Category:613 Pavement Repair

| Maintenance Planning Guideline |

| Maintenance Planning Guideline for Pavement Repair |

| Video |

| Concrete Repair |

613.1 Construction Inspection for Sec 613

613.1.1 Full Depth Pavement Repairs (Sec 613.10)

Full depth pavement repairs are made on concrete pavement at locations where joints have failed. The tendency over many years has been to make too many pavement repairs, particularly on projects with overlays in excess of 3 in. When a joint is cut out and patched there are then 2 new joints where previously there was only 1. In the long term this often creates more problems than it solves. Joints or cracks that have faulted but are stable are better left alone, particularly if the project is set up with a multi-lift overlay. The "Distress Identification Manual" prepared by the Strategic Highway Research Program (SHRP) is an excellent resource for the inspector in evaluating joints and cracks. There is a copy of that manual in every project office. Contact your Liaison Engineer in Construction and Materials for assistance. Full depth pavement repairs should be made according to the specifications and Standard Plan 613.00. The patch should be placed on sound subgrade, so recompact or remove and replace as appropriate. It is critical to the long-term durability of the pavement that load transfer across the joints be established. Take care installing dowels. Equipment that damages the existing pavement should not be allowed.

Method of Measurement

Saw Cuts

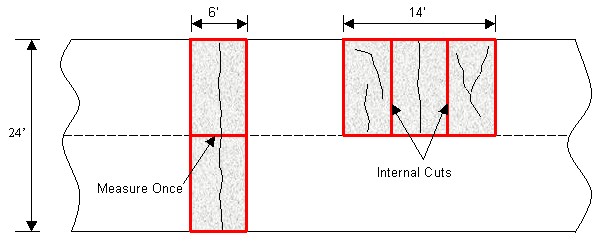

If there is a pavement repair across the roadway in two lanes or more, such as 6 ft. x 24 ft. on a dual lane highway, the saw cut along the longitudinal joint between the lanes should only be measured once for payment purposes. This specification allows for internal saw cuts in repair areas that are longer than 6 ft. This specification is based on the largest slab (6 ft. in length) that may be reasonably removed without doing damage to subgrade and/or the slab to remain in place. There may be special equipment available that can remove larger slabs. If internal saw cut are used, the following equation should be used to determine payment for the number of internal saw cuts:

Example: Pavement repair is 14 ft. long.

- Additional internal saw cuts would be at contractor expense.

Dowel Bars

Dowel bar quantities are provided in the contract plans and field measured on an individual basis, regardless of whether they are installed in a basket or drilled into the adjacent slab (Pay Item Nos. 6131017 and 6131015, respectively).

Basis of Payment

Payment for the perimeter saw cut along the shoulder joint for a pavement repair should be provided when the shoulder is concrete and the shoulder is tied to the pavement. If the shoulder is asphalt, or concrete but not tied, no saw cut is typically necessary; however, if the concrete pavement cannot be removed without damaging the shoulder, payment for a saw cut should be provided.

Repair depths for composite pavements, consisting of one or more asphalt overlays on the original PCC pavement, cannot always be accurately estimated on plan drawings, because of uncertainty regarding rehabilitation histories. Contract provisions do not guarantee maximum repair depth limits, and the contractor is expected to assume some risk when bidding on a project with full depth repairs, However, in the case of full depth repair(s) greatly exceeding their plan thickness, Resident Engineers can use the following guidelines for compensating contractors for the actual excess material:

- Measure the depths of at least three random full depth repairs. The set of measurements should be performed for each typical design depth shown in the plans. Calculate the average depth for each typical section. Additional measurements should be included in the average if the inspector notices obvious variations in depth.

- If the average measured repair depth is over 2 inches greater than the typical section depth in the plans, then calculate the average repair depth measured in the field.

- Calculate the anticipated excess volume of the repairs for each typical section in cubic yards by multiplying the depth greater than two inches over the plan depth by the total area as follows:

- where

- CEV = concrete volume in excess of two inches greater than plan depth (c.y.)

- DFIELD = average measured repair depth (inches)

- DPLAN = typical plan depth in plans (inches)

- ATOTAL = total full repair area (s.y.)

- where

- If a CEV can be calculated for a full depth repair project, the Resident Engineer may issue a change order with a lump sum contingent item for the actual cost to the contractor of the excess amount of concrete furnished. No additional payment will be provided for other full depth repair pay items.

