Category:206 Excavation for Structures

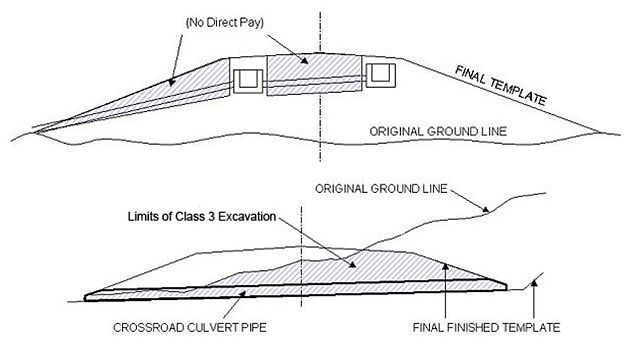

Excavation quantities for structures, when measured, are calculated in accordance with Fig. 206.2, Fig. 206.4, Fig. 206.5 and applicable standard plans. Refer to Sec 206 for MoDOT’s specifications.

| Figures |

| Figure 206.2, Maximum Limits for Class 3 Excavation |

| Figure 206.4, Maximum Limits for Class 4 Excavation |

| Figure 206.5, Maximum Limits for Class 4 Excavation for Extending an Existing Culvert |

Contents

206.1 Class 1 and 2 Excavation

In general, Class 1 Excavation and Class 2 Excavation will apply to excavation for bridges and large retaining walls. Class 1 includes all excavation above a specified elevation indicated on the plans while Class 2 Excavation includes all excavation below this specified elevation. The classification of excavation for all structures will be shown on the plans.

206.2 Class 3 Excavation

Class 3 Excavation applies to excavation for pipe installations such as pipe culverts, utilities, retrofit pipe culverts (extensions), drop inlets and manholes. Estimated quantities should be included in the plans. Sec 206 defines the payment limits for Class 3 Excavation. When two pipe diameters are shown on the plans, the larger of the two diameters will be used to calculate plan quantity.

When trenching is required for utility pipe, retrofit culvert installations (extensions), manholes or drop inlets, Class 3 Excavation quantities are calculated and included with the pay item (refer to Sec 206).

206.3 Class 4 Excavation

Class 4 Excavation applies to excavation for box culverts, small retaining walls and other miscellaneous structures. Sec 206 provides for the payment of plan quantities of Class 4 Excavation for box culverts not classified as bridges, so care is exercised in computing the quantities.

Field quantities are measured for box culverts classified as bridges. Each structure is checked carefully on the field checks, and appropriate notes are made to ensure that the quantities are as accurate as possible. A common error is to compute only the quantities below the ditch flowline where the structure approaches or exceeds the width of the natural ditch. Class 4 Excavation does not include removal of existing headwalls or portions of the existing box culvert. These items should be handled as removal of improvements for roadway culverts or partial removal of culvert concrete for bridge culverts. Care is exercised to avoid duplicate payment for the same excavation, such as computing Class 4 Excavation where channel change quantities or roadway excavation has been computed.

206.4 Construction Inspection Guidelines for Sec 206

Description (for Sec 206.1). As specified.

Depth of Excavation (for Sec 206.2). The bottom slab of concrete box-type structures should be placed on reasonably dry foundation material of sufficient uniformity to prevent differential settlement of the structure. The foundation need be only sufficiently stable that the foundation material does not become mixed with concrete as the bottom slab is being placed.

Foundation Stabilization and Tests (for Sec 206.3). Some material may have a high organic content or may be a soil that will not permit satisfactory construction of the bottom slab even when properly drained. When this situation exists authorization may be given to remove and replace material, with payment to be made in accordance with Sec 206.6.3. It is the contractor's responsibility to provide a satisfactory foundation at the contractor's own expense except when foundation material at grade is inherently unsound. Inherently unsound material is material that, even if properly drained, would prevent satisfactory installation of reinforcing steel and placement of concrete.

