806.1 Erosion Control Measures

Contents

- 1 806.1 Erosion Control Measures

- 1.1 806.1.1 Surface Roughening

- 1.2 806.1.2 Temporary Berms

- 1.3 806.1.3 Temporary Slope Drains

- 1.4 806.1.4 Interception Ditches and Let down Structures

- 1.5 806.1.5 Permanent Diversions

- 1.6 806.1.6 Temporary Pipe and Temporary Construction Crossings

- 1.7 806.1.7 Temporary Seeding

- 1.8 806.1.8 Permanent Seeding and Mulch

- 1.9 806.1.9 Fiber Reinforced Matrix

- 1.10 806.1.10 Erosion Control Blankets and Turf Reinforcement Mats

806.1 Erosion Control Measures

Erosion control measures are intended to eliminate or minimize the movement of sediment deposits from the site or right of way. Permanent erosion control measures, such as channel armoring, sodding, seed and mulch etc., should be utilized as soon as possible to control erosion, reduce the maintenance cost associated with temporary sediment control measures, and improve the overall appearance of the project.

806.1.1 Surface Roughening

Surface roughening is a temporary erosion control best management practice that will reduce runoff velocity and erosion potential by increasing infiltration and sediment trapping. Utilizing surface roughening has shown to aid in the establishment of vegetative cover prior to seed and mulching operations. This practice is intended for areas which have been cleared and grubbed and are awaiting application of temporary or permanent seed, or installation of other structural controls such as ditch checks, rock dams, or sediment basins.

806.1.1.1 Design Considerations

Surface roughening is difficult to achieve on short, steep slopes where heavy equipment cannot traverse slopes sufficiently. If slopes are not of sufficient length to allow adequate equipment travel, other erosion control BMP’s should be considered such as erosion control blankets or fiber reinforced matrix (FRM).

806.1.1.2 Construction Considerations

Contractors should be encouraged to use surface roughening if they intend to apply seed through hydro-seeding operations. Without adequate surface preparation, rills will develop following hydro-seeding operations when equipment tracks run parallel with the ditch line. Surface roughening can be accomplished using one of the three following methods:

Tracking is accomplished by tracking construction equipment (dozer, high lift, etc.) vertically up and down slopes in order to create horizontal depressions, perpendicular to the runoff path, on the soil surface. Depressions left by the tracks reduce storm water velocity and the potential for concentrated runoff, which leads to rill formation. Tracking can lead to significant soil compaction, which does help lock soil particles in place; however, it is not conducive for root production and grass growth. Care should be taken in deciding which slopes to track. Tracking is typically recommended for sandy soils, where risk of excessive compaction is reduced.

Grooving is accomplished by constructing a series of ridges and depressions that run along the contour of a slope. The grooves can be created using a disks, harrows, chisel plows, loader teeth, or any other available implement that will produce a grove no more than 3 inches deep and no more than 15 in. apart.

Stair-stepping is the construction of earthen stair steps to reduce runoff velocity and encourage sedimentation on steeper slopes that will not be mowed. The stairs should be constructed with the vertical rise of the step less than or equal to 1 foot. The horizontal run of the steps should be longer than the vertical rise of the step and sloped inward toward the vertical step face to promote sedimentation.

806.1.2 Temporary Berms

A temporary berm is a temporary ridge of compacted soil with or without a shallow ditch, constructed at the top of fill slopes or transverse to centerline on fills. The purpose of these ridges is to divert storm runoff from small areas away from steep slopes and direct this water to temporary outlets where the water can be discharged with minimum slope erosion.

806.1.2.1 Design Considerations

Type B Berms may be used as a temporary perimeter control structure where slopes are less than 2% and permanent vegetation is present on the downgrade side of the structure They are also used transverse to grade to divert runoff to stabilized slope drains. Since temporary berms are usually installed as earth work is underway, and there is no way to predict the amount of work that might be accomplished during the course of a day’s work, temporary berms will not usually appear on contract plans.

806.1.2.2 Construction Considerations

Type B Berms are specified when embankment operations are shut down over extended periods of time (i.e., winter), will be constructed to specified dimensions (see Standard Plan 806.10) and will be machine compacted with a minimum of three passes over the entire width of the berm with a dozer tread, grader wheel, etc. Temporary Type B berms must drain to a compacted outlet at a slope drain. The top width of these berms may be wider and the side slopes flatter on transverse berms to allow equipment to pass over these berms with minimal disruption.

