751.37 Drilled Shafts

Contents

- 1 751.37.1 General

- 2 751.37.2 General Design Procedure and Limit States

- 3 751.37.3 Design for Axial Loading at Strength Limit State

- 3.1 751.37.3.1 Axial Resistance for Individual Drilled Shafts in Rock (qu ≥ 100 ksf)

- 3.2 751.37.3.2 Axial Resistance for Individual Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core (5 ksf ≤ qu ≤ 100 ksf)

- 3.3 751.37.3.3 Axial Resistance for Individual Drilled Shafts in Weak Rock from Standard Penetration Tests (Neq ≤ 400 blows/ft)

- 3.4 751.37.3.4 Axial Resistance for Individual Drilled Shafts in Weak Rock from Texas Cone Penetration Tests (1 in. ≤ TCP ≤ 10 in.)

- 3.5 751.37.3.5 Axial Resistance for Individual Drilled Shafts in Weak Rock from Point Load Index Tests (5 ksf ≤ Is(50) ≤ 40 ksf)

- 3.6 751.37.3.6 Axial Resistance for Individual Drilled Shafts in Cohesive Soils (su ≤ 5 ksf)

- 3.7 751.37.3.7 Axial Resistance for Individual Drilled Shafts in Cohesionless Soils

- 3.8 751.37.3.8 Geotechnical Resistance from Load Tests

- 3.9 751.37.3.9 Evaluation of Group Effects

- 4 751.37.4 Design for Axial Loading at Serviceability Limit States

- 5 751.37.5 Design for Lateral Loading at Strength and Service Limit States

- 6 751.37.6 Structural Resistance of Drilled Shafts

- 7 751.37.7 References

- 8 751.37.8 Commentary

- 8.1 Commentary on EPG 751.37.1 General

- 8.2 Commentary on EPG 751.37.2 General Design Procedure and Limit States

- 8.3 Commentary on EPG 751.37.3 Geotechnical Resistance for Axial Loading at Strength Limit States

- 8.3.1 Commentary on EPG 751.37.3.1 Axial Resistance for Individual Drilled Shafts in Rock (qu ≥ 100 ksf')

- 8.3.2 Commentary on EPG 751.37.3.2 Axial Resistance for Individual Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core (5 ksf ≤ qu ≤ 100 ksf)

- 8.3.3 Commentary on EPG 751.37.3.3 Axial Resistance for Individual Drilled Shafts in Weak Rock from Standard Penetration Tests (Neq ≤ 400 blows/ft)

- 8.3.4 Commentary on EPG 751.37.3.4 Axial Resistance for Individual Drilled Shafts in Weak Rock from Texas Cone Penetration Tests (1 in. ≤ TCP ≤ 10 in.)

- 8.3.5 Commentary on EPG 751.37.3.5 Axial Resistance for Individual Drilled Shafts in Weak Rock from Point Load Index Tests (5 ksf ≤ Is(50) ≤ 40 ksf)

- 8.3.6 Commentary on EPG 751.37.3.6 Axial Resistance for Individual Drilled Shafts in Cohesive Soils (su ≤ 5 ksf)

- 8.3.7 Commentary on EPG 751.37.3.7 Axial Resistance for Individual Drilled Shafts in Cohesionless Soils

- 8.3.8 Commentary on EPG 751.37.3.8 Geotechnical Resistance from Load Tests

- 8.3.9 Commentary on EPG 751.37.3.9 Evaluation of Group Effects

- 8.4 Commentary on EPG 751.37.4 Design for Axial Loading at Serviceability Limit States

- 8.4.1 Commentary on EPG 751.37.4.1 Settlement of Individual Drilled Shafts using Approximate Method

- 8.4.2 Commentary on EPG 751.37.4.2 Settlement of Individual Drilled Shafts using t-z Method

- 8.4.3 Commentary on EPG 751.37.4.3 Settlement of Drilled Shafts in Groups

- 8.4.3.1 Commentary on Settlement of Shaft Groups in Cohesive Soils

- 8.4.3.2 Commentary on Settlement of Shaft Groups in Cohesionless Soils Using Standard Penetration Test Measurements

- 8.4.3.3 Commentary on Settlement of Shaft Groups in Cohesionless Soils Using Cone Penetration Test Measurements

- 8.4.3.4 Commentary on Settlement of Shaft Groups in Rock

- 8.5 Commentary on EPG 751.37.5 Design for Lateral Loading at Strength and Service Limit States

- 8.6 Commentary on EPG 751.37.6 Structural Resistance of Drilled Shafts

- 8.7 Commentary on EPG 751.37.7 References

751.37.1 General

| Commentary for EPG 751.37.1 General |

These guidelines address procedures for design of drilled shafts used as foundations for bridge piers, bridge abutments, roadway signs, and other miscellaneous structures. The guidelines were established following load and resistance factor design (LRFD) concepts. The provisions provided herein are intended to produce foundations that achieve target reliabilities established by MoDOT for structures of different operational importance. The four classes of operational importance include minor or low volume route, major route, major bridge costing less than $100 million, and major bridge costing greater than $100 million. Additional background regarding development of these provisions and supportive information regarding use of these provisions is provided in the accompanying commentary.

Drilled shafts can be an economical alternative to spread footing or driven pile foundations. They can be constructed in a wide variety of soil and rock conditions and designed to support a wide range of loading conditions. Drilled shafts should be considered:

- To accommodate sites where depth to bedrock is too short for pile embedment but too deep for spread footings.

- For large design loads. (Eliminates the need for large quantities of piles).

- To provide resistance against large lateral and uplift loads.

- To eliminate the need for cofferdams.

- To provide protection against scour.

- To accommodate concerns associated with the effects of pile driving (e.g. vibrations or interference with battered piles).

- When obstructions or other conditions may make pile driving difficult.

- To provide resistance to settlement when displacement tolerances are small.

751.37.1.1 Dimensions and Nomenclature

| Commentary for EPG 751.37.1.1 Dimensions and Nomenclature |

Dimensions to be established in design include the overall length of the shaft and the shaft diameter. For shafts that will be socketed into bedrock, the length and diameter of the rock socket must also be established. Table 751.37.1.1 defines the nomenclature used for these dimensions and provides relevant minimum and/or maximum values for the respective dimensions.

Table 751.37.1.1 Summary of drilled shaft dimensions with minimum and maximum values

| Dimension | Description | Minimum Value | Maximum Value | Comment |

|---|---|---|---|---|

| D | Nominal shaft diameter (Overall) | 18”1 | -- | Min. 6” increments |

| L | Length of shaft (Overall) | -- | -- | -- |

| Ds4 | Nominal socket diameter | -- | --2 | Min. 6” increments |

| Ls4 | Length of rock socket | Ds3, 5 | -- | -- |

| 1 Shaft diameter shall be at least 6” greater than column diameter when shaft is directly connected to the column and not a footing cap or bent cap. | ||||

| 2 Sockets installed through casing shall have diameters 6” less than the outside diameter of the casing. | ||||

| 3 Minimum rock socket length Ls ≥ Ds shall be measured from the anticipated tip of the casing. | ||||

| 4 The dimensions “Ds” and “Ls” are not explicitly used in any of the design equations that follow in favor of generally referring to the diameter of any segment of an overall shaft as “D” which can be a rock socket segment. This is not entirely true for the dimension “Ls” which is explicitly used as part of a settlement design equation that follows. Judicial use of the appropriate segment and use of the appropriate diameter and length of a segment is implicit to the correct use of the design equations that follow. (See EPG 751.37.2 General Design Procedure and Limit States.) | ||||

| 5 See Design Aid: Minimum Rock Socket Length | ||||

The length to diameter ratio of drilled shafts should generally be in the following range: 3 ≤ L/D ≤ 30

The nomenclature used in these guidelines has intentionally been selected to be consistent with that used in the AASHTO LRFD Bridge Design Specifications (AASHTO, 2009) to the extent possible to avoid potential confusion with methods provided in those specifications. By convention, references to other provisions of the MoDOT Engineering Policy Guide are indicated as “EPG XXX.XX” throughout these guidelines where the Xs are replaced with the appropriate article numbers. Similarly, references to provisions within the AASHTO LRFD Bridge Design Specifications are indicated as “LRFD XXX.XX”.

751.37.1.2 Materials

| Commentary for EPG 751.37.1.2 Materials |

Concrete used for drilled shaft construction shall be Class B-2 concrete with minimum compressive strength, = 4 ksi.

751.37.1.3 Casing

| Commentary for EPG 751.37.1.3 Casing |

All drilled shafts shall have permanent casing installed through overburden soils to prevent caving of these soils during construction unless conditions are such that the shafts can be more effectively and reliably constructed without casing or using temporary casing. Welded or seamless steel permanent casing shall be in accordance with Sec 701. Approval from the MoDOT Geotechnical Section is required for use of temporary casing or uncased shafts with or without drilling slurry.

Rock sockets shall be uncased.

Permanent Casing Thickness Design and Plan Reporting:

- Any drilled shaft for a major bridge over a river or lake or any drilled shaft longer than 80 feet or any drilled shaft greater than 6 feet in diameter shall have a minimum casing thickness of 1/2 inch specified unless a greater thickness is required by design for strength. The thickness of casing in either case shall be shown on the bridge plans and noted as a minimum.

- All other drilled shafts shall not have a minimum casing thickness specified unless a specific thickness is required by design for strength. The minimum thickness in the latter case shall be shown on the bridge plans and noted as a minimum.

- For drilled shaft stiffness computations and load distribution analysis, use the minimum casing thickness required. When a minimum casing thickness is not required, assume a casing thickness of 3/8” for the analysis.

751.37.1.4 General Design Considerations

| Commentary for EPG 751.37.1.4 General Design Considerations |

The following issues shall be considered for design of drilled shafts:

Scour

The potential for scour and its effect on the axial and lateral strength and serviceability of drilled shafts shall be investigated.

Ground Water

The effects of variable ground water levels and buoyancy shall be taken into account in evaluating drilled shaft strength and serviceability limit states.

Downdrag

Downdrag shall be considered when strength and serviceability are evaluated. For drilled shafts socketed into rock and overlain with soil that has the potential to settle, downdrag shall be considered as an applied load and predicted according to LRFD 3.11.8. Downward movements of 0.1 to 0.5 in. are enough to mobilize full downdrag. The top 5 ft. and a bottom length equal to the shaft diameter shall not be included in calculating downdrag. Allowance shall be given for an increase in the undrained shear strength of the soil within compressible strata as consolidation occurs.

Uplift

The effects of uplift shall be considered for drilled shafts in cohesive soils, not socketed into rock.

Group Effects

Shafts designed with relatively close spacing shall be evaluated considering group effects. Specific methods and modifications to account for group effects differ according to the soil/rock type that the shaft is founded within as provided in EPG 751.37.3.9.

The redundancy factor ηR from LRFD 1.3.4 shall not be applied for design of drilled shafts.

751.37.1.5 Related Provisions

| Commentary for EPG 751.37.1.5 Related Provisions |

The provisions of these guidelines were developed presuming that design parameters required to apply the provisions are established following current MoDOT site characterization protocols as described in EPG 321. Specific attention is drawn to EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation. The provisions provided in these guidelines presume that parameter variability, as generally represented by the coefficient of variation (COV), is established following procedures in EPG 321.3.

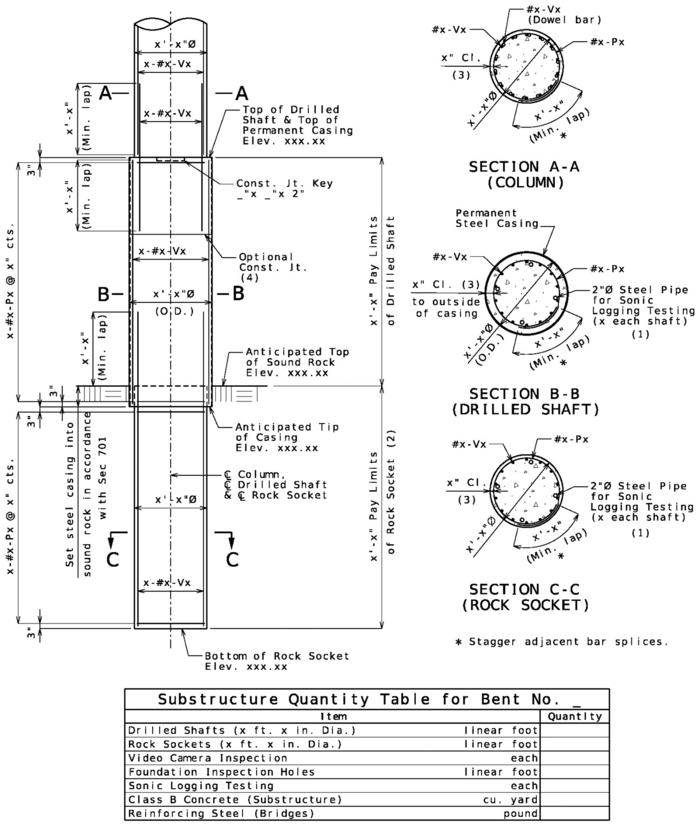

751.37.1.6 Drilled Shaft General Detail Considerations

Pay items shown in above table are for example only, show actual pay items and quantities in plan details for specific project.

Notes:

- (1) Number of pipes (equally spaced) for Sonic Logging Testing:

- Diameter ≤ 2.5 ft: 2 pipes

- Diameter >2.5 ft but ≤ 3.5 ft: 3 pipes

- Diameter >3.5 ft but ≤ 5.0 ft: 4 pipes

- Diameter >5.0 ft but ≤ 8.0 ft: 5 pipes

- Diameter >8.0 ft: 6 pipes

- Single diameter reinforcing cage is typically used. Modify details based on design for single or multiple-diameter cages and splice location(s).

- See EPG 751.37.1.3 for casing requirements and alternatives.

- When determining P bar diameter for barbill, assume 3/8” casing unless otherwise specified.

- See EPG 751.50, G8, for notes to include for drilled shafts and rock sockets (starting at G8.1).

