106.3.2.93 TM-93, Alkali Carbonate Reactivity Screening

This test method establishes the procedures for identifying potential alkali carbonate reactivity (expansion) and acceptance of aggregate used in concrete pavements and masonry. This test method applies to new quarries, new ledges (and combinations of ledges), existing quarries and ledges.

106.3.2.93.1 Means of Evaluating Aggregate Alkali Carbonate Reactivity

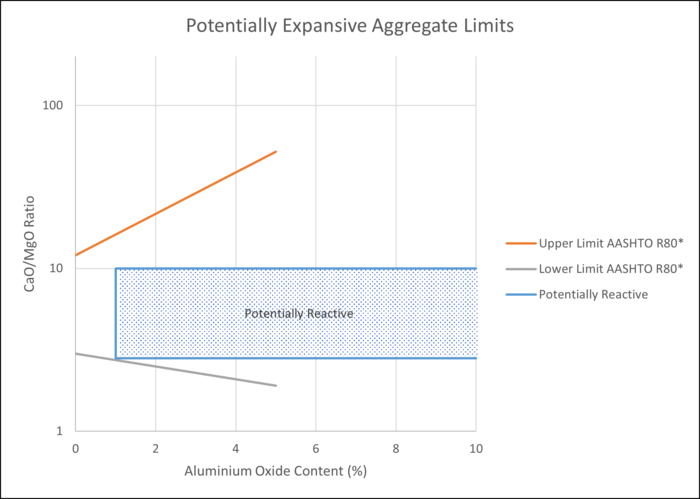

1. Chemical Analysis

The chemical analysis of aggregate reactivity is an objective, quantifiable and repeatable test. MoDOT will perform the chemical analysis per the process identified in ASTM C 25 for determining the aggregate composition. The analysis determines the calcium oxide (CaO), magnesium oxide (MgO), and aluminum oxide (Al2O3) content of the aggregate. The chemical compositions are then plotted on a chart with the CaO/MgO ratio on the y-axis and Al2O3 percentage on the x-axis per Fig. 2 in AASHTO R 80. Aggregates are considered potentially reactive if the Al2O3 content is greater than or equal to 1.0% and the CaO/MgO ratio is either greater than or equal to 3.0 or less than or equal to 10.0 (see chart below). See flow charts in 106.3.2.93.2 for approval hierarchy.

* MoDOT’s upper and lower limits of potentially reactive (shaded area) aggregates.

2. Petrographic Examination

A petrographic examination is another means of determining alkali carbonate reactivity. The sample aggregate for petrographic analysis will be obtained at the same time as the source sample. MoDOT personnel shall be present at the time of sample. The petrographic sample shall be placed in an approved tamper-evident container (provided by the quarry) for shipment to petrographer. Per ASTM C 295, a petrographic examination is to be performed by a petrographer with at least 5 years of experience in petrographic examinations of concrete aggregate including, but not limited to, identification of minerals in aggregate, classification of rock types, and categorizing physical and chemical properties of rocks and minerals. The petrographer will have completed college level course work in mineralogy, petrography, or optical mineralogy. MoDOT does not accept on-the-job training by a non-degreed petrographer as qualified to perform petrographical examinations. MoDOT may request petrographer’s qualifications in addition to the petrographic report. The procedures in C 295 shall be used to perform the petrographic examination. The petrographic examination report to MoDOT shall include at a minimum:

- Quarry name and ledge name; all ledges if used in combination

- MoDOT District quarry resides

- Date sample was obtained; date petrographic analysis was completed

- Name of petrographer and company/organization affiliated

- Lithographic descriptions with photographs of the sample(s) examined

- Microphotographs of aggregate indicating carbonate particles and/or other reactive materials

- Results of the examination

- All conclusions related to the examination

See flow charts in EPG 106.3.2.93.2 for the approval hierarchy. See EPG 106.3.2.93.3 for petrographic examination submittals. No direct payment will be made by the Commission for shipping the petrographic analysis sample to petrographer, or for the petrographic analysis performed by the petrographer.

3. Concrete Prism/Beam Test

ASTM C 1105 is yet another means for determining the potential expansion of alkali carbonate reactivity in concrete aggregate. MoDOT will perform this test per C 1105 at its Central Laboratory. Concrete specimen expansion will be measured at 3, 6, 9, and 12 months. The test specimens will be considered alkali carbonate reactive (expansive) if the specimens expand greater than 0.015% at 3 months, 0.025% at 6 months, or 0.030% at 12 months. See flow chart in EPG 106.3.2.93.2 for the approval hierarchy.