806.1.3 Temporary Slope Drains

A temporary slope drain is used to carry water down slopes to reduce erosion and consists of stone, concrete or asphalt gutters, half-round pipe, metal pipe, plastic pipe, or flexible rubber pipe.

806.1.3.1 Design Considerations

Temporary Slope Drains are beneficial on high, steep slopes to limit runoff from concentrating down the embankment where rills and gullies can form quickly. Plans should show slope drains on fill and some cut slopes at approximately 500-foot intervals. Engineering judgment shall be used when developing quantities; soil type, slope, and roadbed profiles may require intervals shorter than 500 ft.

806.1.3.2 Construction Considerations

All temporary slope drains are to be adequately anchored to the slope to prevent disruption by the force of the water flowing in these drains. The inlet end must be properly constructed to channel water into the temporary drain. The outlet ends shall have some means of dissipating the energy of the water to reduce erosion downstream. Unless otherwise specified, all temporary slope drains will be removed when no longer necessary and the site will be restored to match the surroundings.

806.1.4 Interception Ditches and Let down Structures

Interception ditches and letdown structures are typically permanent erosion control BMPs that capture storm water run-on or runoff and transport it down slopes through stabilized channels. These constructed channels are meant to reduce the likelihood of gully formation and allow for the establishment of permanent vegetative cover on the face of the slope.

806.1.4.1 Design Considerations

When designing interception ditches and letdowns, as well as roadside and median ditches, it is important to consideration the drainage area, soil type, slope and ditch shape in order to determine if the shear stresses within the ditch will be of a high enough value to warrant a liner beyond just vegetative cover. Clear zone considerations must be taken into account when determining the appropriate ditch line. Lining solutions can vary from rock riprap, erosion control blankets, turf reinforcement mats or other products capable of withstanding concentrated, erosive flows based on the required shear stress,.

806.1.4.2 Construction Considerations

Interception ditches and letdown structures shall be constructed as shown on the plans or as directed by the engineer. Channel armoring should be installed in accordance with Standard Plan 609.60 or in accordance with the manufactures recommendations. Armoring should be installed as soon as possible to reduce the potential erosion of the channel bottom.

806.1.5 Permanent Diversions

On large, steep back slopes permanent diversion berms or terraces are used transverse to grade to divert runoff to stabilized slope drains. Such diversions will enable the establishment of permanent vegetative cover on the slopes and will reduce the likelihood of gully formation.

806.1.6 Temporary Pipe and Temporary Construction Crossings

A temporary pipe is a conduit used temporarily to carry water under a haul road, silt fence, etc. It is used to convey normal and expected high flows at temporary stream crossings, preventing the contractor's equipment from coming in direct contact with the water when crossing active streams or intermittent streams created during heavy rainfalls.

806.1.6.1 Design Considerations

Temporary construction crossings or the use of temporary pipes must be considered in the design phase. MoDOT does not design stream crossings but proper permits, such as a 404 permit, must be obtained before any impacts to regulated jurisdictional streams begin. MoDOT’s Environmental Section should be engaged early to determine any impacts to streams and allow sufficient time to procure all agreements and permits required from the various regulating agencies.

Temporary stream crossings can be conduits for sediment to find its way into the stream due to gaps in perimeter BMPs along the stream bank. Storm water should be diverted away from locations where stream crossings potentially could be constructed or design erosion sediment control plan to adequately protect these areas.

806.1.6.2 Construction Considerations

Temporary pipes will be placed to match the existing stream grade so aquatic life is allowed to pass unimpeded.

806.1.7 Temporary Seeding

This work shall consist of preparing and fertilizing a seedbed and furnishing and sowing of seed. The purpose of temporary seeding is to produce a quick ground cover to reduce erosion in disturbed areas that are expected to be re-disturbed at a later date or if groundcover needs to be established in non-favorable seeding seasons.

806.1.7.1 Design Considerations

Temporary seeding will be a critical component of temporary stabilization for projects with land disturbance. Temporary seeding shall follow Sec 806.50 and mulching shall be included as a separate bid item in accordance with Sec 802. Temporary Seeding should be provided for 100% of areas that will be seeded with Warm Season grasses. This is necessary because, per Sec 805.3.1.2, warm season grass seeding is restricted to the period from Oct. 15 through April 15, and the SWPPP disallows postponement of seed/mulch following grading. If the project includes special provisions that requires any warm-season grass areas to be graded after Oct. 15, but prior to Spring, then those areas can be excluded from Temporary Seeding. Any quantity of Temporary Seeding needed for temporary staged construction should also be provided. A quantity for Mulching should also be provided for all areas of Temporary Seeding. Warm season grass areas that are temporarily seeded and subsequently overseeded after Oct. 15 do not require a second application of mulching.

