905.3 Transportation Impact Analysis

905.3.1 Introduction

A Transportation Impact Analysis (TIA) evaluates the potential adverse effects of proposed projects on surrounding and supporting transportation infrastructure and services. A TIA determines if the adverse effects constitute significant impacts, and, if so, how the significant impacts can be mitigated. The guidance in this article was developed to provide a technical approach to TIAs that is consistent, instills confidence in its findings, and sets MoDOT up for success in managing Missouri’s transportation system safely and reliably.

905.3.1.1 Background

Transportation Impact Analysis (TIA) is one of the critical activities for a project and can influence the project schedule, scope, and budget, as well as NEPA and AJR approvals. TIAs can impact the effort associated with all planning efforts including traffic data collection, forecasting, and analysis. Each transportation project is unique and the approach for individual projects should be modified to fit each unique project. As such, when developing the TIA, there must always be a balance between the project’s goals and objectives, available schedule and budget, and the complexity of the analysis to be performed, particularly analysis involving microsimulation or the Highway Safety Manual (HSM).

905.3.1.2 Purpose

MoDOT recognizes the critical role that TIAs have on their ability to program and implement projects that provide great value to their customers. The purpose of EPG 905.3 Transportation Impact Analysis is to ensure that TIAs developed for MoDOT are consistent with the traffic engineering and transportation planning standards of practice and include the latest research and industry best practices. EPG 905.3 Transportation Impact Analysis provides direction to project managers, project engineers and planners, consultants, and all TIA users on how TIAs should best be incorporated into a transportation project’s development.

| Technical References | |

| Accompaniment to Volume Development | |

| Accompaniment to HCS | |

| Accompaniment to Synchro/SimTraffic | |

| Accompaniment to VISSIM | |

905.3.2 Methodology and Scoping

During the development of a TIA, it is important to assess current and future safety and traffic operation conditions and the effectiveness of potential solutions using traffic and safety analysis methodologies and tools. There are several analysis methodologies and tools available for use that all vary in their scope, capabilities, methodology, input requirements, and output. The goals of EPG 905.3.2 Methodology and Scoping are to assist traffic engineers, planners, and project managers in the selection of the appropriate analysis tools and to enable effective communication of the analysis methodology and workplan through appropriate scoping documentation. The MoDOT TIA Methods and Assumptions Report is the deliverable by which MoDOT stakeholders can accomplish the goals of EPG 905.3.2 Methodology and Scoping. More information about this report template is in EPG 905.3.2.5 Scope the Project.

The steps for selecting appropriate traffic and safety analysis methodologies, tools, and scoping workplans include the following:

- 1. Understand available traffic and safety analysis tools

- 2. Identify the project’s analytical phase

- 3. Determine the project’s analytical context

- 4. Select appropriate Analysis Tool(s)

- 5. Scope the analysis methodology and workplan through the completion of the MoDOT TIA Methods and Assumptions Report template.

905.3.2.1 Overview of Traffic and Safety Analysis Tools

905.3.2.1.1 Traffic Analysis Tools

Traffic analysis tools are some of the most efficient methods to evaluate transportation improvement projects. EPG 905.3.2.1 addresses quantifiable traffic operations analysis tool categories, but does not include real-time or predictive models. Traffic analysis tools include software packages, methodologies, and procedures, and are defined as tools typically used for the following tasks:

- • Evaluating, simulating, or optimizing the operations of transportation facilities and systems.

- • Modeling existing operations and predicting probable outcomes for proposed design alternatives.

- • Evaluating various analytical contexts, including planning, design, and operations/construction projects.

Traffic analysis tools can be categorized into the general categories of sketch planning, travel demand models, analytical/deterministic models, and microscopic simulation models. Table 905.3.2.1.1 provides a description of these categories, in addition to pros and cons of each model type and examples of the analysis tool types. Note that travel demand models are used primarily in long-range planning completed before capacity analysis and are not covered in detail in EPG 905.3 Transportation Impact Analysis. However, the utilization of travel demand models in traffic forecasts is covered in EPG 905.3.4.6 Traffic Forecast Types and Tools and EPG 905.3.4.7 Forecast Application.

Table 905.3.2.1.1, Traffic Analysis Tool Categories

| Analysis Tool Category | Description | Pros | Cons | Examples of Tools |

|---|---|---|---|---|

| Sketch Planning | Produces general order-of-magnitude estimates of travel demand and traffic operations in response to transportation improvements. | • Simple & low cost • Data needs low (just highly aggregated data) |

• Limited in scope • Restricted presentation capabilities • Limited analytical robustness |

• HCS • CAPX1 |

| Travel Demand Models2 | Mathematical models that forecast future travel demand based on current conditions and future projections of household and employment characteristics. | • Good for use in forecasting regional population, employment, and traffic growth • Consideration of destination choice, mode choice, time-of-day travel choice, and route choice |

• Poor representation of operational characteristics of traffic • Large models have lengthy model run durations and large storage needs. |

• TransCAD • VISUM • Cube • Emme |

| Analytical/Deterministic | Uses static formulas to determine the relationships of flow, speed, and density of the traffic stream. | • Quickly predict capacity, density, speed, delay, and queuing • Good for analyzing isolated or small-scale transportation facilities |

• Limited in their abilities to analyze network or system effects on traffic flow • Does not model the variability in driver/vehicle characteristics. |

• HCS • Synchro • SIDRA |

| Microscopic Simulation Model | Simulates the movement of individual vehicles based on vehicle and driver behavior theories. | • Good for analyzing large-scale transportation facilities • Interactions with other vehicles and adjacent intersections help determine MOEs |

• Requires a great amount of time and effort to build and calibrate • Can require large computer processing time and storage requirements |

• SimTraffic • VISSIM |

| 1 More information about CAPX is available. 2 Travel Demand Models are used primarily in long-range planning completed before capacity analysis and are not covered in detail in EPG 905.3. EPG 905.3.4.6 Traffic Forecast Types and Tools includes travel demand models and other common forecasting traffic forecasting tools. Additional information on travel demand models is available. | ||||

The common analysis software tools are summarized below:

- • Highway Capacity Software (HCS): HCS is a deterministic software that is based off the equation-based methodologies of the Highway Capacity Manual (HCM). HCS can be used quickly and easily with simplistic parameters and inputs. Since HCS is strictly equation-based, it does not have the ability to analyze oversaturated conditions where queues dynamically interact between closely spaced network elements, such as ramps and intersections.

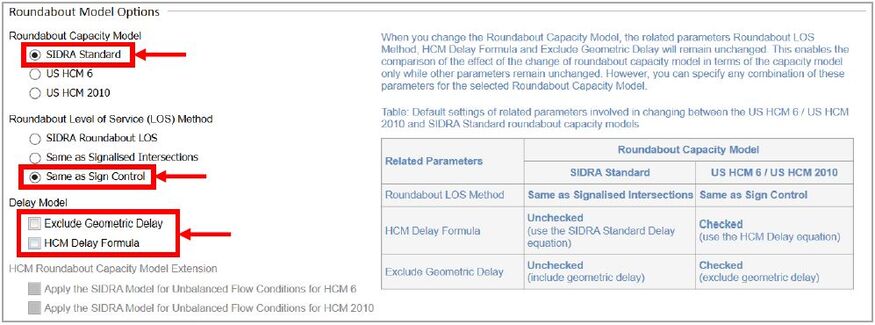

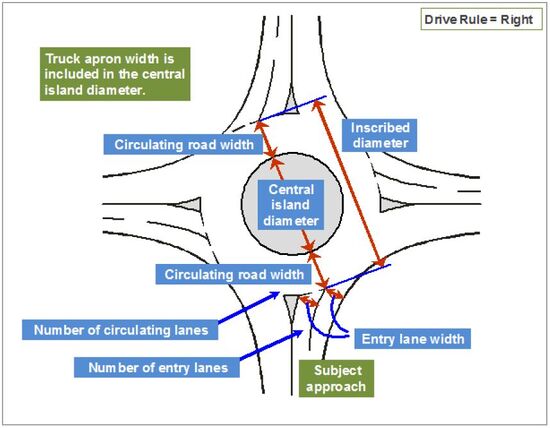

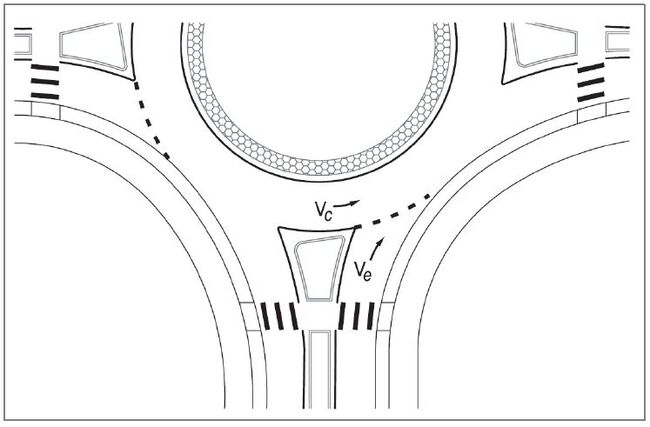

- • SIDRA Intersection Software: The Signalized and Unsignalized Intersection Design and Research Aid (SIDRA) software is a deterministic tool that can be used to analyze roundabout operations, signalized and unsignalized intersections, single-point urban interchanges, and signalized midblock crossings for pedestrians. In the United States, SIDRA is primarily used to analyze roundabout operations because of its ability to model the effects of gap-acceptance (including roundabout geometry) on roundabout Level of Service (LOS).

- • Synchro Software: Trafficware’s Synchro is a macroscopic analysis and optimization software application that supports HCM methodologies and the Intersection Capacity Utilization method for determining intersection capacity. Synchro is ideally used to analyze arterials and networks of multiple signalized and/or stop/yield-controlled intersections. The Synchro software application allows users to code roadway networks in a map-based interface (with aerial imagery overlays if desired) in addition to specifying key parameters in roadway link and intersection node tables. Then the user can specify the types of measures of effectiveness (MOEs) to quantify in auto generated summary reports. Note that Synchro is a companion model to SimTraffic (SimTraffic analysis for a project is first accessed in the Synchro interface).

- • SimTraffic Software: SimTraffic is a microsimulation tool that simulates the movement of individual vehicles based on vehicle and driver behavior theories. SimTraffic is a companion model to Synchro that simulates the coded transportation network (network is coded in Synchro) and measures the performance of each individual vehicle as they move through the system. Since each individual vehicle will react differently to the influences of other vehicles, pedestrians, bicyclists, roadway geometry, and grades, models with the same geometric and volume inputs will generate slightly different results, similar to how an intersection in the field will perform differently day-to day under otherwise identical conditions. Note that SimTraffic models generally have greater data requirements than Synchro models.

