751.1 Preliminary Design

Contents

- 1 751.1.1 Overview

- 2 751.1.2 Bridges/Boxes

- 2.1 751.1.2.1 End Slopes/Spill Fills

- 2.2 751.1.2.2 Wing Lengths

- 2.3 751.1.2.3 Live Load Determination

- 2.4 751.1.2.4 Skew Angle

- 2.5 751.1.2.5 Bridge Width

- 2.6 751.1.2.6 Vertical and Horizontal Clearances

- 2.7 751.1.2.7 Structure Type Selection

- 2.8 751.1.2.8 Box Culverts

- 2.9 751.1.2.9 Girder Type Selection

- 2.10 751.1.2.10 Longer Bridges

- 2.11 751.1.2.11 Staged Construction

- 2.12 751.1.2.12 Temporary Barriers

- 2.13 751.1.2.13 Seismic (Earthquake) Design Category A, B, C and D Considerations

- 2.14 751.1.2.14 Temporary Bridges

- 2.15 751.1.2.15 Bridges Over Railroads

- 2.16 751.1.2.16 Historical Bridge Considerations

- 2.17 751.1.2.17 Preliminary Cost Estimate

- 2.18 751.1.2.18 Bridge Memorandums

- 2.19 751.1.2.19 Soundings (Borings)

- 2.20 751.1.2.20 Substructure Type

- 2.21 751.1.2.21 Type of Footings

- 2.22 751.1.2.22 Types of Piling

- 2.23 751.1.2.23 Estimating the Lengths of Piles

- 2.24 751.1.2.24 Drilled Shafts

- 2.25 751.1.2.25 Excavation Datum

- 2.26 751.1.2.26 Seal Courses

- 2.27 751.1.2.27 Cofferdams

- 2.28 751.1.2.28 Webs

- 2.29 751.1.2.29 Protection of Spill Slopes and Side Slopes

- 2.30 751.1.2.30 Design Exceptions

- 2.31 751.1.2.31 Finishing Up Design Layout

- 2.32 751.1.2.32 FHWA Submittal

- 2.33 751.1.2.33 Aesthetic Enhancements

- 2.34 751.1.2.34 Blast Loading Considerations

- 2.35 751.1.2.35 Bridge Approach Slabs

- 2.36 751.1.2.36 Bridge End Drainage

- 3 751.1.3 Wearing Surfaces/Rehabs/Redecks/Widenings

- 3.1 751.1.3.1 Overview

- 3.2 751.1.3.2 Documentation

- 3.3 751.1.3.3 Bridges on Resurfacing Projects

- 3.4 751.1.3.4 Barrier or Railing Type, Height and Guidelines for Curb Blockouts

- 3.5 751.1.3.5 Deck Repairs

- 3.6 751.1.3.6 Deck Treatment

- 3.7 751.1.3.7 Bridge Approach Slabs

- 3.8 751.1.3.8 Bridge End Drainage

- 3.9 751.1.3.9 Environmental Considerations: Asbestos and Lead

- 4 751.1.4 Retaining Walls

| Forms |

| Structural Rehabilitation Checklist |

751.1.1 Overview

751.1.1.1 Introduction

The Preliminary Design of a structure begins with the district submitting a Bridge Survey indicating their need for a structure, and ends with the completion of the Substructure Layout or TS&L submittal (type, size and location). This article is intended to be a guide for those individuals assigned the task of performing the Preliminary Design or “laying out” of a structure.

The types of structures can be broken into five categories:

- 1.) Bridge over Water

- 2.) Bridge over Roadway or Railroad

- 3.) Box Culvert over Water

- 4.) Retaining Wall (CIP walls taller than 5 ft., MSE walls adjacent to bridge end bents)

- 5.) Rehabilitation or Modification of Existing Structure

In addition to the following information, the Preliminary Design shall consider hydraulic issues where applicable.

751.1.1.2 Bridge Survey Processing and Bridge Numbering

The Preliminary Design process starts with the receipt of the Bridge Survey. The following is a list of steps that are taken by the Bridge Survey Processor.

Assign a Bridge Number to the Structure

The Bridge Division assigns bridge numbers in Bloodhound to all new, rehabilitated or modified structures (i.e., bridges, box culverts (see EPG 750.7.4.3 Summary of Responsibilities), CIP retaining walls over 5 ft. tall and MSE walls adjacent to bridge end bents).

Enter the Bridge Number, survey received date and feature crossed in the Bloodhound database.

New Structures:

- New structures are numbered in ascending order using the next available bridge number. Numbering for new structures (except timber structures) start at A0001 thru A9999 and will be followed by B1000 thru B9999. (Note: B0001 thru B0581 were used for the Safe and Sound Bridge Replacement Program.)

- New timber bridges are numbered in the same manner using the letter “T” instead of the letter “A”.

Temporary Structures:

- Temporary bridges use the same number as the new bridge with the letter “T” added to the end (i.e., the temporary bridge for A8650 would be A8650T).

Rehabilitated or Modified Structures (Except when rehabilitation is only for structural steel coating):

- Single Structures (Includes twin structures with individual bridge numbers):

- Structures without a suffix letter on the existing bridge number will be numbered using the existing bridge number and a suffix number added that corresponds to the number of rehabilitations or modifications to the structure (i.e., bridge number A0455 becomes A04551 upon its first rehabilitation or modification and A04552 upon its second).

- Single Structures with the Suffix “R”:

- Structures that have the suffix “R” on the bridge number are usually bridges that have been rehabilitated or modified in the past, but in some cases bridges were given the suffix “R” to denote it as a replacement for a bridge with the same number. Review the existing bridge plans to determine if the “R” was for a rehabilitation or replacement. Structures that have been previously rehabilitated should replace the “R” with a suffix number corresponding to the total number of rehabilitations to the structure (i.e., bridge number A0444R would become A04442 (second rehab. or mod.), bridge number A0055R2 would become A00553 (third rehab. or mod.), etc.). For structures where the “R” denotes it as a replacement, the suffix number corresponds to the number of rehabilitations or modifications and the “R” is dropped (i.e., bridge number L0428R becomes L04281 for the first rehabilitation). If the “R” suffix was removed in a previous rehabilitation, the next suffix number is used regardless if the original structure was a rehabilitation or replacement.

- Twin Structures with the Same Bridge Number:

- Twin structures with the same bridge number will use a different suffix number for each structure. The numbering is similar to a single structure with the lower suffix number being used on the eastbound or southbound structure and the next suffix number being used on the westbound or northbound structure (i.e., bridge number A0144 would become A01441 for the eastbound bridge and A01442 for the westbound bridge. A future rehabilitation would become A01443 for the eastbound bridge and A01444 for the westbound bridge). Twin bridges with an “R” suffix on the bridge number would receive the suffix numbers using the same rules, but with the same consideration given to the “R” as it is for a single structure.

Structural Steel Coating (Use when all bridge pay items are related to structural steel coatings):

- Rehabilitations that consist only of structural steel coatings use the existing bridge number plus the suffix “-Paint” (i.e., bridge number A2100 would become A2100-Paint and bridge number A150010 (multiple rehabilitations) would become A150010-Paint). A future rehabilitation consisting of only structural steel coatings would use the suffix “-Paint2” only if no other rehabilitations have been completed since the previous coating rehabilitation.

Removal of Existing Bridge Structures:

- When a bridge structure is removed and not replaced by a new bridge structure or is removed under a separate contract, the suffix “-Remove” should be added to the latest bridge number (i.e., bridge number T0415 would become T0415-Remove and bridge number K01651 would become K01651-Remove).

Re-using Bridge Numbers:

- Bridge numbers that were assigned to new structures that were never built are only reused if the proposed structure is at the same crossing location that the bridge number was originally assigned to.

- Bridge numbers that were assigned to rehabilitate or modify structures where the work was not completed may reuse the previous bridge number by adding the suffix “_02” to the bridge number (i.e., bridge number A6545 had plans developed for deck repairs and was assigned the bridge number A65451, but the work was never completed. At a later date, bridge A6545 is set up to be redecked; the bridge number assigned to the redeck would be A65451_02). This suffix is only recorded in Bloodhound for tracking purposes and is not shown as part of the bridge number on file folders or final plans.

Create Job Folders

Check to see if a Correspondence File has been created. If the Correspondence File has been created, record the Bridge Number(s) in Bloodhound and make a Preliminary Design File for each structure received. If the Correspondence File has not been created, make a Correspondence File, an outer folder and a Preliminary Design File for each structure received. Here is the information for each type of folder/file:

| Folder Type | Required Information on Folder | |

| Outer (pink label) | County, Route and Job No. | |

| Correspondence | County, Route and Job No. | |

| Preliminary Design | County, Route, Bridge No., Location and Job No. |

Also, be sure to notify by email the Structural Resource Manager and the appropriate Structural Project Manager or Structural Liaison Engineer, if known, when a new Correspondence File is created. The email subject line should include the Job No., County, Route and Bridge No. Include the name of the Bridge Division contact in the email, either the Structural Project Manager or the Structural Liaison Engineer.