- (2) See EPG 751.37.1.1 Dimensions and Nomenclature for Design Aid: Minimum Rock Socket Length.

- (3) When difference between drilled shaft and column diameter is 6" a single reinforcement cage is typically used for the socket and shaft and the vertical reinforcement extends into the column. A separate column steel cage is then placed around the protruding shaft reinforcement without requiring an adjustment to minimum cover for rock socket or column reinforcement. When difference between drilled shaft and column diameter is 12” either the vertical column steel or dowels will need to be extended into the shaft or the cover in the socket and shaft will need to be increased to allow the shaft reinforcement to extend into the column. In the former scenario an optional construction joint is recommended as discussed in note 4 for oversized shafts. In the latter scenario the same number of vertical bars should be used in the shaft and column to allow the shaft bars to be tied to the column cage. Any reduction in cage diameter required for fit-up shall be considered in design.

- (4) When difference between drilled shaft and column diameter is greater than 12" (oversized shaft generally 18" to 24" larger than column), show "Optional construction joint" at bottom of column/dowel reinforcement in the drilled shaft and use EPG 751.50 Standard Detailing Notes G8.8 and G8.9 in plan details.

- (1) Number of pipes (equally spaced) for Sonic Logging Testing:

| Bridge Standard Drawings (Drilled Shafts - DSS → As Built Drilled Shaft Data [DSS_01]) |

| As Built Drilled Shaft Data (PDF) |

751.37.2 General Design Procedure and Limit States

| Commentary for EPG 751.37.2 General Design Procedure and Limit States |

Drilled shafts should be sized (diameter and length) to support the required factored loads in the most cost effective manner possible without excessive deflections. The initial diameter and length of drilled shafts are generally established considering vertical loading at the strength limit state(s) according to EPG 751.37.3. The resulting shaft should then be evaluated at the axial and lateral serviceability limit states (settlement and lateral deflection) according to EPG 751.37.4 and EPG 751.37.5, where the shaft dimensions shall be adjusted if serviceability requirements are not satisfied.

The Strength Limit State and applicable Extreme Event Limit States shall be investigated when calculating the soil and structural resistance of the drilled shaft. The Service I Limit State shall be used when evaluating lateral deflection and settlement.

Guidance

There are three major types of drilled shaft construction that influence how a drilled shaft is designed. MoDOT exclusively designs and details drilled shafts with permanent casing and rock sockets as given as Case No. 1. The two cases that follow are rare and require the recommendation or approval of the Geotechnical Section and shall be shown on the plans. See EPG 751.37.1.3 Casing.

- 1. Permanently cased shaft through soil and socketed into rock. A reduced shaft diameter for rock socket is required. This case shall be used for all MoDOT projects unless otherwise allowed by the Geotechnical Section. For axial loading and settlement computations substitute D with Ds and L with Ls which are equal to the diameter and length of the rock socket since the required resistance to loading and settlement are computed for segment of the shaft in rock only (Rock sockets to be installed through casing shall have diameters 6” less than the inside diameter of the casing to allow for clearance and insertion of rock excavation re-tooling equipment.).

- 2. Permanently cased or temporarily cased or uncased shaft through soil and not socketed into rock. For axial loading and settlement computations use D = diameter of shaft.

- 3. Temporarily cased or uncased shaft through soil with a reduced or same shaft diameter for soil than/and for rock socket respectively. For axial loading and settlement computations use the appropriate diameter and length of shaft as the case may be for the design segment under investigation.

Permanently cased shafts shall not be allowed to use frictional resistance of the soil for either a drilled shaft with or without a rock socket.

Temporarily cased shafts may use the frictional resistance of the soil only for the case where a rock socket is not used (see the Geotechnical Section).

Recommendation or approval from the Geotechnical Section is required for use of temporary casing or uncased shafts with or without drilling slurry.

Note on Definitions:

- 1. Where L,i is defined, Li shall mean the length of the shaft segment through soil or through rock.

- 2. Where L is defined, L shall mean overall shaft length including the length of the rock socket.

751.37.3 Design for Axial Loading at Strength Limit State

| Commentary for EPG 751.37.3 Design for Axial Loading at Strength Limit State |

Geotechnical resistance to axial loading at the relevant strength limit state shall be computed as the sum of tip resistance and side resistance unless conditions are present that may prevent reliable mobilization of tip resistance (e.g. karst conditions with known or likely voids that cannot be specifically identified or characterized). Shafts should be sized such that the factored geotechnical resistance to axial loads exceeds the factored axial loads:

| (consistent units of force) | Equation 751.37.3.1 |

where:

- RR = factored axial shaft resistance (consistent units of force),

- RsR = factored side resistance (consistent units of force),

- RpR = factored tip resistance (consistent units of force) and

- = factored load for the appropriate strength limit state (consistent units of force).

Tip resistance and side resistance shall be computed according to the provisions of EPG 751.37.3 for the material type(s) encountered. The Structural Project Manager or Structural Liaison Engineer shall be consulted before utilizing design methods other than those provided in EPG 751.37.3 for calculating the geotechnical resistance of drilled shafts.

The factored side resistance for drilled shafts shall be established from factored unit side resistance values for the relevant soil/rock conditions as provided in this article. For stratified ground conditions or where the shaft dimensions change (e.g. at tip of temporary or permanent casing, or at top of rock socket), the shaft shall be divided into segments with practically uniform shaft geometry and soil/rock properties and unit side resistance values determined for each shaft segment. The total factored side resistance shall then be computed as the sum of the factored resistance values for each shaft segment:

| (consistent units of force) | Equation 751.37.3.2 |

where:

- n = number of shaft segments,

- = factored unit side resistance for shaft segment i (consistent units of stress),

- = perimeter interface area for shaft segment i (consistent units of area),

- = resistance factor for unit side resistance along shaft segment i (dimensionless),

- = nominal unit side resistance along shaft segment i (consistent units of stress),

- Di = shaft diameter for shaft segment i (consistent units of length), and

- Li = length of shaft segment i (consistent units of length).

and shall be determined in accordance with the provisions of this article, based on the material type present along the respective shaft segment.

Side resistance shall generally be neglected or reduced, as recommended by the Geotechnical Section, over shaft segments with permanent casing and over any length of rock socket that is deemed unusable.

The factored tip resistance for drilled shafts shall be established from factored unit tip resistance values for the relevant soil/rock conditions as provided in this article. The appropriate tip resistance shall be established for the soil/rock located between the tip of the shaft and two diameters below the tip of the shaft. The factored tip resistance shall be computed as

| (consistent units of force) | Equation 751.37.3.3 |

where:

- = factored unit tip resistance (consistent units of stress),

- = cross-sectional area of the shaft at the tip (consistent units of area),

- = resistance factor for unit tip resistance (dimensionless),

- = nominal unit tip resistance (consistent units of stress), and

- D = shaft diameter at the tip of the shaft (consistent units of length).

and shall be determined in accordance with the provisions of this article, based on the material type present within a depth of 2D below the tip of the shaft.

Tip resistance shall be neglected, as recommended by the Geotechnical Section, when the shaft tip is located within karstic rock or other conditions where tip resistance cannot be reliably determined.

The specific methods and resistance factors for determining nominal and factored side and tip resistance shall be selected based on the material type(s) present along the sides and beneath the tip of the shaft:

- EPG 751.37.3.1 shall generally be followed to estimate resistance for shafts in rock from results of uniaxial compression tests on intact rock core with uniaxial compressive strengths (qu ) greater than 100 ksf;

- EPG 751.37.3.2 shall generally be followed to estimate resistance for shafts in weak rock from results of uniaxial compression tests on rock core with uniaxial compressive strengths (qu ) greater than 5 ksf but less than 100 ksf;

- EPG 751.37.3.3 shall generally be followed to estimate resistance for shafts in weak rock from results of Standard Penetration Tests with equivalent N-values (Neq ) less than 400 blows/foot;

- EPG 751.37.3.4 shall generally be followed to estimate resistance for shafts in weak rock from results of Texas Cone Penetration Tests with measured penetrations (TCP) greater than 1 inch/100 blows but less than 10 inches/100 blows;

- EPG 751.37.3.5 shall generally be followed to estimate resistance for shafts in weak rock from results of Point Load Index Tests with Point Load Indices (Is(50) ) less than 40 ksf;

- EPG 751.37.3.6 shall generally be followed to estimate resistance for shafts in cohesive soils with undrained shear strengths (su ) less than 5 ksf; and

- EPG 751.37.3.7 shall generally be followed to estimate resistance for shafts in cohesionless soils.

Additional guidance on selection of specific methods and resistance factors based on the material types encountered is provided in the commentary to these guidelines.

751.37.3.1 Axial Resistance for Individual Drilled Shafts in Rock (qu ≥ 100 ksf)

| Commentary for EPG 751.37.3.1 Axial Resistance for Individual Drilled Shafts in Rock (qu ≥ 100 ksf) |

Side Resistance for Drilled Shafts in Rock (qu ≥ 100 ksf)

The nominal unit side resistance for shaft segments located in rock shall be computed as a function of the mean uniaxial compressive strength of the intact rock according to (Horvath and Kenney, 1979)

| (ksf) | Equation 751.37.3.4 |

where:

- qs = nominal unit side resistance for the shaft segment (ksf),

- = mean value of uniaxial compressive strength of rock core along the shaft segment (ksf), and

- = compressive strength of concrete (ksi).

- αE = factor to account for discontinuities in the rock

Note that this expression is dimensional so values must be entered in the units specified.

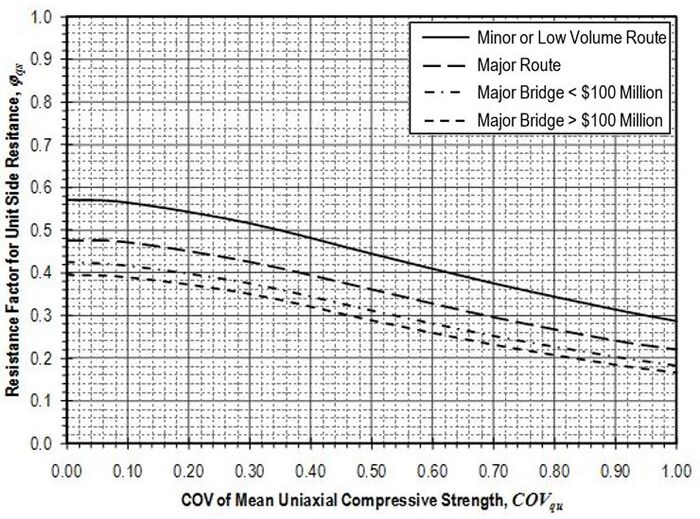

Resistance factors to be applied to the nominal resistance values (qs ) determined according to the provisions of this article shall be established from Figure 751.37.3.1.1 based on the coefficient of variation of the mean uniaxial compressive strength . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over the length of the shaft segment. Values for should similarly reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Values for shall be estimated based on the expected concrete compressive strength for the shaft.

The nominal unit side resistance predicted using Equation 751.37.3.4 shall be limited to a maximum value of ksf where is input in units of ksi. This limit corresponds to 35 ksf for concrete with = 4 ksi.

A factor αE to account for discontinuities in the rock following O’Neill and Reese (1999) shall be used to reduce the nominal unit side resistance calculated by equation 751.37.3.4. The reduction factor shall only be applied to rock with recovery ratios less than 80% and RQD less than 50. Interpolation may be used. The reduction factor shall be determined and included as part of the nominal unit side resistance by the Geotechnical Section.

| RQD | αE | |

|---|---|---|

| Closed Joints | Open Joints | |

| 100 | 1.0 | 0.85 |

| 70 | 0.85 | 0.55 |

| 50 | 0.60 | 0.55 |

| 30 | 0.50 | 0.5 |

| 20 | 0.45 | 0.45 |

Tip Resistance for Drilled Shafts in Rock (qu ≥ 100 ksf)

The nominal unit tip resistance for shafts founded on rock shall be computed as (adapted from Wyllie, 1999)

| (consistent units of stress) | Equation 751.37.3.5 |

where:

- qp = nominal unit tip resistance for the shaft (consistent units of stress),

- = mean value of the uniaxial compressive strength (consistent units of stress) and

- m and s = empirical constants describing the rock mass strength (dimensionless).