106.3.2.93.2 Approval Process for Potential Alkali Carbonate Reactive Aggregate

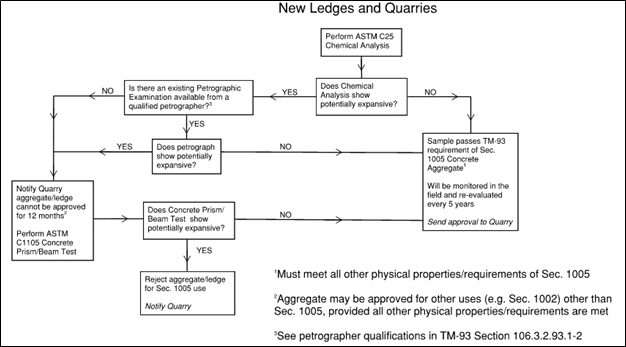

1. Process for New Ledges and New Quarries The flowchart shown in Figure 1 shows the process for determining alkali carbonate reactivity (expansiveness) in new ledges and quarries. It is important to note TM-93 is only for determining whether or not aggregate is potentially expansive. All other requirements of Sec. 1005 shall be met for the ledge(s) to be approved for use in pavement or masonry concrete.

Should ASTM C 1105 test method need to be performed on the aggregate, the quarry will be notified by District personnel that this test method requires 12 months to complete, and during those 12 months, the aggregate cannot be approved for use in pavement or masonry concrete. The aggregate however, can be considered for other uses based on meeting required specifications.

Figure 1. Process for determining alkali carbonate reactivity for new ledges and quarries.

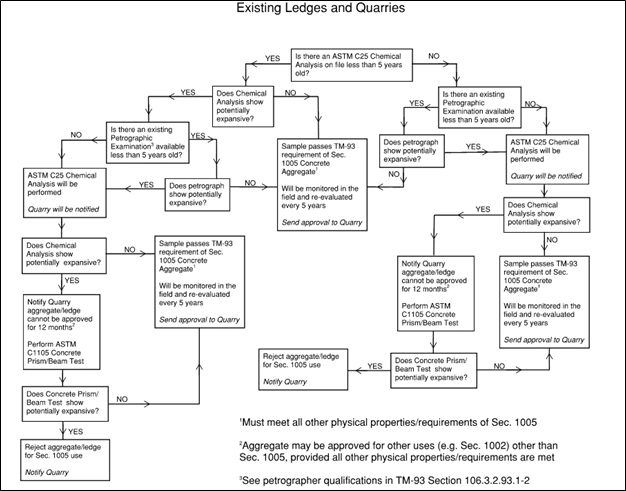

2. Process for Existing Ledges and Existing Quarries

The flowchart shown in Figure 2 shows the process for determining alkali carbonate reactivity (expansiveness) in existing ledges and quarries. It is important to note TM-93 is only for determining whether or not aggregate is potentially expansive. All other requirements of Sec. 1005 shall be met before the ledge(s) are approved for use in pavement or masonry concrete.

Should ASTM C 1105 test method need to be performed on the aggregate, the quarry will be notified by District personnel that this test method requires 12 months to complete, and during those 12 months, the aggregate cannot be approved for use in pavement or masonry concrete. The aggregate however, can be considered for other uses based on meeting required specifications.

Figure 2. Process for determining alkali carbonate reactivity for existing ledges and quarries.

106.3.2.93.3 Submitting Petrographic Examinations Reports to MoDOT

1. Petrographic Examination Reports

Petrographic examination reports can be used in the process to determine the alkali carbonate reactivity (expansiveness) of aggregate. See petrographer requirements in Section 109.3.2.93.1. When a quarry obtains a petrographic examination report, the report shall be submitted to the District Construction and Materials Department of the district the quarry resides. The submittal can be made electronically or can be an original hard copy mailed/delivered to the district. Hard copy reports will be scanned/digitized for easier file storage. Regardless of whether or not the petrographic examination report shows the aggregate is potentially expansive, MoDOT will retain the report. The district will forward the report to Central Office Construction and Materials Division for document retention. This will allow time to prepare for ASTM C 1105 testing if necessary.

All petrographic reports will be digitally stored by Central Office Construction and Materials Division.