Calculate Drainage Information

For structures over streams or waterways, calculate the drainage area and length of stream. Generate a drainage summary and include this information along with a map showing the drainage area for the structure and the area surrounding it in the Preliminary Design folder. If the drainage area is less than 1.5 sq. miles, consult the Structural Resource Manager to determine if preliminary design by the Bridge Division is necessary. The accuracy of the drainage area should be to the nearest 0.1 sq. mile for drainage areas less than 10 sq. miles and to the nearest 1 sq. mile for drainage areas greater than or equal to 10 sq. miles. When another stream intersects the subject stream near the downstream side of the proposed structure, create a separate drainage summary for the intersecting stream and include it in the Preliminary Design folder.

Process Electronic Files

When the electronic files listed in EPG 747.1.2 Bridge Survey Submittals are received, verify that the drawing scales are correct and that the necessary reference files are included. Also, review all Bridge Survey Sheets and the Bridge Survey Checklist for accuracy and completeness. The Bridge Survey Processor may have to work with the district to correct any discrepancies and/or omissions.

Add the newly assigned bridge number to the files and place a hard copy in the layout folder.

Final Step for Bridge Survey Processor

Once all of these steps are completed, the Bridge Survey Processor should deliver the Correspondence File, outer folder and the Preliminary Design Folder(s) to the Structural Resource Manager. An acknowledgement email is sent to the district contact(s) informing them that the Bridge Division has received the Bridge Survey. The email subject line should include the Job No., County and Route. Include the Bridge No(s). and the name of the Bridge Division contact in the email.

Once the survey is found to be complete and accurate, the Survey Complete date should be entered into Bloodhound. This date should match the Surv Rec date if no changes were made. If the survey is not complete or contains inaccuracies as submitted, we need to work with the district to fill in the blanks. If the omissions affect the timeline for completing the preliminary design, the Survey Complete date should reflect the date when we have all the information needed for the preliminary design to move forward without delay. If there is a delay in the bridge division review of the survey, this time should not count against the district in the survey complete date. The Bridge Survey Processor should work closely with the preliminary designer and SPM to determine the proper Survey Complete date in this case. For example, a bridge survey is received on 9/16/2016. Initial review by the bridge survey processor shows a complete survey. The job sits for five weeks while a preliminary resource comes available. Review by the preliminary designer shows a profile grade that is unusable and the preliminary design cannot progress until the grade situation is corrected. It takes four weeks for the grade to get worked out. The Survey Complete date should be four weeks after the Surv Rec date (10/14/2016). The district would not be penalized for our five week delay in reviewing the survey. This date is important because it will help us track when bridge surveys are turned in relative to when they are complete and when the project is due to Design.

751.1.1.3 Beginning Preliminary Design

The Preliminary Designer should meet with the Structural Project Manager to go over the Correspondence and Preliminary Design files to see if anything out of the ordinary has come up at Core Team Meetings prior to that date. It is important to include any correspondence or calculations used in the laying out of the structure in the bound portion of the Preliminary Design Folder.

The Preliminary Designer should then examine the Bridge Survey closely for any errors or omissions. Consult EPG 747 Bridge Reports and Layouts. Pay special attention to the scales used. Make sure the district's submittal includes photographs and details of staging and/or bypasses, if applicable. Verify that the proposed roadway width meets the NBI criteria for minimum bridge roadway width to avoid building a deficient bridge. Contact the district to resolve any discrepancies or questions.

A visit to the bridge site by the Preliminary Designer may be warranted to help determine Manning’s “n” values, examine adjacent properties, etc. If you decide to make this trip, advise the Structural Project Manager and the district contact since they may also want to attend.

Vertical Alignment and Bridge Deck Drainage

Laying out a bridge should consider deck drainage concerns for bridges on flat grades and sagging vertical curves and other vertical alignment issues as given in EPG 230.2 Vertical Alignment and EPG 230.2.10 Bridge Considerations.

751.1.1.4 Coordination, Permits, and Approvals

The interests of other agencies must be considered in the evaluation of a proposed stream-crossing system; cooperation and coordination with these agencies must be undertaken. Coordination with the State Emergency Management Agency (SEMA), the U.S. Coast Guard, the U.S. Army Corps of Engineers, and the Department of Natural Resources is required.

Required permits include:

- U.S. Coast Guard permits for construction of bridges over navigable waterways.

- Section 404 permits for fills within waterways of the United States from the U.S. Army Corps of Engineers.

- Section 401 Water Quality Certification permits from the Missouri Department of Natural Resources.

- Floodplain development permits for work in special flood hazard areas from the State Emergency Management Agency (SEMA).

Section 404 and Section 401 permits are obtained by the Design Division. U.S. Coast Guard permits are obtained by the Bridge Division. The Bridge Division will obtain floodplain development permits for projects that include structures in a regulated floodplain. The Design Division will obtain floodplain development permits for other projects involving roadway fill in a regulated floodplain.

Copies of approved U.S. Coast Guard permits and floodplain development permit/applications are sent to the district, with a copy to the Design Division.

See MoDOT and the Environment for more information on the required permits.

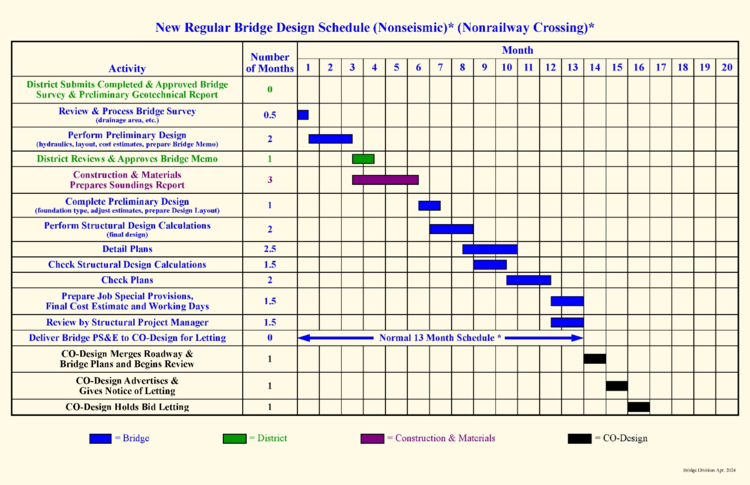

751.1.1.5 New Regular Bridge Design Schedule (Nonseismic) (Nonrailway Crossing)

*13 months minimum required for multi-span bridge design with seismic details or seismic details and abutment seismic design. 13 months minimum required for single-span bridge design with abutment seismic design or seismic details. 24 months minimum required for complete seismic analysis of multi-span bridge design. 24 months minimum required for Railway Crossing bridge design.

751.1.2 Bridges/Boxes

751.1.2.1 End Slopes/Spill Fills

The end slopes are determined by the Construction and Materials Division and are supplied to the Bridge Division by way of the Preliminary Geotechnical Report. If this report is not in the Correspondence file, contact the district to get a copy of it. The Bridge Division has made a commitment to the districts that we will have the bridge plans, specials and estimate completed 12 months after the date the Bridge Survey and Preliminary Geotechnical Report are received. The "12 month clock" does not start ticking until both the Bridge Survey and the Preliminary Geotechnical Report are in the Bridge Division.

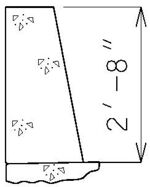

When laying out a skewed structure, adjust the end slope for the skew angle. On higher skews, this will have a significant effect on the lengths of the spans. Often the slope of the spill fills will be steeper than the roadway side slopes. On a skewed structure, this makes it necessary to "warp" the slopes.

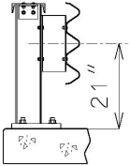

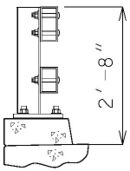

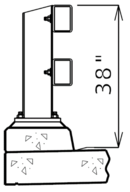

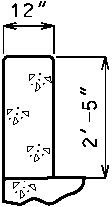

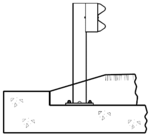

Whenever there will be a berm under any of the spans, its elevation should be such that there is a minimum of 4 feet clear between the ground line and the bottom of the girder as shown below.

If a rock cut is encountered in the spill slope, a slope of 1:1 may be used to the top of the rock.

751.1.2.2 Wing Lengths

The purpose of wings is to contain and stabilize the abutment fill as the roadway transitions to the bridge. For stream crossings in particular, the wings also protect the abutment during extreme hydraulic events.

