106.3.2.7 TM-7, Rebound Hammer for Opening Strength of Full Depth Concrete Pavement Repairs

| Rebound Hammer |

|

|

|

This method describes a procedure for using the rebound hammer to determine the opening strength of full depth concrete pavement repairs.

106.3.2.7.1 Apparatus

The apparatus shall consist of the following:

1. Rebound hammer, consisting of a spring-loaded steel hammer which when released strikes a steel plunger in contact with the concrete surface. The spring-loaded hammer must travel with a consistent and reproducible velocity. The rebound distance of the steel hammer from the steel plunger is measured on a linear scale attached to the frame of the instrument.

2. Abrasive stone, consisting of medium-grain texture silicon carbide or equivalent material.

3. Verification anvil, used to check the operation of the rebound hammer. An instrument guide is provided to center the rebound hammer over impact area and keep the instrument perpendicular to the anvil surface. The anvil shall be constructed so that it will result in a rebound number of at least 75 for a properly operating instrument.

106.3.2.7.2 Verification

Rebound hammers shall be serviced and verified annually and whenever there is reason to question their proper operation. The functional operation shall be verified on the test anvil. Typically, a properly operating rebound hammer will result in a rebound number of 80 ±2 when tested on the anvil. The test anvil must be supported on a rigid base to obtain reliable rebound numbers.

106.3.2.7.3 Procedure

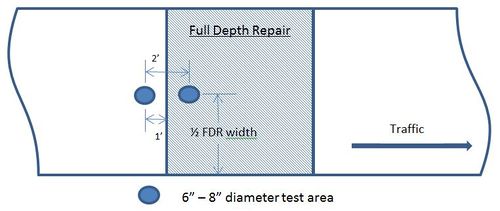

1. Test Areas. Two areas will be tested: one on the full depth concrete patch and one on the adjacent existing concrete slab. Each test location will be centered transversely along the repair and centered longitudinally approximately one foot from the repair joint and two feet from each other. Each test area will be between 6 in. and 8 inches in diameter.

2. Surface Prep. Heavily textured test areas shall be ground smooth with the abrasive stone. Each test area should have similar smooth textures. Any loose mortar or other detritus shall be thoroughly brushed away. Any free surface water shall be removed.

3. Testing. Testing temperatures shall be 40°F or higher. The rebound hammer shall be held firmly so that the plunger is perpendicular to the test area surface. The device shall be gradually pushed toward the test surface until the hammer impacts. After impact, constant pressure shall be maintained on the device and, if necessary, the button on the side to lock the plunger in its retracted position shall be depressed. The rebound number on the scale shall be recorded to the nearest whole number. Ten readings shall be taken in each test area with no impact points closer than one inch of each other. If the impact crushes or breaks through a near-surface void, the reading shall be disregarded and another impact location shall be tested. The same rebound hammer shall be used for both test areas.

|

|

4. Calculation. The ten readings shall be averaged. If any reading differs by more than 6 units from the average, it shall be discarded and the average of the remaining readings shall be calculated. If more than two readings differ from the average, the entire set of readings shall be discarded and rebound numbers shall be determined at ten new locations within the test area.

The ratio of the average rebound in the full depth patch test area over the average rebound in the full depth patch test area (RNN) shall be calculated.

- Rebound Ratio Number (RNN) =