- All existing guardrail not warranted by present standards is to be removed.

- New guardrail or remanufactured guardrail, not salvage rail, is to be used for all projects except those involving only guardrail height adjustment.

- If no guardrail currently exists at a particular location along the roadway, then none is to be constructed as a portion of a project that provides only resurfacing of the roadway unless:

- 1. Other locations of guardrail are adjusted as described in this subsection or,

- 2. Warranted by an analysis of accident history or,

- 3. Obstacles are introduced within the clear zone (i.e. signing, signals, lighting, etc.), which require guardrail according to existing criteria or,

- 4. On NHS Routes only as required by current design criteria.

- Wherever possible, and if the proposed shoulder slope does not exceed AASHTO recommendations, resurfacing of the shoulder is to be tapered to minimum thickness (½ in. aggregate size). If this can be done and the guardrail remains at a minimum height of 26 ½ in., no adjustments to the rail are necessary. The accepted AASHTO range in cross-slope for bituminous shoulders is 2% to 6%. If the shoulder surfacing cannot be tapered to minimum thickness without exceeding the 6% maximum, low guardrail must be raised to 29 in. New guardrail is to be constructed to present standards and the surfacing on the shoulder is to be constructed to the minimum slope in order to accept a future resurfacing without further modifying the guardrail. In any case, it is emphasized that the shoulder surfacing is not planned merely to justify guardrail modifications. A maximum of 8% algebraic difference in the slope of pavement and shoulder at the pavement edge is permitted.

- Wherever the resurfacing of the travelway and the shoulders results in a relative guardrail height less than 26 ½ in., the height must be adjusted to 29 in.

Standard Plan 606.00 provides information for new guardrail delineators. - Any unconnected bridge approach guardrail is to be connected to the bridge by an acceptable transition design. This work is to be accomplished in conjunction with any significant roadway work in the same area.

Approved crashworthy end terminals meeting NCHRP 350 Test Level 3 (TL-3) criteria are to be used on all roadways with posted speed limits greater than 45 mph. Test Level 2 (TL-2) end terminals may be used on roadways with posted speed limits of 45 mph or less, and Test Level 1 (TL-1) end terminals may be used on roadways with posted speed limits of 30 mph or less. TL-1, TL-2, and TL-3 require successful tests of an 1800 lb. (800 kg) car impacting a barrier at 20 degrees, and a 4,400 lb. (2000 kg) pickup truck impacting a barrier at an angle of 25 degrees and at speeds of 30 mph, 45 mph, and 60 mph, respectively.

On 3R/4R and safety improvement projects that include the installation of guardrail, it is important to upgrade the existing roadside elements in the following order:

- 1. All turned-down, blunt ends or other noncompliant NCHRP 350 end terminals must be replaced with an approved end terminal (see Standard Plan 606.30). Associated “length of need” improvements, include both upstream and downstream ends of the guardrail according to current design criteria, are also to be made. (Length of Need, or LON, is defined as the total length of a longitudinal barrier needed to shield an area of concern by containing or redirecting an errant vehicle.) As an element of this activity, existing guardrail constructed with steel blockouts and 6 ft. posts without 2 ft. of level ground behind the guardrail are to be left in place.

- 2. All noncompliant NCHRP 350 attachments of guardrail to a bridge end must be replaced using an approved bridge anchor section (see Standard Plans 606.22and 606.23 ).

- 3. In addition, guardrail is to be provided to close median bridge gaps.

- 4. When it is necessary to replace more than 50% of an existing length of guardrail (not constructed to existing criteria) as a result of slides or extensive damage, the entire length of guardrail is to be removed and replaced with new guardrail according to current design criteria.

- 5. Fixed objects within the clear zone of the mainline roadway are to be removed, relocated, redesigned or shielded in accordance with current design criteria. Fixed objects include non-breakaway signs and luminaries, trees, culvert ends, non-traversable drop inlets, etc. These improvements could be delayed until rehabilitation of the roadway surface is provided so long as the rehabilitation is contained in any of the first three years of the STIP.