Construction Guidance for Sec 206.3.1. If the foundation consists of material that can be stabilized by draining, it is the contractor's responsibility to provide drainage at the contractor's expense. For example, with sandy materials and high groundwater table, one method contractor’s has used successfully has been a well point drainage system.

Construction Requirements (for Sec 206.4).

As specified.

Foundation Excavation Protection (for Sec 206.4.1). Any employee whose duties include entering excavations must receive training on general excavation safety. Employees whose duties include evaluation of protective systems, such as cofferdams or shoring, must also meet the requirements of a “competent person.” The Risk Management Manual, Section 2.4, defines “competent person” as: “One who is capable of identifying existing and predictable hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.”

Construction Guidance for Sec 206.4.1.1 Employees who lack either formal education or extensive on the job experience may become a “competent person” by attending training provided by the Employee Development section of Human Resources. General excavation training for newer employees is also available.

Construction Guidance for Sec 206.4.1.2 It is the responsibility of the resident engineer to ensure that a “competent person” evaluates protective systems before any MODOT employee is allowed to enter an excavation. If there is any doubt, Section 206 of the Standard Specifications requires the contractor to demonstrate the adequacy of any protective system prior to beginning work. Inspection activities should be suspended until safety of the excavation is assured.

Construction Guidance for Sec 206.4.1.3 No MODOT employee are to enter an excavation unless someone meeting the requirements of a “competent person,” as defined by OSHA’s Excavation Standard, is on site to monitor their safety at all times. That second person need not necessarily be another MODOT employee but may be a contractor representative who meets the description of a “competent person.” It is the responsibility of each employee to ensure that someone is monitoring their safety before entering an excavation.

Foundation Key (for Sec 206.4.2). As specified.

Foundation Subgrade (for Sec 206.4.3). As specified.

Culverts on Rock (for Sec 206.4.4). As specified.

Footing Construction (for Sec 206.4.5). As specified.

Footing Drainage (for Sec 206.4.6). As specified.

Cofferdams (for Sec 206.4.7). As specified.

Temporary Shoring (for Sec 206.4.8). Bridge Division does not review signed and sealed, temporary shoring, temporary bent, or temporary falsework plans submitted by contractors. The sole responsibility for the design and safety of such structures is entirely the contractor's. There will be some exceptions, such as cofferdams for major river bridges, or other specialized situations, but these will be specifically identified. Review by Bridge Division, however, should be sought when the contractor's temporary structure would affect any permanent MoDOT facility, such as by welding or bolting to one of our bridges or for stage construction. When you receive the plans from the contractor confirm that they have been signed and sealed. If you have no concerns with the submittal, it can be accepted, and the contractor can proceed. For design requirements for contractor option to use temporary MSE wall system see EPG 720.2 Design Requirements.

Seal Courses (for Sec 206.4.9). Where seal courses are required in the contract, thickness and elevation of seal course are fixed. Where seal courses are options in the contract the resident engineer shall determine if they should be used.

Seal course concrete is placed in an enclosure so the top of the seal course will be at the elevation established for the bottom of footing. The surface elevation of the seal course is checked by use of a flat board on the end of a pole or a flat surfaced weight on a rope. Additional excavation below plan grade for the bottom of footing will normally be paid for at the price bid for the appropriate class of excavation, except where the entire cofferdam is a bid item in the contract. Where a seal course is installed at the contractor's election the concrete and any excavation below plan grade established for the bottom of footing will be at the contractor's expense.