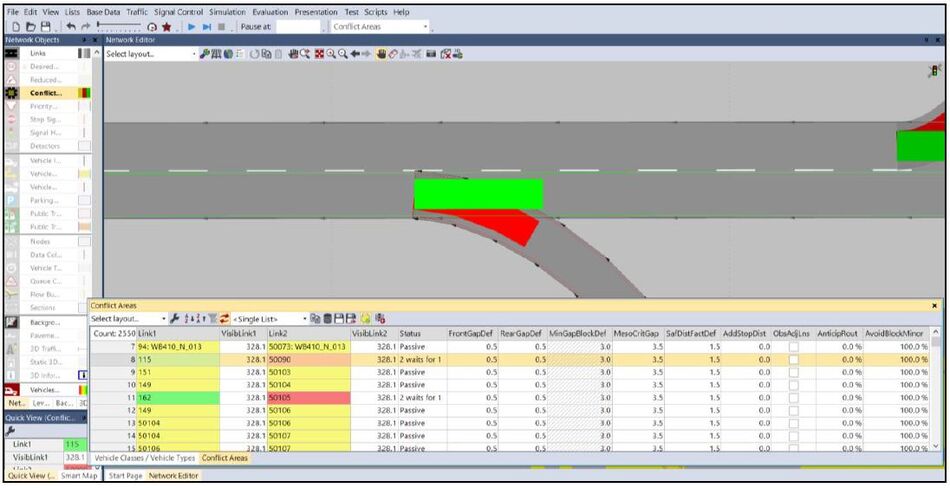

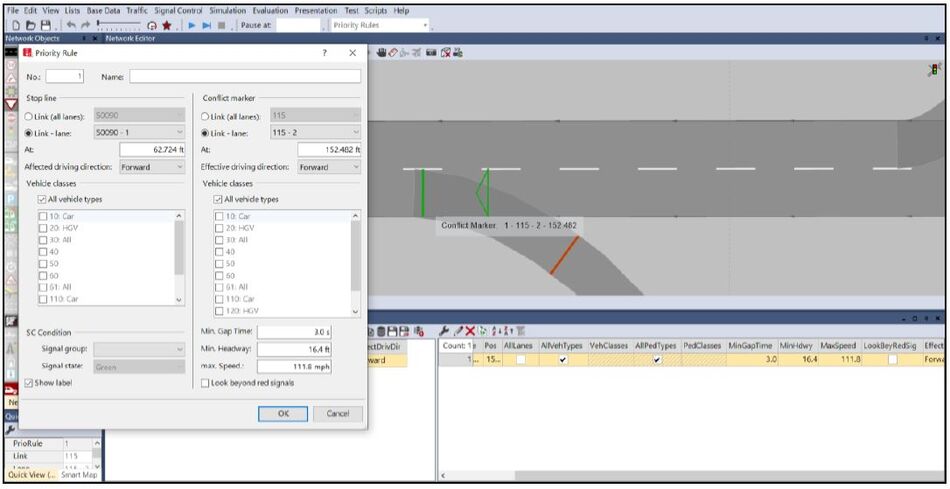

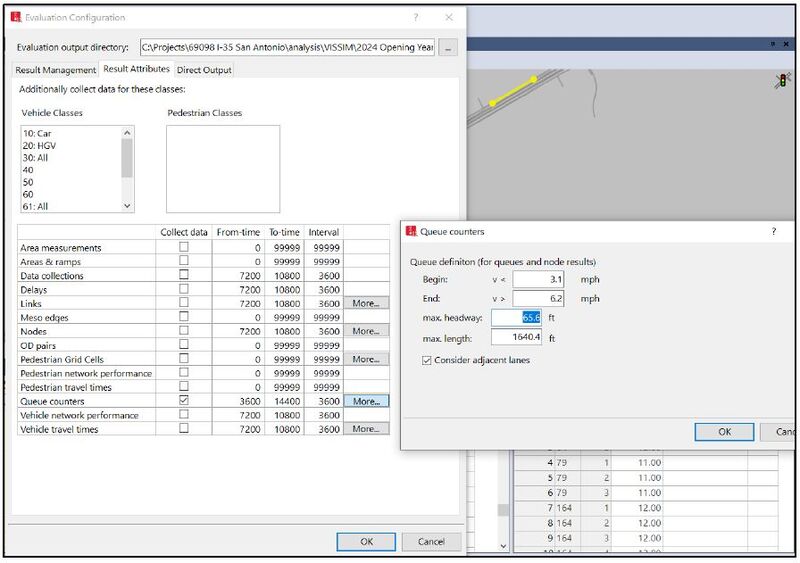

- • VISSIM Software: VISSIM (translated “Verkehr In Staedten SIMulation” in German) software is a microsimulation tool that is used to analyze multimodal traffic flows. VISSIM is capable of analyzing signal prioritization and optimization, dynamic traffic assignments, freeway operations, traffic management strategies, pedestrian flows, and the interaction of different transportation modes. Traffic flows are simulated by moving the driver-vehicle units and by using a car-following and lane-changing logic that allows drivers from multiple lanes to react to each other.

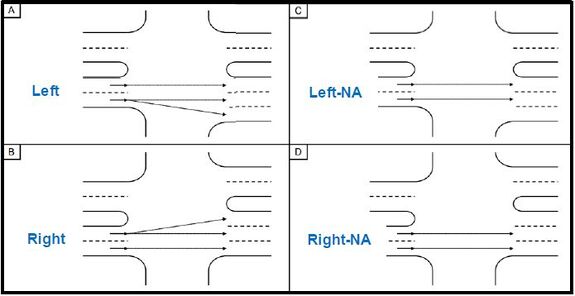

- VISSIM’s extensive analysis, microsimulation, and animation capabilities make it one of the most labor-intensive analysis tools available. The tool is especially effective at analyzing complex and unique geometrics and traffic patterns. It can be used to evaluate arterials and freeways, but it should not be used to analyze two-way-left-turn (TWLTL) lanes.

905.3.2.1.2 Safety Analysis Tools

Highway Safety Manual (HSM) provides comprehensive countermeasure selection guidance for the various crash pattern types for particular locations, including along roadway segments, at signalized and unsignalized intersections, and for bicyclist and pedestrian related issues. Within the HSM, crash modification factors (CMFs) are introduced as values used to determine the predicted reduction in crashes from implementing a chosen countermeasure(s). Quantitative safety evaluations can be performed using the following tools that utilize HSM methodology:

- • MoDOT Crash Prediction Tool: The MoDOT Crash Prediction Tool is internal to MoDOT staff and utilizes Transportation Management Systems (TMS) data to analyze rural two-lane highways. The tool is used for network screening and project safety analysis; it automates crash data and provides the Level of Service for Safety (LOSS) and predicted and expected crashes.

- • HSM Spreadsheets: The HSM spreadsheets provide high-level overviews of the predicted number of crashes within a study corridor.

- • ISATe: The ISATe is an analytical tool to examine safety performance and to predict crashes on freeways and interchanges. This tool is a version of the HSM spreadsheet and allows for the analysis of speed change lanes, as well as ramps and ramp terminals.

- • IHSDM: The IHSDM is a suite of software analysis tools that support HSM procedures and methodologies and are used to evaluate the safety and operational effects of geometric design decisions on highway projects.

Additional resources that can be used to supplement the tools above and assist in conducting safety analyses include, but are not limited to:

- • MoDOT Crash Statistics Map: The MoDOT Crash Statistics Map is internal to MoDOT, but can be accessed externally with permission. It allows users to get a visual representation of crashes and their locations across the state. It also allows users to pull historical crash data and filter that information based on various crash and roadway attributes, such as crash type or curve radius. Data can also be filtered by more specific criteria, such as crashes involving older drivers or pedestrians. Results can be exported to either Excel or PDF for use.

- • Crash Modification Factors (CMFs): CMFs are values used to determine the predicted reduction in crashes from implementing a chosen countermeasure(s). Refer to EPG 905.3.6.2.8 Crash Modification Factors (CMF) for more information.

- • Missouri’s Strategic Highway Safety Plan (SHSP): Missouri’s SHSP is the state’s plan (collaboratively developed with stakeholders throughout Missouri) to reduce fatal and serious injury crashes through an assessment of current and desired performance and a comprehensive collection of data-driven strategies. Additionally, there are regional Highway Safety Plans that are tailored to individual regions in Missouri and are used to inform the SHSP.

For more detailed information about available safety analysis tools and the appropriate applications of safety analyses, refer to EPG 905.3.6 Safety Analysis.

905.3.2.2 Identify the Project’s Analytical Phase and Appropriateness of TIA

After the user understands the general background of analysis and safety tools available, the first project-specific step is to identify the analytical phase of the TIA project. The analytical phase is the stage of planning/engineering and the level of analysis at which traffic capacity analysis and/or safety analysis will be completed. Listed below is an explanation of the general analytical phases:

- • Generalized Planning: High level analysis of transportation system elements to obtain general order-of-magnitude estimates of performance-based capacity constraints and operational control.

- • Conceptual Planning: Broad criteria and system performance-based analysis on geometric and physical capacity constraints and operational systems such as traffic control and land use.

- • Preliminary Engineering, Design, Operational: Detailed system performance-based analysis on individual user interactions, geometry, and operational elements.

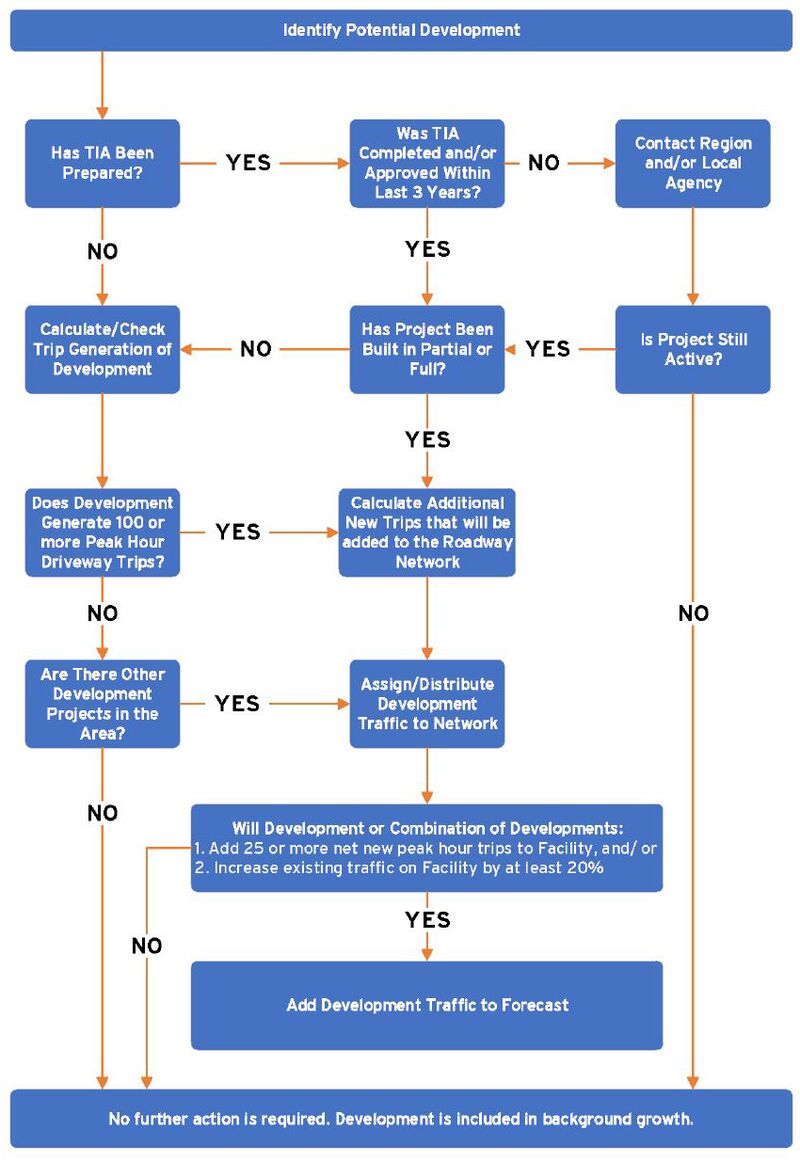

The determination of whether a TIA should be completed should be determined by factors such as if there is a new development that will generate 100 or more peak hour driveway trips or if the existing traffic on an adjacent facility will increase by at least 20%. For more details on potential triggers to determine when a TIA should be completed for a development, refer to Figure 905.3.4.8.1. Refer to EPG 941 Permits and Access Requests for additional information on permits and access requests.