- 6. Maintenance/Emergency crossovers located in the median are to be improved in accordance with current clear zone requirements. Additionally, the portion of interchange ramps located within the clear zone of the mainline roadway is to be upgraded. However, these improvements could be delayed until rehabilitation of the roadway surface is provided so long as the rehabilitation is contained in any of the first three years of the STIP.

This listing is a guide for the design team to address individual guardrail improvements on individual projects. It is not intended to be a strict guide for the selection of projects or the allocation of funds.

606.1.3.2 Approved Crashworthy End Terminals

Crashworthy end terminals are the devices used to provide an acceptable level of safety to the end of a roadside barrier or fixed object. Such treatment is required because of the serious consequences that result from a vehicle impacting an untreated barrier. An untreated end can cause an impacting vehicle to abruptly stop, become unstable or roll; it can even penetrate the passenger compartment, all of which increase the risk to the vehicle’s occupants.

An approved crashworthy end terminal is a device or system that has met the safety requirements contained in the NCHRP 350 and has been accepted by the FHWA. The safety requirements of NCHRP 350 are based on several parameters among which are rate of deceleration, tendency to roll, and penetration of the passenger compartment. Within NCHRP 350 are six different test levels that vary depending on the speed, angle of impact and weight or type of vehicle. The test level required for highways in the state highway system is usually Test Level 3 (TL-3). An end treatment satisfying this test level will safely handle the impact of vehicles as large as a 4,400 lb (2000 kg) pickup truck impacting at 62 mph (100 km/h). When the generic term “approved crashworthy end terminal” is used, it most often refers to a TL-3 device. Designers should refer to the information pertaining to crashworthy end terminals available on MoDOT’s website.

Crashworthy end terminals located within 10 ft. of the edgeline will be marked with a Type 3 Modified Object Marker.

The end terminals have been classified into five groups: Type A, B, C, D and E. The type of classification does not reflect any national standards, only MoDOT classification for specification purposes. Additional information on crashworthy end terminals and internet links to terminals approved by MoDOT are available at MoDOT's end terminal website or EPG 1040.4 Crashworthy End Terminal and Qualified Plastic Guardrail Block.

Type A Crashworthy End Terminal. A Type A terminal is an end treatment used for one-sided barriers such as roadside guardrail or roadside concrete barrier. Type A devices can also be used on one-sided barriers in the median, provided sufficient clear space is available behind the system to allow opposite direction traffic to recover from an errant path.

Type B Crashworthy End Terminal. A Type B terminal is an end treatment used for double-sided barrier, most often in the median. Such a device can safely be impacted from several angles including, in most cases, the entirely opposite direction. Type B terminals cannot, however, be installed in paved surface locations unless the installation is temporary and the paved area is to be resurfaced after the system’s removal.

Type C Crashworthy End Terminal. A Type C terminal is an end treatment used for double-sided barrier, in gore areas and in the median. Like the Type B, this device can be safely impacted from several angles usually ranging from head-on to the entirely opposite direction. Type C terminals, however, may be installed in both paved and unpaved surface locations, but must be installed on an asphalt or concrete pad in non-paved areas.

Type D Crashworthy End Terminal. A Type D terminal has all of the installation and performance parameters of the Type C, but must be at least 80% reusable and have the ability to be reset manually with minimal or no repairs. Type D terminal should be used in gore areas or medians where moderately frequent impacts are expected, i.e., more than one impact every two years.

Type E Crashworthy End Terminal. A Type E terminal has all of the installation and performance parameters of the Type C, but is a self-restoring unit that functions properly after at least 2 impacts, without any manual resetting procedures.

If any of the following conditions exists a Type E terminal should be used:

- Gore areas or medians with a high frequency of expected impacts, i.e., more than one impact every year.

- Geometrics and/or traffic volumes present greater than normal potential for harm to workers during repair.

Sand Barrels. Sand barrels are a crash cushioning system most often used to shield fixed objects that cannot be removed or relocated. Sand barrels are recommended for temporary usage such as in work zones. A benefit/cost analysis is to be conducted before sand barrels are used in a permanent application. For more information, refer to EPG 612.2 Sand-Filled Impact Attenuators (Sand Barrels).