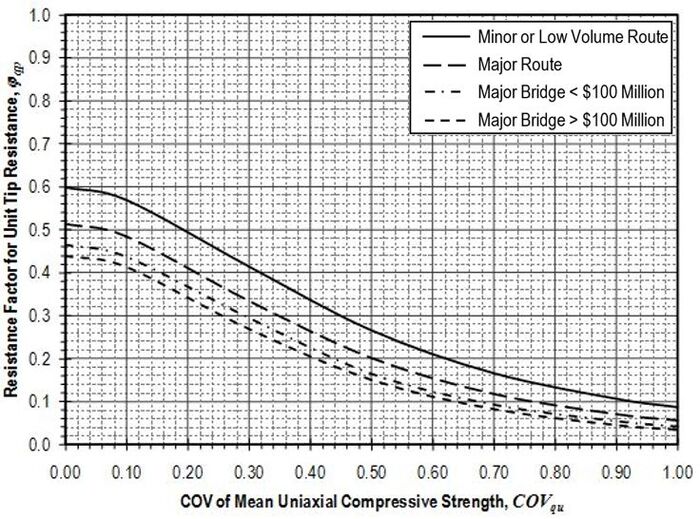

Resistance factors to be applied to the nominal resistance values (qp) determined according to the provisions of this article shall be established from Figure 751.37.3.1.2 based on the coefficient of variation of the mean uniaxial compressive strength . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for , m and s shall be taken as mean values for the rock over a depth of 2Ds below the tip of the shaft. Values for should similarly reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

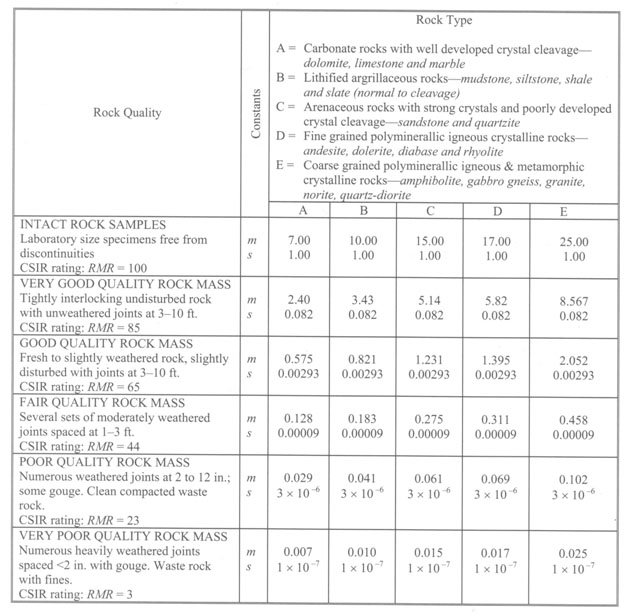

Values for the rock mass parameters m and s can be established as:

| (dimensionless) | Equation 751.37.3.6 | |

| (dimensionless) | Equation 751.37.3.7a | |

| (dimensionless) | Equation 751.37.3.7b |

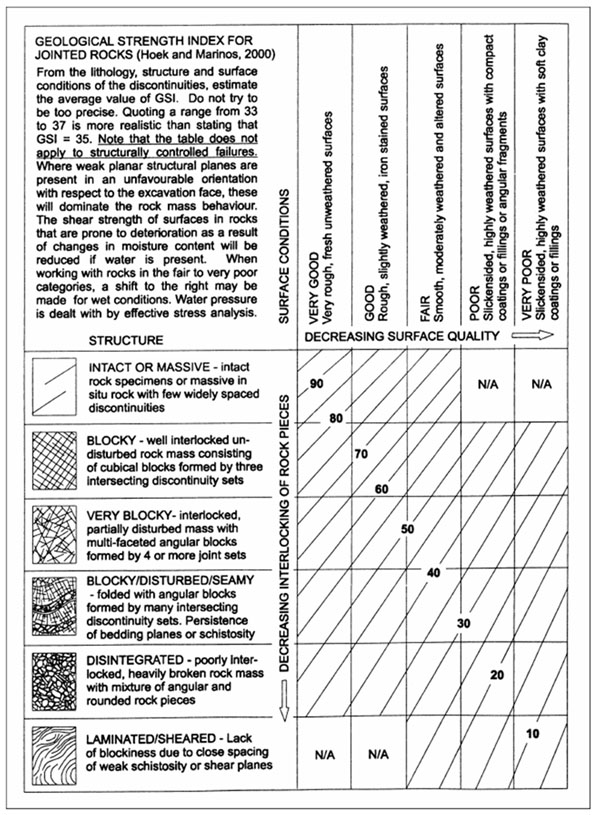

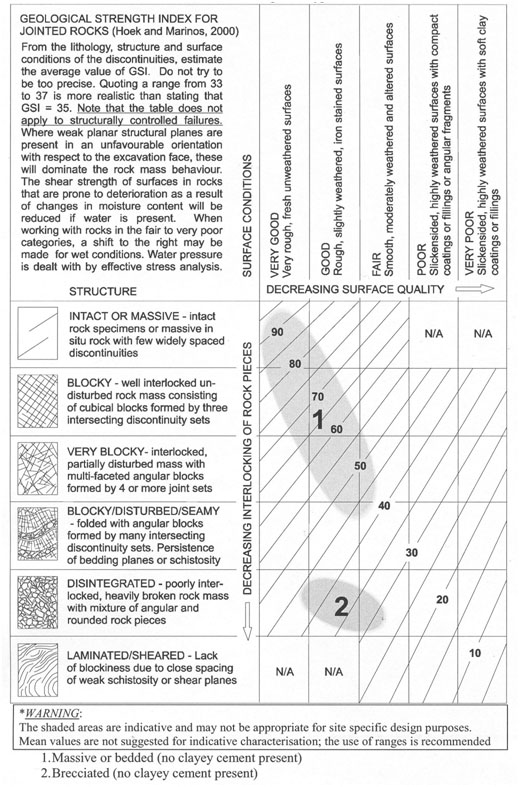

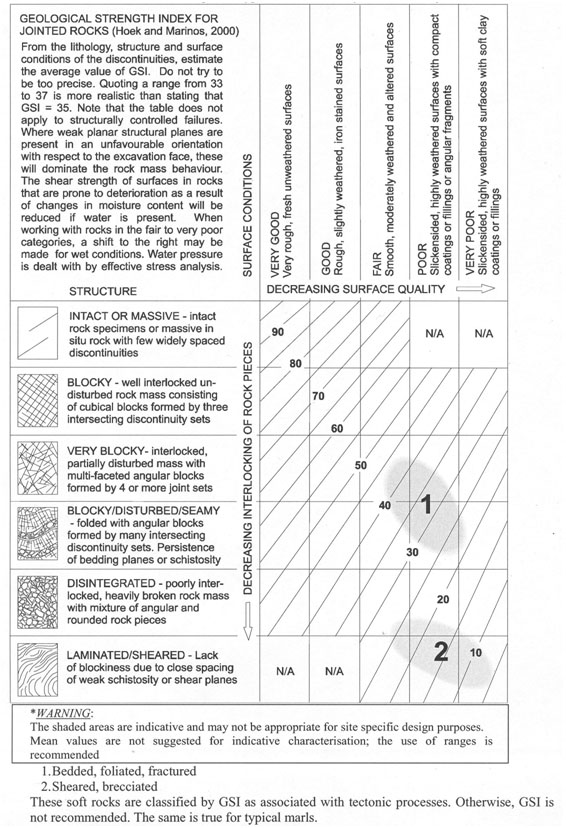

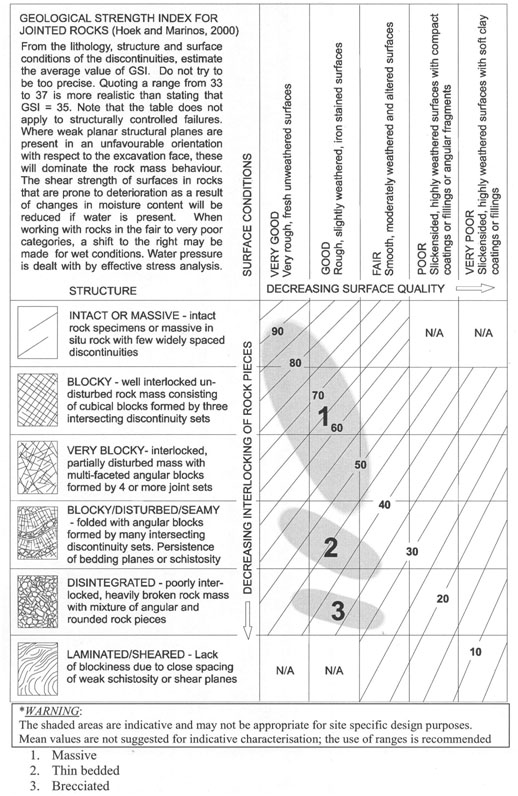

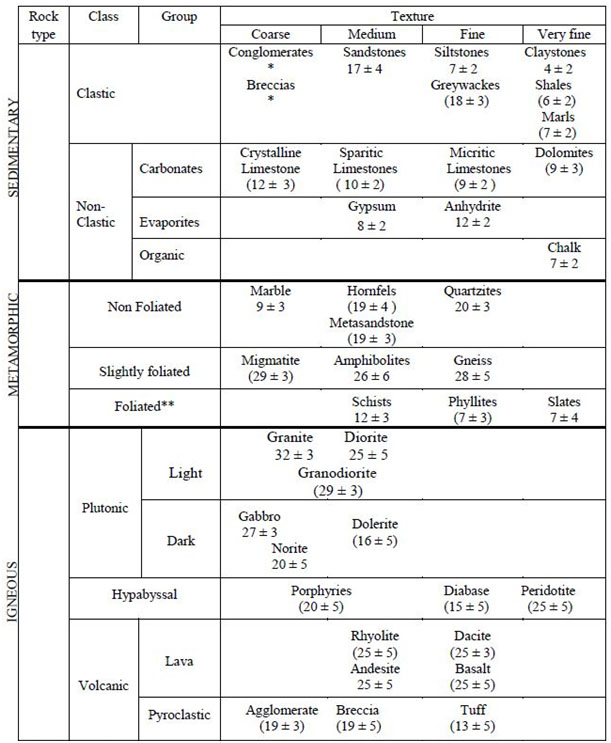

where mi is a material constant corresponding to rock type and GSI is the Geological Strength Index. The value for mi can be estimated from Table 751.37.3.1.2 or determined more precisely from triaxial tests (Hoek and Brown, 1997). For routine design, mi can be approximated as 10 for limestones and dolomites, as 6 for shales, siltstones, and mudstones, and as 17 for sandstones. Values for GSI can be estimated from rock mass characterizations using the Rock Mass Rating (RMR) system for rock masses with RMR greater than 25 (Hoek and Brown, 1997). Using this approach, GSI is calculated as:

| (dimensionless) | Equation 751.37.3.8 |

where

Ri = Rock Mass Rating system rating parameters (dimensionless).

GSI is thus equivalent to the RMR value with the groundwater rating term, R5, taken as 10.

Values for GSI to be used in Equations 751.37.3.6 and 751.37.3.7, or values for m and s to be used in Equation 751.37.3.5, can also be established using alternative methods described in the commentary to this subarticle.

The nominal tip resistance predicted using Equation 751.37.3.5 shall be limited to a maximum value of 400 ksf unless greater resistance can be verified by a load test.

* Conglomerates and breccias may present a wide range of mi values depending on the nature of the cementing material and degree of cementation, so they may range from values similar to sandstone, to values used for fine grained sediments (even under 10).

** These values are for intact rock specimens tested normal to bedding or foliation. The value of mi will be significantly different if failure occurs along a weakness plane.

751.37.3.2 Axial Resistance for Individual Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core (5 ksf ≤ qu ≤ 100 ksf)

| Commentary on EPG 751.37.3.2 Axial Resistance for Individual Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core (5 ksf ≤ qu ≤ 100 ksf) |

Side Resistance for Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core (5 ksf ≤ qu ≤ 100 ksf)

The nominal unit side resistance for shaft segments located in weak rock shall be computed from measurements of uniaxial compressive strength on rock core as (Loehr et al., 2011a; Loehr et al., 2011b)

| (ksf) | Equation 751.37.3.9 |

where:

- qs = nominal unit side resistance for the shaft segment (ksf) and

- = mean uniaxial compressive strength of rock core along the shaft segment (ksf).

Note that this expression is dimensional so values must be entered in the units specified.

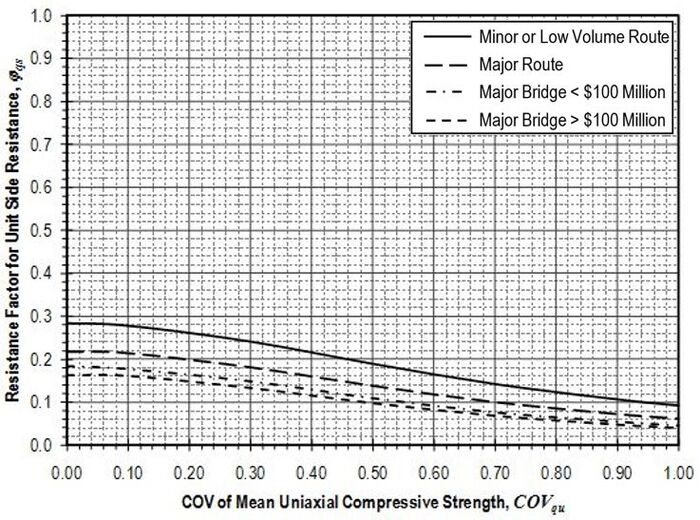

Resistance factors to be applied to the nominal resistance values (qs) determined according to the provisions of this article shall be established from Figure 751.37.3.2.1 based on the coefficient of variation of the mean uniaxial compressive strength . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over the length of the shaft segment. Values for should similarly reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment.

The nominal unit side resistance predicted using Equation 751.37.3.9 shall be limited to a maximum value of 30 ksf unless greater resistance can be verified by a load test.

Tip Resistance for Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core (5 ksf ≤ qu ≤ 100 ksf)

The nominal unit tip resistance for shafts founded on weak rock shall be computed from measurements of uniaxial compressive strength on rock core as (Loehr et al., 2011a; Loehr et al., 2011b)

| (ksf) | Equation 751.37.3.10 |

where:

- qp = nominal unit tip resistance for the shaft (ksf), and

- = mean uniaxial compressive strength for rock at the shaft tip (ksf).

Note that this expression is dimensional so values must be entered in the units specified.

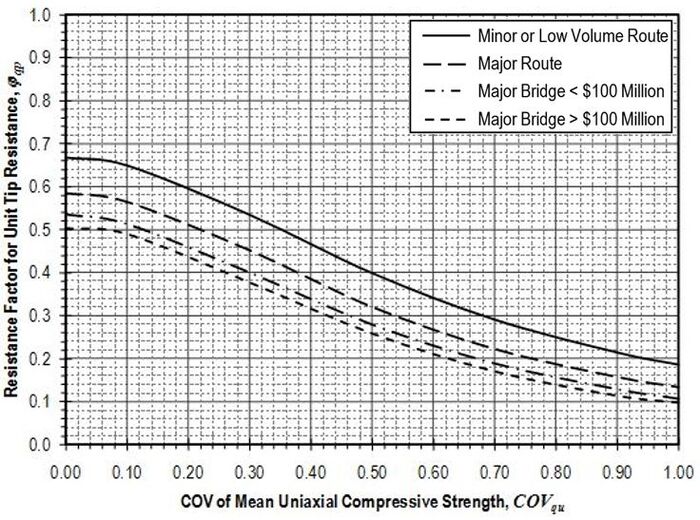

Resistance factors to be applied to the nominal resistance values (qp) determined according to the provisions of this article shall be established from Figure 751.37.3.2.2 based on the coefficient of variation of the mean uniaxial compressive strength . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over a depth of 2Ds below the tip of the shaft. Values for should similarly reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

The nominal tip resistance predicted using Equation 751.37.3.10 shall be limited to a maximum value of 400 ksf unless greater resistance can be verified by a load test.