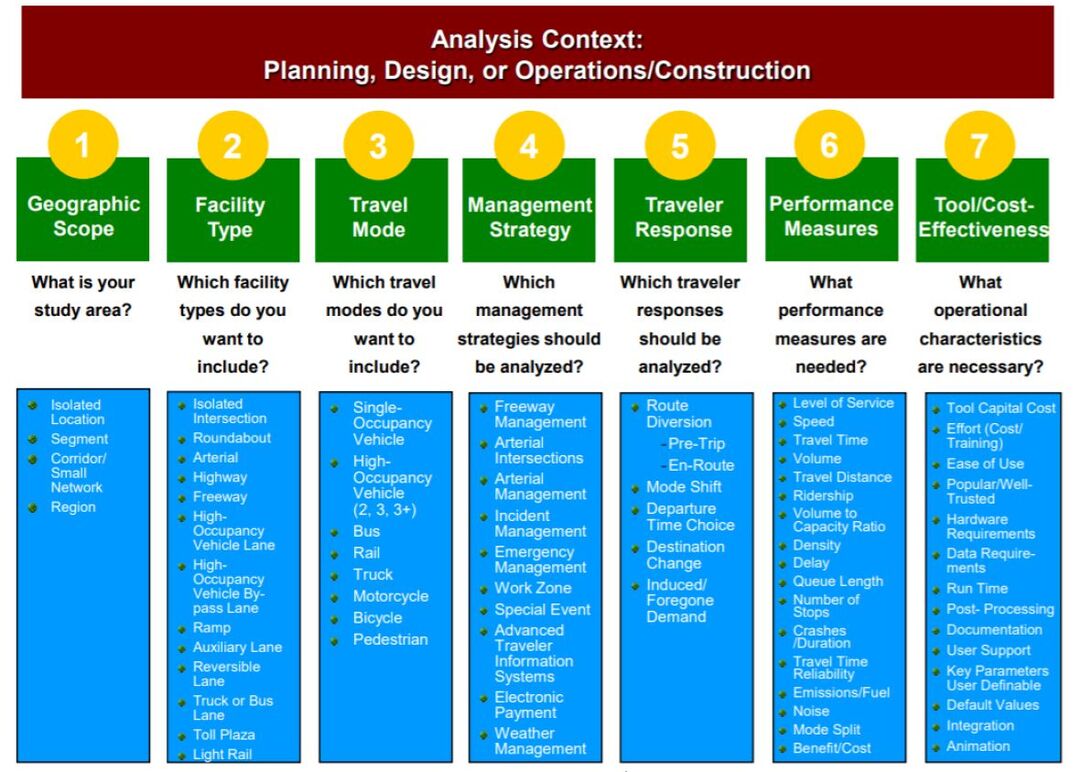

905.3.2.3 Determine the Project’s Analytical Context

Source: FHWA Report Number HOP-16-072, Scoping and Conducting Data-Driven 21st Century Transportation System Analyses, published January 2017

A project’s analytical context should be determined by assessing the following attributes of a project. These attributes are summarized in Fig. 905.3.2.3.1 and listed below:

- 1. Geographic Scope: The study area size of the project. General categories include an isolated intersection or interchange, a roadway segment, a corridor or small network, and an entire citywide or countywide region.

- 2. Facility Type: The transportation facility type(s) that will be analyzed during the project. Examples of facility types include arterials, highways, ramps, and isolated intersections, among other facility types.

- 3. Travel Mode: The travel mode is the means by which transportation facility users will be traveling on the facility. This includes data collection and accurate estimates to determine the proportional breakdown of all vehicle, transit, bicycle, and pedestrian usage.

- 4. Management Strategy: The transportation management strategies that should be analyzed.

- 5. Traveler Response: This attribute indicates how travelers can change their route of travel, change their travel time, use a different mode of transportation, change their destination, or cancel/create a new trip. These traveler responses would be measured due to responses to different operational improvements.

- 6. Performance Measures: The ability of the analysis tool to produce various performance measures in the areas of safety, efficiency, mobility, productivity, and the environment. Common performance measures/MOEs include but are not limited to the list below:

| • Level of Service (LOS) | • Queue Length | |

| • Speed | • Vehicle Miles Traveled (VMT) | |

| • Travel Time | • Vehicle Hours Traveled (VHT) | |

| • Volume Desired (Demand) | • Travel Time Reliability | |

| • Actual Volumes (throughput) | • Crash Reductions | |

| • Ridership | • Benefit/Cost | |

| • Volume-to-Capacity (v/c) | • Lives Saved | |

| • Density | • Serious Injuries Reduced | |

| • Delay |

- Two items that are important to understand for assessing performance measures include:

- Typical MOEs by Study Type: Contextualize how MOEs considered will be used for varying study types. Table 905.3.2.3.2 summarizes typical volume-based, time-based, and accessibility MOEs to be aware of based on study type.

Table 905.3.2.3.2, Typical MOEs by Study Type

| Study Type | Traffic Volume-Based MOEs | Typical Time-Based MOEs | Accessibility MOEs |

|---|---|---|---|

| Air quality conformity analysis | Area-wide Vehicle Miles of Travel | Speeds | |

| Asset management, including bridge and pavement needs | Link-specific volumes | ||

| Capital Improvement Program, prioritization | Benefit/cost,Level of Service | ||

| Congestion management process | Corridor volumes | Speeds | |

| Corridor mobility studies | Intersection Level of Service, intersection turning movements, traffic volumes | Segment travel times | Conflict point comparisons to weight access restrictions1 |

| Demand management plans | Number of peak-hour trips, Level of Service | Vehicle Hours of Delay | |

| Environmental impact statements | Vehicle Miles of Travel, emissions, traffic crashes | Vehicle Hours of Travel | |

| Evacuation plans | Hourly traffic volumes, throughput | Travel times | |

| Facility design and operations | Design hour traffic volumes | ||

| Highway feasibility studies | Benefit/cost, screenline volumes, Level of Service | Vehicle Hours of Travel | Access to labor market and jobs2 |

| Interchange justification requests | Traffic volumes,Level of Service | ||

| Roadway (general and freight) long-range planning | Vehicle Miles of Travel,Level of Service | Vehicle Hours of Travel | Access to labor market and jobs2 |

| Traffic impact studies | Intersection turning movements, Level of Service, delay per vehicle | ||

| Note: table is based on NCHRP 765 Table 2-1. 1 Applicable to both capacity and safety analyses 2 Access to the labor market and jobs (as studied at the long-range planning and feasibility study planning levels) can be studied through an assessment of delay and travel time and the constraining factors of capacity and congestion to accessing employment destinations. Regional travel demand models can be used to assess these MOEs for an entire region and to do a select link analysis that identifies a proportional breakdown of how facilities are being used to access key employers. Additionally, stakeholder surveys or travel-time contours can be used to review access to labor markets. Travel-time contours have been used to illustrate the effects of congestion on access to destinations (including the labor market and jobs). Travel-time contour maps are similar to topographical maps, with lines encircling a destination that radiate outward and do not touch. The spacing between the lines corresponds to the travel times needed to traverse them for a given distance (closely spaced lines would correspond to slower speeds than widely spaced lines). | |||

- Typical MOEs by Analysis Tool: Table 905.3.2.3.3 provides common MOEs reported for common analysis software tools. Note that the focus of Table 905.3.2.3.3 is on comparing and contrasting the traffic operations MOEs between multiple analysis tools. It is not an exhaustive list of MOEs and does not include safety MOEs. Most safety focused tools report similar MOEs. The key differences for the safety tools include the level of detail that the particular tool can drill down to.

Table 905.3.2.3.3, Typical MOEs analyzed by Analysis Tool

| Traffic Operations MOE | HCS | SIDRA | Synchro | SimTraffic | VISSIM1 |

|---|---|---|---|---|---|

| Average (Mean) Queue Length (feet) | ✔ | ✔ | |||

| 50th Percentile (Median) Queue Length (feet) | ✔ | ✔ | ✔ | ||

| 95th Percentile Queue Length (feet)2 | ✔ | ✔ | ✔ | ✔ | ✔ |

| Maximum Queue Length (feet) | ✔ | ✔ | |||

| Volume-to-Capacity (v/c) Ratio | ✔ | ✔ | ✔ | ||

| Density (passenger car/lane/mile) | ✔ | ||||

| Density (vehicles/lane/mile) | ✔ | ✔ | |||

| Control Delay (seconds/vehicle) | ✔ | ✔ | ✔ | ||

| Microsimulation Delay (seconds/vehicle) | ✔ | ✔ | |||

| Travel Time (seconds) | ✔ | ✔ | ✔ | ||

| Reliability (Percentile Travel Time Indices) | ✔ | ||||

| Percent of Time Spent Following | ✔ | ||||

| Space Mean Speed (mph) | ✔ | ✔ | ✔ | ✔ | ✔ |

| Time Mean Speed (mph) | ✔ | ||||

| 1 VISSIM can be used to specify any percentile queue results from 0% to 100%. 2 The 95th percentile queue parameter in both SimTraffic and VISSIM are computed values (not based on “observed”/simulated trips). Therefore, the maximum queue is recommended for both SimTraffic and VISSIM instead. Refer to Table 905.3.5.2.3.5 Queue Lengths in Synchro and Sim Traffic for more discussion. | |||||

- For general background information, definitions, and the typical usage of MOEs, refer to the FHWA Traffic Analysis Toolbox Volume VI: Definition, Interpretation, and Calculation of Traffic Analysis Tools MOEs.

- 7. Tool/Cost Effectiveness: Evaluate the management and operational considerations for selecting the most appropriate tool based on financial, personnel, or skill-related resource requirements.

905.3.2.4 Analysis Tool Selection

Table 905.3.2.4 displays a general list of traffic analysis and safety tools to select, which are determined by a project’s level of analysis and facility type. For a more detailed method to determine an appropriate traffic analysis tool, refer to MoDOT Analysis Tool Selection. Both the generalized and detailed tool analysis methods to select a tool are only guidance to help the user. Additional, project specific concerns, such as the analysis objective and project constraints should always be considered when selecting an analysis tool.