Example: The contractor repairs a total of 400 s.y. of a composite pavement with full depth concrete. The plan depth in the typical sheet for the composite pavement is 14 inches. The average measured repair depth is 17.5 inches. The contractor can produce invoices verifying a unit price cost from the ready-mix supplier of $125 per cubic yard.

- $2083.75

- In the case of a project where the contractor has their own plant and is also the supplier, the Resident Engineer will request an actual unit material cost from the contractor and evaluate it for reasonableness against local supplier rates.

613.1.2 Class A Partial Depth Pavement Repairs (Sec 613.20)

Description

Class A partial depth pavement repair is used when the concrete pavement is structurally sound, but has spalling or localized surface delamination at joints, cracks, edges or interior areas; and either (1) the concrete pavement will not be resurfaced or (2) will be resurfaced with ≤ 3 inches of asphalt. If there is evidence of D-cracking near the spalled or delaminated area, then Class A repairs might not adequately address the problem and full depth concrete repairs should be considered instead.

Hot Pour Polymer-Modified Resin-Based Material Alternate

An exception exists where a hot pour, polymer-modified, resin-based material may be specified in lieu of standard Class A patch material that is for partial depth repairs in concrete that will not be diamond ground or cold milled for final surface texture nor diamond ground or cold milled prior to an asphalt overlay. Diamond grinding and cold milling tend to pull out and/or melt the hot pour material in addition to potentially gumming up grinding and milling heads in the equipment.

The material is mixed and heated on site as recommended by the product manufacturer. The advantage of this using this repair material is greater flexibility, such that inserts are not required to reform joints or cracks, and surface texture preparation becomes less critical. The disadvantages include greater difficulty in controlling surface finishing and the problem with grinding/milling stated above.

Current NJSP-19-01, "Partial Depth Concrete Pavement Repair Using Hot Applied Polymer Modified Repair Material" governs the materials and construction requirements for this material.

If a hot pour, polymer-modified, resin-based material is specified the contractor shall certify, by letter with the contract acceptance, that the material is in Materials Qualified List Field Section 613 Table 1.

Construction Requirements

The specifications and Standard Plan 613.00 describe the requirements for this item of work. Care should be taken when removing the concrete so that the dowels and remaining concrete are not damaged. If damage is caused by the contractor’s means and methods it should be repaired at no additional expense to the Commission. If the depth of repair is over half the thickness of the existing pavement, then full depth pavement repair should be used.

613.1.3 Class B Partial Depth Pavement Repairs (Sec 613.30)

Description

Class B partial depth pavement repair is similar to Class A but it is used on projects that include resurfacing in excess of 3 in. Instead of using concrete as the repair material, bituminous mix is used. The reason for allowing asphalt instead of concrete under thicker asphalt overlays is there is less likelihood that the partial depth repair will deform under heavy traffic.

613.1.4 Class C Partial Depth Pavement Repairs (Sec 613.35)

Class C partial depth repairs are the only type that should be specified for asphalt, either in full depth asphalt pavements or composite (AC over PCC) pavements (assuming in the latter situation the removal limits do not extend into the PCC pavement, in which case Class B partial depth repairs would be used).

Class C partial depth repair is generally intended for pavements that require several relatively small repairs, many of which may be less than full lane width, and not of significant length. If all of the needed repairs are full lane width, and of significant length (>100 ft.), it is more cost effective to use conventional pay items, i.e. cold milling and the appropriate tons of hot mix asphalt.

Class C partial depth repair is more commonly used on projects that do not include cold milling of the entire roadway (mill/fill), however, if the pavement failure extends deeper than the planned depth of cold milling, than Class C should be used to the depth necessary to stabilize the failure. In this case, consult with the pavement engineer on whether to specify completion of the Class C repair prior to the mill/fill, or after the mill but before the overlay.

Regardless of how the repairs are specified (Class C Partial Depth or conventional mill/fill), it is important that all repair areas be listed in the Summary of Quantities by location and size (length & width). Letting bidders know this information will result in prices that are much more in line with the actual work needed and will avoid unnecessary inflation of bid prices due to risk. For example, repairing two locations that are 100 SY each would be priced at a fraction of the cost of 25 small repairs of the same quantity but spaced throughout the project. Bidders need to know this so that they can include the real costs of traffic control set-ups, type of equipment needed, and manual labor. It is, however, acceptable and advisable to include an extra 10% in the summary of quantities that is unspecified in location to account for distressed areas that may occur after design but prior to actual construction.