Temporary Seeding is not required for areas that are designated to receive Cool Season grass seeding. Per Sec 805.3.1.1, either full or partial cool season seeding is required immediately following grading, regardless of the season. Overseeding of cool season seeded areas may also be required depending on when the original seeding occurred (see Sec 805.3.1.1 for overseeding requirements). Additional mobilization should be provided on projects where construction activities disturb an acre or more over the life of a project (see EPG 618 Mobilization).

806.1.7.2 Construction Considerations

Temporary seeding and mulch applications are to be a continuous operation on all cut and fill slopes, waste sites, and borrow pits during the construction process. All disturbed areas shall be seeded and mulched with permanent seeding during allowable seeding timeframes outlined in EPG 805 Seeding. When permanent seeding cannot be placed due to seeding time restrictions, or when work will be halted in an area for more than 14 days, temporary seeding shall be used to establish temporary stabilization to eliminate erosion. Seeding and mulching shall be done as soon as possible after completion of the earthwork, not to exceed 14 days, weather permitting.

Mulch placed over temporary seed mixtures shall be applied in accordance with the provisions of Sec 802 of the Missouri Standard Specifications for Highway Construction. Fertilizer shall be applied at the rate specified in Sec 806.50 of the Missouri Standard Specifications for Highway Construction. Lime will usually not be required for temporary seeding but will be applied according to governing specifications when a permanent seed mixture is used.

806.1.8 Permanent Seeding and Mulch

Growth from permanent seed and mulch provides permanent stabilization of disturbed areas not covered by final building materials. Permanent seed mixtures incorporate a variety of native, non-native, legumes, and cover crops to establish vegetative cover suitable to prevent erosion and maintain the integrity of our roadways.

806.1.8.1 Design Considerations

All projects that have land disturbance activities of any amount must include permanent seed and mulch or other permanent BMPs to stabilize those areas without a vegetative root zone. Consideration must be provided for projects with high fill or cut slopes to provide adequate quantities for bidding. Final quantities will be field measured but accuracy in the design phase will reduce costly contact over runs. Additional mobilization should be provided on projects where construction activities disturb an acre or more over the life of a project (see EPG 618 Mobilization).

Fertilizer, lime, and seed recommendations shall be requested from the Roadside Section of the Maintenance Division for all projects.

806.1.8.2 Construction Consideration

Final stabilization of disturbed areas shall be initiated within 24 hours after final grading has ceased for those areas, and must be completed within 14 calendar days. Allowances for weather and equipment breakdown will be made but delays must be documented in the project specific SWPPP.

Permanent seeding and mulch following temporary seeding will be performed according to Secs 805 and 802, respectively of the Missouri Standard Specification for Highway Construction and will only be permitted during the favorable seeding seasons.

806.1.9 Fiber Reinforced Matrix

Fiber Reinforced Matrix (FRM) is a hydraulically applied (spray-on) erosion control product that bonds to, and blankets bare soil. It is typically applied with a truck or trailer mounted sprayer or by walking the affected areas with a hose sprayer. According to manufacturers, FRMs lock in moisture and nutrients to promote seed germination. Since these products are applied through spray-on application, they can conform to the contours of a slope and therefore can be applied to rough seedbeds.

806.1.9.1 Design Considerations

FRM should be considered on projects with steep slopes where history has shown grass growth to be problematic. FRM’s are not an overspray material; they provide superior slope protection that is comparable to erosion control blanket. These products can be applied to any soil type, except sandy material, on any slope and can be used in place of any of the erosion control blankets (ECBs) discussed in EPG 806.8.6.3.9 Erosion Control Blankets and Turf Reinforcement Mats. These products are not designed to withstand concentrated flows within ditches, drainages or streams. In some instances, especially on longer and/or steeper slopes, it may be necessary to install slope disruptors (wattles/socks/logs/etc.) perpendicular to the sheet flow to decrease runoff velocities down the face of the slope and protect the FRM application from concentrated flows.