The lengths of the wings at the end bents are to be determined prior to the issuance of the Bridge Memorandum. There are two reasons for this. First, the district will use these lengths to determine the placement of their guardrail (bridge anchor section). Second, if the lengths of the wings exceed 22 ft. for seismic design category A or 17 ft. for seismic design category B, C or D, they will have to be broken into a stub wing and a detached wing wall. If this happens, then you will need to include this extra cost in your Preliminary Cost Estimate and request soundings for the wall. The request for soundings for the wall should include a request for the determination of the allowable bearing of the soil (if in cut - assume piling if it is in fill) and the angle of internal friction for the material retained by the detached wing wall. Also include the bottom of wing footing elevation.

In order to use a standard end section for Type D barrier on a short turned-back wing, consider increasing the wing length so that the barrier end section is at least 8 feet long.

Unequal Wing Lengths

Wing lengths at each end of a bridge could be unequal because of several factors: grade of roadway under, superelevation of bridge, skew of the bridge, and/or other ramps/roads/slopes adjacent to the bridge structure, e.g., stream access roads or unusual geomorphic conditions.

Set/determine the wing lengths using the control points, as shown in Embankment at Bridge Ends, which may be used for both grade separations and stream crossings. This is done after the end bent location is determined. If estimated wing lengths are within 3 ft., they should be made equal and based on the longer wing length. Make sure no slope is steeper than that recommended in the geotechnical preliminary report. Slightly flatter slopes are acceptable. The contractor will warp the slopes to fit the wing tip locations.

Equal wing lengths are preferable at stream crossings to mitigate scour, improve erosion control and improve/mitigate parallel water flow along wing and side embankment. Also, since wing lengths are reported to districts for use in estimating rock slope protection limits, unequal lengths (especially on the upstream side) could mistakenly lead to the unfavorable condition of allowing for less than adequate rock side slope protection.

Judgement is required since no two estimated wing lengths at a bridge end will be exactly equal. More often equal wing lengths are used.

On divided highway bridges with high skews and shallow end slopes, the wing lengths on the median side of the bridge may be less than the other side due to the difference in sideslope between the median and the outside.

751.1.2.3 Live Load Determination

The live load requirements for a structure shall be HL-93

On box culverts, the actual live load applied to the structure is dependent upon the amount of fill on top of the box; however, see Structural Project Manager for the live load that goes on the Bridge Memorandum.

751.1.2.4 Skew Angle

Determining the most appropriate skew angle for the structure involves some judgement. On bridges over streams, pick the angle that will allow floodwater to pass through the bridge opening with the least amount of interference from intermediate bent columns. Another consideration on meandering streams is to avoid a skew which will cause the spill fill – side slope transition from blocking the stream. Often a trip to the field may be justified just for determining the angle (you can even ask the district to stake some different skews for you to observe in the field).

On stream crossings, avoid skews between zero and five degrees and try to use five-degree increments. On grade separations, often the skew must be accurate to the nearest second to maintain minimum horizontal clearances.

Keep all bents on a bridge parallel whenever possible and avoid skews over 55 degrees (30 degrees for adjacent prestressed concrete beams). Also keep in mind that the higher the skew, the higher the Preliminary Cost Estimate due to the beam caps and wings being longer.

751.1.2.5 Bridge Width

For bridge width requirements, see EPG 231.8 Bridge Width.

751.1.2.6 Vertical and Horizontal Clearances

751.1.2.6.1 Grade Separations

| Minimum Design Clearances for New Bridges | ||

|---|---|---|

| Facility Under Bridge | Vertical Clearance under Superstructure1 | Horizontal Clearance |

| Interstate and Principal Arterial Routes | 16’-6” over roadway including auxiliary lanes and shoulders | Clear zone clearances from the edge of the traveled way (includes shoulders and auxiliary lanes) are obtained from the District Design Division. The vertical clearance is required for the full width of the clear zone. Barrier is required if unable to locate obstacles outside clear zone (columns, beams, walls, coping, 3:1 [1V:3H] slopes or steeper). If a barrier is required the minimum distance to the barrier shall be specified on the Bridge Memorandum as the horizontal clearance otherwise the clear zone clearance shall be used. See EPG 751.2.2.6 Other Loads and Standard Plans 606.01, 606.51 and 617.10 for typical barrier and railing options. |

| Other State Routes with Volumes ≥ 1700 vpd | 16’-6” over roadway including auxiliary lanes and shoulders | |

| Other State Routes with Volumes < 1700 vpd | 15’-6” over the roadway including auxiliary lanes and shoulders2 | |

| Other Streets and Roads | 14’-6” (15’-6” commercial zones) over the roadway including auxiliary lanes and shoulders2 | |

| Railroads | 23’-0” inside 18’-0” opening or as required by railroad (23’-4” for UPRR, 23’-6” for BNSF)3 | 14’-0” and 22’-0” from centerline4,5 (25’-0” eliminates collision walls) |

| 1 Roadway vertical clearances are based upon AASHTO minimums with an additional 6 inches to accommodate future resurfacing of the roadway. An additional 1 ft. is required for pedestrian overpass facilities over roadways. Vertical clearances shown are also applicable when the facility under the bridge is being carried by a bridge. 2 To provide continuity of travel for taller vehicles exceptions can be made both rural and urban for any routes connecting to the systems where taller vehicles are allowed but not to exceed 16.5 feet. 3 Clearance is measured from the top of rails (from top of high rail on superelevated track). The required 18-ft. opening centered on the track shall be increased on each side of centerline 1.5 inches per each degree of curvature for any track crossed. 4 Fourteen feet is a preferred minimum. The absolute minimum is 9 ft. from the centerline plus 1.5 inches per each degree of any track curvature. 5 The minimum clearance of 22 ft. to be provided on one side of the track(s) is for off-track maintenance. If it is not obvious on which side of the track(s) this clearance is provided, a decision should be obtained from railroad's local representative. Assistance from Multimodal Operations may be required in some situations. | ||

| Clearance over Traffic During Construction (New and Existing Structures) |

|---|

| Roadways: Consult with the structural project manager or the structural liaison engineer and the district contact for minimum allowable vertical and horizontal clearance. Vertically this is usually 12 to 18 inches below the final minimum vertical clearance. Horizontally this is usually a minimum number of lanes or minimum size of opening required during the project while specifying the locality of the opening (e.g. centered on existing lanes, two 12-ft. lanes minimum in each direction, etc.). These clearances shall be specified on the Bridge Memorandum to be used in the note required on the final plans. For note see EPG 751.50 A3. All Structures. |

| Railroads: If feasible, 15 ft. horizontally from centerline of track and 21.5 ft. vertically from tops of tracks (from top of high rail on superelevated track). If either of these clearances is not feasible then obtain acceptable clearances from the railroad projects manager. For the detail required on the final plans showing minimum clearances during construction over railroads, see EPG 751.5.2.1.2.7 Features Crossed. |

| Deficient Vertical Clearances on Interstates |

|---|

| Refer to EPG 131.1.7 Deficient Vertical Clearances on Interstates for information about coordinating minimum vertical clearance for grade separation structures with the Defense Department. |

751.1.2.6.2 Stream Crossings

For vertical clearance on stream crossings, see EPG 748.3 Freeboard.

751.1.2.7 Structure Type Selection

Both steel and prestressed concrete girders shall be considered on all structure type selections. As the required span length of the structure increases to bridge the obstruction, deeper girder sections will be required. As a general rule of thumb, span to superstructure depth ratios (S/D) will be on the order of 20 to 30 with the higher numbers being slender, flexible structures.

Preliminary designers should consider these structure types as the span length increases with the top of the list providing the least amount of span capability. Economic consideration should be given to the selection of steel or concrete superstructures. Recent and relevant bid history for each structure type should be reviewed during the preliminary design phase.

- Concrete Box Culvert (single, double or triple cell)

- Prestressed or Reinforced Concrete Slab

- Adjacent Prestressed Concrete Box or Voided Slab Beams (with approval of Structural Project Manager)

- Shallow Depth Girder Sections: Wide Flange Steel Beams, Spread Prestressed Concrete Beams (Box or Voided Slab), Prestressed I-Girders (Type 2, 3, 4 or 6), or Prestressed NU-Girders (PSNU-35 or PSNU-43)

- Intermediate Depth Girder Sections: Plate Girder, Prestressed Bulb-Tee Girder (63.5” or 72.5") or Prestressed NU Girder (PSNU-53, 63, 70 or 78)

- Deep Girder Sections: Plate Girder (greater than 78” web depth)

Voided slab beams are currently only produced by one manufacturer and therefore a long transport may need to be considered in the bridge memo estimate.