When a concrete seal course is used in a watertight cofferdam it must be thick enough to resist the upward pressure of water and/or outside materials. The minimum thickness of seal will be shown in the plans or special provisions when the contract requires and provides payment for a seal course. The seal thickness is established for a maximum water head or elevation, which is usually shown on the plans. If the contractor elects to provide a seal course to permit placement of the footing for the contractor's operations, the contractor will select the minimum thickness of seal. Total uplift force on the seal is called buoyancy or hydrostatic pressure and is equal to the weight of water displaced by the cofferdam. Since concrete weighs about 7/3 times the weight of water, the depth of concrete inside the cofferdam will generally be at least 3/7 times the depth of excavation below water surface. Allowance is made for resistance to uplift provided by friction forces between the concrete and the face of cofferdam sheeting and by hold down capacity of previously placed drilled caissons or piling which extend through the seal to the future footing. If the seal course used is thinner than would be required by buoyancy conditions, extreme care is necessary to ensure that the seal course is secured against the sheeting to provide proper interface friction. Sometimes where such a thinner seal course is used the cofferdam must be anchored or weighted to prevent floating. When a concrete seal course is placed the concrete must be allowed to develop adequate strength before the water above it is pumped from the cofferdam. If water is pumped down too soon, strength will be inadequate and the uplifting force from water below the seal may cause cracking of the seal and/or "blow ins" near the interface of seal course and sheeting.

Unsatisfactory or malfunctioning seal courses must be repaired or replaced by the contractor at his expense. Numerous methods have been successfully used in the solution of specific problems. The most common is probably pressure grouting of the leaking area. The grout must then be allowed to set and develop adequate strength before pumping the water down again.

During prolonged cold weather conditions the rapid conductance of heat by steel sheeting may retard the cure of concrete at the interface between the seal and the cofferdam. This is a common cause of leakage or failure. It can be prevented by supplemental heating inside the cofferdam.

After the seal has cured and the water has been pumped down, the surface must be cleaned of soft laitance, sediment, or loose material. High spots within the area of the footing forms should be chipped off and any excessively low spots filled with concrete to provide a solid base for the footing.

After the substructure unit has been constructed to the point where cofferdams may be removed, removal must be done in a manner to avoid damage to the seal or footing. Only if specifically permitted by contract may portions of the cofferdam struts or shoring be left in place.

When a seal course is specified in a contract it should not be omitted or changed without approval by the Construction and Materials Division. If the seal course is omitted, the bottom of footing shall be placed at the elevation shown on the plans. If placing the bottom of footing at plan elevation is not possible, the footing or other parts of the substructure may need to be redesigned. The Bridge Division should be contacted.

Backfill (for Sec 206.4.10). As specified.

Porous Backfill (for Sec 206.4.11). As specified.

Flowable Backfill (for Sec 206.4.12). As specified.

Excavation Classification (for Sec 206.4.13). Several classifications for structures are provided to provide adequate compensation due to the various difficulties of structure excavation.

- Class 1 and Class 1 in Rock; established for bridges and large retaining walls for excavation above a plan specified elevation;

- Class 2 and Class 2 in Rock; established for bridges and large retaining walls for excavation below the plan specified elevation;

- Class 3 and Class 3 in Rock; established for utility runs, retrofit pipe culverts (extensions), drop inlets or manholes;

- Class 4 and Class 4 in Rock; established for culvert classified as bridges, small retaining walls and other miscellaneous structures.

Method of Measurement (for Sec 206.5).

As specified.

Basis of Payment (for Sec 206.6).

Undergrading (for Sec 206.6.1). Payment for stabilizing foundations should be authorized only after the contractor has provided adequate drainage to establish that the material is unsuitable. Undergrading must be authorized by documentation record.

If the contingent item of granular backfill is involved, an approved change order is required before payment can be made. Payment is allowed for the actual delivered material cost only.

Construction Guidance for Sec 206.6.1.1. Sometime the contractor elects to undergrade a few inches and backfill with granular material at the contractor's expense to provide an easily maintained base on which to construct the culvert. This is a satisfactory procedure. Payment should not be authorized for removal or replacement of material in this situation, or when the foundation is unsuitable due to improper methods of construction. If the underlying foundation is inherently unsound and must be removed to a substantial depth to obtain stability, the contractor is to be compensated for the excavation and the delivered cost of the granular backfill material.

Culvert Cleanout (for Sec 206.6.10). Culverts shall be cleaned of all silt and debris and contractor should protect against re-silting until final stabilization. Consult the plans and JSPs for any special instructions. Payment shall be made for a single cleanout per structure. If the culvert silts back in prior to project completion, the contractor shall reclean at no additional cost.