751.37.3.3 Axial Resistance for Individual Drilled Shafts in Weak Rock from Standard Penetration Tests (Neq ≤ 400 blows/ft)

| Commentary for EPG 751.37.3.3 Axial Resistance for Individual Drilled Shafts in Weak Rock from Standard Penetration Tests (Neq ≤ 400 blows/ft) |

Side Resistance for Drilled Shafts in Weak Rock from Standard Penetration Tests (Neq ≤ 400 blows/ft)

The nominal unit side resistance for shaft segments located in weak rock shall be computed from Standard Penetration Test (SPT) measurements as (Pierce et al., 2011)

| (ksf) | Equation 751.37.3.11 |

where:

- qs = nominal unit side resistance for the shaft segment (ksf) and

- = equivalent SPT N-value along the shaft segment (blows/foot).

Note that this expression is dimensional so values must be entered in the units specified.

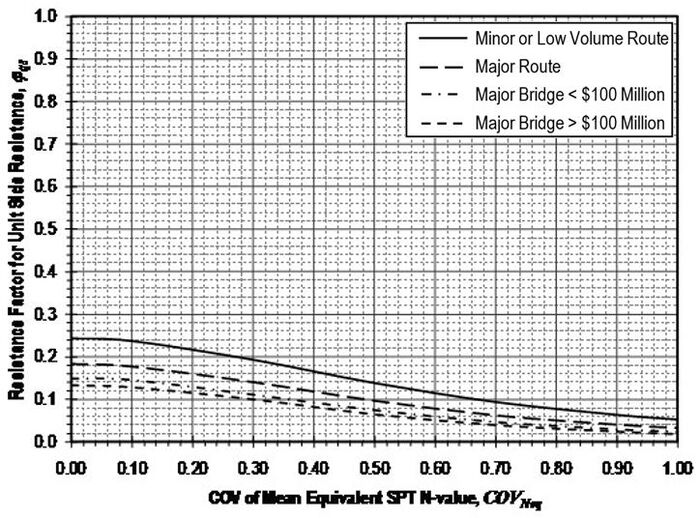

Resistance factors to be applied to the nominal resistance values (qs) determined according to the provisions of this article shall be established from Figure 751.37.3.3.1 based on the coefficient of variation of the mean equivalent SPR N-value . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over the length of the shaft segment. Values for should similarly reflect the variability of the mean equivalent N-value for the rock over the shaft segment.

The nominal unit side resistance predicted using Equation 751.37.3.11 shall be limited to a maximum value of 30 ksf unless greater resistance can be verified by a load test.

Tip Resistance for Drilled Shafts in Weak Rock from Standard Penetration Tests (Neq ≤ 400 blows/ft)

The nominal unit tip resistance for shafts founded on weak rock shall be computed from Standard Penetration Test (SPT) measurements as (Pierce et al., 2011)

| (ksf) | Equation 751.37.3.9 |

where:

- qp = nominal unit tip resistance for the shaft (ksf) and

- = mean equivalent SPT N-value for rock at the shaft tip (blows/foot).

Note that this expression is dimensional so values must be entered in the units specified.

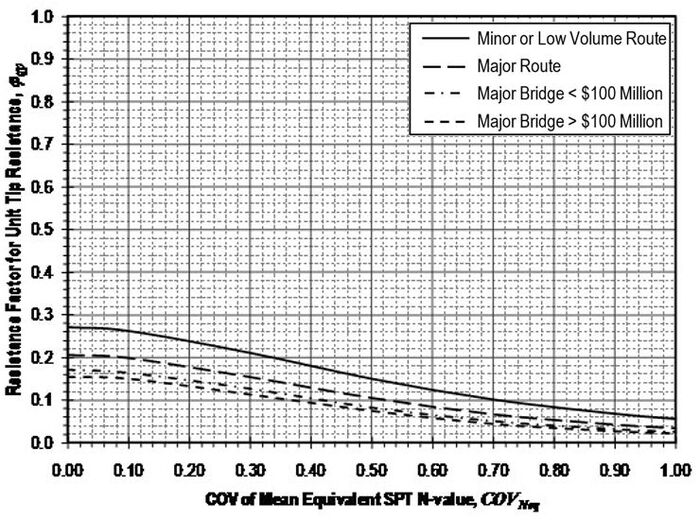

Resistance factors to be applied to the nominal resistance values (qp) determined according to the provisions of this article shall be established from Figure 751.37.3.3.2 based on the coefficient of variation of the mean equivalent SPR N-value . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over a depth of 2Ds below the tip of the shaft. Values for should similarly reflect the variability of the mean equivalent N-value for the rock over the distance 2Ds below the tip of the shaft.

The nominal tip resistance predicted using Equation 751.37.3.12 shall be limited to a maximum value of 400 ksf unless greater resistance can be verified by a load test.

751.37.3.4 Axial Resistance for Individual Drilled Shafts in Weak Rock from Texas Cone Penetration Tests (1 in. ≤ TCP ≤ 10 in.)

| Commentary for EPG 751.37.3.4 Axial Resistance for Individual Drilled Shafts in Weak Rock from Texas Cone Penetration Tests (1 in. ≤ TCP ≤ 10 in.) |

Side Resistance for Drilled Shafts in Weak Rock from Texas Cone Penetration Tests (1 in. ≤ TCP ≤ 10 in.)

The nominal unit side resistance for shaft segments located in weak rock shall be computed from Texas Cone Penetration Test (TCPT) measurements as (Pierce et al., 2011)

| (ksf) | Equation 751.37.3.13 |

where:

- qs = nominal unit side resistance for the shaft segment (ksf) and

- = mean value of penetration from TCPT measurements for rock along the shaft segment (inches/100 blows).

Note that this expression is dimensional so values must be entered in the units specified.

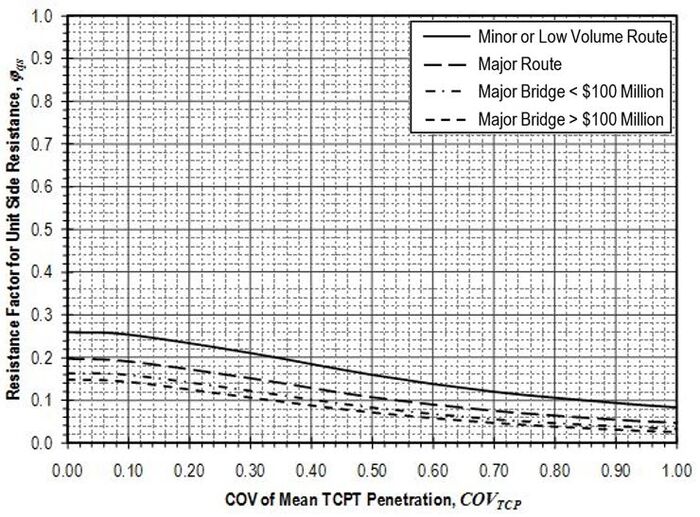

Resistance factors to be applied to the nominal resistance values (qs) determined according to the provisions of this article shall be established from Figure 751.37.3.4.1 based on the coefficient of variation of the mean TCP-value . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over the length of the shaft segment. Values for should similarly reflect the variability of the mean TCP-value for the rock over the shaft segment.

The nominal unit side resistance predicted using Equation 751.37.3.13 shall be limited to a maximum value of 30 ksf unless greater resistance can be verified by a load test.

Tip Resistance for Drilled Shafts in Weak Rock from Texas Cone Penetration Tests (1 in. ≤ TCP ≤ 10 in.)

The nominal unit tip resistance for shafts founded on weak rock shall be computed from Texas Cone Penetration Test (TCPT) measurements as (Pierce et al., 2011)

| (ksf) | Equation 751.37.3.14 |

where:

- (qp) = nominal unit tip resistance for the shaft (ksf) and

- = mean value of penetration from TCPT measurements for rock at the tip of the shaft (inches/100 blows).

Note that this expression is dimensional so values must be entered in the units specified.

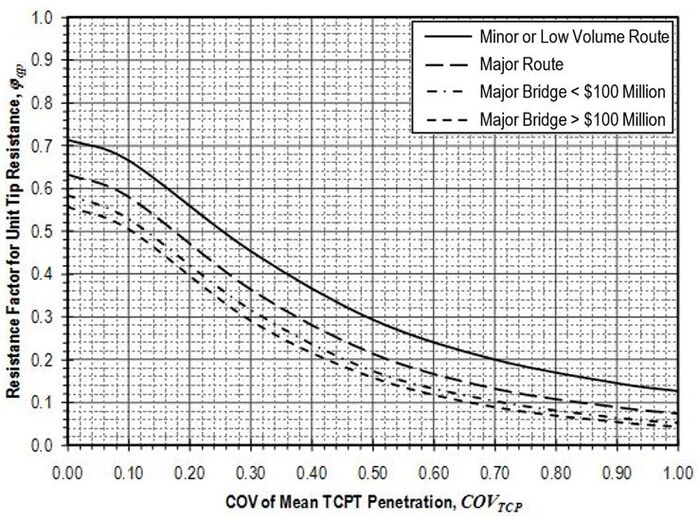

Resistance factors to be applied to the nominal resistance values (qp) determined according to the provisions of this article shall be established from Figure 751.37.3.4.2 based on the coefficient of variation of the mean TCP-value . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over a depth of 2Ds below the tip of the shaft. Values for should similarly reflect the variability of the mean TCP-value for the rock over the distance 2Ds below the tip of the shaft.

The nominal tip resistance predicted using Equation 751.37.3.14 shall be limited to a maximum value of 400 ksf unless greater resistance can be verified by a load test.

751.37.3.5 Axial Resistance for Individual Drilled Shafts in Weak Rock from Point Load Index Tests (5 ksf ≤ Is(50) ≤ 40 ksf)

| Commentary for EPG 751.37.3.5 Axial Resistance for Individual Drilled Shafts in Weak Rock from Point Load Index Tests (5 ksf ≤ Is(50) ≤ 40 ksf) |

Side Resistance for Drilled Shafts in Weak Rock from Point Load Index Tests (5 ksf ≤ Is(50) ≤ 40 ksf)

The nominal unit side resistance for shaft segments located in weak rock shall be computed from Point Load Index Test measurements as (Loehr et al., 2011a; Loehr et al., 2011b)

| (ksf) | Equation 751.37.3.15 |

where:

- qs = nominal unit side resistance for the shaft segment (ksf) and

- = mean corrected point load index value for rock along the shaft segment (ksf).

Note that this expression is dimensional so values must be entered in the units specified.

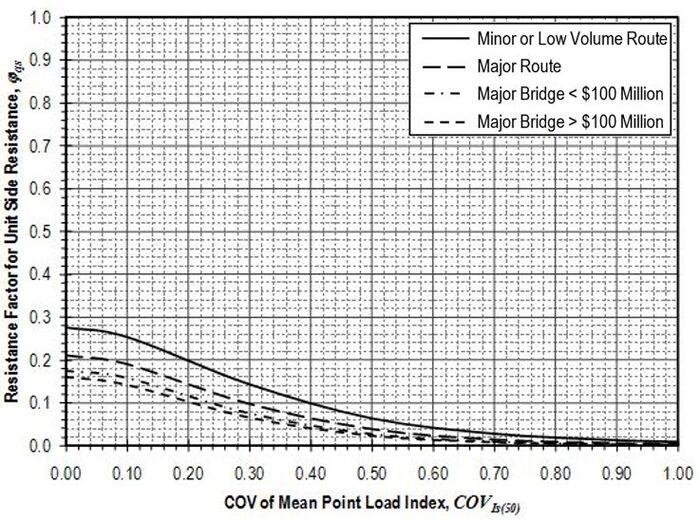

Resistance factors to be applied to the nominal resistance values (qs) determined according to the provisions of this article shall be established from Figure 751.37.3.5.1 based on the coefficient of variation of the mean Is(50)-value . Values for Is(50) and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for Is(50) shall be taken as mean values for the rock over the length of the shaft segment. Values for should similarly reflect the variability of the mean Is(50)-value for the rock over the shaft segment.

The nominal unit side resistance predicted using Equation 751.37.3.15 shall be limited to a maximum value of 30 ksf unless greater resistance can be verified by a load test.

Tip Resistance for Drilled Shafts in Weak Rock from Point Load Index Tests (5 ksf ≤ Is(50) ≤ 40 ksf)

The nominal unit tip resistance for shafts founded on weak rock shall be computed from Point Load Index Test measurements as (Loehr et al., 2011a; Loehr et al., 2011b)

| (ksf) | Equation 751.37.3.16 |

where:

- qp = nominal unit tip resistance for the shaft (ksf) and

- = mean corrected point load index value for rock at the tip of the shaft (ksf).

Note that this expression is dimensional so values must be entered in the units specified.

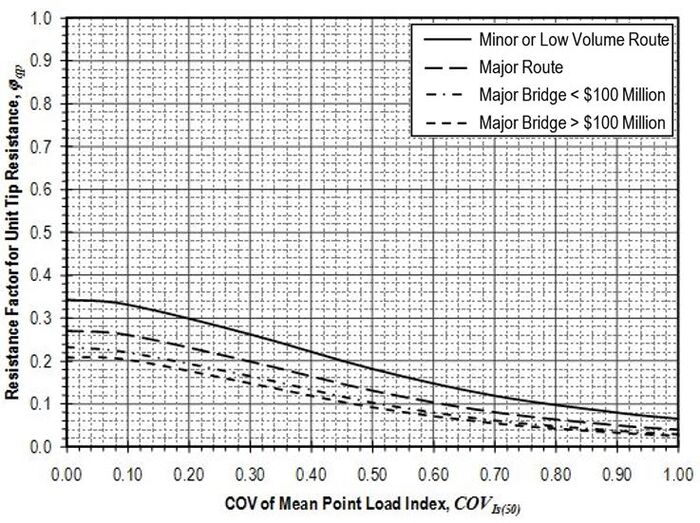

Resistance factors to be applied to the nominal resistance values (qp) determined according to the provisions of this article shall be established from Figure 751.37.3.5.2 based on the coefficient of variation of the mean Is(50)-value . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the rock over a depth of 2Ds below the tip of the shaft. Values for should similarly reflect the variability of the mean Is(50)-value for the rock over the distance 2Ds below the tip of the shaft.