606.1.3.3 Bullnose Guardrail System

The bullnose guardrail system is to be used in the medians of expressways or freeways to shield drivers from hazards, such as bridge piers and other obstacles. It is not a crashworthy end terminal, but is rather a non-gating barrier principally constructed of Type E guardrail. As long as the median’s vertical differences are minimal or can be graded, the bullnose guardrail system is the preferred treatment for new construction. The bullnose guardrail system requires at least 15 ft. of median width for its construction. The bullnose guardrail system is not to be erected between twin bridges. Alternatives are available for twin bridge protection in Standard Plan 606.01. Consult Standard Plan 606.30 for grading requirements and other important details.

606.1.3.4 Anchored in Backslope Guardrail

In areas of a roadway cut section, or where the road is transitioning from cut to fill, designers are encouraged to consider the application of anchored in backslope guardrail. Often this can be accomplished by extending the guardrail beyond the length-of-need to tie the guardrail into the backslope. When properly designed and located, this type of anchor provides full shielding for the identified hazard, eliminates the possibility of an end-on impact with the terminal, and minimizes the likelihood of the vehicle passing behind the rail.

606.1.3.5 End Treatment

The guardrail is to be extended outside of the clear zone, or the guardrail end is to be embedded into an adjacent embankment or attached to a solid rock face to eliminate the need for a crashworthy end terminal. If these options are not practical, all approach ends of guardrail, as illustrated by the standard plans, are provided with an approved crashworthy end terminal and a separate payment is made for each crashworthy end terminal. The district is to indicate on the plans where a crashworthy end terminal is to be installed. All downstream ends on two-way roadways are provided with an approved crashworthy end terminal. Downstream ends on dual lane highways need only be treated with end anchors.

606.1.3.6 High Fills

Guardrail for embankments is specified on plans for roads with 400 AADT or more. For roads under 400 AADT, guardrail is optional, however, good design judgment requires guardrail when conditions warrant. Guardrail is not normally warranted for embankment height on projects where clear zones are utilized. However, guardrail may be warranted as shown on Figs. 5.1 through 5.3 in the AASHTO Roadside Design Guide. Combinations of embankment height and slope that plot above the curve indicate a need for guardrail. Combinations plotting below the curve indicate conditions are less severe without guardrail. However, other factors contributing to accident severity such as hazards located either on or at the toe of the slope are to be taken into consideration.

606.1.3.7 Fixed Objects

Guardrail protection for fixed objects such as trees or utility poles may be necessary. If this protection is required, the protection is determined from the near lane on one-direction roadways and from both lanes on a two-direction roadway. Guardrail is warranted in advance of any fixed object located within the clear zone provided the object is potentially more damaging than the guardrail if struck by a vehicle and the object cannot be economically removed, relocated, or made crashworthy by means of breakaway type construction. The fixed object is termed the area of concern and the required type and length of guardrail depends on the size of the object, the distance from the travelway, the AADT, and the design speed. The length of need of guardrail is the length of the obstacle plus the length of the approach barrier adjacent to traffic (and opposing lane, if needed). The length of need and the flare rate of the guardrail shall be determined in accordance with the procedures contained in Section 5.6.4 of the AASHTO Roadside Design Guide. The general geometric data covering the length of need are illustrated on Figure 5.24 of the Roadside Design Guide.

606.1.3.8 Aesthetic Guardrail

Aesthetic guardrail is available for projects located along scenic highways, at scenic overlooks or at other locations where a rustic appearance may be appropriate. Wood, composite or recycled materials are often the primary constituents of this type of guardrail. Because aesthetic guardrail would be expected to cost more than typical guardrail, additional funding shall come from the local jurisdictions, enhancement funds, other non-department sources or a combination of these.

There are no aesthetic crashworthy end treatments approved by MoDOT. Designers incorporating aesthetic guardrail on a project are to refer to the information pertaining to crashworthy end treatments available on MoDOT’s website. Designers are to be aware that for the proper design of guardrail from some manufacturers, the length of need is to begin at least 100 feet downstream from the terminal.

Care is to be taken by the designer to consider whether a specific appearance is desired for the aesthetic guardrail. If a specific appearance is deemed appropriate in order to coordinate with existing facilities or some other aspect of the scenic location, the designer is to specify the system desired with a Job Special Provision.