Often site conditions warrant the use of shallower depth girder sections to maximize vertical clearance over roads or railroads or to maximize freeboard over streams. When contemplating these situations, the preliminary designer should work with the district highway designer to provide several structure depth options with corresponding roadway profile grade raises. It may be that a more expensive bridge structure results in an overall minimized project cost. High strength concrete or high-performance steel grades may allow the preliminary designer to span longer distances with shallower structures. These higher strength materials may also be used to eliminate girder lines as roadway width increases.

On multi-span structures, it is generally more efficient to have a balanced span arrangement where the end spans are approximately 10 percent shorter than the intermediate spans. This type of arrangement balances the positive moment demand at the midspans with the negative moment demand at the intermediate bents and allows optimization of the structural cross section. For example, a span layout of (67’ - 76’ - 67’) is structurally more efficient than (70’-70’-70’).

751.1.2.8 Box Culverts

Most districts prefer a box culvert to a bridge because of the lower maintenance costs; however, if a stream crossing is on the borderline between a box culvert and a bridge, each option should be explored and presented to the district. The presentation to the district should include the cost estimate for each option as well as a recommendation as to which option is preferred by the Bridge Division. Multi-cell box culverts shall be avoided on streams with reported medium to heavy drift because the interior wall creates a snag point and drift will have difficulty passing through the box culvert resulting in clogging and likely undermining of the culvert. Single-cell box culverts may be used if the opening is sized to allow drift to pass. If the stream being crossed is a drainage ditch it is advisable to have the district contact the drainage district to see if they have any specific objections (i.e. drift etc.) to using a culvert at the proposed location. Approval of proposed structure layout by the drainage district may be required, see EPG 747.3.4 Bridge Permits or Approvals by Other Agencies.

751.1.2.8.1 Hydraulic Design

A general rule of thumb for the use of a culvert is that it can handle about 1,000 cfs per cell with 3 cells being the usual maximum. This can vary if the slope of the streambed is unusually flat or steep. Another rule of thumb is that the water from a drainage area of less than 5 square miles can usually be handled by a concrete box culvert. Curves or bends should be avoided when possible. See EPG 750.2.3.2.2 Head Loss Due to Bends when curves or bends will be used.

For details of hydraulic design, see EPG 750.2 Culverts.

Hydraulic designs and plans for some small box culverts are handled by the district. See EPG 750.7.4.3 Summary of Responsibilities for responsibility for analysis, design and final plans preparation.

751.1.2.8.2 Environmental Requirements

See EPG 750.7.3 Environmental Requirements for details of embedment, velocity and conveyance requirements.

751.1.2.8.3 Layout

751.1.2.8.3.1 Size

When sizing the proposed concrete box culvert, use Standard Box Culvert Sizes whenever possible. For information on standard box culverts sizes, see EPG 750.7.4.1 Standard Plans. For additional information on culvert size, see EPG 750.7.4.4 Size.

751.1.2.8.3.2 Length

The inside face of the headwall is located at the intersection of the roadway fill slope and the top of the top slab of culvert. Typically, the longest barrel is produced considering this intersection point upgrade. Flared inlets, varying roadway widths, clear zones and guardrail placement are possible exceptions to this rule.

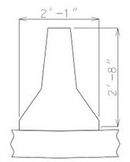

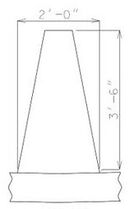

When clear zones are provided, locate the inside face of the headwalls of the culvert at or beyond the edge of the roadway clear zone. In situations of very low fill, contact the district to determine if the use of guardrail is preferred to placing the headwalls beyond the edge of the clear zone. When clear zones are not provided the district will determine the need for guardrail on a case by case basis. Typically when guardrail is to be used over a culvert the typical section will show a 3’-5” shoulder widening as shown in Standard Plan 606.00. Consult the district if it is unclear whether adequate clear zones are provided or if guardrail is to be used over a box culvert. If the fill over the culvert is shallow, guardrail attachment may need to be provided. It may be advisable to lengthen culverts with shallow fill slightly to provide room for future guardrail attachments if guardrail over the box culvert is not provided.

751.1.2.8.3.3 Roadway Fill

Minimum roadway fill height is determined at the outside shoulder line and is the greater of 1 ft. or the thickness of the pavement and base material specified in EPG 750.7.11.1 Minimum Fill Heights. Pavement and shoulder widths and thicknesses are determined on a project by project basis. Pavement and shoulder details (i.e., width, thickness, alternate pavement options) can be obtained from the district if needed, but based on maximum pavement thicknesses and minimum shoulder widths, fill heights at the outside of the shoulder of 20 ½” or greater on major routes or 14 ½” or greater on minor routes will not require pavement or shoulder details. For more information on pavement and shoulder widths and thicknesses see Other Aspects of Pavement Design and EPG 231 Typical Section Elements of Roadways.

Roadway fill outside of the shoulders shall be warped (in the past this was referred to as the fill being “rolled up and over”) to provide a minimum of 12 in. of cover where the top of the culvert could be exposed. A standard note should be shown on the Bridge Memorandums (Memos) regarding warping the roadway fill. Cases where this could occur are:

- 1. Culvert ends with shallow fill and headwalls located outside of the clear zone.

- 2. Median of a divided highway with shallow fill.

- 3. Flared Inlets

- 4. Auxiliary lane or outer road with skews different than that of the mainline

- 5. Steep grade with a wide or skewed culvert.

For additional information of roadway fill, see EPG 750.7.11 Overfill Heights.

751.1.2.8.3.4 Fill Settlement

Check the Preliminary Geotechnical Report for recommendations concerning fill settlements and the use of collar beams on longer box culverts. Cambering of the culvert should also be considered when fill settlements are appreciable. For more information, see EPG 750.7.9 Camber in Culverts.

751.1.2.8.4 Precast Box Culvert Sections

If the use of precast box culvert sections will not be allowed to be substituted for cast-in-place construction or if precasting is required it should be noted on the bridge memorandum and on the bridge plans.

Precast option for box culvert extensions will be permitted using a cast-in-place connection where the centerline of new cells is not laterally displaced more than 15° (maximum) from the centerline of existing cells for each cell extension.

751.1.2.8.5 Abrasion

If a culvert requires design for abrasion it should be noted on the bridge memorandum. For more information see EPG 750.7.4.2 Abrasion of Interior Surfaces.

751.1.2.9 Girder Type Selection

Once it has been determined that the structure will have girders, the types of girders to be used must be identified. To check the vertical clearance or freeboard, the maximum span length of each type of girder must be known. See EPG 751.22 P/S Concrete I Girders or EPG 751.14 Steel Superstructure. Adjustments will need to be made if the span ratios become greater than 1.25.

If it is determined that the roadway profile grade will need to be raised (or lowered) to provide additional vertical clearance or freeboard, the preliminary designer should notify the district contact as soon as possible. It is best to provide the district with several options of varying profile grade elevation increase with varying structural depth. Larger grade elevation increases typically result in longer bridges as spill slopes dictate bridge length. The preliminary designer and district contact should work together to minimize the overall project cost even if the bridge cost is slightly more expensive. Consider the various structure types listed in EPG 751.1.2.7 Structural Type Selection when selecting the girder type. Also consider that adding girder lines or using higher strength material (concrete or steel) may allow longer or shallower spans for a given girder cross section. As a last resort, request a design exception for the substandard item.

751.1.2.9.1 Concrete Girder Options

Prestressed girder selection should use the following order for trial sizing and spanning:

- Prestressed or reinforced concrete slab beams

- Prestressed Concrete Box Beams

- MoDOT Standard Prestressed Girders Type 2, 3, 4 and 6

- NU Standard Prestressed Girders Type 35, 43, 53, 63, 70 and 78

- MoDOT Bulb-Tees Type 7 and 8

For span lengths longer than 125 feet for prestressed concrete, the girders become very heavy and are difficult to transport to the site and often require two or more large cranes to place on the supports. The preliminary designer should discuss this with the district, and have it documented on the Constructability Questionnaire noted in EPG 751.1.2.18.3 Supporting Documents.

751.1.2.9.2 Steel Girder Options

When considering steel structures, the preliminary designer must decide if the girders should be painted or fabricated from weathering steel. If site-specific conditions allow, the use of unpainted weathering steel (ASTM A709 Grades 50W and HPS70W) should be considered and is MoDOT’s preferred system for routine steel I-girder type bridges due to its performance, economic and environmental benefits. Cost savings are realized because of the elimination of the initial paint system as well as the need for periodic renewal of the paint system over the life of the structure.

Weathering steels provide significant environmental and worker safety benefits as well. Since they do not require initial and periodic repainting of the whole bridge, emissions of volatile organic compounds (VOC) are reduced. Also, they generally do not require coating removal or disposal of contaminated blast debris over the service life of the structure. By eliminating the need for periodic repainting, the closing of traffic lanes can be prevented as well as the associated hazards to painters, maintenance workers, and the travelling public.