Table 905.3.2.4, Typical Traffic and Safety Analysis Tools by Level of Analysis

| Level of Analysis | Facility Type | ||||||

|---|---|---|---|---|---|---|---|

| Category | Description | Isolated Intersections/Interchanges | Interconnected Intersections/Interchanges | Roundabouts | Freeways | Urban/Suburban Arterials | Rural Two-Lane Highways and Multi-Lane Highways |

| Generalized Planning | • High level analysis • General order-of-magnitude estimates • Performance-based capacity constraints and operational control |

HCS CAPX HSM1 ISATe2 |

HCS HSM1 ISATe2 |

HCS CAPX SIDRA HSM |

HCS ISATe |

HCS Synchro HSM |

HCS HSM MoDOT Prediction Tool3 |

| Conceptual Planning | • Broad criteria and system performance based analysis • Geometric and physical capacity constraints • Operational systems such as traffic control and land use |

HCS Synchro SimTraffic HSM1 ISATe2 IHSDM |

Synchro SimTraffic VISSIM HSM1 ISATe2 IHSDM |

SIDRA VISSIM IHSDM |

HCS VISSIM ISATe IHSDM |

HCS Synchro SimTraffic VISSIM HSM IHSDM |

HCS HSM IHSDM MoDOT Prediction Tool3 |

| Preliminary Engineering; Design; Operational | • Detailed system performance-based analysis • Individual user interactions • Geometry • Operational elements |

HCS Synchro SimTraffic VISSIM HSM1 ISATe2 IHSDM |

Synchro SimTraffic VISSIM HSM1 ISATe2 IHSDM |

SIDRA VISSIM IHSDM |

HCS VISSIM ISATe IHSDM |

Synchro SimTraffic VISSIM HSM IHSDM |

HCS HSM IHSDM MoDOT Prediction Tool3 |

| Note: Red Text is for safety tools. Also, HSM is short for “HSM Spreadsheets.” 1 HSM Spreadsheets are appropriate for intersections and ramp terminal intersections, but not interchanges. 2 ISATe is appropriate for interchanges, but not intersections. 3 The MoDOT Prediction Tool is appropriate for rural two-lane highways only. | |||||||

905.3.2.4.1 Use of Complementary Traffic Analysis Tools

There are certain situations where it is beneficial to use multiple analysis tools to blend together the complementary capabilities and strengths of certain tools. A few common situations of blending tools together are provided below. Note that this list is not intended to be prescriptive nor comprehensive.

Synchro and SimTraffic

MoDOT recommends that SimTraffic runs be completed for transportation projects where traffic volumes are at or near capacity or where operations in one part of the study area are expected to have a noticeable impact on other study area locations. This will allow decisionmakers to form a more complete understanding of the traffic flow patterns for a particular project. To help inform this decision, Table 905.3.2.4.1 displays a comparison of key attributes that Synchro and SimTraffic have:

Table 905.3.2.4.1, Synchro and SimTraffic Comparison

| Attribute Descriptions | Synchro | SimTraffic |

|---|---|---|

| High-level planning study | ✔ | ✔ |

| Geometry and volume attributes are key inputs | ✔ | ✔ |

| Software can optimize signal timings | ✔ | |

| Interactions with other vehicles and adjacent intersections help determine MOEs | ✔ | |

| Realistic traffic simulations can be displayed | ✔ | |

| Does not require large computer processing time and storage requirements | ✔ | |

| A single error at one intersection will NOT impact all intersections | ✔ | |

| Better suited to anticipate delay when upstream bottlenecks exist | ✔ | |

| Better suited to show delay when queuing and blocking problems exist | ✔ |

Synchro and HCS

This could occur when a project encompasses an arterial, an interchange, and multiple freeway segments when microsimulation is NOT required. In this scenario:

- • Traffic conditions would be undersaturated. Otherwise, a microsimulation tool should be used.

- • HCS would be used to analyze freeway merging, diverging, and weaving segments

- • Synchro would be used to analyze the signalized intersections along the arterial as well as the operations on the arterial facility.

Synchro or HCS and VISSIM

This could occur when a project encompasses an arterial, an interchange, and multiple freeway segments when microsimulation is required. In this scenario:

- • Traffic conditions would be undersaturated, but microsimulation would still be needed.

- • HCS would be used to analyze the operations of the freeway.

- • Synchro would be used to analyze the signalized intersections of the arterial.

- • Synchro could be used to develop optimized traffic signal timings for VISSIM.

- • VISSIM would be used to analyze the intersections, arterials, interchanges, and freeway operations to simulate interactions in one model.

Synchro and SIDRA

This could occur when a project encompasses an arterial that includes a roundabout and one or more signalized or unsignalized (non-roundabout) intersections. In this scenario:

- • Microsimulation would NOT be needed.

- • Synchro would be used to analyze the signalized and unsignalized (non-roundabout) intersections of the arterial.

- • SIDRA would be used to analyze the operations of the roundabout.

SIDRA and VISSIM This could occur for the analysis of a roundabout with oversaturated traffic conditions or with impacts to adjacent intersections. In this scenario:

- • Microsimulation would be needed.

- • SIDRA would be used, initially, to analyze the operations of the roundabout.

- • VISSIM would be used to analyze the roundabout (and adjacent intersections). This could include microsimulation results and animation.

905.3.2.5 Scope the Project

It is important for the project manager, modeler, reviewer, and other involved personnel to develop an effective plan for conducting the necessary analysis. All parties also must agree on assumptions to be made to complete the analysis. The TIA Methods and Assumptions Report will ensure that expectations are set before any analysis is performed and it sets the stage for effective communication throughout the process. The intent is for this report to be updated as methodologies and assumptions change during the project. This report can then be referenced and appended to later project reports.

The intent of EPG 905.3.2.5 Scope the Project is to inform the TIA Methods and Assumptions Report template, which includes section numbers that correspond to the step numbers below.

- 1. Stakeholder Acceptance: Identify and coordinate with the appropriate stakeholders. The TIA Methods & Assumptions Report provides a section to enter key stakeholders that include “MoDOT Representative,” “FHWA Representative,” and “County/Municipal Representative.” Additional stakeholders can be documented as needed.

- 2. Understand Project Background Information. (“Introduction” section in TIA Methods & Assumptions Report): Identify the project’s need for study, previous studies completed, the study’s schedule, and key project stakeholders.

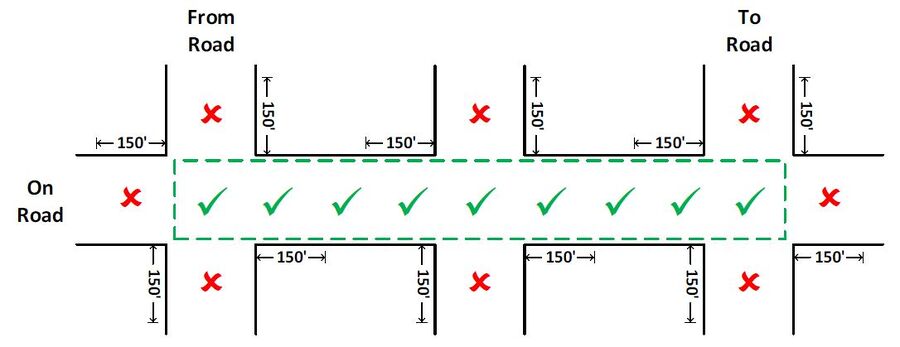

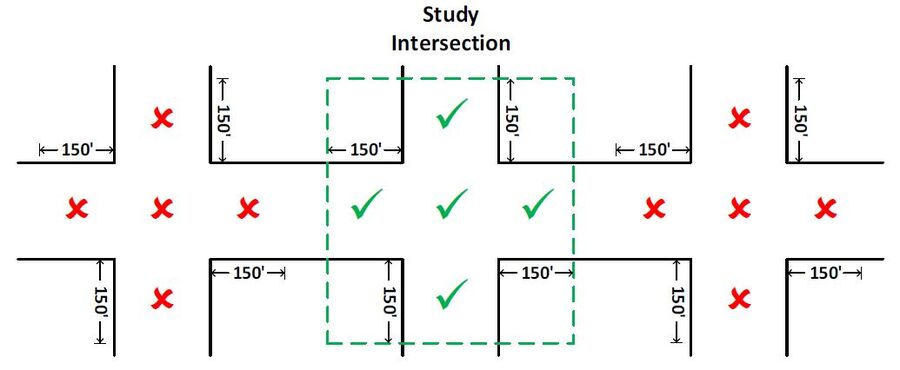

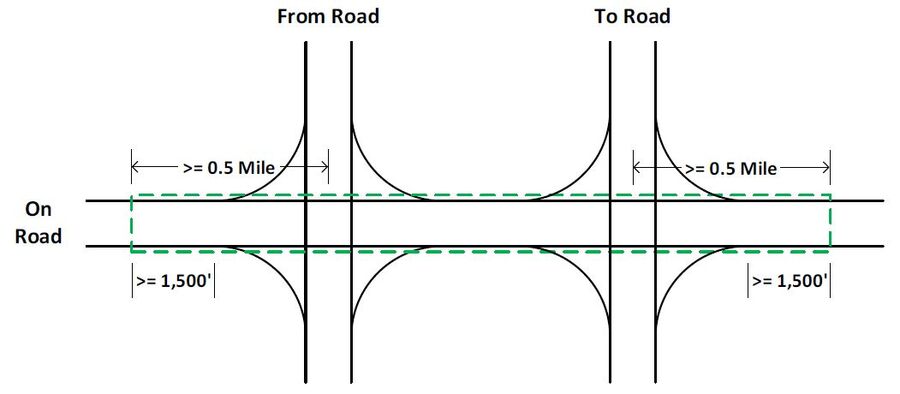

- 3. Definition of the Study Area: Determine the study area based on the logical geographic termini, the project purpose and need, and the expected limits of potential impacts. It is especially important to ensure that the analysis study area is extensive enough in its geographic reach to reasonably estimate transportation and land development impacts. This may differ for the traffic analysis and the safety analysis. The study area should be agreed upon by the project team, including FHWA when applicable, during project scoping. Below is guidance for typical study limits of different project types.

- Freeways – at least one interchange beyond construction limits, including that interchange’s on and off ramps closest to the construction at a minimum or an evaluation of the full adjacent interchanges if required and agreed upon by all stakeholders in the project scoping process

- Ramp terminals – one major intersection beyond construction limits and to the next interchange on freeway. In cases where next intersection is close (e.g., outer road), consider the functional area of the interchange.

- Arterials – one major intersection on either end of the project. Include minor streets at least up to next major upstream intersection or end of street, to the greatest extent possible. 1000 feet is desirable for queue evaluation, even if space may not be physically available.

- 4. Analysis Years/Periods: Information is provided below on time of day analysis and on typical analysis years. Sometimes this step is best completed iteratively with Step 6 (traffic forecasting) to determine appropriate horizon years based on forecasting assumptions and constraints (refer to Step 6). This may differ for the traffic analysis and the safety analysis.