No approved end terminal exists for most types of aesthetic guardrail. Therefore, in these cases, the end of the rail must be terminated into a backslope or extended to a point outside the clear zone. Specifications in Sec 606 have been prepared in anticipation of the eventual production of approved end terminals for aesthetic guardrail.

606.1.3.9 Bridge Ends

Guardrail is placed at bridge ends in accordance with typical locations shown in the standard plans for all roads. Approved crashworthy end terminals are provided on guardrail placed for bridge end protection. Guardrail placed for bridge end protection is anchored to the bridge end by a bridge anchor section. In retrofit projects having non-standard transitions and slopes, the connector plates for bridge anchor sections may be slightly adjusted to produce a vertical terminal connector. Refer to Standard Plans 606.22and 606.23. Existing bridge end connections that do not conform to current standards are to be considered for replacement or modification. In order to determine the appropriate solution for the specific non-standard bridge end connection, the Bridge Division Liaison Engineer is to be consulted. Where guardrail at the downstream end of a one-way bridge is necessary because of a high fill or other condition, the guardrail is connected to the bridge anchor section.

On certain low-volume highways throughout the state, bridge ends may be delineated in lieu of shielding. This option is viable where the operating speed is less than 60 mph and the AADT is 400 or fewer vehicles per day.

The delineation-only option is primarily governed by the parameters of speed and volume. Irrespective of any values for these parameters, however, the use of delineation-only is prohibited on Major Highways (Principal Arterials and above) as well as the National Highway System (NHS).

Use of the delineation-only option is not recommended on bridge ends in areas of poor geometry (horizontal alignment, vertical alignment, sight distance, etc.). Nor is it recommended in areas with an accident history (as calculated between two points at least 0.25 miles from either approach) in excess of the statewide average for similar road. If further analysis of either of these situations proves the delineation option to be viable, then a design exception should be obtained for its use.

Additionally, the delineation-only option should be limited to those bridge replacements or rehabilitations where the existing structure was unshielded and the existing roadway template cannot reasonably accommodate the installation of guardrail without some modification.

Turned down ends offer a solution to terminating guardrail at some bridge ends, or other roadside obstacles, on certain, low-volume highways throughout the state. While the use of these terminals has generally been discontinued for new construction, they may represent appropriate design for roads with low traffic volumes, traveled by motorists who are generally familiar with the roadway and it’s geometrics.

Use of turned down ends is primarily governed by the parameters of speed and volume. Irrespective of any values for these parameters; however, the use of turned down ends are prohibited on the following:

- Major highways

- The National Highway System (NHS)

- Areas of poor geometry

- Areas with an accident history in excess of the statewide average for similar road

- Areas of posted speed 60 mph or greater

Neither an existing higher order end terminal, nor an existing turned down end installation is to be replaced with a new turned down end. The use of a turned down end should be limited to those areas where they will both yield an increase in safety over the existing situation and leave the area reasonably safe.

Turned down ends may represent reasonably safe design when the posted speed is less than 60 mph and the AADT is 400 or fewer vehicles per day.

A design exception is to be obtained for every location in which a new turned down end treatment is proposed. This exception simply documents why the engineer believes the installation represents a reasonable level of safety

Guardrail is not generally used to protect traffic from the ends of bridges carrying a crossroad or street over the through lanes in developed areas where speed controls exist or sidewalks are provided. If however, at ends of such bridges the roadway is in a high fill or has sharp curvature, guardrail may be considered.

606.1.3.10 Bridge Piers and Sign Trusses

Guardrail is specified for protection of traffic from bridge piers and sign trusses with the exception of those piers and trusses where the footings are located outside the clear zone. Typical treatments are indicated in the standard plans. Bridge piers located close to the roadway are marked with a Type 2 Object Marker.

606.1.3.11 Signs

Guardrail protects traffic from signposts that cannot be equipped with a breakaway assembly. Typical treatments are indicated in the standard plans.