806.1.9.2 Construction Consideration

It is important when using these products to apply them according manufacturer’s specifications and to assure there is complete surface coverage on the affected area to prevent potential failure due to improper application. In order to accomplish this, it is important to spray slopes from multiple, varying directions. In some instances, especially on longer and/or steeper slopes open graded matting may be required to anchor the material to the slope to prevent slope shear. Manufacturer recommended application rates are summarized in the table below. Examples of FRMs include products such as Flexterra®, Flexible Growth MediumTM, EcoFlexTM and Flex Guard®.

| Slope Condition | Application Rate (lbs/acre) |

|---|---|

| < 3H:1V | 3000 |

| > 3H:1V and < 2H:1V | 3500 |

| >2H:1V and < 1H:1V | 4000 |

| >1H:1V | 4500 |

To ensure product quality and performance, all FRMs must meet the following specifications:

| Minimum FRM Performance and Physical Requirements Property | Required Value |

|---|---|

| Thermally Processed Fiber by Weight | 75% ± 10% |

| 100% Bio-degradable Interlocking Fibers | 5% ± 2% |

| Organic Tackifiers and Activators | 10% ± 2% |

| Moisture Content | 10% ± 3% |

| Organic Matter | 90% minimum |

| Color | Colored to contrast application area, shall not stain concrete or painted surfaces. |

| FRM Property | Test Method | Required Value | |

|---|---|---|---|

| Physical | Mass Per Unit Area | ASTM D6566* | 12.0 oz/yd2 minimum |

| Thickness | ASTM D6525* | 0.22 in. minimum | |

| Ground Cover | ASTM D6567* | 99% minimum | |

| Wet Bond Strength | ASTM D6818* | 9 lb/ft | |

| Water Holding Capacity | ASTM D7367 | 1500% minimum | |

| Flexural Rigidity (wet) | ASTM D6575* | 5 oz-yd maximum | |

| Endurance | Functional Longevity | ASTM D5338 | Minimum of 12 months |

| Performance | Cover Factor | MoDOT Approved Large Scale Testing | 0.01 maximum |

| % Effectiveness | MoDOT Approved Large Scale Testing | 99% minimum | |

| Cure time | MoDOT Approved Large Scale Testing | 98% Effective 2 hours after application | |

| Vegetation Establishment | ASTM D7322* | 800% minimum | |

| Environmental | Ecotoxicity | EPA 2021.0 | 96-hr LC50 > 100% |

| Effluent Turbidity | MoDOT Approved Large Scale Testing | 100 NTU Maximum | |

| Biodegradability | ASTM D5338 | 100% Minimum | |

| * ASTM test methods developed for Rolled Erosion Control Products (RECPs) that have been modified to accommodate Hydraulic Erosion Control Products (HECPs). | |||

806.1.10 Erosion Control Blankets and Turf Reinforcement Mats

Erosion control blankets (ECBs) and plastic netting are used to prevent erosion of seeded areas for a period of time sufficient for the seed to produce a root system capable of providing permanent erosion protection. Blankets are manufactured with wood fiber (excelsior), jute, coconut coir fiber, and synthetic materials. Blankets are used where the volume or velocity of runoff exceeds ditch check capabilities, where sediment from the project can severely impact an environmentally sensitive water body or where the roadway soil types are highly susceptible to erosion.

ECBs are typically used to prevent sheet, rill, or gully erosion on slopes and some lower flow channels. Turf reinforcement mats (TRMs) may be used on steep slopes or slope areas with concentrated flow, but are typically used in channels

806.1.10.1 Design Consideration

Erosion control blankets and turf reinforcement mats must be considered for:

| Fill slopes greater than 10 feet high | Ditch slopes greater than 10 percent | |

| Highly erodible soils | Fluctuating water levels | |

| High ditch flows | High sheet flow | |

| Standard seeding and mulching will not withstand anticipated runoff | ||

| Around high quality water bodies. | ||

ECBs, TRMs, or an equivalent erosion control practice is recommended for most slopes steeper than 1V:3H (3:1), depending on soil type. Incorporation of ECBs adjacent to the edge of pavement in concentrated flow areas, such as the low side of a super elevated section, have proven to reduce edge drop off by stabilizing the slope until grass growth establishes. Protecting slopes from erosion requires several actions that must be taken together. No single approach will be successful, especially if the slope is long, steep, or has highly erodible soils. Even when using blankets or mats, it may be necessary to incorporate temporary berms and slope drains, slope disruptors and other BMPs to ensure slope stabilization. At culvert outlets, overflow structures or transition areas, it may be necessary to use a transition mat (e.g., ScourStop™, ShoreMax™, etc.) directly over a TRM in order to add additional scour protection in these highly erosive areas.