- a. Time of Day Analysis: Typically, only AADT forecasts are needed for planning level studies. Project-level operational analysis will typically include AM and PM peak period forecasts. Safety studies may perform time of day analysis at specific locations, such as schools, which see disproportionate volumes during peak hours. Determine if a peak period of one hour is sufficient, or if a longer period is needed to capture the buildup and dissipation of congestion.

- b. Specify Analysis Years: The appropriate years to analyze for a project vary based on how the project will be used. A 20-year horizon after the opening year of the project, at minimum, is typically used to forecast future travel demand on the network. The planning horizon could be shorter for design projects.

- Table 905.3.2.5 provides basic information about typical analysis years studied. All of the analysis years listed should be included in the project analysis, unless otherwise justified and discussed with the appropriate MoDOT representatives. For all projects, it is important that the “Existing Base Year” be included due to its importance for model calibration to existing year traffic conditions.

Table 905.3.2.5, Analysis Years

| Year | Description |

|---|---|

| Existing Base Year | A base year that is typically as close as possible to the current year. |

| Assumed Interim/Opening Year | Expected future year that the project will open; in the case of phased projects this might be a sequence of intermediate analysis years. |

| Horizon/ Design Year | A future analysis year that is at least 20 years into the future after the opening year of the project. |

| Horizon Years for Safety Projects | Use the life cycle length of the longest countermeasure for the horizon year. Consider setting a maximum safety horizon year of 20 years after the opening year of the project and documenting special circumstances if setting a horizon year longer than 20 years out is necessary. |

- 5. Design Alternatives: Determine all appropriate design alternatives that the study will consider. This step will require collaboration with stakeholders. Sometimes this step is best completed iteratively with Step 6 (traffic forecasting) to determine appropriate alternatives based on future travel demand. The design alternatives may not be known during the initial scoping of the project but will be determined during the study.

- 6. Traffic Forecast: A traffic forecast should be completed to understand current and future travel demand on study area facilities. This involves determining the appropriate forecast scenarios and assessing the characteristics that are influencing travel demand.

- a. Determine Appropriate Forecast Scenarios:

- i. Determine if additional transportation projects (other than the subject project) should be included in the forecast. A common situation includes projects that are assumed to be completed in a forecast Future Year as the result of a Metropolitan Planning Organization’s (MPO’s) Metropolitan Transportation Plan (usually fiscally constrained or committed, but not illustrative projects).

- ii. Verify if multiple changes to land use characteristics and/or socioeconomic data (e.g., households, population, employment) should be forecasted.

- iii. Determine the different transportation project geometric alternatives that should be forecasted (e.g., multiple bypass scenarios that could potentially bypass a town going to either the east or west).

- b. Assess Travel Demand Characteristics: Complete an early assessment of the current and anticipated travel demand in the study area. Examples of items to document include:

- i. The nature of demand in the corridor in terms of trucks versus passenger cars, through versus local trips, or non-discretionary trips (such as commute to work) versus discretionary trips (such as shopping trips).

- ii. Unique major generators in the corridor.

- iii. What magnitude of growth in travel demand is anticipated?

- iv. The extent of need for the project based on today’s travel conditions versus anticipation of growth.

- a. Determine Appropriate Forecast Scenarios:

- 7. Traffic Operations Analysis: Determine and document the appropriate traffic operations analysis software program(s) and software version for use in the study. This decision should be made in coordination with stakeholders. Refer to EPG 905.3.2.1 Overview of Traffic and Safety Analysis Tools through EPG 905.3.2.4 Analysis Tool Selection for detailed information to help inform the decision-making process for selecting a tool.

- 8. Safety Analysis: Determine and document the appropriate safety analysis software program(s) and software version for use in the study. This decision should be made in coordination with stakeholders. Refer to EPG 905.3.2.1 Overview of Traffic and Safety Analysis Tools through EPG 905.3.2.4 Analysis Tool Selection and EPG 905.3.6 Safety Analysis for detailed information to help inform the decision-making process for selecting a tool.

- 9. Conclusion: Document a brief summary of the study’s intent and methodology.

- 10. Record of Revision: If applicable, document the revision number, date of revision, and content that has been revised.

905.3.3 Data Collection

905.3.3.1 Overview

Federal Highway Administration's (FHWA) Traffic Monitoring Guide (2016) describes federal guidelines for establishing and maintaining traffic monitoring programs and guidance for traffic monitoring methodologies. The guide especially focuses on maintaining a continuous data program, a short duration data program, calculations and computations to apply to raw data, and quality assurance processes.

In addition to federal guidelines, state-level departments of transportation (DOTs) usually have monitoring systems responsible for programming, collecting, analyzing and reporting traffic volume and vehicle classification data on Interstates and highways in their jurisdiction. MoDOT maintains an online interactive AADT map that is updated annually. This map breaks down traffic by both generalized vehicle classifications and directional, hourly volume breakdowns. Disclaimer: MoDOT’s interactive AADT map shows volumes at some locations that are associated with actual count data and some data that are estimated volumes (not based on count data). If the analyst has any data concerns, then please contact the MoDOT TMS unit.

For transportation projects, it is important to work with MoDOT to determine how to best analyze existing traffic count data provided by MoDOT or other local sources and if additional project-specific short duration counts will be needed to meet project needs. EPG 905.3.3 Data Collection will answer these guiding questions about traffic data collection:

- 1. Why Collect Count Data – Understand the needs of the project

- 2. When Gather Count Data – Determine if or when to collect data

- 3. What Count Data to Collect – Assess what type of data is needed.

905.3.3.2 Understand the Needs of the Project (The “Why”)

To determine what traffic count data is needed, it is important to think about the background of a transportation project’s goals. The NCHRP 765 states that “analysts should be cognizant of the context in which the information they produce will be used and come to an understanding about the MOEs to be published and presented at the outset of a study.”

Developing an understanding of the data collection needs for a project takes place during project scoping. The MOEs to be used during the study should help inform the data collection needs. See EPG 905.3.2.3 Determine the Project’s Analytical Context for guidance about the determination of MOEs.

General questions to consider when determining data needs are:

- • Do we need intersection turning movement count data?

- • Will only particular peak hour data be required, or will a 24-hour estimation of a typical weekday’s travel be needed?

- • What additional data will be necessary to address project-specific MOEs (such as queue lengths, vehicle speeds, travel time, etc.)?

905.3.3.3 Determine If or When to Best Collect Data (The “When”)

Is New Traffic Data Needed?

Age limits for the relevancy of traffic counts are context sensitive to the regional characteristics (urban, rural, or suburban) and recent growth patterns of an area (i.e., has there been recent developments that would influence traffic volumes?). MoDOT recommends that new traffic count data should be collected if the most recent, available data is more than three years old.

As noted in EPG 905.3.3.1 Overview, MoDOT maintains an online interactive AADT map that is updated annually and includes both generalized vehicle classifications and directional, hourly volume breakdowns. MoDOT’s official AADT data should be the first data source to refer to when determining data needs. However, always be cognizant if turning movement counts or other data breakdowns (e.g., 15-minute volume bins, vehicle speeds, etc.) will be needed in addition to existing AADT data. (EPG 905.3.3.4 Assess What Type of Data is Needed (The “What”) elaborates on this.)

Regardless of the precise age of the pre-existing count data, it is important to determine what the unique data needs are for a transportation project. General questions to help determine if new count data is needed are:

- • Is there pre-existing count data that has been collected within the past three years that is reflective of present-day traffic patterns for the area?

- • Have there been recent changes to the general area’s transportation network?

- • Have there been recent land use changes or new developments completed in the area?

Please refer to EPG 905.3.3.5 Data Collection Plan and Checklist for guidance about documenting assumptions.

When to Collect Data

For most traffic studies, it is important for traffic counts to reflect normal weekday and/or peak hour traffic conditions (unless performing special studies). Certain conditions may not yield the best or most accurate data. FHWA's Traffic Monitoring Guide advises that traffic counts should not be collected on Fridays, for example, since they tend to have lower morning volumes and slightly higher afternoon volumes than other weekdays. The guide also states that traffic volumes on Mondays can be fairly similar to typical weekdays, but if you are to complete traffic counts on a Monday, be sensitive to the location (i.e., Monday counts in areas influenced by rural, recreational areas can experience patterns similar to a Friday). As a result, it is recommended to avoid collecting traffic count data on Mondays and Fridays altogether and only collect data from Tuesday to Thursday. Exceptions would include unique studies where special event and/or recreational trips are a concern, though even then, it is advised to provide the special event/recreational data as a supplement to typical (Tuesday – Thursday) weekday traffic data.

Determining when not to collect data can provide more accurate information. MoDOT recommends the following traffic count rules for when NOT to collect data:

- • Sundays, Mondays, Fridays and Saturdays

- • When public schools are not in session (generally, late May through early August, depending on the study area; the exact timeframe should be confirmed prior to collecting traffic data)

- • During holiday periods when travel patterns are not routine (from a week before Thanksgiving to a week after New Year)

- • Days when special events at major traffic generators may disrupt routine traffic patterns

- • During special events that generate traffic that is not typical of everyday operations

- • During or immediately following significant inclement weather events (e.g., blizzards, heavy rain, etc.)

- • During federal and/or state issued advisories or restrictions (an example would be travel advisories issued for the COV-19 pandemic)

- • During the week following a time change due to the start or end of Daylight-Savings Time

- • During construction in or near the project area

- • During traffic incidents (e.g., crashes) that disrupt normal traffic patterns

- • During off-peak season when traffic is typically influenced to be lower than during a seasonal peak. For example, it may not be desirable to count roadways around the Lake of the Ozarks during winter, when demand is significantly less than during the summer.

905.3.3.4 Assess What Type of Data is Needed (The “What”)

The following guidelines are recommended for intersection turning movement counts, roadway segment counts, data needed for various software tools, and the determination of vehicle classifications that will be used for traffic and safety analysis. Other data may be needed for traffic and safety analysis, but the below count data has specific MoDOT requirements. Other data collected should follow standard industry practices.

Intersection Turning Movement Count Recommendations

- • For a transportation project that includes multiple intersections, collaborate with all appropriate parties to determine what intersections need turning movement counts. Turning movement counts are typically needed if:

- o The intersecting road carries at least 400 vehicles per day.

- o The intersection has turning movement count data older than three years. Also, ensure that the recently collected count includes all appropriate data needed for the project.

- • Provide generalized personal vehicle and heavy truck classifications (collecting heavy trucks in MoDOT standardized categories is preferred – refer to Vehicle Classifications)

- • Collect the data in 15-minute intervals

- • If trying to estimate peak hour traffic volumes only, then collect at least two-hours in each peak period. Existing segment hourly counts can be used to inform the timing for the two-hour counts, but typically 7:00 AM to 9:00 AM and 4:00 PM to 6:00 PM will include the peak hours.

- • Strongly consider a minimum 12-hour turning movement count from 6 AM to 6 PM if trying to estimate 24-hour traffic volumes, if the traffic peak may occur during midday, and/or if a signal warrant analysis is anticipated

- • Collect bi-directional data for all turning movements (covers both directions).

