Category:1080 Structural Steel Fabrication

| MGS Information |

| Current General Services Specifications (MGS) By Subject |

Refer to Sec 1080 for MoDOT’s specifications.

1080.1 High Strength Bolts

| Videos Showing Strain Testing to Determine Yield Strength | |

| Truss Chord Member for bridge in Knox Co. | PT Bar for Mississippi River bridge in City of St. Louis |

All bolts, nuts, and washers should be from a PAL supplier in accordance with Pre-Acceptance Lists (PAL). If a supplier proposes to furnish structural steel connectors and is not on PAL, a request is to be made to the Construction and Material Division for acceptance into the PAL program. Once satisfactory submittals have been received, the supplier will be placed on the PAL. Bolts, nuts, and washers, for use other than bridge construction and in quantities less than 50, may be accepted from a PAL supplier without a PAL identification number.

Construction inspection requirements for bolts, nuts and washers are given in EPG 712.1.5 High Strength Bolts And Washers. Materials inspection requirements are given in EPG 712.2.4.1 High Strength Bolts and Lab testing requirements in EPG 712.3.2 Procedure.

1080.1.1 Samples Taken at PAL Manufacturer Facilities

Prior to visiting a PAL supplier or manufacturer facility, the Cognos report “PAL Shipments Within Date Range” should be run for the facility to determine what material has been given MoDOT PAL numbers. For each PAL material, the sample shall consist of six pieces rather than determined from lot quantities as given in EPG 1080.1.2 Sample Sizes. An individual sample shall consist of bolts, nuts, or washers as these are treated as different materials in the PAL system.

1080.1.2 Sample sizes

1080.1.2.1 ASTM A307 Bolts

Samples for Laboratory testing are only required when requested by the State Construction and Materials Engineer, or when field inspection indicates questionable compliance. When samples are taken, they are to be taken as shown in the following table. When galvanized bolts, nuts and washers are submitted to the Laboratory, a minimum of 3 samples of each are required for Laboratory testing.

| 3 for lots of 0 to 800 pcs. | Each sample is to consist of one bolt, nut and washer. Submit for dimensions, weight (mass) of coating, mechanical properties. |

| 6 for lots of 801 to 8,000 pcs. | |

| 9 for lots of 8,001 to 22,000 pcs. | |

| 15 for lots of 22,001+ pcs. |

1080.1.2.2 ASTM F3125 Grade A325 Bolts

Samples for Laboratory testing shall be taken and submitted as follows: All lots containing 501 or more high strength bolts shall be sampled and submitted to the Laboratory for testing. If no lot offered contains 501 or more bolts, sample 10 percent of the lots offered, or one lot, whichever is greater. A lot is defined as all bolts of the same size and length, with the same manufacturer's lot identification, offered for inspection at one time. Samples shall be taken as follows:

| Number of Bolts in the Lot | Number of Bolts Taken for a Sample* |

|---|---|

| 150 and less | 3 |

| 151 through 800 | 3 |

| 801 through 8,000 | 6 |

| 8,001 through 22,000 | 9 |

| 22,001 plus | 15 |

| * A minimum of 3 samples will be required for galvanized materials. | |

All lots containing 501 or more high strength nuts shall be sampled and submitted to the Laboratory for testing. If no lot offered contains 501 or more nuts, sample 10 percent of the lots offered or one lot, whichever is greater. A lot is defined as all nuts of the same grade, size, style, thread series and class, and surface finish, with the same manufacturer's lot identification, offered for inspection at one time. Samples shall be taken as follows:

| Number of Nuts in the Lot | Number of Nuts Taken for a Sample* |

|---|---|

| 800 and under | 1 |

| 801 through 8,000 | 2 |

| 8,001 through 22,000 | 3 |

| 22,000 and over | 5 |

| * A minimum of 3 samples will be required for galvanized materials. | |

All lots containing 501 or more high strength washers shall be sampled and submitted to the Laboratory for testing. If no lot offered contains 501 or more washers, sample 10 percent of the lots offered, or one lot, whichever is greater. A lot is defined as all washers of the same type, grade, size and surface finish, with the same manufacturer's lot identification, offered for inspection at one time. Samples shall be taken as follows:

| Number of Washers in the Lot | Number of Washers Taken for a Sample* |

|---|---|

| 800 and under | 1 |

| 801 through 8,000 | 2 |

| 8,001 through 22,000 | 3 |

| 22,000 and over | 5 |

| * A minimum of 3 samples will be required for galvanized materials. | |

1080.1.3 Bolts for Highway Lighting, Traffic Signals or Highway Signing

Bolts, nuts, and washers for highway lighting, traffic signals, or highway signing shall meet the requirements given in EPG 712.1.5 High Strength Bolts, except that mechanical galvanization of bolts, nuts and washers for highway lighting or traffic signals shall meet requirements of ASTM B695, Class 55. Field determination of weight (mass) of zinc coating, when specified, is to be determined by magnetic gauge in the same manner as described EPG 901.17 Material Inspection for Sec 901 except that a smaller number of single-spot tests will be sufficient. Samples for Central Laboratory testing are only required when requested by the State Construction and Materials Engineer or when field inspection indicates questionable compliance. When samples are taken, they are to be taken at the frequency and of the size shown in Table 1040.2.1.2 Sampling Requirements.

Bolts, nuts, and washers for traffic signals shall also be inspected for conformance with Section 902.4. Additionally, for traffic signals, anchor bolts and nuts or high strength bolts and nuts, except those meeting requirements of ASTM F3125 Grade A325, shall be accompanied by a test report certified to be representative of the mechanical tests for each size in each shipment.

1080.2 Fabrication Inspection Shipment Release (FISR)

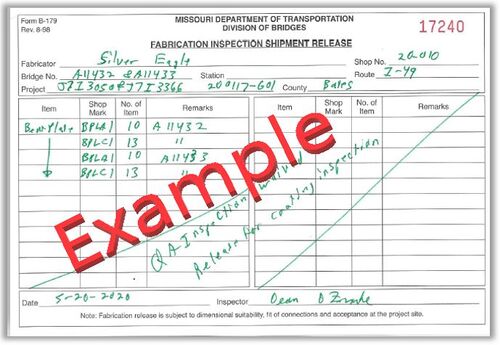

A FISR is issued by email to the fabricator and the Resident Engineer and the fabricator shall send the FISR to the contractor. A scanned copy of the FISR with the shop inspection documentations will be put in the project folder in eProjects with a naming convention similar to “7500_BridgeNo_Shop_Inspection_Materialname.pdf” with the Content Type being “BR Bridge Fabrication”. This documentation may or may not yet be in eProjects when the material arrives on the project site. The point of releasing steel fabricated items is that when construction inspector receives the FISR, the construction inspector will know that Bridge Division Fabrication Section has inspected/cleared the items listed on the FISR and the items were ready for shipment. This prevents the fabricator from sending something that has been rejected, not accepted by the fabrication inspector, or is in need of repairs. Bridge Division Fabrication Section will inspect anything as directed by the contract plans and documents. An example of an FISR is shown below.

1080.2.1 Items with Shop Drawings Reviewed and Inspected by Bridge Division Fabrication Section

Shop drawings will be submitted in accordance Sec 1080.3.2. Group email address Fabrication@modot.mo.gov is to be used for submitting shop drawings, Weld Procedures Specification (WPS), Request For Information (RFI), etc. This email address will direct the submittal to correct person for processing. Shop drawings will be reviewed, finalized drawings will be stamped and placed in eProjects and items will have FISRs issued. Should material arrive on the jobsite without FISRs being issued, the construction inspector will immediately inform the contractor that material will not be accepted until FISRs are issued.

Sec 607 pay items which are:

- Ornamental/Décor/Chain Link Fences and Handrails on bridges and retaining walls which are assigned Bridge No’s.

Sec 712 pay items which are:

- Finger Plate Expansion Device

- Flat Plate Expansion Device

- Bridge Mounted Sign Support Brackets

- Steel or Cast Bearings & Anchor Bolts

- Bridge Girders & Beam Fabricated Steel Parts

- Bridge Retrofit Steel Parts, Beams, Angles, Channels, WT’s, Restrainers, Plates, etc.

- Bridge Truss Fabricated Steel Parts

- Cable Stay Fabricated Steel Parts

- Clam Shells or Jackets for Pier Columns

- Steel grid floor

- Drain scuppers

- Steel Box Cross-Girder Beam Caps & Doors

- Fabrication Shop Applied Paint

- Bridge Rail (Two Tube Structural Steel)

Sec 713 pay items which are:

- Bridge Guardrail (W or Thrie Beam) (Do not inspect rail, but do inspect fabricated items requiring shop drawings)

Sec 716 pay items which are:

- Laminated Neoprene Bearing Pad Assembly & Anchor Bolts

- Type N PTFE Bearing & Anchor Bolts

- POT Bearing & Anchor Bolts

Sec 717 pay items which are:

- Expansion Joint Systems (Must have fabricated steel armor)

- Preformed Compression Expansion Joint System

- Strip Seal Expansion Joint System

- Modular Expansion Joint System

- Other Expansion Joint Systems

- Steel Parts for Neoprene Troughs at Expansion Joints

- Temporary Bridge Steel Parts

- High Mast Lighting Poles

- Inspection Walkways

- Sign Truss Walkways

- Dynamic Message Sign Trusses

- Overhead Sign Trusses - Aluminum (Std. Plan 903.10) & Anchor bolts

- Butterfly Sign Trusses - Steel (Std. Plan 903.12) & Anchor bolts

- Cantilever Sign Trusses - Steel (Std. Plan 903.12) & Anchor bolts

- Overhead Sign Trusses - Steel (Std. Plan 903.60) & Anchor bolts

1080.2.2 Items with Shop Drawings Reviewed But Not Inspected by Bridge Division Fabrication Section

Shop drawings will be reviewed, finalized drawings will be stamped and placed in eProjects and will not have release FISRs issued. Group email address Fabrication@modot.mo.gov is to be used for submitting shop drawings, Request For Information (RFI), etc.

- P/S Concrete Girders and Beams

- P/S Concrete Deck Panels

- Precast Concrete Culverts (non-standard designs, reviewed by Bridge Division Final Design Staff)

- SIP Deck Forms

- MSE Walls and Soil Nail Walls with Bridge No.’s

- Structural Plate Pipe and Pipe Arches (Sec 1023)

1080.2.3 Items Bridge Division Fabrication Section Does Not Review and Inspect

- Anything in Standard Plans book except Std. Plan 903.10, Std. Plan 903.12 and Std. Plan 903.60 which is listed above.

- Precast Drop Inlets

- Precast Concrete Culverts (standard designs per Sec 1049.4, ASTM C1577)

- Anything made of wood or rubber

- Ornamental/Décor/Chain Link Fences and Handrails (not on bridges and retaining walls not assigned Bridge No.’s)

- Piling

- Reinforcing Steel

- Steel Diaphragms for P/S Concrete Girders

- PVC drains

- Standard 8 x 4 slab drains

- Deadman Anchors Components

- Drilled Shaft Casing

- Cofferdams (unless otherwise stipulated by contract documents)

- Falsework (unless otherwise stipulated by contract documents)

- MSE Walls and Soil Nail Walls done by District (No Bridge # assigned)

- Sway bracing

- Bar Dams

- Grates & Frames for Drainage systems

- Field Applied Paint

- Roadway Guardrail

- Sound Walls

- High Mast Lighting Fixtures

- Signal Poles

- Light Poles

- Sign Poles

- Highway Signs Posts Type S, C or B (Std. Plan 903.05, Std. Plan 903.06, Std. Plan 903.07, Std. Plan 903.08)

- Galvanizing (Inspected by Materials)

- Metal Culverts