606.1.3.12 Outer Roadways

Criteria for guardrail use on outer roadways are the same as for other roads except for the shoulder side adjacent to a through lane. Guardrail is specified along outer roadways where the outer roadway is 10 ft. or more above the main roadway, and the shoulder of the outer roadway is less than 25 ft. from the top of the roadway backslope. Sometimes it is more economical to move the outer roadway back sufficiently to eliminate the requirement for guardrail. Guardrail along outer roadways is installed with the face of the rail toward the outer roadway. Type B guardrail may be required if the guardrail is within the limits of the clear zone for the through lanes.

606.1.3.13 Headwalls

Guardrail is usually not used to protect traffic from headwalls located outside of the shoulder line of roadways without clear zones unless warranted by high fills. Exceptions include interstate safety modification projects where clear zones are not added and where it may not be economically feasible to extend a large box culvert to locate the headwall outside the clear zone point.

When an obstacle such as a culvert headwall is located close to the shoulder line, a longer, unsupported span (up to 25 ft.) can be accomplished by omitting posts and double nesting the rail. This allows motorist safety to be enhanced by providing uninterrupted guardrail instead of transitioning to other forms of barrier. Refer to Standard Plan 606.00. Headwalls located within the shoulder or immediately adjacent to the roadway on two-lane, two-way roads are marked with a Type 3 Object Marker. These object markers are not used on interstates, full shoulder-width bridges or at obstructions outside the shoulder point.

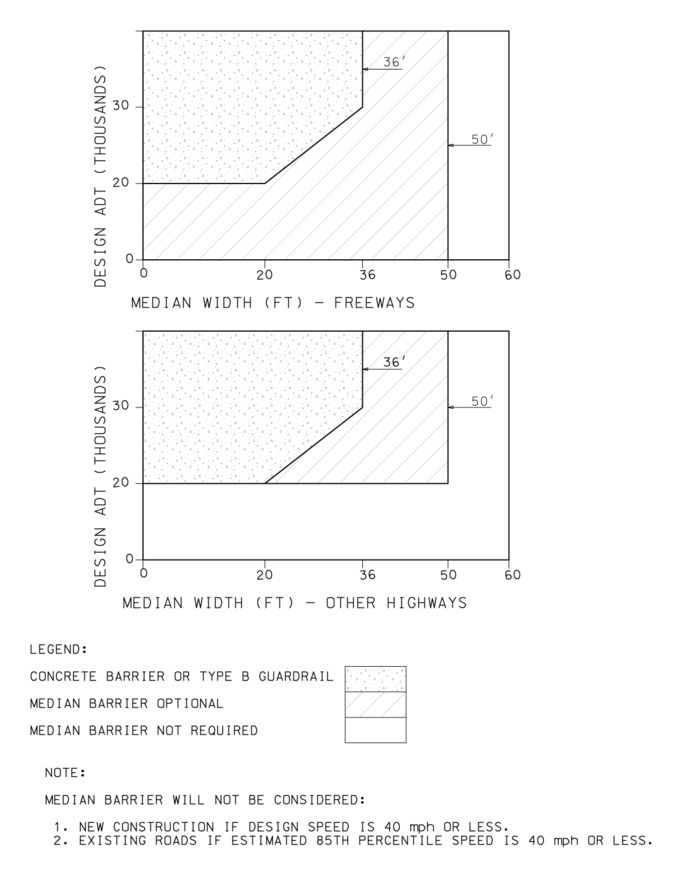

606.1.3.14 Medians

Guardrail may be specified in medians to provide a positive barrier. Guardrail may also be specified to convert an existing raised curb median to a barrier median provided the center of the guardrail is placed 21 in. above the pavement elevation at the curb face. Type B guardrail may be used on a raised median width of 2 ft. back-to-back. For greater widths, two single lines of Type A guardrail will be required. For medians of variable widths, a detail in the standard plans provides for transition from Type B to Type A guardrail. Approved crashworthy end terminals are added only at the beginning and ending of a total run of guardrail and not at each break caused by intersections and median openings. Breaks caused by intersections and median openings will be closed by means of a crashworthy special end treatment. For medians on divided pavements where grade differential will not permit standard clear zones, the slope is to be modified to provide as safe a slope treatment as possible. Guardrail will not be required except for exceptional or unusual conditions.