Roadway Segment Count Recommendations

- • For a transportation project that includes roadway segments, review existing MoDOT AADT data to determine what recent data is available. Roadway segment counts are recommended if:

- o It supplements the turning movement counts with project-specific roadway segment counts. These segment counts should be at strategically important locations to capture key traffic patterns and assess the influence of nearby traffic generators.

- o There is a gap in recent, relevant historic AADT on the roadway. Typically, it is advised to use traffic data that is no older than three years old.

- o The only available historic AADT on MoDOT’s Interactive AADT map are volume estimates that are not based on actual count data (confirm with the MoDOT TMS unit if there are any concerns or questions about data source).

- • Provide generalized personal vehicle and heavy truck classifications (collecting heavy trucks in MoDOT standardized categories is preferred – refer to Vehicle Classification)

- • Collect the data in one-hour intervals at a minimum (15 minutes preferred)

- • Collect the data for a minimum contiguous 24- to 48-hour period, or one to two weeks if daily variation throughout the week is desired

- • Collect bi-directional data (covers both directions).

Origin-Destination Data Collection Recommendations

Origin-destination (O-D) data is appropriate for some projects to be used for loading traffic demand data into a microsimulation model. O-D data is summarized in a matrix table that displays the number of trips (traffic demand) traveling from each origin (table row) to each destination (table column) in the study area.

Due to the additional cost constraints of collecting the data through typical O-D collection methods (e.g., Bluetooth wireless readers, aerial observation, and third-party probe data providers), it is recommended that the analyst discuss the appropriateness of O-D data collection with MoDOT before proceeding. O-D data is especially useful for complex corridors where traffic patterns affect operations such as closely spaced intersections and certain freeway weaving segments.

Typical Data Needs for Software Tools

For transportation projects that utilize software tool analysis, it is important to understand analysis-specific data needs and input parameters that can often vary based on different analysis tools. Table 905.3.3.4 provides information about the typical traffic and roadway input parameters needed to utilize each analysis tool.

Table 905.3.3.4, Typical Input Data for Different Analysis Types

| Input Data Category | Traffic Analysis Tool | |||||

|---|---|---|---|---|---|---|

| HCS | SIDRA | Synchro/SimTraffic | VISSIM | HSM | ||

| Traffic Operations and Control Characteristics | Speed | ✔ | ✔ | ✔ | ✔ | |

| Speed Limit | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Driver Behavior | ✔ | |||||

| Parking | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Signs | ✔ | ✔ | ||||

| Signals (Timing and Phasing) | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Detectors | ✔ | ✔ | ✔ | |||

| Intersection Control Type | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Right/Left Turn Treatment | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Railroad Crossing | ✔ | ✔ | ✔ | |||

| Lane Restrictions | ✔ | |||||

| Toll Facility | ✔ | |||||

| Ramp Metering | ✔ | |||||

| Traffic Characteristics | Demand | ✔ | ✔ | ✔ | ✔ | ✔ |

| Queue | ✔ | ✔ | ✔ | |||

| Capacity/Saturation Flow | ✔ | ✔ | ||||

| Pedestrian Counts | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Bicycle Counts | ✔ | ✔ | ✔ | ✔ | ||

| Bus & Transit | ✔ | ✔ | ✔ | |||

| Fleet Characteristics | ✔ | ✔ | ✔ | ✔ | ||

| Occupancy | ✔ | |||||

| Major Traffic Generators | ✔ | |||||

| Roadway Characteristics | Road Classification | ✔ | ✔ | ✔ | ✔ | ✔ |

| Cross Section | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Geometry | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Roadside | ✔ | ✔ | ✔ | |||

| Access Control | ✔ | ✔ | ✔ | |||

| Access Density | ✔ | ✔ | ✔ | |||

| Aerial Images | ✔ | ✔ | ✔ | |||

| Note: “HSM” is used to represent all HSM-based tools because all the HSM-based tools use similar data inputs. Additionally, red check marks are used to distinguish safety tools (i.e., “HSM”) from operations analysis tools. | ||||||

Vehicle Classifications

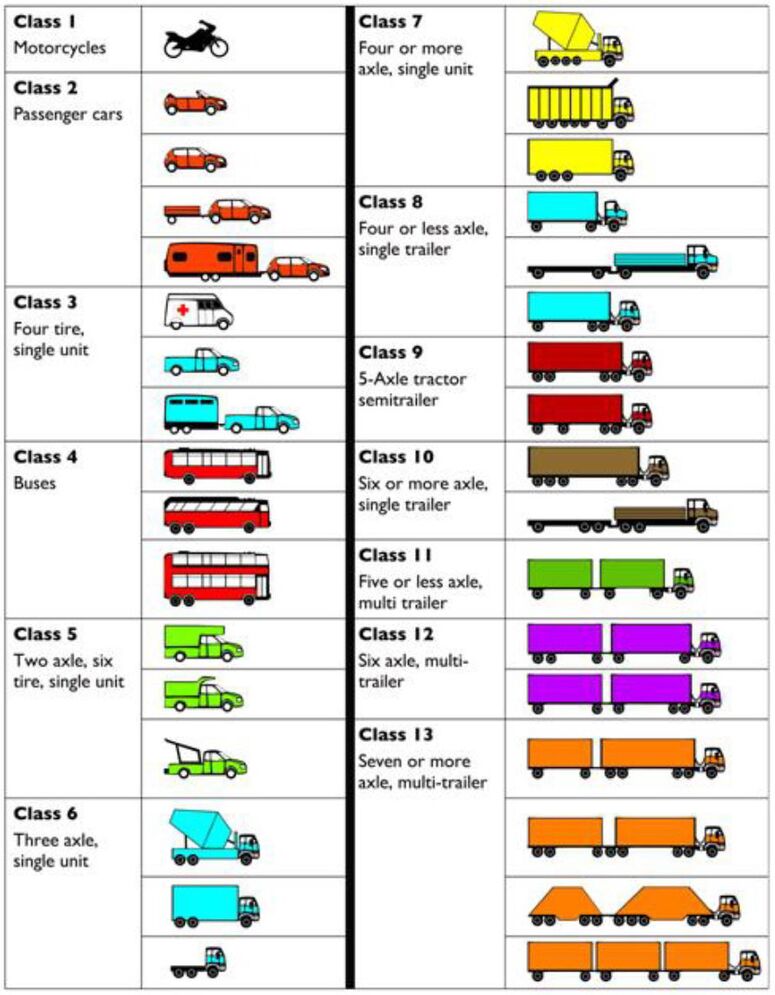

FHWA's Traffic Monitoring Guide classifies all vehicles into 13 distinctly different categories. Figure 905.3.3.4.1 is a FHWA graphic of these 13 different categories.

For the purposes of a traffic study, a heavy truck percentage provides the ratio of heavy trucks to overall vehicles on a roadway segment. MoDOT typically classifies vehicle proportions into the following six classifications for data collection purposes:

- • Motorcycles (FHWA Class 1)

- • Passenger Cars (FHWA Class 2)

- • Panel Trucks (i.e., Two-Axle, Four-Tire Single Unit Vehicles) (FHWA Class 3)

- • Buses (FHWA Class 4)

- • Single Unit Trucks (FHWA Classes 5, 6, 7)

- • Combination Semi-Trailers (FHWA Classes 8 – 13).

905.3.3.5 Data Collection Plan and Checklist

The data collection plan documents what, when, and how data will be collected. The checklist will ensure that project deliverables, check-in points, and other considerations (including traffic data needs) are effectively communicated and documented throughout the project development process.

905.3.4 Traffic Forecasting and Volume Development

905.3.4.1 Purpose

EPG 905.3.4 details methodology options and best practices for developing traffic volume estimates and forecasts to be used in the planning for, and development of, transportation projects. Accurate and timely traffic volume estimates are crucial for ensuring the success of transportation projects through each stage, including transportation impact analyses (TIAs).

The following guidance provides information on best practices as identified through a review of both federal and state level guideline documents. It is important to note that this traffic volume development and forecasting information are predominantly the product of recommended guidelines rather than strict policy requirements. The National Cooperative Highway Research Program (NCHRP) 765 Report, Analytical Travel Forecasting Approaches for Project-Level Planning and Design (2014), summarizes this distinction:

- “Project-level traffic forecasting has an underlying codification at the federal, state/MPO, and industry guideline level. In most cases, traffic forecasting procedures are the product of recommended guidelines rather than strict policy requirements. Thus, there is tremendous variation in practitioner procedures.

- “At the federal level, traffic forecasting is required for air quality analysis, major investment projects and highway design projects undertaken by the federal government (Special Report 288, FHWA [22]). Traffic forecasting is also an integral part of several standard transportation processes, such as highway design—see the AASHTO Policy on Geometric Design (121), and the Highway Capacity Manual (21)."

Underlying federal codification for traffic forecasts includes 23 USC 109 and 23 CFR 625 that state plans and specifications for National Highway System (NHS) projects shall provide for a facility that will “adequately serve the existing and planned future traffic of the highway in a manner that is conducive to safety, durability and economy of maintenance.”

905.3.4.2 Background

Traffic volumes describe the number of vehicles at a point on a roadway and are the most basic, readily understood output of the traffic forecasting and analysis processes. Traffic volume-based measures deal with the quantity of use of transportation facilities. The quantity can either be calculated at a specific point on a transportation network or between origins and destinations. Demand is associated with a specific time frame anywhere from 15 minutes to a 365-day annual period.

The NCHRP 765 Report provides the following summary for traffic volumes:

- "Volumes can describe how the distribution and magnitude of demand change across different supply/demand scenarios. Volumes can describe throughput—a measure of the quantity of transportation activity that can be accommodated at a single point or multiple points on a transportation network. Volumes are also a critical input to assessments of congestion and economic and environmental impact.”

Traffic forecasts are produced to assess transportation performance under different assumptions about transportation supply and demand. A traffic forecast uses existing traffic volume counts, historic traffic volume trends, travel demand model projections (if available), land use plans and socioeconomic data to predict traffic volumes and traffic flow patterns for a given year in the future. A traffic forecast is typically developed for a specific transportation project and is used for subsequent capacity analysis, geometric design and pavement design.

905.3.4.3 Daily Traffic Volume Refinement

After raw short-term traffic count data is collected, it should be processed by factoring it into Average Annual Daily Traffic (AADT) using factors that can be requested from MoDOT Transportation Planning Division. This process is accomplished using the following steps:

- 1. Axle Correction Factor (ACF): If the count method includes vehicle axle data (i.e., tube counts), then an ACF should be used to adjust the axle counts into vehicle counts. An ACF is developed from classification counts by dividing the total number of vehicles by the total number of axles.

- 2. Partial Weekday Traffic Count Adjustment: If partial weekday data was collected, then an adjustment factor is used to convert partial weekday traffic count data to 24-hour weekday daily traffic volume estimates, also known as Average Daily Traffic (ADT). The adjustment factor is representative of the percentage of 24-hour traffic volumes that typically occur on a weekday during the time range specified (e.g., 6 AM – 6 PM for a 12-hour traffic count). The adjustment factor usually varies by the type of roadway facility (e.g., interstate, US route, state highway, etc.).