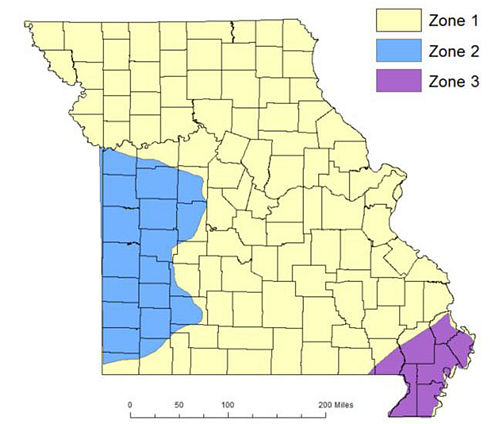

The implementation of erosion control blankets must be performed by geographic location of the project. The following map shows each Missouri County assigned a zone delineated by erosion susceptibility.

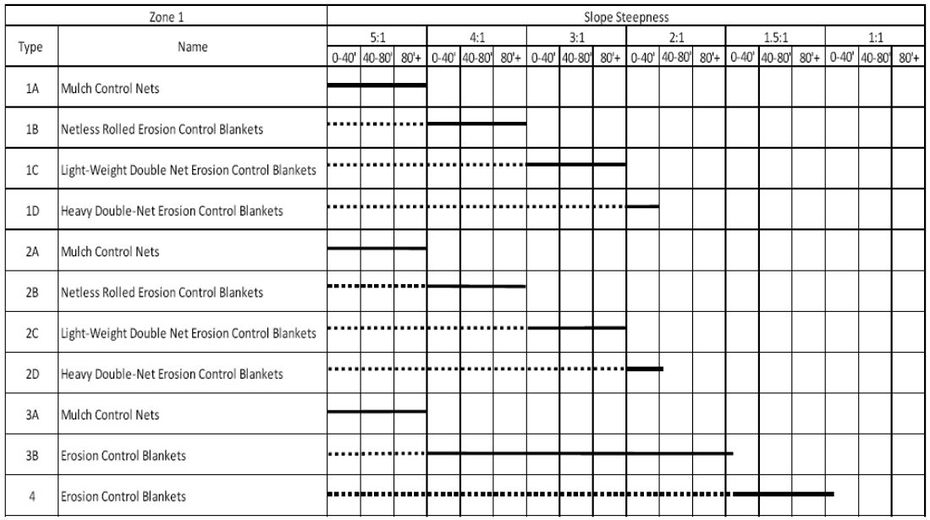

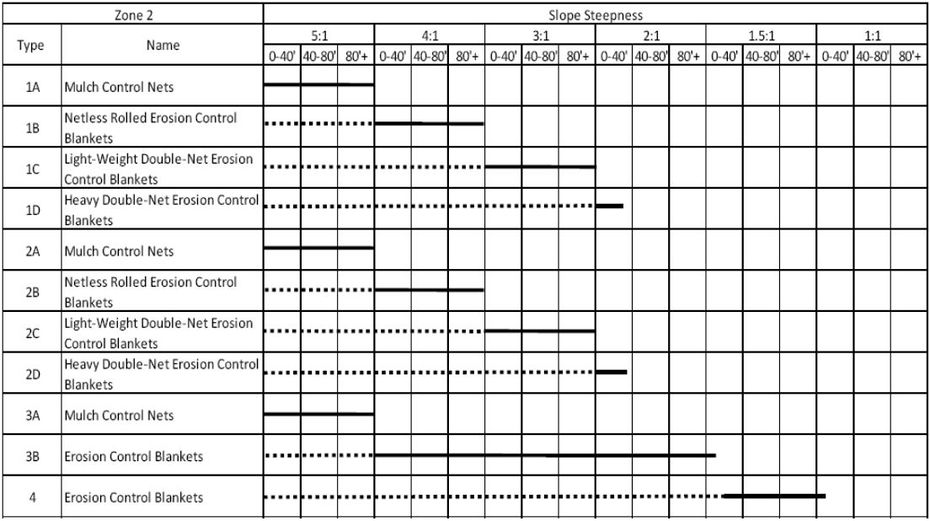

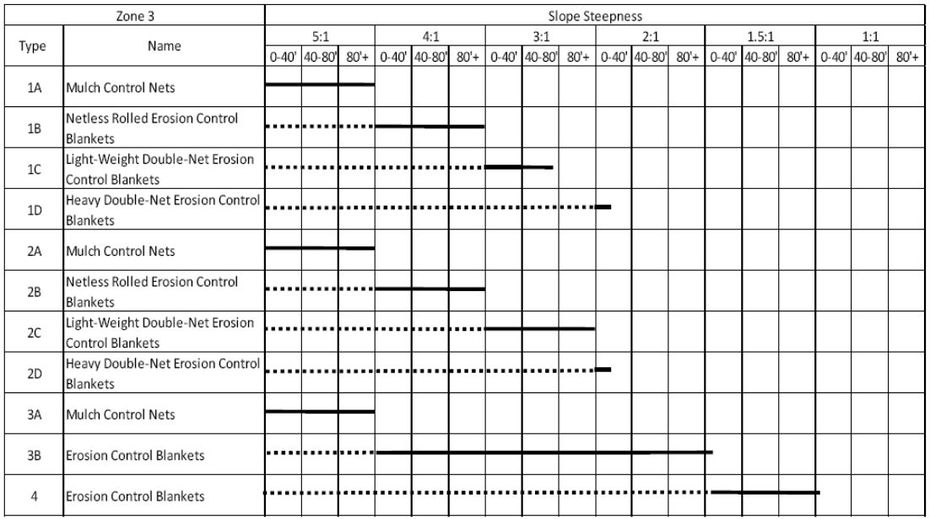

When the project county zone is identified, the ECB design shall be based off of the following design table for the corresponding zone. Counties overlapping zones should use the higher zone for design. All Type 2, Type 3, and Type 4 ECBs are assumed to include silt fences as supplementary BMPs. Instituting silt fences with Type 1 ECBs would increase the maximum allowable slope length by a factor of 4. The following design charts are a visual aid in designing ECBs for a given application. The dashed lines indicate instances where an ECB can be used, and the bold lines indicate instances when an ECB should be used. The engineer’s discretion is to be used to determine the appropriate service life for the site when selecting the appropriate ECB type (Type 1 – 3 months, Type 2 – 12 months, Type 3 – 24 months, Type 4 – 36 months).

| ECB Type | Name | Max Slope (H:V) | Maximum Length (Ft) | ||

|---|---|---|---|---|---|

| Zone 1 | Zone 2 | Zone 3 | |||

| 1A | Mulch Control Nets | 5:1 | 990 | 750 | 495 |

| 1B | Nettles Rolled Erosion Control Blankets | 4:1 | 605 | 450 | 305 |

| 1C | Light-Weight Double-Net Erosion Control Blanket | 3:1 | 150 | 115 | 75 |

| 1D | Heavy Double-Net Erosion Control Blanket | 2:1 | 40 | 30 | 20 |

| 2A | Mulch Control Nets | 5:1 | 1110 | 840 | 560 |