The nominal tip resistance predicted using Equation 751.37.3.16 shall be limited to a maximum value of 400 ksf unless greater resistance can be verified by a load test.

751.37.3.6 Axial Resistance for Individual Drilled Shafts in Cohesive Soils (su ≤ 5 ksf)

| Commentary for EPG 751.37.3.6 Axial Resistance for Individual Drilled Shafts in Cohesive Soils (su ≤ 5 ksf) |

Side Resistance for Drilled Shafts in Cohesive Soils (su ≤ 5 ksf)

The nominal unit side resistance for shaft segments located in cohesive soils shall be computed from measurements of undrained shear strength using the “α-method” as (e.g. Reese et al., 2006)

| (consistent units of stress) | Equation 751.37.3.17 |

where:

- qs = nominal unit side resistance for the shaft segment (consistent units of stress),

- α = an empirical coefficient (dimensionless) and

- = mean value of the undrained shear strength for the soil along the shaft segment (consistent units of stress).

The value for α shall be taken as

| (dimensionless) | Equation 751.37.3.18 |

where is the mean undrained shear strength input in units of ksf.

Note that this expression is dimensional so values must be entered in the units specified.

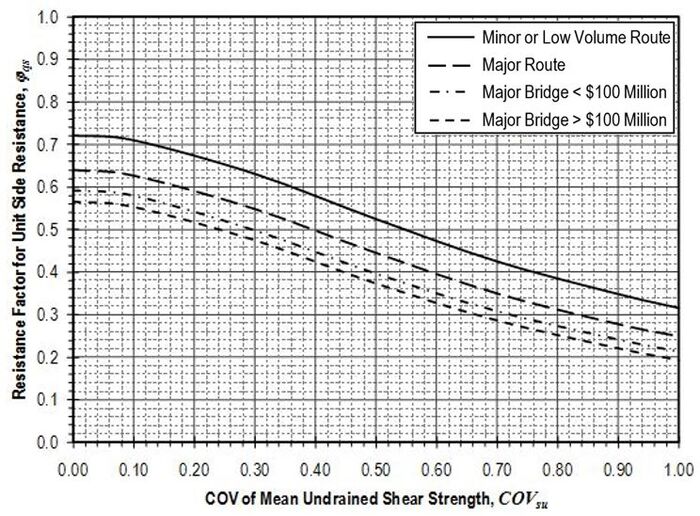

Resistance factors to be applied to the nominal resistance values (qs) determined according to the provisions of this article shall be established from Figure 751.37.3.6.1 based on the coefficient of variation of mean undrained shear strength . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the soil over the length of the shaft segment. Values for should similarly reflect the variability of the mean undrained shear strength for the soil over the shaft segment.

The value for α predicted using Equation 751.37.3.18 shall be limited to a maximum value of 1.0.

In cohesive soils, side resistance along the top 5 ft. of the shaft and a distance of one shaft diameter above the tip of the shaft shall be ignored.

Tip Resistance for Drilled Shafts in Cohesive Soils (su ≤ 5 ksf)

The nominal tip resistance for shafts founded on cohesive soils shall be calculated from measurements of undrained shear strength according to:

| (consistent units of stress) | Equation 751.37.3.19 |

where:

- qp = nominal unit tip resistance for the shaft (consistent units of stress),

- = mean value of the undrained shear strength of the soil (consistent units of stress) and

- Nc = bearing capacity factor (dimensionless).

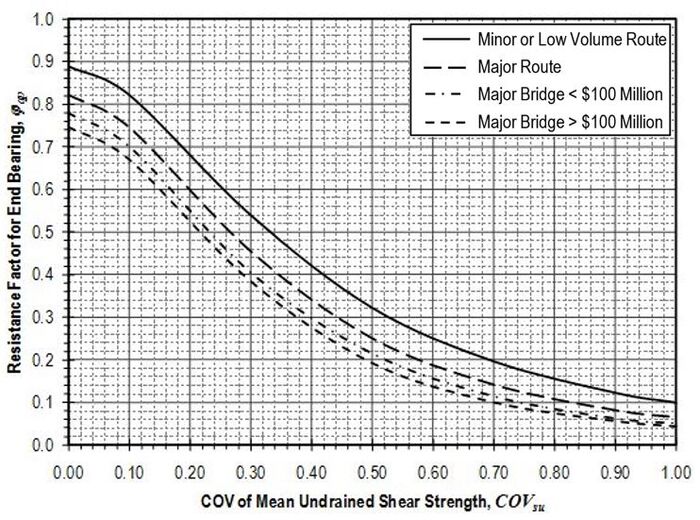

Resistance factors to be applied to the nominal resistance values (qp) determined according to the provisions of this article shall be established from Figure 751.37.3.6.2 based on the coefficient of variation of the mean undrained shear strength . Values for and shall be determined in accordance with methods described in EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation for the site and location in question. Values for shall be taken as mean values for the soil over a depth of 2D below the tip of the shaft. Values for should similarly reflect the variability of the mean undrained shear strength for the soil over the distance 2D below the tip of the shaft.

The value for Nc shall be taken as

| (dimensionless) | Equation 751.37.3.20 |

where:

- Z = depth of the tip of the shaft from the ground surface (consistent units of length), and

- D = shaft diameter (consistent units of length).

The value for Nc predicted using Equation 751.37.3.20 shall be limited to a maximum value of 9.0.

For ≤ 0.5 ksf, Nc shall be multiplied by 0.67.

The nominal unit tip resistance predicted using Equation 751.37.3.19 shall be limited to a maximum value of 80 ksf unless greater resistance can be verified by a load test.

751.37.3.7 Axial Resistance for Individual Drilled Shafts in Cohesionless Soils

| Commentary for EPG 751.37.3.7 Axial Resistance for Individual Drilled Shafts in Cohesionless Soils |

Side Resistance for Drilled Shafts in Cohesionless Soils

The nominal unit side resistance for shaft segments located in cohesionless soils shall be computed using the “β-method” as

| (consistent units of stress) | Equation 751.37.3.21 |

where:

- qs = nominal unit side resistance for the shaft segment (consistent units of stress),

- β = an empirical correlation factor (dimensionless) and

- σ'v = average vertical effective stress for the soil along the shaft segment (consistent units of stress).

The value for β shall be taken as (O’Neill and Reese, 1999)

| (for N60 ≥ 15) | Equation 751.37.3.22a | |

| (for N60 < 15) | Equation 751.37.3.22b |

where 0.25 ≤ β ≤ 1.2 and

- z = depth below ground surface to center of shaft segment (ft.) and

- N60 = average SPT N-value corrected for hammer efficiency (blows/ft).

If permanent casing is used, the side resistance shall be adjusted with consideration of type and length of casing used.

The resistance factor to be applied to the nominal unit side resistance shall be taken as 0.55.

Tip Resistance for Drilled Shafts in Cohesionless Soils

The nominal unit tip resistance for shafts founded on cohesionless soils shall be computed from corrected SPT N-values, N60 (O’Neill and Reese, 1999).

For N_60≤50:

| (ksf) | Equation 751.37.3.23 |

where:

- qp = nominal unit tip resistance for the shaft (ksf) and

- N60 = average SPT N-value corrected for hammer efficiency (blows/ft).

For N60 ≥ 50:

| (ksf) | Equation 751.37.3.24 |

where:

- qp = nominal unit tip resistance for the shaft (ksf),

- N60 = average SPT N-value corrected for hammer efficiency (blows/foot),

- pa = 2.12 ksf = atmospheric pressure (ksf).

- = vertical effective stress for the soil at the tip of the shaft (ksf).

Note that these expressions are dimensional so values must be entered in the units specified.

The resistance factor shall be taken as 0.50 for Equation 751.37.3.23 and as 0.55 for Equation 751.37.3.24.

751.37.3.8 Geotechnical Resistance from Load Tests

| Commentary for EPG 751.37.3.8 Geotechnical Resistance from Load Tests |

If drilled shaft resistance is determined by load test, the resistance factor shall be taken as 0.7 regardless of the soil conditions.

751.37.3.9 Evaluation of Group Effects

| Commentary for EPG 751.37.3.9 Evaluation of Group Effects |

Group effects for drilled shafts shall be evaluated as described in EPG 751.37.3.9. Procedures for evaluation of group effects generally involve use of a group efficiency factor, consideration of an “equivalent pier”, or both. Application of the group efficiency factor requires that the nominal resistance for individual shafts be multiplied by the factor η to reflect the nominal average resistance of the shafts within a group:

| (consistent units of force) | Equation 751.37.3.25 |

where:

- R = nominal resistance of an individual shaft (consistent units of force),

- R* = modified shaft resistance accounting for group effects (consistent units of force) and

- η = group efficiency factor established as described in this article.

Note that the group efficiency factor (η) used here is different from the redundancy factor (ηR) discussed in EPG 751.37.1.4. Additional discussion regarding the redundancy factor is provided in the commentary.

Consideration of an “equivalent pier” requires evaluation of the shaft group as a hypothetical, monolithic pier encompassing the block of soil and shafts enclosed within the outer perimeter of the shaft group.

The specific method to be used differs with geologic setting as described in the remainder of this article.

Group Effects in Cohesionless Soils

For shafts deriving resistance predominantly from cohesionless soils, the nominal resistance of individual shafts in the group shall be reduced by an efficiency factor, η, determined based on the spacing of the shafts:

- for shafts with center-to-center spacing equal to 2.5 shaft diameters, η = 0.65

- for shafts with center-to-center spacing equal to 4.0 shaft diameters or more, η = 1.0, and

- for shafts with intermediate spacing, the value for η shall be linearly interpolated between these values.

These efficiency factors shall apply regardless of conditions of contact between the cap and ground.

Group Effects in Cohesive Soils

For shafts deriving resistance predominantly from cohesive soils, the nominal resistance of the pile group shall be taken as the lesser of the following values:

- The nominal resistance of an equivalent pier consisting of the shafts and the block of soil within the area bounded by the shafts, or

- The sum of the nominal resistances for each individual shaft in the group.

For the latter value, the nominal resistances for individual piles shall be reduced by an efficiency factor, η, if the soil is soft and the cap may not be in firm contact with the ground. In such cases, the efficiency factor, η, shall be determined based on the spacing of the shafts:

- η = 0.65 for shafts with center-to-center spacing equal to 2.5 shaft diameters,

- η = 1.0 for shafts with center-to-center spacing equal to 6.0 shaft diameters or more, and

- For intermediate shaft spacing, the value for η shall be linearly interpolated between these values.

Note that the efficiency factors shall only apply if the soil is soft and the cap is not in firm contact with the ground. For all other conditions, no efficiency factor shall be applied when comparing the total resistance for the equivalent pier with the cumulative resistance from the individual shafts.

The resistance factors to be applied for the equivalent pier evaluation shall be 0.60 (AASHTO, 2009). Resistance factors for summation of the individual shaft resistances shall be those provided in EPG 751.37.3.1 through EPG 751.37.3.8.

Group Effects in Rock

For shafts deriving resistance predominantly from rock, the nominal resistance of the pile group shall be taken as the lesser of the following:

- The nominal resistance of an equivalent pier consisting of the shafts and the block of soil/rock within the area bounded by the shafts, or

- The sum of the nominal resistances for each individual shaft in the group.

No efficiency factor shall be applied to the individual pile resistances when evaluating the latter condition.

751.37.4 Design for Axial Loading at Serviceability Limit States

| Commentary for EPG 751.37.Commentary on EPG 751.37.4 Design for Axial Loading at Serviceability Limit States |

Drilled shafts shall be dimensioned so that there is a small likelihood that shafts will settle more than tolerable settlements, generally established from consideration of span length. This shall be accomplished by comparing a factored settlement computed for a shaft with dimensions established from EPG 751.37.3 with an established tolerable settlement. If the factored total settlement determined from these provisions is found to be less than or equal to the tolerable settlement, i.e. if

| (consistent units of lengths) | Equation 751.37.4.1 |

where:

- δR = factored total settlement (consistent units of length) and

- δtol = tolerable settlement (consistent units of length),

the limit state is satisfied and the probability of shaft settlement exceeding the tolerable settlement is less than or equal to the target probability established by MoDOT. If the factored total settlement is determined to exceed the tolerable settlement, the probability of foundation settlement exceeding the tolerable value is greater than the target probability established by MoDOT. In such cases, the shaft dimensions shall be increased until the factored total settlement is less than or equal to the tolerable settlement.

Resistance factors provided in this article were established to produce factored settlements that have a target probability of being exceeded. Target probabilities of exceedance were established by MoDOT for structures of different operational importance. Additional information regarding development of the resistance factors and application of the resistance factors for settlement calculations are provided in the commentary that accompanies these guidelines.

For this provision, the tolerable settlement shall be taken as

| (consistent units of lengths) | Equation 751.37.4.2 |

where:

- δtol = tolerable settlement (consistent units of length) and

- S = span between adjacent bridge bents (consistent units of length).

Factored settlements shall be determined as provided in this article. Settlement shall be evaluated for the Service I limit state.

Two alternative approaches are provided in these guidelines for determining the factored total settlement of drilled shafts. The first approach is based on an approximate factored load-settlement relationship for an individual shaft. The second approach utilizes the “t-z” method to predict the factored settlement for the shaft. Greater factored settlements will generally be predicted using the approximate method both because it tends to be conservative at working loads and because it involves greater variability and uncertainty. It is expected that the approximate method will generally be used for preliminary evaluation of settlement. If the settlement determined from the approximate method satisfies the serviceability requirement of Equation 751.37.4.1, the shaft dimensions can be considered acceptable. If use of the approximate method produces factored settlements that do not satisfy Equation 751.37.4.1, designers should consider performing evaluations using the more precise t-z method to evaluate whether serviceability is satisfied prior to increasing the dimensions of the shaft to satisfy serviceability requirements.