- 3. Average annual daily traffic (AADT): The ADT value is converted to AADT, which represents the average traffic volume throughout the year considering typical traffic conditions. A true AADT is developed by utilizing a full year of traffic count data, such as data generated from a permanent traffic counter. However, AADT can also be estimated with short-term traffic counts (usually a 24- to 48-hour period) using the following formula:

- AADT = ADT × Seasonal Adjustment Factor

905.3.4.4 Design Hour Traffic Volume Refinement

For most traffic analyses, AM and PM peak period (one or more hours) traffic volumes will be needed. Often design hour volumes are also needed, especially for design studies. The key phrases below are important to estimate the design hour characteristics of a location:

- • Design Hour: An hour with a traffic volume used for designing the geometric and control elements of a facility. The design hour selected will allow the designed facility to accommodate peak hour traffic during most days. The Highway Performance Monitoring System considers the hour corresponding to the 30th highest hourly volume of the year as the design hour. In the absence of continuous counters to determine the 30th highest hourly volume of the year, local jurisdictions and/or Metropolitan Planning Organizations (MPOs) can adjust their design hour based on local facility-specific traffic conditions (refer to Page 22 of the FHWA Traffic Data Computation Method Pocket Guide).

- • Design hourly volume (DHV): The volume of vehicles that travel through a segment of roadway during the design hour. The DHV is used for making roadway structural and capacity design decisions in the design year because traffic volume varies by hour and from day to day throughout the year. The formula for calculating the DHV using a design hour factor (K) is:

- DHV = K × AADT

- • Design Hour Factor/K Factor: The proportion of the AADT that occurs during the design hour. K-factors are typically estimated to be between 8% and 12%, with lower K-factors generally occurring on primary routes and higher K-values occurring on secondary routes. In the absence of available traffic data, a planning level estimate of K=10% is sometimes assumed (for high level, sketch planning ONLY). For further information about the typical weekday and weekend hourly distribution of traffic volumes, refer to Figures 1.1 through 1.5 of FHWA’s Measures for Congestion, Reliability, and Freight Step-by-Step Metric Calculation Procedures (Published June 2018).

- K = DHV/AADT

- • Peak Hour Directional Split (D Factor): The percentage of the total two-way peak hour traffic that occurs in the dominantly traveled direction.

905.3.4.5 Traffic Volume Balancing

Raw traffic volumes along a corridor will have inconsistencies when initially tabulated. These differences in Base Year traffic volumes are frequently the result of the presence of other intersecting roadways along a corridor or traffic data collection method variations (e.g., data collected on different days, counter error, unexpected traffic incidents, etc.). Future Year traffic volumes will frequently have inconsistencies due to varying growth rates applied along the corridor.

It is generally beneficial for a traffic forecast to “balance” the traffic volumes, which refers to the process of eliminating the traffic volume difference between multiple points completely. The NCHRP 765 states that “balancing helps to 'clean' traffic volume data by tempering the effects of outliers and counting errors.”

For certain forecasts or project locations, balancing might not affect the overall quality of the traffic forecast. However, balancing is needed for microsimulation models or for any analysis type where the difference between the traffic volumes of two given points does not match their predicted traffic volumes for intersection roadways or driveways. Also, it is important to balance traffic volumes when an Origin-Destination (O-D) trip table matrix will be used for subsequent capacity analysis. Balanced traffic volumes will result in a faster convergence when the O-D matrix estimation is applied because the matrix estimation algorithms tend to fluctuate when attempting to match conflicting goals.

The following methods are available to balance traffic forecast volumes are summarized in Table 905.3.4.5. Engineering judgement is recommended to determine which method is appropriate based on traffic volume data available.

Table 905.3.4.5, Typical Traffic Volume Balancing

| Method | Description | Pros | Cons |

|---|---|---|---|

| Split the Difference | Add half of the total link imbalance to the lower volume intersection and subtract the remainder of the total link imbalance to the higher volume intersection. | Realistic results | Time consuming, especially if multiple intersections are completed |

| Higher Volume Distributed | Use the higher volume from one intersection to override the lower volume of the adjacent intersection and then distribute the volume difference based on the existing turning movement count distributions. | Realistic results | Time consuming |

| Higher Volume Through | Use the highest volume and carry it through the other locations adding the excess traffic only to the through movements. | Ease of calculations | Conservatively high through volumes relative to turning movement volumes at lower volume intersections. |

| Spreadsheet Link Volume Forcing | Use the link volume forcing option of the NCHRP 255 spreadsheet to automatically balance/smooth volumes. This method should be used with caution and does not always produce the desired outcome if convergence cannot be reached. | Automated calculations | May not produce all desired results |

| Combination | A combination of all or some of the other methods. For example, the NCHRP Override process may be used first to get the volumes closer to being balanced, and then a combination of the Higher Volume Distributed method at the internal intersections and the Higher Volume Through at the network termini could be used. | Realistic results | Time consuming |

General Balancing Rules of Thumb:

General “rules of thumb” to help the analyst make sound decisions for balancing traffic volume data include:

- • Understand data deficiencies: Understand the locations of where data collected is more likely accurate, defensible, and verifiable by multiple sources. Rely on those data sources to carry forward traffic volumes during balancing.

- • Balance the project’s needs between realistic results and efficient calculations: If a high-level analysis is being completed and it is acceptable to maintain conservatively high volumes in certain locations, then perhaps the analyst could consider using the “higher volume through” method. That method in high-level planning would not be time consuming relative to the analysis needs at that stage. If the analysis level is preliminary engineering and greater detail is needed, then perhaps a combination of various methods is needed where the analyst can start with one method and iteratively adjust when comparing to other methods.

- • Determine level of error and if new data is needed: If the volumes being balanced are 10% or more off, then the analyst should revisit the data and determine if errors have been made in the data processing or the traffic forecast. If the data is inaccurate, then consider collecting additional data.

905.3.4.6 Traffic Forecast Types and Tools

There are two general types of traffic forecasts: planning-level forecasts and project-level forecasts.

- 1. Planning-level forecasts typically do not require current traffic data to be collected. If traffic data is collected, it is usually limited to just roadway segment data with no turning movement counts required. Planning-level forecasts are either completed (1) during long range transportation planning for any given project or regional analysis (at least 20-year horizon required by FHWA for MPO planning), or (2) during the project planning and programming for a “preservation” project. A “preservation” project includes roadway resurfacing, reconditioning, pavement replacement, roadway maintenance or bridge rehabilitation/replacement. Regional travel demand models and historic AADT growth rates are typically used for planning-level forecasts.

- 2. Project-level forecasts require both turning movement count and roadway segment traffic data to be collected. Project-level forecasts are completed during the project planning and programming for widening, new location, bridge replacement (if capacity changes are made) and new roadway capacity or new development-based projects. Regional travel demand models, historic AADT growth rates, turning movement analyses and new development trip generation analyses (as needed) are typically used for project-level forecasts.

Traffic Forecasting Tool(s): In coordination with understanding the applicable forecast type, it is important to understand the most appropriate tool to use for a traffic forecast, given factors such as the transportation project needs, size and complexity of the project, and resources available. The NCHRP 765 lists the most common forecasting tools as summarized in Table 905.3.4.6.

Table 905.3.4.6, Common Traffic Forecasting Tools

| Tool | Description | When to Apply | Potential Shortcomings |

|---|---|---|---|

| Growth Rate | Focuses on extending the observed traffic growth patterns at a given location to a future year. | • No travel demand model is available • Historic growth in the study area is stable and expected to remain that way in the future • Project is small in size and complexity • Resources and/or time in schedule is unavailable for more in-depth analyses |

These methods do not naturally focus the constraining factor of a roadway’s capacity. |

| Trend Line Analysis | Review and analyze existing, historic AADT data to calculate trend line growth rates for medium-term and long-term timeframes (often 10 to 20 years in the past). Outlier data points will be eliminated from the analysis as appropriate. | ||

| Time-Series Analysis | Estimates traffic volumes as a function of time and, perhaps, a small set of explanatory variables. | ||

| Turning Movement Analysis | The process of analyzing, refining, and balancing turning movement count data for intersections studied as part of a traffic forecast. | • Daily intersection turning movement counts • Design hour intersection turning movements volumes and factors |

Does not focus on estimating base year to future year growth. Is typically done in conjunction with other tools. |

| Travel Demand Model | A series of mathematical equations that represent how choices are made when people travel. A travel demand model combines a network (supply) with population and employment by location (demand for travel). A travel demand model can encompass roadway networks and population/employment for an entire metropolitan region. |

• Travel demand model is available for the region studied • Growth in the study area is anticipated to change at varying rates relative to historic growth • Resources and project schedule is available for model utilization |

Is not always appropriate for projects of small size and complexity (e.g., small road bridge replacement or site development with no roadway network forecast needed) |

| Traffic Simulation Model | Traffic simulation models are designed to emulate the behavior of traffic in a transportation network over time and space to predict system performance. | When the quantification of peak hour volumes, capacity, Level of Service, travel times, or other measures of effectiveness (MOEs) are needed in addition to daily forecasted volumes. | Is not a standalone forecasting tool. Is typically applied for an in-depth capacity analysis after forecasted traffic volumes have been determined. |

Utilizing a travel demand model is the preferred tool for developing a traffic forecast if a travel demand model is available for a study area. It is important to confirm with the MPO or appropriate local entity that the regional travel demand model has been approved by the region before utilization of the model. Regions such as St. Louis and Kansas City are usually robust in consistently approving model updates, but always verify from the appropriate sources before using.

Growth rates, trend line analyses, and time-series analyses are all similar and have some overlap. The differences are that the emphasis points for each tool are “constant growth rate over time” (growth rate tool), historic traffic volume data regression lines (trend line analysis), and extrapolating trends over a period of time that can be either constant or variable in growth (time-series analysis).

Turning movement analyses are typically completed in conjunction with other tools and traffic simulation models are often completed for traffic capacity analyses, which are developed subsequently after traffic forecasts.

905.3.4.7 Forecast Application

The development of a traffic forecast includes the following steps:

- 1. Collect and Review Data

- a. Collect data from the existing available data sources, including but not limited to:

- i. AADT for the past 10 to 20 years

- ii. Other pre-existing traffic count data

- iii. Previous traffic forecasts for the project and other relevant forecasts in the general area

- iv. Information from available plans, including local land use plans, relevant demographic data and regional transportation plans

- v. Consultation with local planners, engineers and other appropriate parties regarding traffic patterns, pending development plans, land use plans and historic growth

- vi. On-site field investigation.

- b. Develop historic AADT rates for long- and mid-term (approximately 20 and 10 years, respectively) historic growth. Look for natural breaks in the data as well as data anomalies.

- c. Collect project-specific traffic count data as needed

- d. Convert raw project-specific daily count data to AADT estimates using seasonality and other factors

- a. Collect data from the existing available data sources, including but not limited to:

- 2. Develop Base Year No-Build (i.e., existing no build) volumes. The scenario may include intersection quadrant turning movements, design data (K & D factors, heavy truck percentages), and be balanced unless otherwise specified.