Partial coating of weathering steel is required near expansion joints. See EPG 751.14.5.8. Periodic recoating or overcoating will be required, however, on a much smaller scale than the whole bridge with the effect that lane closures and associated hazards are greatly reduced compared to painted steel.

Although weathering steel is MoDOT’s preferred system for routine I-girder bridges with proper detailing, it should not be used for box girders, trusses or other structure types where details may tend to trap moisture or debris. There are also some situations where the use of weathering steel may not be advisable due to unique environmental circumstances of the site. Generally, these types of structures would receive high deposits of salt along with humidity, or long-term wet conditions and individually each circumstance could be considered critical.

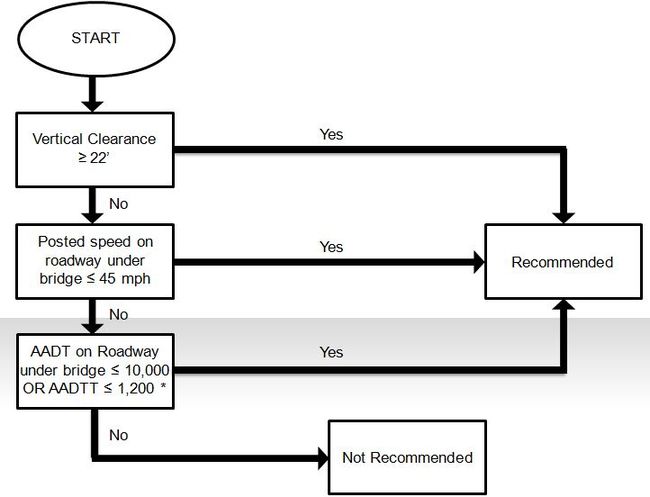

The FHWA Technical Advisory T5140.22 October 1989 should be used as guidance when determining the acceptability of weathering steel. Due to the large amounts of deicing salts used on our highways which ultimately causes salt spray on bridge girders, the flowchart below should be used as guidance for grade separations. The flowchart, Fig. 751.1.2.9, below, is general guidance but is not all inclusive. There may be cases based on the circumstances of the bridge site where the use of weathering steel is acceptable even though the flowchart may indicate otherwise. In these cases, follow MoDOT’s design exception process.

Weathering steel may be used for stream crossings where 1) the base flood elevation is lower than the bottom of girder elevation and 2) the difference between the normal water surface and bottom of girder elevations is greater than 10 ft. for stagnant and 8 ft. for moving bodies of water. Where the difference in elevations is less than noted, weathering steel may be used upon approval of the Assistant State Bridge Engineer.

Additional documents that can be referenced to aid in identifying the site-specific locations and details that should be avoided when the use of weathering steel is being considered include:

- 1. Transporation Research Board. (1989). Guidelines for the use of Weathering Steel in Bridges, (NCHRP Report 314). Washington, DC: Albrecht, et al.

- 2. American Iron and Steel Institute. (1995). Performance of Weathering Steel in Highway Bridges, Third Phase Report. Nickerson, R.L.

- 3. American Institute of Steel Construction. (2022). Uncoated Weathering Steel Reference Guide. NSBA

- 4. MoDOT. (1996). Missouri Highway and Transportation Department Task Force Report on Weathering Steel for Bridges. Jefferson City, MO: Porter, P., et al.

The final brown rust appearance could be an aesthetic concern. When determining the use of weathering steel, aesthetics and other concerns should be discussed by the Core Team members, with input from Bridge Division and Maintenance Division.

If weathering steel cannot be used, the girders should be painted gray (Federal Standard #26373). If the district doesn’t want gray, they can choose brown (Federal Standard #30045). If the district or the local municipality wants a color other than gray or brown, they must meet the requirements of EPG 1045.5 Policy on Color of Structural Steel Paint. System G paint is the preferred system on all steel plate girders. See EPG 751.6.2.11, EPG 751.6.2.12 and EPG 751.14.5.8 for further guidance on paint systems.

751.1.2.10 Longer Bridges

For bridges that are longer than normal (more than 6 spans being a general rule of thumb), other items must be considered. If the feature you are crossing allows flexibility in bent placement, the most cost-efficient span length is one that will result in the cost of one span's superstructure being equal to the cost of one bent. For example, calculate the cost of one intermediate bent, and then adjust the length of the span until the cost of the girders, slab and curb equal the cost of the bent. The use of higher strength concrete in Prestressed I-Girders or high performance steel in plate girders can allow spans to be increased approximately 20% as a means to eliminate intermediate bents.

Another item to consider is the placement of expansion devices. Be sure to include the costs of the expansion devices and deadman anchors (if applicable) in your Preliminary Cost Estimate.

751.1.2.11 Staged Construction

If the new structure being laid out replaces an existing structure on the same alignment, the default method of handling traffic during construction is to close the road and detour traffic. The new substructure should be spaced to avoid the existing substructure units if at all possible.

If the district determines the road cannot be closed, the options for handling traffic include staged construction or using a temporary bypass. If a temporary bypass is used, determine whether the district can size some drainage-diversion pipes for the bypass. If the district decides pipes cannot be used, then a temporary bridge is necessary, and a separate Bridge Survey/Memo/Bridge No. is required.

If the district decides to use staged construction, one important item to verify in this situation is that the new girders will clear the existing substructure. Another item to consider in setting up the staging is the placement and attachment requirements of the temporary concrete traffic barrier relative to the bridge deck and meeting horizontal distance requirements from the edge of the deck, which determines whether the temporary concrete traffic barrier is attached to the deck and how it is attached.

- For staged bridge construction with MSE walls at the abutments, consider specifying location of temporary MSE walls on the plan details. The interior angle between MSE walls and temporary MSE walls should be greater than 70°. However, if unavoidable, then interior angle shall be absolute minimum 65°. Temporary MSE wall option for staged bridge construction shall not be used when bridge skew is greater than 25°.

Sometimes due to limited space or to retain improved foundation material or to retain existing slope contractor may need to provide temporary shoring prior to constructing temporary MSE wall systems in staged construction, but only the temporary MSE wall should be indicated on the plans. For design requirements of MSE wall systems, see 720 Mechanically Stabilized Earth Wall Systems.

751.1.2.12 Temporary Barriers

Bridge Plans must note whether temporary concrete traffic barrier is attached or freestanding, and if attached, whether they are attached with tie-down straps or bolt through deck attachment. Coordination is required with district Design. See EPG 617.1 Temporary Traffic Barriers for more guidance.

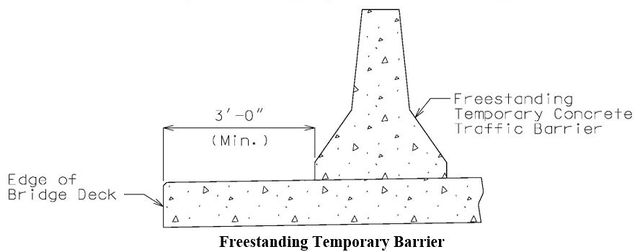

- a. Where sufficient distance is available to accommodate lateral deflection of barriers: No attachment is required. Note on plans as “Freestanding” or “No attachment required”.

- b. Where sufficient distance is not available to accommodate lateral deflection of barriers: Tie-down strap system is required. (Refer to Standard Plan 617.20.) Coordinate with district Design to provide a minimum of four connected temporary concrete traffic barrier sections on approach slab roadway.

- c. Where lateral deflection cannot be tolerated: Bolt through deck system is required. (To be used only on existing decks that will be removed and that have sufficient strength.) (Refer to Standard Plan 617.20.) Coordinate with district Design division for required transition barrier attachments that may be used on any deck, existing or new, where lateral deflection is not permitted with approval of the Structural Project Manager or Structural Liaison Engineer.

For all other applications of a freestanding temporary concrete traffic barrier, the preferred installation method requires a 2 ft. buffer area behind the barrier to allow for lateral deflection in both work areas and lane separation situations.

Regardless of deflection distance (buffer area) available, if the bridge deck is super elevated or has a large roadway slope, a freestanding temporary concrete traffic barrier should not be used because the barrier has the potential for movement (“walking”) due to gravity forces and vibrations acting on the barrier.

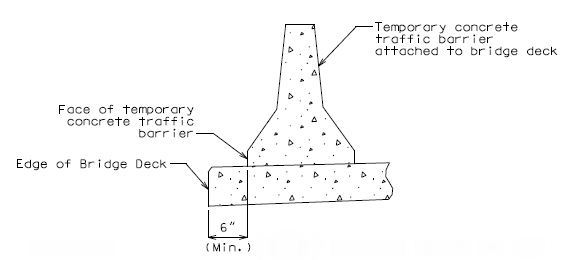

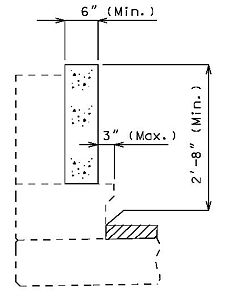

When a temporary concrete traffic barrier is adequately attached to a bridge deck (refer to Standard Plan 617.20) a minimum distance of 6 in. shall be provided from the edge of the bridge deck to the face of the barrier.