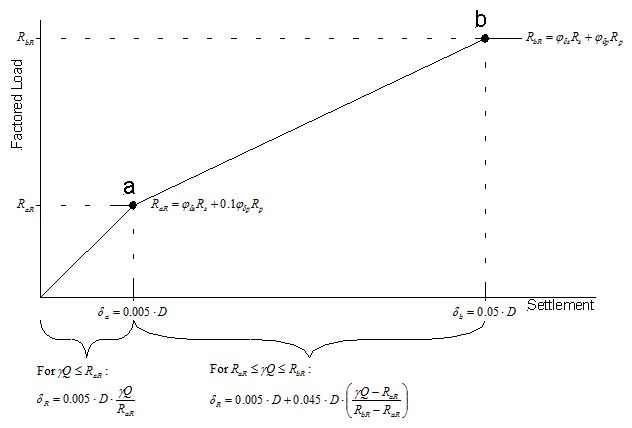

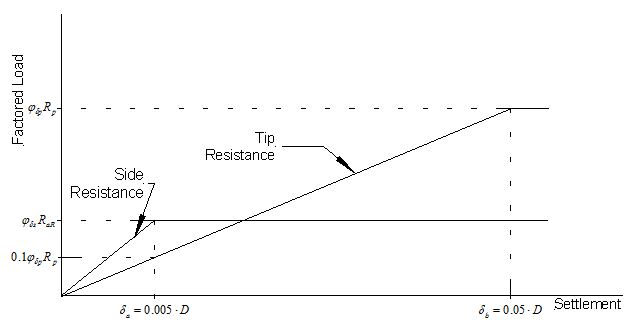

751.37.4.1 Settlement of Individual Drilled Shafts using Approximate Method

| Commentary on EPG 751.37.4.1 Settlement of Individual Drilled Shafts using Approximate Method |

Prediction of factored settlement due to factored service loads shall be determined as follows depending on the magnitude of factored loads relative to the magnitude of factored side and tip resistance:

If :

| (consistent units of lengths) | Equation 751.37.4.3 |

where:

- = factored load for the appropriate serviceability limit state (consistent units of force),

- RsR = total factored side resistance determined according to the provisions of this article (consistent units of force),

- RpR = factored tip resistance determined according to the provisions of this article (consistent units of force),

- δR = factored total settlement of shaft due to factored service loads (consistent units of length),

- D = shaft diameter (consistent units of length) and

- δeR = factored elastic compression of the unsupported length of the shaft (consistent units of length).

If :

| (consistent units of lengths) | Equation 751.37.4.4 |

where:

- = factored load for the appropriate serviceability limit state (consistent units of force),

- RsR = total factored side resistance determined according to the provisions of this article (consistent units of force),

- RpR = factored tip resistance determined according to the provisions of this article (consistent units of force),

- δR = factored total settlement of shaft due to factored service load (consistent units of length),

- D = shaft diameter (consistent units of length) and

- δeR = factored elastic compression of the unsupported length of the shaft (consistent units of length).

Note that if , the factored service load exceeds the maximum factored resistance of the shaft and the limit state cannot be satisfied without increasing the dimensions of the shaft.

The factored side resistance in Equations 751.37.4.3 and 751.37.4.4 shall be established from factored unit side resistance values for the relevant soil/rock conditions as provided in this article. For stratified ground conditions or where the shaft dimensions change (e.g. at tip of temporary or permanent casing, or at top of rock socket), the shaft shall be divided into segments with practically uniform shaft geometry and soil/rock properties and unit side resistance values determined for each shaft segment. The total factored side resistance shall then be computed as the sum of the factored resistance values for each shaft segment:

| (consistent units of force) | Equation 751.37.4.5 |

where:

- n = number of shaft segments,

- = factored unit side resistance for shaft segment i (consistent units of stress),

- = perimeter interface area for shaft segment i (consistent units of area),

- = settlement resistance factor for side resistance along shaft segment i (dimensionless),

- qs-i = nominal unit side resistance along shaft segment i (consistent units of stress),

- Di = shaft diameter for shaft segment i (consistent units of length) and

- Li = length of shaft segment i (consistent units of length).

Values for qs-i shall be determined in accordance with the provisions of EPG 751.37.3, based on the material type present along the respective shaft segments. Values for shall be established as provided subsequently in this article. Side resistance shall generally be neglected or reduced, as recommended by the Geotechnical Section, over shaft segments with permanent casing and over any length of rock socket that is deemed unusable for consistency with evaluations performed for strength limit states.

The factored tip resistance in Equations 751.37.4.3 and 751.37.4.4 shall be established from factored unit tip resistance values for the relevant soil/rock conditions as provided in this article. The appropriate tip resistance shall be established for the soil/rock located between the tip of the shaft and a distance of 2D below the tip of the shaft. The factored tip resistance shall be computed as

| (consistent units of force) | Equation 751.37.4.6 |

where:

- = factored unit tip resistance (consistent units of stress),

- = cross-sectional area of the shaft at the tip (consistent units of area),

- = settlement resistance factor for tip resistance (dimensionless),

- qp = nominal unit tip resistance (consistent units of stress) and

- D = shaft diameter at the tip of the shaft (consistent units of length).

The value for qp shall be determined in accordance with the provisions of EPG 751.37.3, based on the material type present within a depth of 2D below the tip of the shaft. The value for shall be established as provided subsequently in this article. For consistency with evaluations for strength limit states, tip resistance shall be neglected, as recommended by the Geotechnical Section, when the shaft tip is located within karstic rock or other conditions where tip resistance cannot be reliably determined.

The factored elastic compression of the unsupported length of the shaft shall be determined as

| (consistent units of length) | Equation 751.37.4.7 |

where:

- δeR = factored elastic compression of the unsupported length of the shaft (consistent units of length),

- = factored load for the appropriate serviceability limit state (consistent units of force),

- L = overall shaft length (consistent units of length),

- Ls = length of the rock socket (consistent units of length),

- Ep = nominal modulus of elasticity for the shaft (consistent units of stress),

- Ap = nominal shaft area (consistent units of area) and

- = settlement resistance factor for elastic compression of the shaft.

Values for the settlement resistance factor for elastic compression of the shaft shall be taken from Table 751.37.4.1 according to the operational importance of the structure.

Table 751.37.4.1 Settlement resistance factors for elastic compression of drilled shafts

| Operational Importance | Settlement Resistance Factor, Φδe |

|---|---|

| Minor or Low Volume Route | 0.68 |

| Major Route | 0.64 |

| Major Bridge <$100 million | 0.61 |

| Major Bridge >$100 million | 0.60 |

Settlement Resistance Factors for Approximate Method for Drilled Shafts in Rock

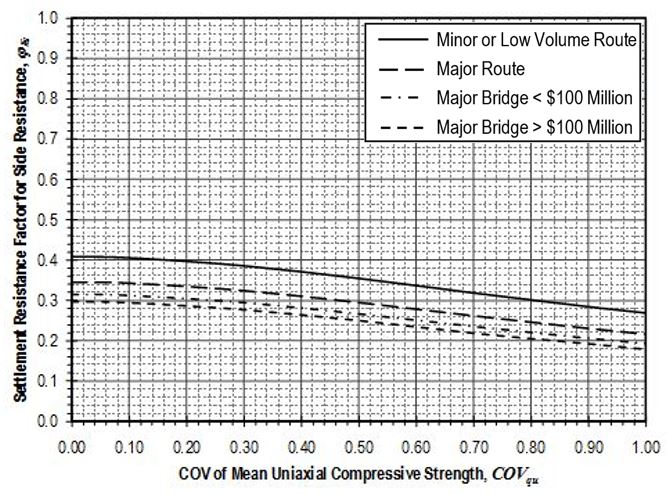

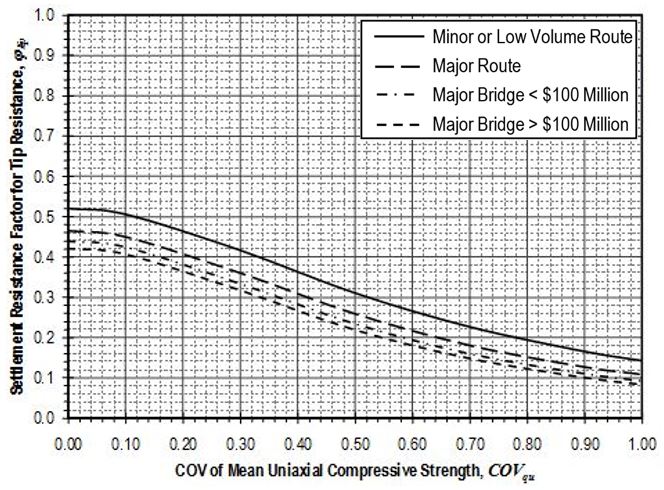

Settlement resistance factors to be applied to side resistance for shaft segments through rock shall be determined from Figure 751.37.4.1.1 based on the coefficient of variation of the mean uniaxial compressive strength, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on rock shall similarly be determined from Figure 751.37.4.1.2 based on values for that reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

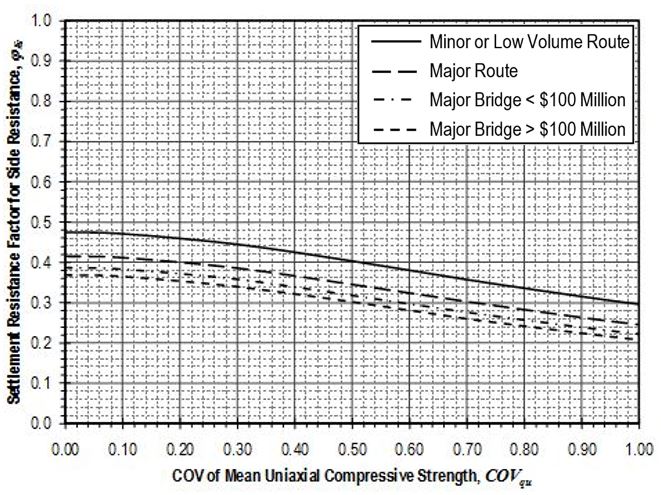

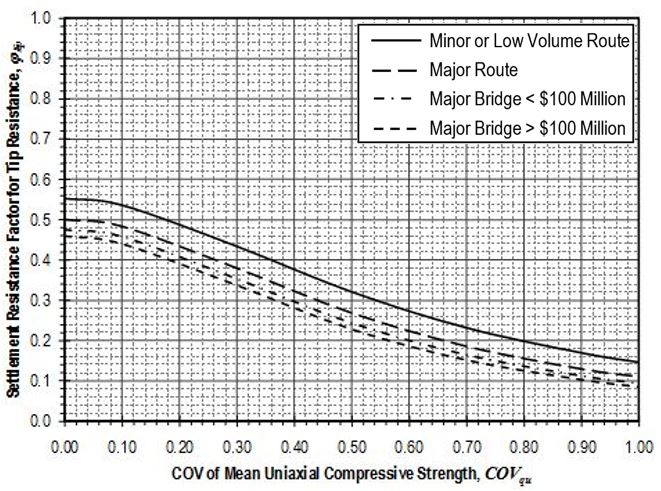

Settlement Resistance Factors for Approximate Method for Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core

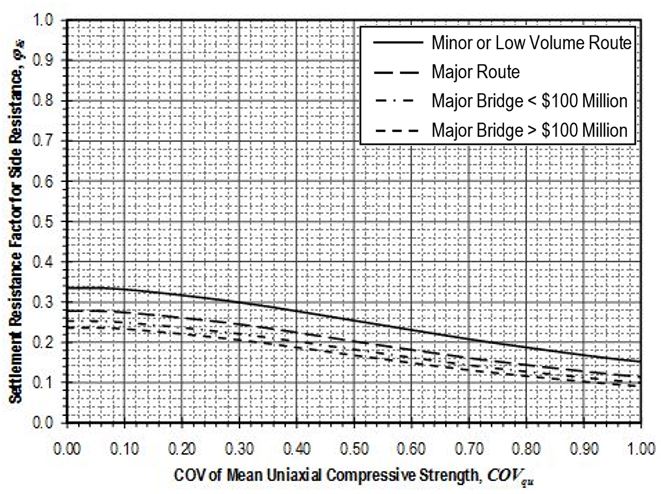

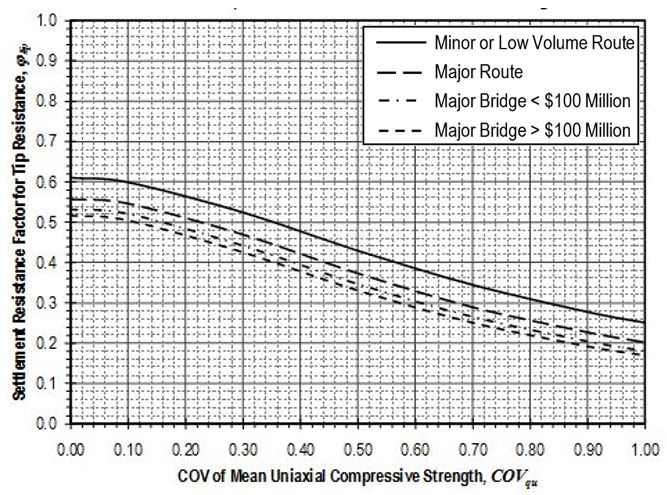

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.1.3 based on the coefficient of variation of the mean uniaxial compressive strength, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.1.4 based on values for that reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