Type B guardrail can be used on a flush median, as shown in the figure below. Type B guardrail is to be used where a median barrier is to be provided but site conditions will not permit the use of a concrete barrier (drainage, visibility requirements, aesthetics, etc.). The concrete barrier is generally limited to the high volume roadways with narrow width medians. Many existing freeways have medians that are wider than 36 ft. (11 m). These medians are of sufficient width to satisfy clear zone requirements, thus making the provision of guard cable optional.

606.1.3.15 Restricted Lateral Clearance

When piers or other obstacles require guardrail treatment, the back of the guardrail post is to be placed 4 ft. from the pier or obstacle. Where the clearance obtained is less than 4 ft. but more than 2 ft., 25 ft. of Type E guardrail shall be used preceding and through the limits of the obstacle. There will be situations with narrow shoulders or with curbed medians when encroachment is not permitted. In such cases, Type E guardrail is to be specified requiring 25 ft. preceding the obstacle and extending through the limits of the obstacle as required. The minimum offset to the obstacle can be eliminated completely by attaching the rail to the obstacle by use of a bridge anchor section.

606.1.3.16 Barricade of Existing Streets and Roads

Where an essentially rural street or road is to be closed for less than approximately five years, permanent barricades as shown on Standard Plan 903.02 and are specified. When the closing of the street or road is anticipated to exceed approximately five years in essentially rural areas, and for closing streets or roads in essentially urban areas regardless of time, either Type 4 Object Markers only or a combination of Type 4 Object Markers and Type D guardrail is specified. Where no hazard exists beyond the end of the closed street or road for a reasonable distance, Type 4 Object Markers are sufficient for delineation. Where a hazard exists beyond the end of the closed street or road that is considered equal to or greater than that created by the use of guardrail, a combination of both Type 4 Object Markers and Type D guardrail is specified. Refer to Standard Plan 903.03.

606.1.3.17 Plans

Guardrail details and typical locations for installation are shown in the standard plans. Guardrail is shown by proper legend on the plan sheets and the station location and quantities are tabulated on the 2B sheets. Quantities are tabulated in 12 ft. 6in. increments. Curved sections of guardrail are to be installed on curves with a radius of 150 ft. or less. The plans specify the lengths of curved guardrail and the radius of curvature. Curved guardrail is not tabulated separately on the plans. Examples of guardrail delineation and tabulation are shown in Sample Plans.

606.1.3.18 Urban Section, Curb and Curb and Gutter

Where barrier curb is used, guardrail is placed with the face at the face of the curb and the center of the rail 23 in. above the pavement elevation at the curb face. Where mountable curb is used, guardrail is placed with the face at the edge of the usable shoulder and the center of the rail 23 in. above the shoulder elevation. Where curb and gutter is used, guardrail is placed with the face at the face of curb and the center of the rail 23 in. above the gutter line. When curbs are constructed directly beneath guardrail, the curb height shall be 4 inches.

606.1.3.19 Use of 7 ft. Guardrail Posts

When a 2-ft. offset for embankments behind the guardrail is not available, 7 ft. guardrail posts at 3 ft. 1½ in. spacing will be required. It is to be noted that the standard plans for many two-lane and dual-lane facilities constructed in the 1960s and early 1970s show an additional 2 ft. offset for embankments placed in front of or behind the guardrail. A field review by the Design Division personnel of selected projects constructed in the 1960s and early 1970s revealed that in most cases the edge of the travelway and the embankment were separated by 12 ft., at least 10 ft. of which was a paved shoulder. This additional width, or 2 ft. offset, which was usually unpaved, is present even though the typical sections for these projects do not show it.

Due to this fact, designers are to conduct a field check to determine whether additional width is available for projects involving extending or replacing guardrail. This field check is to include the District Soils and Geology Technician to determine whether the embankment has eroded or if a slide has occurred. If the original 12 ft. width has significantly eroded, it is to also be determined whether the 2 ft. offset can be restored without causing additional failure.

If the 2 ft. offset was not originally constructed at the location, a cost analysis is to be conducted to determine whether to add a 2 ft. offset to the slope or use 7 ft. posts with 3 ft. 1 ½ in. spacing.

606.1.4 Maintenance Planning Guidelines for Guardrail

Printable Maintenance Planning Guideline for Guardrail.

Index of all Maintenance Planning Guidelines.