751.1.2.13 Seismic (Earthquake) Design Category A, B, C and D Considerations

See EPG 751.9 Bridge Seismic Design for seismic design and detail requirements in accordance with SGS, and LRFD. Utilize provided flow charts.

All new or replacement bridge/wall designs, either nonseismic (meaning a regular static design) or seismic design or detail, must meet Seismic Design Category (SDC) A requirements in accordance with SGS (Seismic Zone 1 of LRFD). Additionally, where applicable bridge seismic designs/details/analysis must meet requirements of the Seismic Design Category B, C, or D in accordance with Bridge Seismic Design Flowchart.

For laying out new or replacement bridges in SDC A, B, C or D (per SGS), the following is important.

- Box culverts are preferable to bridges on stream crossings because they are exempt from seismic design unless crossing a known exposed fault.

- Pile cap intermediate bents and drilled shafts are preferable to open column bents on footings because footings can grow quite large due to seismic forces.

- Minimize the number of expansion joints in the deck because each of these locations may require earthquake restrainers which are very costly.

- Make the superstructure as light as possible, which usually means use steel plate girders or wide flanges instead of prestressed concrete girders where possible.

The new or replacement bridge design schedule for a complete seismic analysis requires 24 months minimum and bridge design schedule for seismic details and/or abutment seismic design requires 13 months minimum. Additional 2 - 3 months is required for review and letting process before the schedule letting. See EPG 751.1.1.5 New Regular Bridge Design Schedule (Nonseismic) (Nonrailway Crossing).

751.1.2.14 Temporary Bridges

If the district will be using a bypass on stream crossings, a temporary bridge may be necessary. The district should first consider using large drainage-diversion pipes to carry the water under the bypass, if the district determines this is not practical, they should submit a Bridge Survey for a temporary bridge on the bypass. Check with the Structural Project Manager for hydraulic design frequency.

Once the number of 40’ spans has been determined, the district should be contacted so they can locate the pieces necessary for the construction of the bridge. Make sure the pieces the district intends to use have the “new” beam caps that take 14” H-pile. The district should provide you with the location of where the pieces are coming from and where they should be taken by the contractor at the end of the project. If the district is unable to find the pieces, then they will need to be contractor furnished. This has a big impact on costs. See Preliminary Cost Estimate.

751.1.2.15 Bridges Over Railroads

Consult the AREMA (American Railway Engineering and Maintenance-of-Way Association) Manual for Railway Engineering located in the Bridge Division’s Development Section for more detailed information. Here are some basic points to keep in mind:

- Railroads often raise their tracks so provide some cushion in your vertical clearance.

- Absolute minimum horizontal clearance shall be 9 feet on each side of track centerline plus 1 1/2 inches per each degree of track curvature. (railroad projects manager of the Multimodal Operations Division will obtain the degree of curvature from the railroad)

- Will the railroad want room for an extra track or maintenance roadway?

- Keep the ballast free drained.

- Drainage needs to be designed for 100-year storm.

- Slope protection shall consist of Type 2, 18-inch thick rock blanket placed on top of permanent erosion control geotextile. Some railroads may require changes to this; however, this will be determined on a case-by-case basis.

- Some railroads also now require the barrier and slab overhangs to be designed to accommodate fences that may be added in the future.

If the face of the columns of an intermediate bent is within 25 ft. of the centerline of the railroad track, a collision wall is required. If the face of the columns of an intermediate bent is within 12 ft. of the centerline the top of the collision wall shall be set at 12 ft. above top of rail otherwise the top of the collision wall shall be set at 6 ft. above top of rail.

The railroad projects manager in the Multimodal Operations Division is a very good resource for answering questions at any stage of the layout. It typically takes a very long time to receive approval of a layout from the railroad. The railroad must approve both the preliminary design and the final plans.

When making a submittal to the railroad project manager for approval of the preliminary design, include three sets of half-sized plat and profile sheets, as well as a copy of the Design Layout.

The new bridge design schedule for a railway crossing bridge requires 24 months minimum. See EPG 751.1.1.5 New Regular Bridge Design Schedule.

751.1.2.16 Historical Bridge Considerations

You also need to check with the Historical Bridge Coordinator in the Design Division when replacing a bridge. There is not a magic age for a bridge for it to become "historical". Age does not matter. All "Bridge Resources" that will be impacted by MoDOT need to be cleared through the Department of Natural Resources (DNR) Historic Preservation Program (HPP) before they can be replaced, demolished, extensively rehabilitated or deeded to a new owner (county, city, etc.). The following is a definition of "Bridge Resources":

- "Bridge Resources are both public and privately owned highway, railroad and pedestrian bridges, viaducts and culverts. This does not include metal and plastic pipes, unless they are encased in an older concrete, stone or brick structure."

The following is the information on this topic supplied to the district (FYI):

- "Bridge Resources on any given job or location study need to be checked out and cleared just like historic buildings (architecture) and archaeological sites. Standard size color photographs can be submitted to the Historic Bridge Coordinator directly and/or attached to the Request for Environmental Assessment (RES) or Questionnaire to Determine Need for Cultural Resources Assessment. The Historic Bridge Coordinator will then determine and execute procedures for clearance, if required."

Bridges that are older than 50 years stand a better chance of being evaluated as eligible for the National Register of Historic Places (NRHP) in Clayton Fraser's 1996 draft Missouri Historic Bridge Inventory. This is a study that was undertaken under STURAA (Surface Transportation and Uniform Relocation Assistance Act of 1987) in order to inventory all potentially NRHP eligible historic bridges in the state. Any of these that are determined NRHP eligible by the HPP will require special mitigation (or avoidance) if they are to be affected by project activities. For this reason, it is important that all bridge resources be identified early in the process.

Usually, bridge resources do not stand in the way of right of way acquisition (A-dates) because they are generally located on roadways that the state already owns; however, there are cases in which bridge resources are privately owned and located on private property. In these rare cases, bridge resources would need to be checked out prior to our right of way acquisition approval.

751.1.2.17 Preliminary Cost Estimate

Box Culverts – A new or replaced box culvert is exempt from seismic design unless crossing a known exposed fault. Submit “Request for soil properties Form A” to Geotech Section and design as a SDC A. If box culvert is crossing a known exposed fault then discuss with Structural Project Manager (SPM) for alternate option.

Bridges and Retaining Walls – For a new or replaced retaining wall or bridge, review Bridge Seismic Planning Flowchart, Bridge Seismic Design Flowchart, preliminary seismic design map and following information.

- Seismic design of overpass should be considered when overpass bridge collapse would greatly impede emergency traffic for the main route. (i.e., No access ramps on a major route or a 1st or 2nd priority earthquake emergency route).

- For preliminary planning and cost estimate use the SDC values shown on preliminary seismic design map. SDC boundaries are shown for soil site class D.

- Site class verification is not required for bridges located in regions SDC A1 or A2, so the preliminary SDC shall be used for plans reporting.

- In the normal design schedule, the Geotechnical section will determine the site class and an accurate SDC, SD1, As for bridges located in the regions encompassed by SDC B, C and D on the preliminary seismic design map. Typically, the SDC will remain the same as shown on the map or get dropped to a lower SDC (e.g., D to C, C to B, B to A2).

- If a bridge gets downgraded to SDC A2 after Geotech analysis and carry a 1st or 2nd priority earthquake emergency route, the bridge shall receive seismic details similar to SDC B. If a bridge gets downgraded to SDC A2 after Geotech analysis and does not carry a 1st or 2nd priority route, it will not require seismic details. If a bridge gets downgraded to SDC A1 after Geotech analysis, it will not require seismic details. Typically, downgrades may result in a reduced project schedule and/or a reduced cost estimate for the bridge.

- Geotechnical section will perform a liquefaction assessment for bridges with a final SDC of C or D and carry a major route or 1st or 2nd priority earthquake emergency route.

Seismic design category (SDC) is divided in SDC A (SD1 < 0.15), SDC B (0.15 ≤ SD1 < 0.30), SDC C (0.30 ≤ SD1 < 0.50) and SDC D (SD1 ≥ 0.50). SDC A is subdivided into SDC A1 (SD1 < 0.10) and SDC A2 (0.10 ≤ SD1 < 0.15). Submit “Soil properties Form A” to Geotech Section for SDC A1 and SDC A2 area bridges, retaining walls and box culverts. Submit “Soil properties Form A” and “Soil properties Form B” to Geotech Section for SDC B, C and D area bridges and retaining walls. For soil properties form, see EPG 751.1.2.19 Soundings (Borings).