- 3. Utilize Travel Demand Model (when available)

- a. Review the Model Validation – Compare the existing model traffic volumes to actual project AADT estimates

- b. Review the Transportation Network – Ensure accuracy of the model base year network relative to the actual transportation network. Also, check that all fiscally constrained MTP projects as identified by an MPO are included in the model’s future year network

- c. Calculate model growth. Per NCHRP 765, there are two methods, which are displayed in Table 905.3.4.7. It is advised that a preferred method be selected by reviewing the results from both methods and evaluating them within the context of existing traffic volumes and turning movements.

Table 905.3.4.7, Model Growth Calculation Methods

| Method | Description | Pros | Cons |

|---|---|---|---|

| Difference Method | Applies the difference between the base year turning movement count and the base year model assignment to the future year model turning movement assignment. Formula: FFdi = future year forecast volume for turning movement i, FAi = future year model assignment, BCi = base year count, BAi = base year model assignment |

Results are not easily inflated by nearby land use changes. | Two items must both be accurate: 1. Model assignment (must be calibrated very closely to traffic count data) 2. The relationship between the base year and future year model assignments must be reasonable |

| Ratio Method | Utilizes a traffic growth factor by dividing the future year model volume by the base year model volume. Formula: FFri = future year forecast volume for turning movement i, BCi = base year count, FAi = future year model assignment, BAi = base year model assignment |

Unlike the difference method, the ratio method can work if model volumes assigned do not calibrate accurately with count data (within reason). The ratio method is primarily focused on the relationship between the base year and future year model assignments. (The NCHRP 765 states that the ratio method is better than the difference method because it is less susceptible to inaccurate model assignment, especially over a long time horizon.) |

Drastic changes in model assignment from base year to future year (from land use changes, for instance) or low model volumes could produce unreasonable growth. |

| Note: NCHRP 255 discussed averaging the results from the ratio and difference methods as a means to reduce the extremes that may be reached by either the ratio or difference method. However, NCHRP 765 supplants NCHRP 255 and advises that the average method not be used because averaging will reduce the accuracy of one method or the other. | |||

- 4. Develop Future Year No-Build Forecast – Apply both model and historic AADT growth to Base Year No-Build traffic volumes to estimate Future Year No-Build traffic volumes. Review and adjust traffic volumes based on knowledge of future land use, professional judgement and to maintain reasonable corridor traffic volume balancing.

- 5. Develop Base Year and Future Year Build Forecasts – Utilize the travel demand model (when available) to determine diversion and/or growth on the transportation network in the study area. Apply the diversion to the No-Build scenarios or the growth to the base scenarios to estimate Build scenario volumes. Review and adjust traffic volumes based on knowledge of network changes, professional judgement and to maintain reasonable corridor traffic volume balancing.

- 6. Coordinate and provide a review period with all appropriate parties during forecast development to ensure that reasonable forecast assumptions are made. Refer to the MoDOT TIA Guidance Methods and Assumptions template.

- 7. Document the forecast using a combination of figure diagrams and a report to explain all assumptions made. Refer to the MoDOT Methods and Assumptions Report Checklist and the Data Collection Plan and Checklist.

905.3.4.8 Forecast for a TIA

TIAs are engineering studies that compare before and after traffic conditions on road networks due to proposed land use changes. EPG 905.3.4.8 Forecast for a TIA focuses on project-level forecasts that are primarily developed to support the creation of TIAs. The forecasting scoping and application steps of a TIA forecast will be similar to the steps listed above. However, additional focus should be provided to identify potential development traffic to add to the forecast. Figure 905.3.4.8.1 guides the user into whether a development should be added to the forecast.

To determine the impact that proposed development(s) will have on future traffic conditions, it is important to identify how development trips will be generated, distributed, and assigned on the roadway network. The following five steps are used to make this determination:

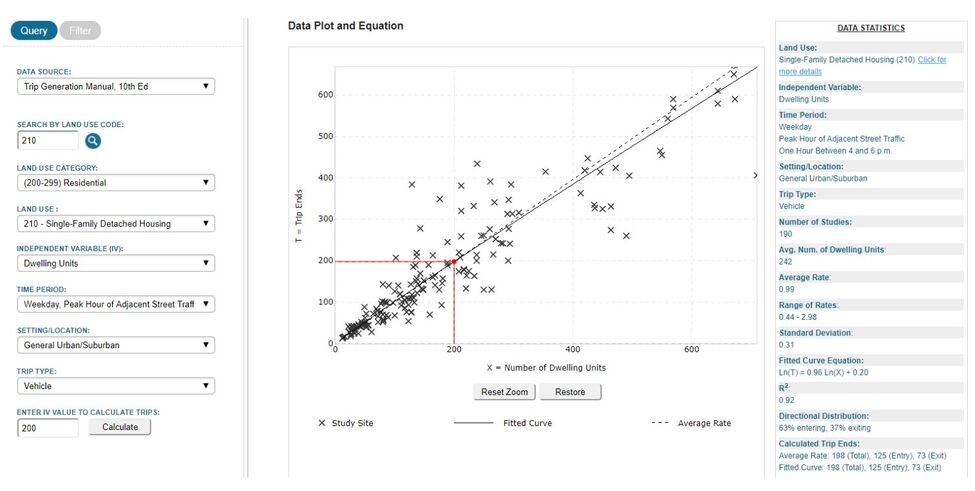

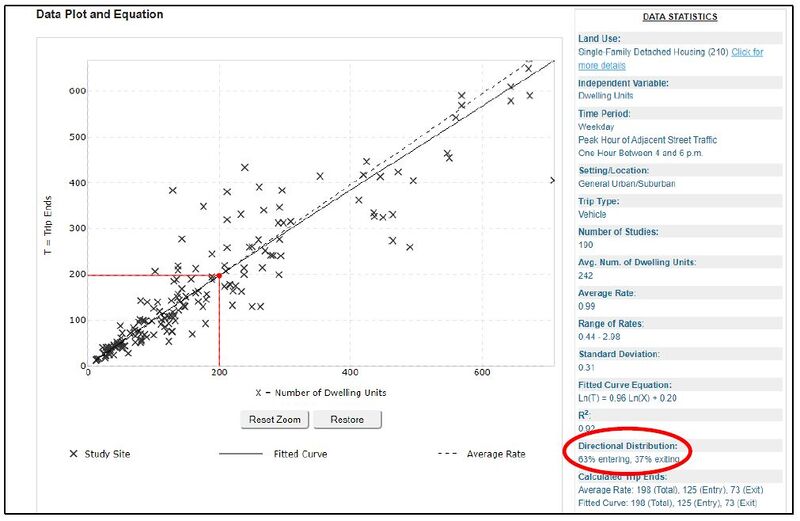

- 1. Assess Trip Generation Potential: The most commonly accepted source for trip generation data on land use development is the Institute of Transportation Engineers (ITE) Trip Generation Manual. The ITE Trip Generation Manual includes trip generation characteristics of a wide variety of land use types. Land use types include port and terminal, industrial, residential, lodging, recreational, institutional, medical, office, retail, and services. Trip generation characteristics for these land use types were determined based on studies completed between the years 1980 and 2017.

- Once the land use category is selected in the ITE Trip Generation Manual, an “independent variable” that the study is based off is selected. Independent variables usually include items such as square feet of development, number of employees, acres of land parcel(s), number of dwelling units, etc. The time period is then selected, which often includes the AM peak, the PM peak hour, weekday totals, and sometimes, weekend days. Also, some land use types can allow you to select a “setting/location” type, but often times it will be default to only one option, such as “General Urban/Suburban” for single-family detached housing.

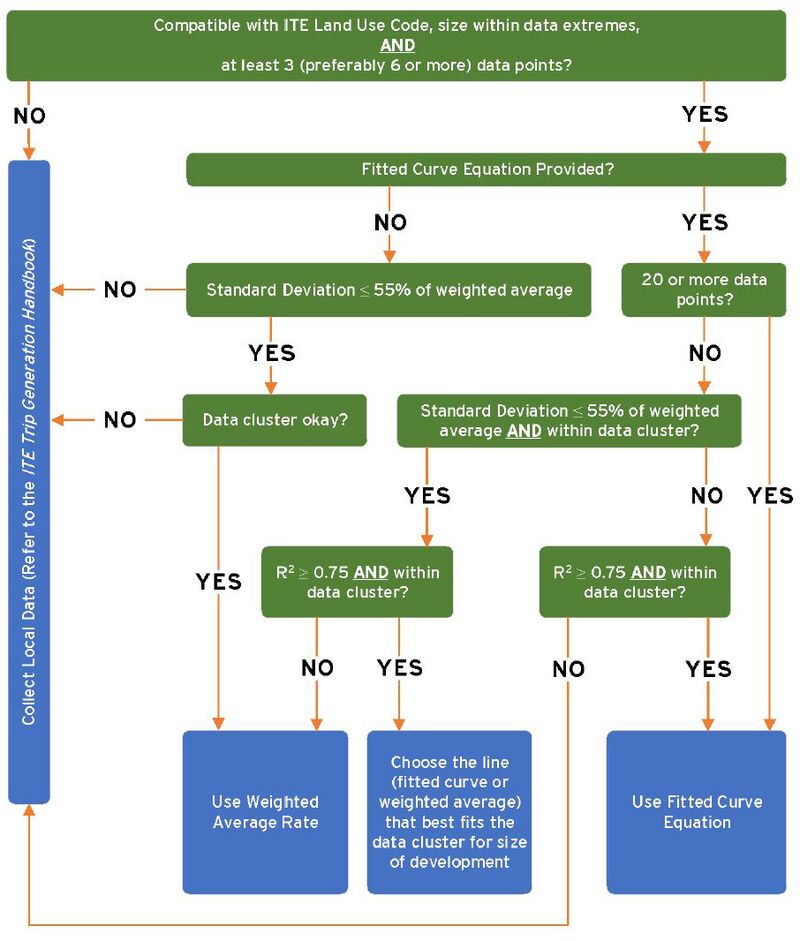

- The ITE Trip Generation Manual provides a web-based app (Figure 905.3.4.8.2 provides example of interface) to determine these study settings and to input the quantity of the project-specific independent variable to calculate an estimated, raw number of trips generated. The number of trips will be calculated using either a fitted curve equation or an average trip rate. In order to determine which method of trip generation calculation is relevant for the project, the reasonableness of the study’s data sample attributes (e.g., R2, standard deviation, and sample size) must be reviewed.

- Figure 905.3.4.8.3 displays a decision-making flow chart from the ITE Trip Generation Handbook, 3rd Edition, to help determine what trip generation method to use.

Source: Figure 4.2 of ITE Trip Generation Handbook, 3rd Edition

- 2. Mode Split: The selection of trip mode choices should be informed by the availability of nearby transit and bicycle/pedestrian infrastructure, a review of available multi-modal count data, and coordination with local planning and engineering partners. Mode choice assumptions should be well documented in the final TIA.