| 2B | Nettles Rolled Erosion Control Blankets | 4:1 | 680 | 515 | 340 |

| 2C | Light-Weight Double Net Erosion Control Blankets | 3:1 | 170 | 130 | 85 |

| 2D | Heavy Double-Net Erosion Control Blanket | 2:1 | 45 | 35 | 20 |

| 3A | Mulch Control Nets | 5:1 | 1110 | 840 | 560 |

| 3B | Erosion Control Blankets | 1.5:1 | 15 | 15 | 10 |

| 4 | Erosion Control Blankets | 1:1 | 10 | 10 | 5 |

806.1.10.2 Construction Consideration

All erosion control blankets (ECBs) and turf reinforcement mats (TRMs) shall be installed according to the manufacturer’s recommendations, including overlap and stapling guidelines. Prior to installation of blankets or mats the ground should be smooth, with no large rocks, vegetation or rills on the surface. The blankets shall be placed smoothly, but loosely, on the soil surface without stretching. Blankets at the top of the slope should be trenched in beyond the crest of the slope to avoid undercutting. Any overlap joints shall be lapped in the direction of water flow. All anchor staples must be fully driven and properly spaced.

Blankets and mats should be inspected at the same frequency as all other erosion and sediment control items. Malfunctions must be repaired in a timely manner or else slope shaping, grading and reinstallation will be required. Removal is not necessary or required because the material will decay and break down on its own or, in the case of TRMs, permanently reinforce the vegetation. Measurements are based on surface area covered.

Product requirements for ECBs and TRMs can be found within Sec 1011. ECBs and TRMs meeting MoDOT specification requirements each have their own physical description that can be obtained from the manufacturer.