The Preliminary Cost Estimate should be neat, legible and dated since a copy of it is included with the Bridge Memo. It should also be rounded to the nearest thousand dollars.

The accepted method of calculating the Preliminary Cost Estimate is to calculate some approximate quantities for the bridge and then multiply them by the unit prices supplied by the Bridge Division Preliminary and Review Section. A spreadsheet should be used to calculate these quantities. To estimate the pounds of reinforcing steel in a structure, multiply the number of cubic yards of concrete in the structure by 125 for bridges. See table below for Box Culverts.

| Table 751.1.2.17, Box Culvert Reinforcing Steel (lbs.) Estimate | |

|---|---|

| Design Fill (ft.) | Concrete (lbs/cy) Multiplier |

| 2.00 | 225 |

| 6.00 | 168 |

| 10.00 | 116 |

| 25.00 | 96 |

| 32.00 | 84 |

The Preliminary Cost Estimate should be increased for the following items: Cost Estimate Guide for rural preliminary design (do not compound all increases using your judgment).

| Bridge in SDC boundaries on preliminary seismic design map |

% Cost Increase | Comments for final SDC |

| SDC A1 SDC A2 (nonseismic) SDC A2 (seismic details) |

0 0 10 |

No cost increase for SDC A1 area bridges and most of the bridges in SDC A2 area. If a bridge carry a 1st or 2nd priority earthquake emergency route and located in SDC A2 area, it will receive seismic details similar to SDC B (i.e. 10% increase). |

| SDC B (single span, seismic details) SDC B (single span, abutment seismic design) SDC B (multi-span) |

0 5 10 |

Cost increase is for seismic details in accordance with the 2023 AASHTO Guide Specifications for LRFD Seismic Bridge Design. If bridge receives a final SDC B and carries a major route or 1st or 2nd priority earthquake emergency route then abutments will be designed for mass inertial forces per SEG 24-02. (i.e. 0 to 5% increase for single span bridges). If a bridge gets downgraded to SDC A2 and does not carry a 1st or 2nd priority route, it will not require seismic details. If a bridge gets downgraded to SDC A1 after Geotech analysis, it will not require seismic details (i.e. no cost increase). |

| SDC C (single span, seismic details) SDC C (single span, abutment seismic design) SDC C (multi-span, seismic details) SDC C (multi-span, complete seismic analysis) |

0 5 10 25 |

25% cost increase is for complete seismic analysis. All bridges receiving a final SDC C and not carrying a major route or 1st or 2nd priority earthquake emergency route will only receive seismic details (i.e. 10% increase). If a bridge carries a major route or 1st or 2nd priority earthquake emergency route, gets downgraded to SDC B, it will only receive seismic details and abutments will be designed for mass inertial forces per SEG 24-02 (i.e. 10% increase).If single span bridge receives a final SDC C and carries a major route or 1st or 2nd priority earthquake emergency route then abutments will be designed for mass inertial forces per SEG 24-02 (i.e. 0 to 5% increase). |

| SDC D (single span, seismic details) SDC D (single span, abutment seismic design) SDC D (multi-span, seismic details) SDC D (multi-span, complete seismic analysis) |

0 10 10 40 |

40 % cost increase is for complete seismic analysis. All bridges receiving a final SDC D after Geotech analysis and do not carry a major route or 1st or 2nd priority earthquake emergency route will only receive seismic details (i.e. 10% increase). If a bridge carries a major route or 1st or 2nd priority earthquake emergency route, gets downgraded to SDC B, it will only receive seismic details and abutments will be designed for mass inertial forces per SEG 24-02 (i.e. 10% increase). If a bridge carries a major route or 1st or 2nd priority earthquake emergency route, gets downgraded to SDC C, it will receive a complete seismic analysis (i.e. 25% increase). If single span bridge receives a final SDC C or D and carries a major route or 1st or 2nd priority earthquake emergency route then abutments will be designed for mass inertial forces per SEG 24-02 (i.e. 5 to 10% increase). |

Item % Cost increase Staged Construction (SDC A) 10 Horizontally Curved (SDC A) 5 Tight Site/Limited Access 3

The following are guidelines for estimating the cost of the removal of existing bridges:

Type of Bridge Removal Cost per Square Foot Simple Structures Over Streams ** Girder Structures Over Roads ** Conc. Slab Structures Over Interstates ** (Quick opening of lanes to traffic)

Consult Bid Tabs for an analysis of the latest bridge removal costs. Bridge Division staff may consult the Pay Item Spreadsheet maintained by the Structural Review Engineer or see EPG 751.6.1 Index of Quantities.

751.1.2.18 Bridge Memorandums

Bridge Memorandums are generated for new and rehabilitated bridge structures including retaining walls. Formal correspondence will not be required for special structural work or miscellaneous structures like high mast tower lighting (HMTL) or small retaining walls equal to or shorter than 5 feet; however, documentation such as a Bridge Memorandum may be a good idea in order to effectively communicate the understanding and agreement to the level of design work proposed and associated construction costs with districts.

751.1.2.18.1 Purpose

The Bridge Memorandum is the instrument which coordinates bridge plan and roadway plan preparation. It is sent to the district to inform them where we plan to put the bridge, what kind of structure it will be, what the Preliminary Cost Estimate is and any other pertinent information. More information is required on more complicated structures. If you are not sure if the district needs to have a certain piece of information concerning the structure, include it on the Bridge Memorandum to be safe. Too much information is better than too little.

An electronic copy of the bridge memorandum and supporting documents are sent to the district for review and signature. If, during the design process, revision to the bridge memorandum by either the district or the Bridge Division becomes necessary, all parties to the memorandum are to be notified immediately. The proposed revisions must be agreed to by all parties that signed the original bridge memorandum.

The Bridge Memorandum also serves as a design layout for structures where the latter is not required, see EPG 751.1.2.31 Finishing Up Design Layout.

751.1.2.18.2 Content

Sample listing of what to include on the Bridge Memorandum:

1. Identify the following classifications if applicable: (Design Implications)

- • All routes involved shall be classified as either:

- o (major), as shown in link.

- o (minor), not a major route and ADT ≥ 400.

- o (low volume), not a major route and ADT < 400.

- • Major bridges with a total length ≥ 1000 feet shall be classified by specifying “(major)” behind the specified bridge number.

- • Priority 1 or 2 earthquake emergency routes shall be classified by specifying “(priority 1 2 EQ)” behind the route classification.

- • All routes involved shall be classified as either:

2. Identify type of structure, span lengths, skew, loading, roadway width, wing lengths and special end fill considerations. For curved structures, specify how the design span lengths are to be measured i.e., “measured along the CL of Roadway”. If plate girder or wide flange beam, further identify them as either weathering or painted steel.

3. Indicate all pertinent profile grade, alignment and superelevation transition information.

4. Identify the fill exception stations or ends of the bridge. The district uses this to coordinate the bridge with their roadway design features such as guardrail. For PSI-Girder bridges, take into account the layout length when calculating these stations.

5. Identify slopes at end bents.

6. Indicate elevation of any berms to be constructed at the end bents.

7. If applicable, call for old roadway fill to be removed to natural ground line.

8. For box culverts, indicate the location of the headwalls and the type of wings to be provided (flared or straight). Also include the upper and lower flow line elevations along the CL of the box.

9. Identify any bridge related items that the district will need to address in their plans or special provisions as a “Roadway Item”.

10. Include the cost estimate for construction (Preliminary Cost Estimate).

11. Include the method of traffic handling while construction is underway. Attach sketches for staged construction when appropriate.

12. For stream crossings, show all pertinent hydrologic data used for the layout of the structure. See EPG 751.5.2.1.5.3 Hydraulic Data for Hydraulic Data tables.

13. For roadway and railroad grade separations, include all minimum vertical and horizontal clearances (final and construction) and include the opening (horizontal limits) of the minimum vertical clearance. The minimum horizontal clearance shall be specified from the edge of the traveled way(s).

14. Quite often, the district will add items to a bridge late in the final design process because they “didn’t think of them” earlier. This often causes extra work due to the necessary redesigns. Include a statement similar to the following to reduce this occurrence:

- "No conduit, lighting, utility supports or sidewalks are to be included in the final plans for this bridge."

- If the district has already indicated that they want special items attached to the bridge, include the specifics on the Bridge Memorandum and modify the above note.

15. The design year AADT (annual average daily traffic) and AADTT (annual average daily truck traffic). Request this from the district if it is not shown on the plat sheet. On grade separations, get the AADT and AADTT for both roads.