613.1.5 Dowel Bar Retrofit (Sec 613.40)

Dowel bar retrofit is used to establish load transfer across a crack. The specifications are clear on the requirements for this item of work.

613.1.6 Cross-Stitching (Sec 613.50)

Cross-stitching is a repair technique for longitudinal cracks that are in reasonably good condition. The purpose of cross-stitching is to maintain aggregate interlock and provide added reinforcement and strength to the crack. The tie bars used in cross-stitching prevent the crack from vertical and horizontal movement or widening. The specifications are clear on the requirements for this item of work.

613.2 Maintenance Full Depth Pavement Repair

Full depth concrete patching is often necessary to repair failures in Portland Cement Concrete pavement. These may be caused by complete failure or disintegration of the concrete by cracking and breaking or by "blowups". This section covers the recommended methods and requirements for full depth patching. Concrete replacement should be programmed annually in all Districts and if possible, operations confined to periods prior to June 1 and after September 1 when traffic volumes are normally at their lowest and temperatures milder.

613.2.1 Determination of Areas to be Patched

The overall need for concrete replacement shall be determined and a speedometer log of the section needing repairs made. The estimated limits of each patch should be determined and these limits marked plainly with yellow or orange paint. The log should show the location of each patch, whether it is in the right or left hand lane, the dimensions of the patch and the estimated amount of concrete required for it. Estimated quantities computed form the log are used to requisition the necessary materials and supplies. A copy of this log is to be furnished to the Special Maintenance Supervisor who will note the actual size and cubic yards used. The Supervisor will also record on the log any additional areas patched during the operation. The optimum size of the area to be patched will vary with the extent of failure or disintegration and the location of cracks and joints. All patches should be squared up as much as possible without sacrificing economy. Joints and cracks adjacent to the area to be patched should be considered as these will usually cause cracking in the new patch. All patches should extend from the edge of pavement to the centerline or longitudinal joint. To reduce the amount on sound material removed a maximum taper of 12:1 may be used. Patches on Interstate Routes and other routes where more than 15% of the traffic is commercial should measure not less than 6 ft. wide measured at the edge of pavement. That measurement for other routes is 5 ft. minimum. In areas of settlement or buckling, the size of the patch may have to be determined by rideability desired, and good concrete removed to obtain a smooth riding surface. In all cases, economy and service of the patch should be considered. This is especially important for areas which have disintegrated for if all the disintegrated material is not removed, the area will have to be repatched within a short time. If the pavement is scheduled for resurfacing within the near future, it may be economical to hold the size of the area to be patched to a minimum.

613.2.2 Concrete Replacement Materials

The standard material for full depth replacement of concrete surfaces is Portland Cement Concrete accelerated with a 2% solution of Calcium Chloride and without air entrainment. A seven (7) bag mix using Type 1 cement is recommended but may be varied according to the table below depending upon ambient temperatures. It is intended that all holes be filled with all lanes open to traffic by 30 minutes before sunset. The concrete patch is to have obtained a strength of 1000 psi before barricades are removed.

| °F | 3 hrs. | 3.5 hrs. | 4 hrs. | 4.5 hrs. | 5 hrs. | 5.5 hrs. | 6 hrs. | |

|---|---|---|---|---|---|---|---|---|

| 40 | 212 | 283 | 340 | 387 | 428 | 449 | 464 | |

| 44 | 255 | 342 | 411 | 467 | 517 | 542 | 560 | |

| 48 | 314 | 420 | 505 | 573 | 635 | 666 | 688 | |

| 52 | 365 | 488 | 587 | 667 | 738 | 774 | 800 | |

| 56 | 416 | 556 | 669 | 760 | 841 | 882 | 912 | |

| 60 | 489 | 653 | 787 | 893 | 989 | 1037 | 1072 | |

| 64 | 548 | 732 | 881 | 1000 | 1107 | 1161 | 1200 | |

| 68 | 627 | 839 | 1010 | 1164 | 1269 | 1331 | 1376 | |

| 72 | 730 | 976 | 1174 | 1333 | 1476 | 1548 | 1600 | |

| 76 | 796 | 1063 | 1280 | 1453 | 1609 | 1687 | 1744 | |

| 80 | 876 | 1171 | 1408 | 1600 | 1771 | 1857 | 1920 | |

| 84 | 971 | 1298 | 1561 | 1773 | 1963 | 2059 | 2128 |

| Concrete yd3 | Sacks of Cement per yd3 of Concrete | |||

|---|---|---|---|---|

| 7 | 7 1/2 | 8 | 8 1/2 | |

| 1 | 3.5 | 3.7 | 4.0 | 4.2 |

| 1.5 | 5.2 | 5.6 | 5.9 | 6.3 |

| 2 | 6.9 | 7.4 | 7.9 | 8.4 |

| 2.5 | 8.6 | 9.2 | 9.9 | 10.5 |

| 3 | 10.4 | 11.1 | 11.8 | 12.6 |

| 3.5 | 12.1 | 13.0 | 13.8 | 14.7 |

| 4 | 13.8 | 14.8 | 15.8 | 16.8 |

| 4.5 | 15.6 | 16.6 | 17.8 | 18.9 |

| 5 | 17.3 | 18.5 | 19.8 | 21.0 |

| 5.5 | 19.0 | 20.4 | 21.7 | 23.1 |

| 6 | 20.8 | 22.2 | 23.7 | 25.2 |

| 6.5 | 22.5 | 24.0 | 25.7 | 27.3 |

| 7 | 24.2 | 25.9 | 27.6 | 29.4 |

| 7.5 | 26.0 | 27.8 | 29.6 | 31.5 |

| 8 | 27.7 | 29.6 | 31.6 | 33.6 |

- *Solution consists of 5 lbs. Of Type I or 4 lbs. Of Type II calcium chloride per gallon of mixing water. This will produce a dosage rate of 2 percent calcium chloride by weight of cement. Use half the amount shown if a 1 percent dosage is desired. Another convenient approximation from the table would be an addition rate of 2 quarts of solution per sack for a 2 percent dosage or 1 quart per sack for 1 percent.

The material is to meet the Missouri Standard Specifications for Highway Construction and be obtained from local suppliers on the basis of competitive bid prices. If a local supplier is not available it may be necessary to mix the material in portable mixers using our own forces. When plant mixed, a Department employee will be assigned to assure the specifications and mix design is met and the quantities shipped are correct.

613.2.3 Patching Crew Requirements

A required crew size of 8 or 12 members is dependent on the amount of concrete patching programmed. Good organization is required to decrease the time this more hazardous operation is in effect on any roadway section. Extensive patching operations shall be under the supervision of a Special Maintenance Supervisor who will assign and reassign workers to various crew components as needed.

The break out crew consists of a hydro-hammer or stinger operator or two breaking hammer operators, three to remove the broken concrete from the hole and load it into a loader and then into trucks and one or more drivers for haul trucks.

A subgrade preparation and forming crew may consist of two to four workers dependent on the condition of the subgrade. One form truck may be needed.

The finishing crew will place, vibrate and finish the concrete and should consist of two workers. One dump truck or one pickup is needed.

Staffing and equipping the crew is further outlined in the Maintenance Planning Guidelines and Traffic Control for Field Operations.

613.2.4 Replacement Procedures Using Concrete

The use of a concrete saw to outline the area to be removed is recommended. When a saw is not available and cracks or joints cannot be used then air chisels may be used to make the outline cut. Air chisels, a hydro hammer or a stinger is then used to break up the concrete to be removed. Moderate care should be exercised to assure a minimum of underbreaking of the pavement adjacent to the patch. The old pavement should be broken into pieces that can be handles and removed easily.

The broken concrete to be stockpiles will be placed in areas where such stockpiles will not detract from the appearance of the roadside, preferably on supplementary roads or in areas which are screened from view. If at all possible, the broken concrete should be dumped in washes or eroded areas at the time it is removed. Area Supervisors should make a special effort to do this and provide additional trucks and personnel as needed. If broken concrete is used for work such as erosion control, a realistic part of the cost of handling and placing should be charged to the appropriate Function Code.

The subgrade shall be properly shaped graded and tamped to conform to the type of pavement being patched. Underpinning will be provided by excavating the subgrade 3 to 6 in. below and 4 to 6 in. back under the slab. It will be tapered out to original subgrade elevation in 18 to 24 in. from the saw cut, providing the subgrade is solid. If the patch is less than 6 ft. longitudinally, tapering back is not required. All the spongy or poor subgrade material shall be removed to a solid base or to a maximum depth of six to eight in. below the bottom of the slab and replaced with concrete. Open graded base material should not be used. If the subgrade is dry it must be wet down before concrete is placed.

Patches 15 ft. or longer will be reinforced with wire mesh and no other steel reinforcing is to be used. When replacing only one lane of concrete, all steel crossing the longitudinal joint is to be cut. The length of any patch should not exceed the design joint spacing.

Two in. thick wood form boards or steel forms shall be used for forming and shall be staked or braced to hold the correct alignment. If the adjacent pavement in another lane is to be removed later, a form board will have to be placed at the centerline. This can be accomplished by removing just enough concrete in the adjacent lane to place the form.

The concrete is then placed in the hole, leveled up, vibrated and struck off with a straight edge. On upper deck sections the concrete is to be brought up only to the top of the original concrete, cured with liquid asphalt and then finished off with asphaltic concrete.

Care must be exercised in finishing in order to obtain a smooth riding surface. Longer patches should be checked with a taut string. The finished texture should conform to the surface of the adjacent pavement, but no smoother than that obtained by a belt or broom. Take an edger and break the bond between the old concrete and the new concrete at joints. The bond should be broken as deeply as possible without scoring or marking the surface while at the same time rounding the edge of the new concrete. Any marking deeper than 1/32 in. will tend to cause a rough riding patch. Date all patches with a 2 in. to 3 in. number to determine their service. Except for upper deck sections, curing should be accomplished by the application of a transparent curing compound.

If the forms do not present a hazard they may be removed the next day. When removed the void left should be filled with dirt, base rock or asphalt mix and compacted. The material used depends upon the type of shoulder involved. Any shoulder repair necessitated by this operation should be made at this time and the cost charged against the Concrete Replacement Function.

613.2.5 Replacement Procedures Using Asphaltic Concrete

The first two steps are the same as those used when patching with Portland Cement Concrete.

Subgrade shall be removed to obtain a minimum depth of 10 in. and when the pavement thickness is 8 in. or greater, the subgrade shall be cut at least 2 in. below the pavement. The patch shall be filled, thoroughly tamped and compacted in lifts of not greater than 3 in. using plant mixed bituminous base course mixture. If a base course mixture is not available a Type B asphaltic concrete mix may be used. The patch shall be allowed to cure before it is opened to traffic.

The rolling of a small amount of dry cement into the surface of the area being patched during final compaction will result in a gray surface, more nearly matching the color of the existing pavement.

613.2.6 Safety Precautions

In addition to standard safety policies and traffic controls the following rules must be observed for concrete replacement operations:

- The work must be conducted with as little inconvenience to traffic as possible. At least one lane must be available for traffic use at all times and free of obstructions. This includes ramps at interchanges.

- Work crews should be protected by working them between or behind equipment. Capable flagmen are to be provided as necessary.

- All patches should be barricaded in accordance with the guidance in Traffic Control for Field Operations.

- Shoulders adjacent to the patch should be kept clear and open to allow traffic to travel on the shoulder if necessary unless a hazard such as a spillway or culvert headwall exists. In this case, a barricade or hazard marker should be placed at the hazard.

- While it is intended that no patches or open holes are left overnight, should it be necessary to do so, the specific guidance in the Traffic Control for Field Operations. shall be followed.

- A responsible crew member must be designated to patrol the area when barricades are in place and workers are not present to assure the safety devices are working. If this is necessary at night then the worker must also check all the traffic control devices that are in place. During storms additional help should be provided and a Supervisor present.

- All lanes should be open to traffic by 5 p.m. Friday. For major holidays and extended weekends all lanes should be open to traffic by 12:00 noon of the day preceding the period or holiday.

613.2.7 Maintenance Planning Guidelines

See Maintenance Planning Guideline for Concrete Replacement - Full Depth (SY).

Index of all Maintenance Planning Guidelines.

613.3 Pavement Repair Design

Where repair work becomes too extensive to be handled by the district maintenance forces, such work may be included in the resurfacing contract. If this repair is to be done by contract, the district indicates on the plans the approximate locations and areas of pavement sections to be repaired in accordance with the requirements of the standard specifications. If 10 or more joints in a lane per mile of a project are proposed to be repaired or if the proposed pavement repair quantities in any lane exceeds 2% of the total lane area for that project, the district should request the Central Office Construction and Materials Pavement Team representative to review the project to verify that the proposed repair is warranted and to determine whether a more economical alternative exists.

Full depth pavement repair consists of removing the existing variable thickness portland cement concrete and replacing with jointed plain concrete pavement. The quantities for subgrade compaction and aggregate for base should be estimated at 10% of the total area of pavement repair. It should be noted that all full depth pavement repairs must be doweled or tied into adjoining pavement to be eligible for federal funds.