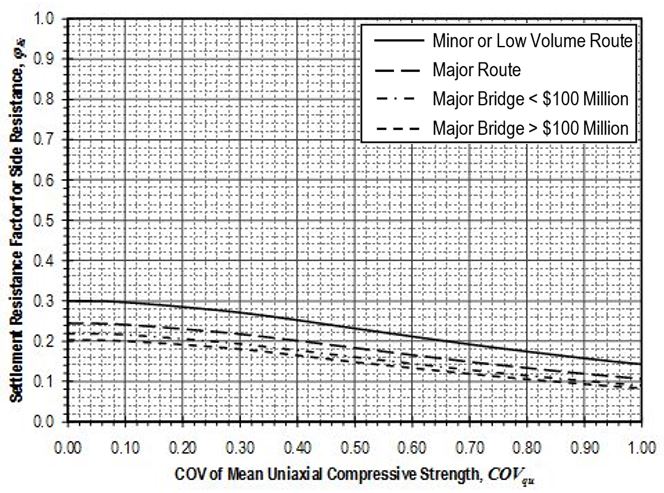

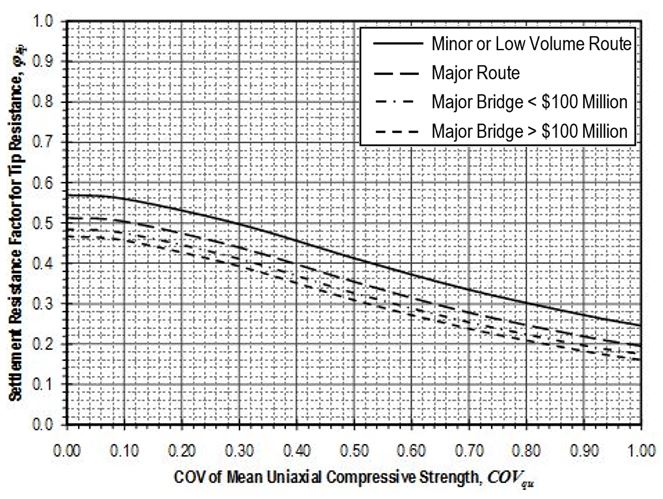

Settlement Resistance Factors for Approximate Method for Drilled Shafts in Weak Rock from Standard Penetration Test Measurements

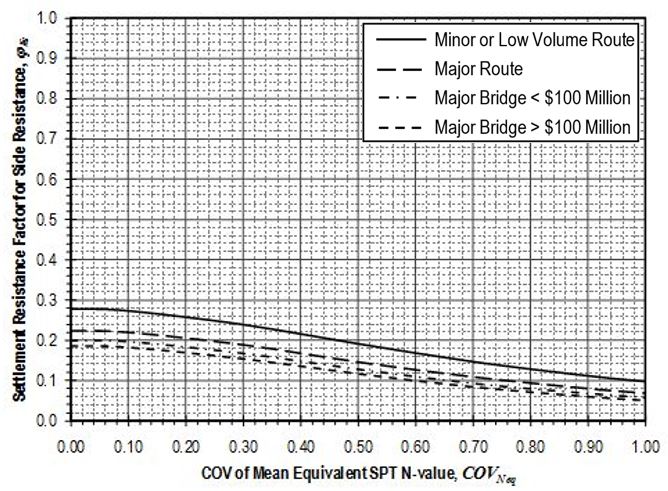

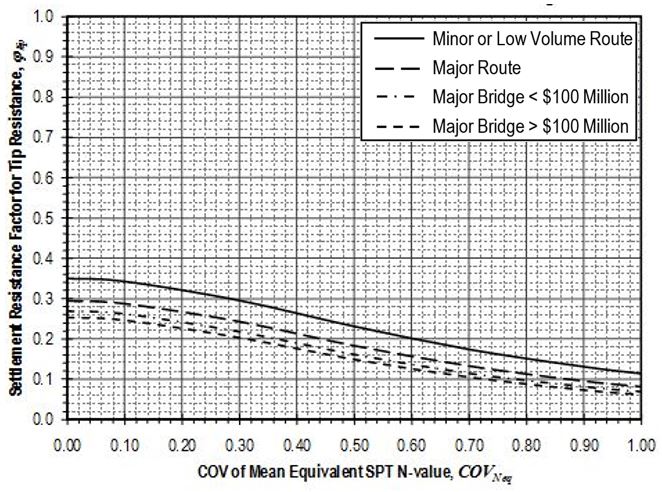

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.1.5 based on the coefficient of variation of the mean equivalent SPT N-value, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean equivalent N-value over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.1.6 based on values for that reflect the variability of the mean equivalent N-value over the distance 2Ds below the tip of the shaft.

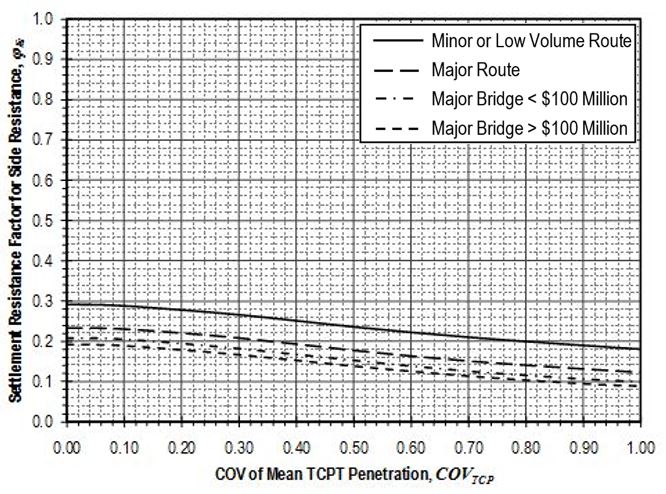

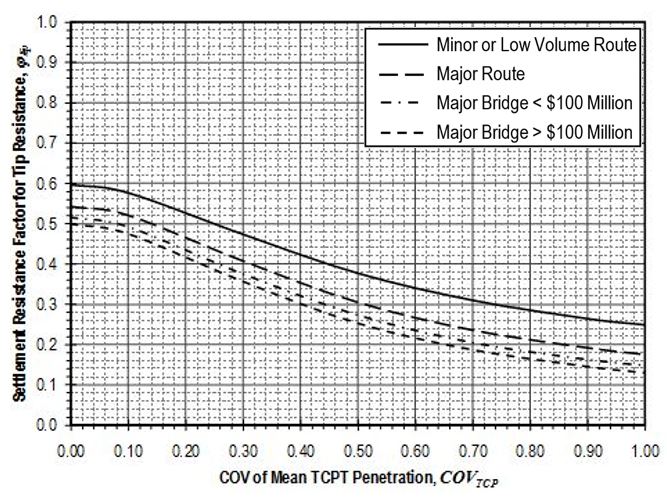

Settlement Resistance Factors for Approximate Method for Drilled Shafts in Weak Rock from Texas Cone Penetration Test Measurements

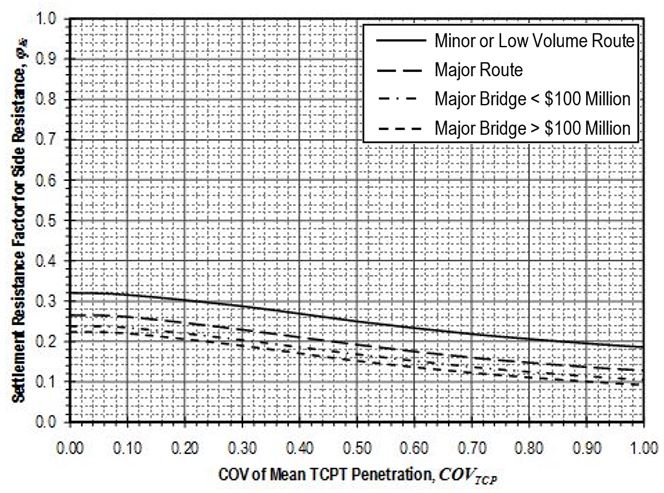

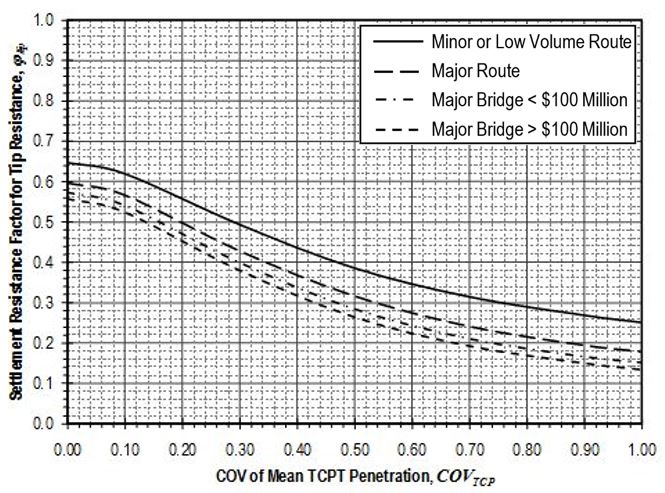

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.1.7 based on the coefficient of variation of the mean TCP-value, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean TCP-value over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.1.8 based on values for that reflect the variability of the mean TCP-value over the distance 2Ds below the tip of the shaft.

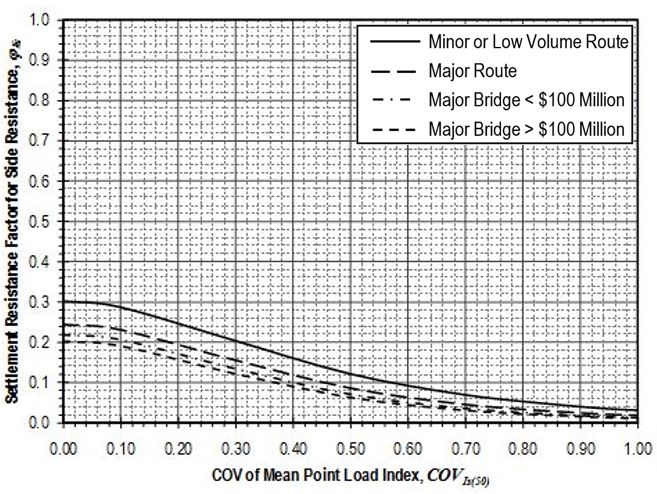

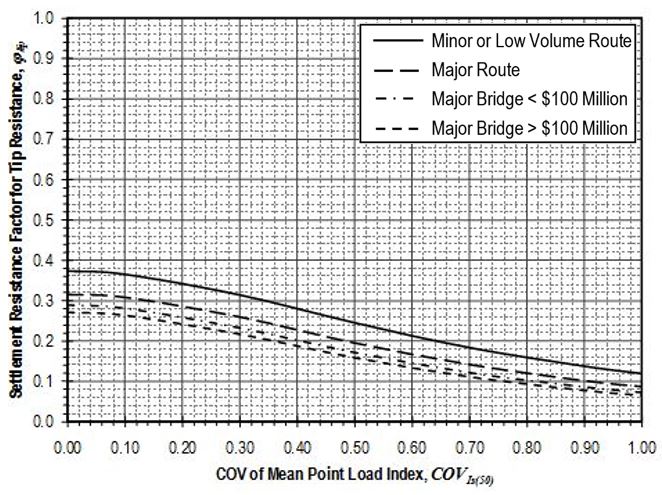

Settlement Resistance Factors for Approximate Method for Drilled Shafts in Weak Rock from Point Load Index Test Measurements

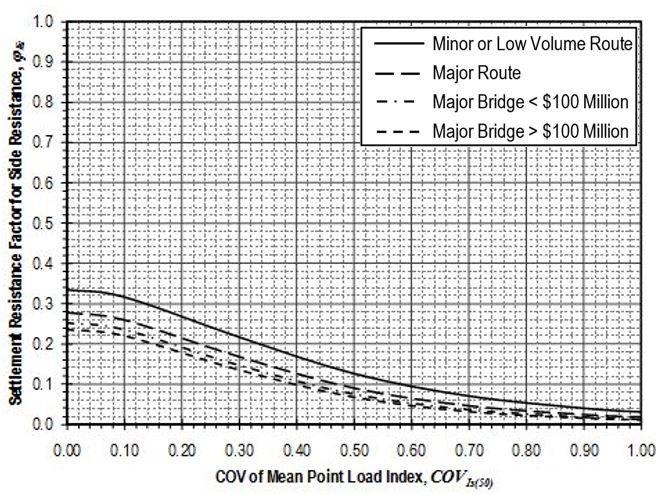

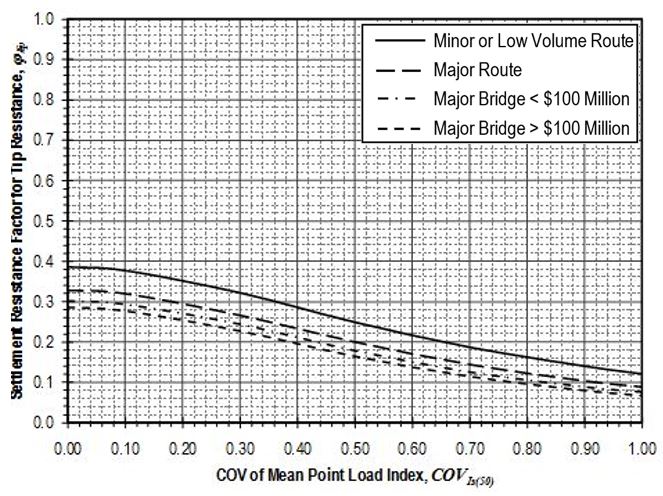

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.1.9 based on the coefficient of variation of the mean Is(50)-value, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean Is(50)-value for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.1.10 based on values for that reflect the variability of the mean Is(50)-value for the rock over the distance 2Ds below the tip of the shaft.

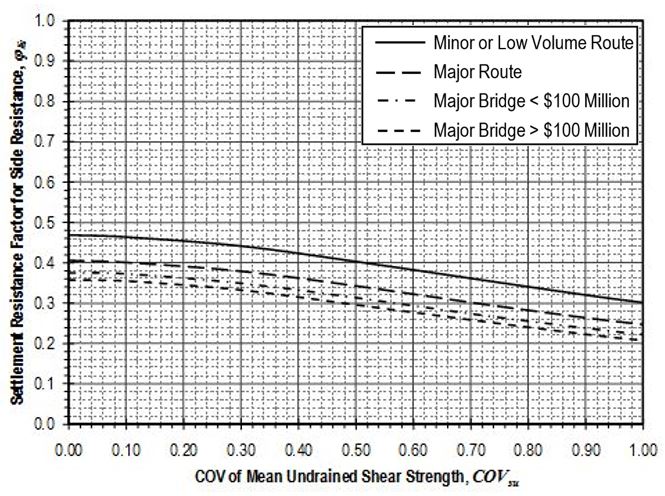

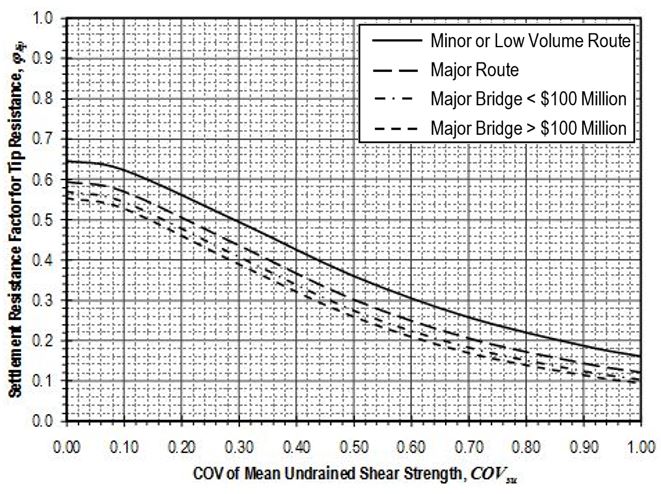

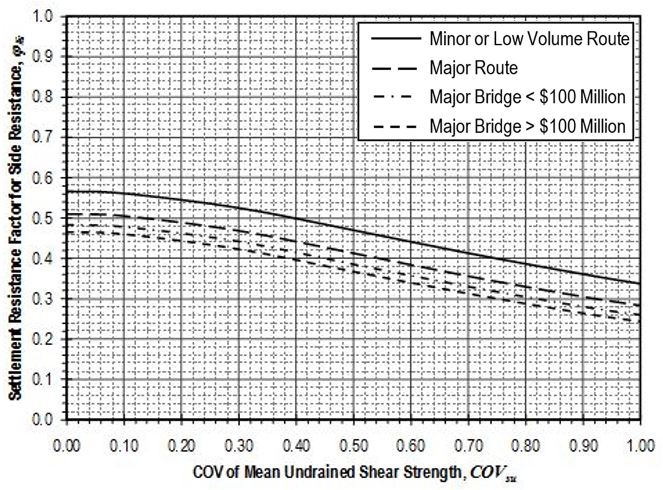

Settlement Resistance Factors for Approximate Method for Drilled Shafts in Cohesive Soils

Settlement resistance factors to be applied to side resistance for shaft segments through cohesive soil shall be determined from Figure 751.37.4.1.11 based on the coefficient of variation of the mean undrained shear strength, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean undrained shear strength for the soil over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on cohesive soil shall similarly be determined from Figure 751.37.4.1.12 based on values for that reflect the variability of the mean undrained shear strength for the soil over the distance 2D below the tip of the shaft.

For shafts founded in soft cohesive soils, consideration shall also be given to including additional settlement induced from time dependent consolidation of the soil.

Settlement Resistance Factors for Approximate Method for Drilled Shafts in Cohesionless Soils

Settlement evaluations for individual drilled shafts in cohesionless soils shall be designed according to applicable sections of the current AASHTO LRFD Bridge Design Specifications.

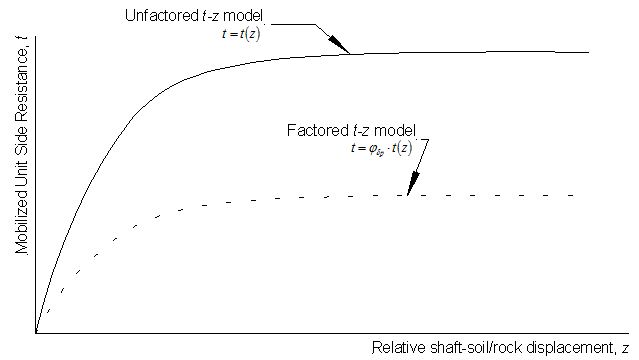

751.37.4.2 Settlement of Individual Drilled Shafts using t-z Method

| Commentary on EPG 751.37.4.2 Settlement of Individual Drilled Shafts using t-z Method |

The “t-z method” is a numerical method for predicting the axial load-displacement response of drilled shafts and other deep foundation members (Reese et al., 2006). The analyses can be performed using commercial specialty software, such as TZPile©, or using common spreadsheet software. Regardless of the method of implementation, the analyses require specification of t-z models that reflect the load transfer characteristics for side resistance, “q-w” models that reflect the load transfer characteristics for tip resistance, and shaft characteristics that reflect the stiffness of the shaft relative to the surrounding soil/rock.

Prediction of factored settlements using the t-z method according to these provisions shall be accomplished by performing t-z analysis using factored t-z and q-w models models as described in more detail in the commentary to this article. The top of shaft settlement predicted using the t-z method for a shaft subjected to the factored service loads and modeled using factored t-z and q-w models shall be taken as the factored total settlement, δR, for use in Equation 751.37.4.1.

Factored t-z models shall be established from a nominal, unfactored t-z model selected to represent the load transfer response in side resistance for relevant soil/rock conditions as

| (consistent units of stress) | Equation 751.37.4.8 |

where:

- tR(z) = factored t-z model for input into analyses using the t-z method (consistent units of stress),

- z = relative displacement between the shaft and the soil/rock along the length of the shaft (consistent units of length),

- = settlement resistance factor for side resistance (dimensionless) and

- t(z) = nominal t-z model selected to represent relevant soil/rock conditions (consistent units of stress).

Values for shall be established according to the soil/rock type and available site characterization data as provided subsequently in this article.

Factored q-w models shall similarly be established from a nominal, unfactored q-w model selected to represent the load transfer response in tip resistance for relevant soil/rock conditions as

| (consistent units of stress) | Equation 751.37.4.9 |

where:

- qR(w) = factored q-w model for input into analyses using the t-z method (consistent units of stress),

- w = relative displacement between the shaft and the soil/rock at the shaft tip (consistent units of length),

- = settlement resistance factor for tip resistance (dimensionless), and

- q(w) = nominal q-w model selected to represent relevant soil/rock conditions at the tip of the shaft (consistent units of stress).

Values for shall be established according to the soil/rock type and available site characterization data as provided subsequently in this article.

Settlement Resistance Factors for t-z Method for Drilled Shafts in Rock

Settlement resistance factors to be applied to side resistance for shaft segments through rock shall be determined from Figure 751.37.4.2.1 based on the coefficient of variation of the mean uniaxial compressive strength, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on rock shall similarly be determined from Figure 751.37.4.2.2 based on values for that reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

Settlement Resistance Factors for t-z Method for Drilled Shafts in Weak Rock from Uniaxial Compression Tests on Rock Core

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.2.3 based on the coefficient of variation of the mean uniaxial compressive strength, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.2.4 based on values for that reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

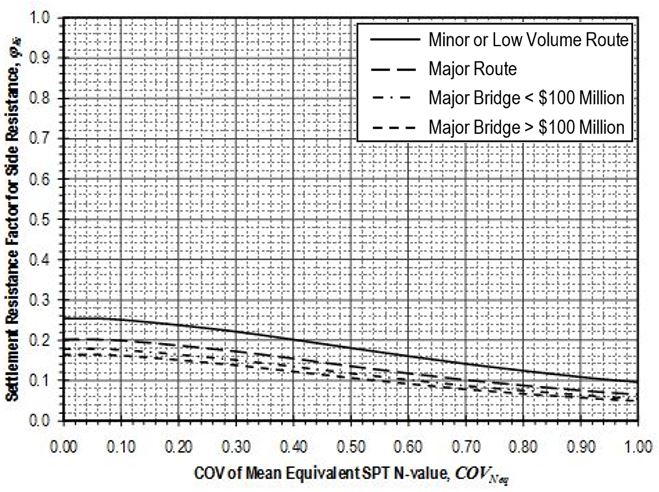

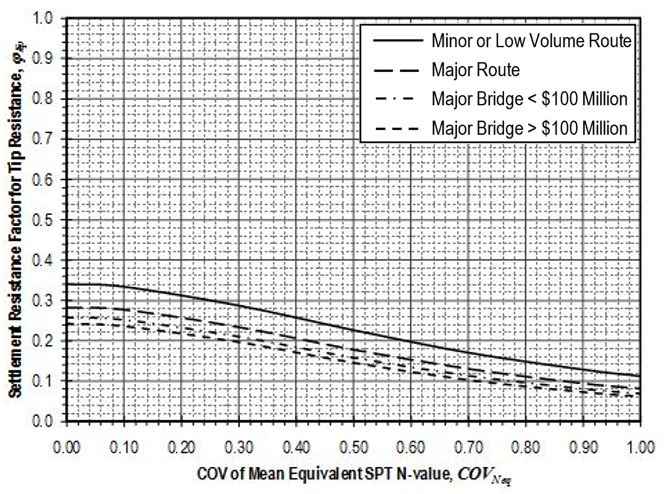

Settlement Resistance Factors for t-z Method for Drilled Shafts in Weak Rock from Standard Penetration Test Measurements

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.2.5 based on the coefficient of variation of the mean equivalent SPT N-value, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.2.6 based on values for that reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

Settlement Resistance Factors for t-z Method for Drilled Shafts in Weak Rock from Texas Cone Penetration Test Measurements

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.2.7 based on the coefficient of variation of the mean TCP-value, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.2.8 based on values for that reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

Settlement Resistance Factors for t-z Method for Drilled Shafts in Weak Rock from Point Load Index Test Measurements

Settlement resistance factors to be applied to side resistance for shaft segments through weak rock shall be determined from Figure 751.37.4.2.9 based on the coefficient of variation of the mean Is(50)-value, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean uniaxial compressive strength for the rock over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on weak rock shall similarly be determined from Figure 751.37.4.2.10 based on values for that reflect the variability of the mean uniaxial compressive strength for the rock over the distance 2Ds below the tip of the shaft.

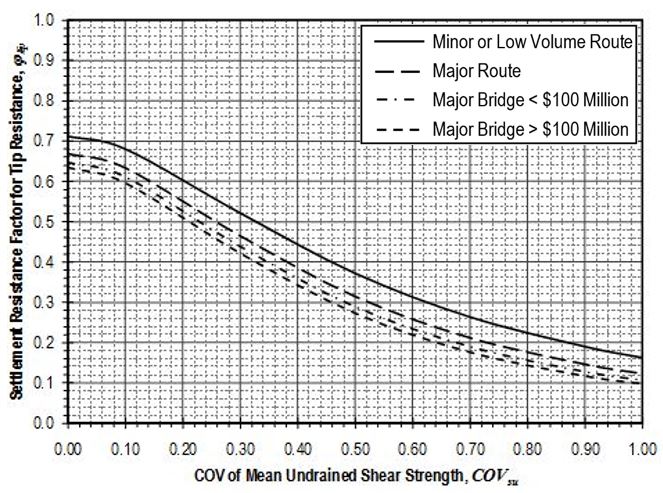

Settlement Resistance Factors for t-z Method for Drilled Shafts in Cohesive Soils

Settlement resistance factors to be applied to side resistance for shaft segments through cohesive soil shall be determined from Figure 751.37.4.2.11 based on the coefficient of variation of the mean undrained shear strength, . Values for shall be determined in accordance with EPG 321.3 Procedures for Estimation of Geotechnical Parameter Values and Coefficients of Variation to reflect the variability of the mean undrained shear strength for the soil over the shaft segment. Settlement resistance factors to be applied to tip resistance for shafts founded on cohesive soil shall similarly be determined from Figure 751.37.4.2.12 based on values for that reflect the variability of the mean undrained shear strength for the soil over the distance 2D below the tip of the shaft.

For shafts founded in soft cohesive soils, consideration shall also be given to including additional settlement induced from time dependent consolidation of the soil.

Settlement Resistance Factors for t-z Method for Drilled Shafts in Cohesionless Soils

Settlement evaluations for individual drilled shafts in cohesionless soils shall be designed according to applicable sections of the current AASHTO LRFD Bridge Design Specifications.

751.37.4.3 Settlement of Drilled Shafts in Groups

| Commentary on EPG 751.37.4.3 Settlement of Drilled Shafts in Groups |

Settlement of Shaft Groups in Cohesive Soils

Settlement of shaft groups in cohesive soils shall be estimated according to EPG 751.38.4.3 using the “equivalent footing” approach described in LRFD 10.7.2.3.

Settlement of Shaft Groups in Cohesionless Soils Using Standard Penetration Test Measurements

Settlement for drilled shaft groups in cohesionless soils can be estimated from SPT measurements as

| (inches) | Equation 751.37.4.10 |

where:

- ρ = settlement of shaft group (inches),

- q = net foundation pressure applied at depth of D'(ksf),

- B = width or smallest dimension of shaft group (feet),

- I = 1 - 0.125(D'/B) ≥ 0.5 = influence factor of the effective group embedment (dimensionless),

- (N1)60 = SPT blow count corrected for overburden stress and hammer efficiency (blows/foot),

- D = 2Db/3 = effective depth of “equivalent footing” and

- Db = depth of embedment of shafts in layer that provides support.

The value for (N1)60 is determined as

| (blows/foot) | Equation 751.37.4.11 |

where:

- CN = = correction factor to account for overburden stress (dimensionless),

- ER = hammer efficiency expressed as percentage of theoretical free fall energy for hammer system actually used (percent) and

- N = uncorrected SPT blow count (blows/foot).

Settlement of Shaft Groups in Cohesionless Soils Using Cone Penetration Test Measurements

Settlement for drilled shaft groups in cohesionless soils can be estimated from CPT measurements as

| (inches) | Equation 751.37.4.12 |

where:

- ρ = settlement of shaft group (inches),

- q = net foundation pressure applied at depth of D'(ksf),

- B = width or smallest dimension of shaft group (feet),

- I = 1 - 0.125(D'/B) ≥ 0.5 = influence factor of the effective group embedment (dimensionless),

- qc = static cone tip resistance (ksf),

- D = 2Db/3 = effective depth of “equivalent footing” and

- Db = depth of embedment of shafts in layer that provides support.