16. For box culverts, always include the following notes:

- Channel bottom shall be graded within the right of way for transition of channel bed to culvert openings. Channel banks shall be tapered to match culvert openings. (Roadway Item)

- If any part of the barrel is exposed, the roadway fill shall be warped to provide 12 inches minimum cover. (Roadway Item) (See EPG 751.1.2.8.3.3, Box Culverts, Roadway Fill.)

17. Also for box culverts, state if guardrail (Roadway Item) is to be provided in lieu of meeting the clear zone requirements. If there will be guardrail over the box culvert and the fill height is less than indicated in EPG 750.7.4.5, Box Culverts, Guardrail Attachment, indicate that attachment of the guardrail to the top slab will be handled in the bridge plans, even though the guardrail itself is a roadway item. For additional information on when to use guardrail attachments, see EPG 751.1.2.8.3.2 Length, Box Culvert, Length.

18. For stream crossings (new structures, widened structures and rehabs where the waterway opening is reduced.) include a statement stating that a Floodplain Development Permit is required or that a Floodplain Development Permit is not required and that the Bridge Division will request such a permit if necessary. Also indicate the flood hazard zone (i.e., A, A1, B) and whether or not the bridge is in a Floodway.

19. On Rehabilitated and widened structures give the current and proposed load rating and load posting as well as the current condition ratings for the deck, superstructure, substructure and scour.

20. Identify the bridge approach slab class major or minor. If a design exception is required or approved, then note accordingly. Identify asphalt mix type (determined by district) when the asphalt bridge approach slab sub-class is an option.

21. Identify the bridge end drainage provisions as determined by district Design. For example, note when concrete aprons at each wing wall will be required (Rdwy. Item). Note when concrete approach pavement (Rdwy. Item) with or without drain basins (Rdwy. Item) will be required, or note when rock blanket will be required that extends up to full length of bridge approach slabs, or when drain flumes (Rdwy. Item) will be required.

22. For redecks or in other cases where the rock blanket elevations are not shown on the bridge plans and the top of the rock blanket is required to be flush to the existing ground line in accordance with the Memorandum of Agreement with SEMA, include the following note:

- The top of rock blanket shall be flush to the ground line as directed by the engineer. (Roadway Item.)

23. For retaining walls, indicate any aesthetic treatments such as concrete staining and form liner requirements. Be specific regarding names, types and colors of staining, and names and types of form liner.

24. Form liners are standard for MSE precast modular panel wall systems. Be specific regarding names, types and colors of staining, and names and types of form liner. See Bridge Standard Drawings → MSE Wall - MSEW.

25. For MSE wall supporting abutment fill: Identify gutter type, fencing, lower longitudinal and lateral drain pipe sizes (type and sizes to be determined by district Design division). (Lateral drain pipes are only required as determined by district Design division.)

26. OPTIONAL Seismic Information for new bridge or wall on Memo: Note “Preliminary Seismic Description: Site Class _, Seismic Design Category _, As = __, SD1 = _, _____”. The last blank should be filled with “non-seismic”, “seismic details”, “abutment seismic design”, “seismic details with abutment seismic design” or “complete seismic analysis”. The provided information is subject to change after Geotechnical Report is released. See Bridge Seismic Planning Flowchart. (This is similar to item no. 9 under EPG 751.1.2.31 Finishing Up Design Layout.)

27. For rehabs, redecks, widenings, recoatings and new replacement structures, see EPG 751.1.3.9 Environmental Considerations: Asbestos and Lead for notes to include.

751.1.2.18.3 Supporting Documents

Supporting documents may provide additional information to the district or request additional information from them. Other documents may need to be included, but at a minimum the following documents should be sent to the district with the Bridge Memorandum:

- Calculations used for the Preliminary Cost Estimate

- Constructability Questionnaire, modify to address project issues

- Layout for Soundings

751.1.2.18.4 Bridge Division Review

Once the Preliminary Designer has the Bridge Memo and supporting documents completed, they are submitted to the Structural Project Manager (SPM) for their review. The SPM will then request a Bridge Memo Conference with the Assistant State Bridge Engineer, the Structural Resource Manager and the Structural Prelim. & Review Engineer. After the review and conference, the Preliminary Designer will update the Bridge Memorandum and supporting documents. The Designer and SPM sign and date the memo by typing their names and the date in the locations provided.

751.1.2.18.5 Bridge/District Agreement Process

The following process will be used to establish agreement between the district and Bridge Division on Bridge Memorandums:

- 1) Bridge Memorandums and supporting documentation will be made available on SharePoint by Bridge Division.

- 2) The Bridge Division preliminary designer or Structural Project Manager (SPM) will email the Transportation Project Manager (TPM) and the District Bridge Engineer a link to the Bridge Memorandum in SharePoint when the memorandum is ready for review by the district. (A link to the Constructability Questionnaire, Cost Estimate, Layout for Soundings, and Request for Soil Properties may also be included.) As part of their review the TPM should forward the Bridge Memorandum to the appropriate Resident Engineer to solicit their input on the Memorandum.

- 3) Changes to the Bridge Memorandum should be made in revision mode or with bold blue text for additions and red strikethrough text for deletion of existing text. (Discussion of proposed changes with the Bridge Division preliminary designer and SPM is recommended before making changes.)

- 4) Once the district’s review of the Bridge Memorandum is complete the approving district personnel should type their names, titles and the date in the appropriate locations.

- 5) TPMs or their designees email the Bridge Division preliminary designer and SPM to inform them the district has reviewed and signed the Bridge Memorandum. A summary explaining any of the changes should be included in the email.

- 6) The Bridge Division preliminary designer or SPM will accept the changes or coordinate with TPMs or their designees to resolve any differences.

- 7) Once all differences are resolved the Bridge Division preliminary designer or the SPM will email the TPM or the TPM's designee indicating the agreement process is complete. Changes made to the Bridge Memorandum after the initial agreement may be handled by email or by the process described above.

751.1.2.18.6 Documentation

The Bridge Memorandum, supporting documents and related correspondence will be stored on the Bridge Division SharePoint page in the Projects -Inwork directory.

A copy of the agreed upon bridge memo is placed in the Layout folder. If changes are made after the initial agreement, a copy of the revised memo should be added to the layout folder and the original bridge memo marked as void with the date of revision noted.

751.1.2.19 Soundings (Borings)

| Additional Information |

| Request for Final Soundings for Structures Form |

| Guidance for Request for Final Soundings for Structures Form |

751.1.2.19.1 Purpose

The borings define subsurface conditions at the project site and are used to determine type of foundation (driven piles, pile cap footing, spread footings, drilled shafts), preliminary estimate of pile lengths and engineering design properties.

Note that two types of soundings are typically provided by a soundings investigation.

- 1. Auger Borings - These are the most typical type of soundings provided due to availability of equipment and low cost. This type of boring is generally stopped immediately upon encountering "hard rock". All description of type of soil and rock encountered is determined in the field.

- 2. Core Samples - These are more time consuming and expensive. They are also subject to the availability of the specialized equipment and are therefore provided as sparingly as possible by the soundings crew. Once "hard rock" is encountered at a coring location, drilling is continued for an additional 10 ft. to ensure a consistent layer of actual hard rock (not a boulder). If a void layer is encountered in the additional drilling, the drilling is continued until another 10 ft. of consistent hard rock is encountered. In addition to field determination of soil layer type and performance of the Standard Penetration Test (SPT), samples are returned to the lab for additional tests such as determination of rock quality (% RQD).

751.1.2.19.2 Required Locations

Bridges – Borings should be requested at each bent. For bents on columns, estimate the number and location of the columns for each bent and request borings for these locations.

Box Culverts – Borings should only be requested for Box Culverts on Rock (no bottom slab). Borings should be requested every 10 ft. along the alignment of both exterior walls for single box culverts and along both the exterior and interior walls for multiple cell culverts.

MSE Walls – Borings should be requested at 25 ft. intervals along the baseline of the MSE Wall and at control points along the wall (such as bend lines). For a MSE Wall that wraps around an end bent, consideration should be given as to whether requesting additional borings in a grid pattern between the walls is necessary.

CIP Concrete Retaining Walls – Borings should be requested at 25 ft. intervals along the wall alignment.

751.1.2.19.3 Required Documents

Plan and Elevation/Profile Sheets. Using MicroStation, the proposed structure should be drawn on the bridge survey plan sheet(s). Boring symbols should be placed at all requested boring locations.

To find the Northing and Easting, the "Label Coordinates" tool in MicroStation can be used. The grid factor, projection factor, coordinate system, zone, horizontal datum and vertical datum will be required information necessary for completing the Request for Final Soundings for Structures Form, all of which should have been provided with the bridge survey report.

Plan and Elevation Sheet(s) of Existing Bridge. When applicable.

Request for Final Soundings for Structures Form. The Guidance for Request for Final Soundings for Structures Form is available.

Instructions to Soundings Party included on the form should be similar to the following: