Difference between revisions of "751.32 Concrete Pile Cap Intermediate Bents"

| (11 intermediate revisions by 2 users not shown) | |||

| Line 119: | Line 119: | ||

|- | |- | ||

|valign="top"|[[Image:751.32 circled 1.gif]] | |valign="top"|[[Image:751.32 circled 1.gif]] | ||

| − | |width="500" align="left"|Use 2'-6" minimum or as determined by the superstructure requirements or the [[751. | + | |width="500" align="left"|Use 2'-6" minimum or as determined by the superstructure requirements or the [[751.9_Bridge_Seismic_Design|minimum support length]] required for seismic criteria (expansion joint bents only) (3" increments) or the minimum beam width required to meet pile edge distance requirement. |

|- | |- | ||

|valign="top"|[[Image:751.32 circled 2.gif]] | |valign="top"|[[Image:751.32 circled 2.gif]] | ||

| Line 159: | Line 159: | ||

=== 751.32.3.3 Encased Pile Cap Bent=== | === 751.32.3.3 Encased Pile Cap Bent=== | ||

| − | Consideration shall be given to [ | + | Consideration shall be given to [https://epg.modot.org/index.php?title=751.1_Preliminary_Design#751.1.2.20_Substructure_Type EPG 751.1.2.20 Substructure Type] before using this type of structure. |

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | ||

| Line 172: | Line 172: | ||

|- | |- | ||

|valign="top"|[[Image:751.32 circled 1.gif]] | |valign="top"|[[Image:751.32 circled 1.gif]] | ||

| − | |width="500" align="left"|Use 2'-6" minimum or as determined by the superstructure requirements or the [[751. | + | |width="500" align="left"|Use 2'-6" minimum or as determined by the superstructure requirements or the [[751.9_Bridge_Seismic_Design|minimum support length]] required for seismic criteria (expansion joint bents only) (3" increments) or the minimum beam width required to meet pile edge distance requirement. |

|- | |- | ||

|valign="top"|[[Image:751.32 circled 2.gif]] | |valign="top"|[[Image:751.32 circled 2.gif]] | ||

| Line 189: | Line 189: | ||

|width="500" align="left"|Minimum of 3 piles at 10'-0" cts., maximum spacing (1" increments). | |width="500" align="left"|Minimum of 3 piles at 10'-0" cts., maximum spacing (1" increments). | ||

|} | |} | ||

| + | |||

| + | ===751.32.3.4 Closed Concrete Intermediate Diaphragms=== | ||

| + | |||

| + | See [[751.22 P/S Concrete I Girders#751.22.3.7.4 Bent Details|EPG 751.22.3.7.4 Bent Details]] for intermediate bent details required for closed concrete intermediate diaphragms. | ||

== 751.32.4 Reinforcement == | == 751.32.4 Reinforcement == | ||

| Line 194: | Line 198: | ||

=== 751.32.4.1 Typical Pile Cap Bent === | === 751.32.4.1 Typical Pile Cap Bent === | ||

| − | + | [[image:751.32.4.1-01-2024.png|center|800px]] | |

| − | |||

| − | |||

| − | |||

| − | | | ||

| − | |||

| − | |||

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{|border="0" cellpadding="3" align="center" cellspacing="0" | {|border="0" cellpadding="3" align="center" cellspacing="0" | ||

|- | |- | ||

| − | |valign="top"|Note:||width=" | + | |valign="top"|Note:||width="550pt" align="left" valign="top"|Locate #4 bars "[[Image:751.32 reinforcement--4 bar under bearing.gif]]" under bearings where required to maintain a 6" maximum spacing of combined stirrups. (#4 bars "[[Image:751.32 reinforcement--4 bar under bearing.gif]]" are not required for Double-Tee Structures.) |

|- | |- | ||

| − | | ||width=" | + | | ||width="550pt"|For epoxy coated reinforcement requirements, see [[751.5 Structural Detailing Guidelines#751.5.9.2.2 Epoxy Coated Reinforcement Requirements|EPG 751.5.9.2.2 Epoxy Coated Reinforcement Requirements]]. Details of [[751.13 Expansion Devices#751.13.1.4 Details of Substructure Protection|protective coating and sloping top of beam to drain]] shall be used when below an expansion device. |

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | | | + | | ||width="550pt"|When dimension “B” is required to be greater than 15” to clear piles by 1 ½”, typical when HP14 and CIP14 or larger diameter piles are used, add intermediate longitudinal bar(s) between piles. The spacing between intermediate bar(s) and full length bars shall not be greater than required by crack control provisions. Ends of intermediate bar(s) shall be hooked. |

| − | |||

| − | |||

| − | |width=" | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | [[image:751.32.4.1.3.jpg|center|700px]] | ||

| + | [[image:751.32.4.1 longitudinal.jpg|center|500px]] | ||

| + | ::::(1) 6” (Max.), add #6 bars as needed. | ||

| + | ::::(2) 9” (Max.), add #6 bars at each face as needed. | ||

| + | ::::(3) Location 2 development length, f'c = 3 ksi: | ||

| + | :::::::::::21" (uncoated) | ||

| + | :::::::::::32" (epoxy coated) | ||

| − | + | See [[751.5 Structural Detailing Guidelines#751.5.9.2.8 Development and Lap Splices|EPG 751.5.9.2.8]] for development and lap splice lengths not given or lengths for scenarios other than those shown. Provide standard hooks if required. | |

| − | |||

| − | |||

| − | |||

| − | | | ||

| − | |||

| − | |||

| − | |||

=== 751.32.4.2 Encased Pile Cap Bent=== | === 751.32.4.2 Encased Pile Cap Bent=== | ||

| Line 262: | Line 224: | ||

Supplemental details for encased pile cap bents are provided. | Supplemental details for encased pile cap bents are provided. | ||

| − | + | [[image:751.32.4.2 part elev 2020.jpg|center|700px]] | |

| − | + | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | {|border="0" cellpadding=" | + | [[image:751.32.4.2 part section 2020.jpg|center|500px]] |

| − | + | {|border="0" cellpadding="3" align="center" cellspacing="0" | |

| − | |||

|- | |- | ||

| − | |align=" | + | |valign="top"|Note:||width="500pt" align="left" valign="top"|When dimension “A” is greater than 18” add intermediate longitudal bar(s) between piles. Ends of bar(s) shall be hooked. Keep 3” minimum clearance between the pile and intermediate bar(s) and do not show on the plans. |

|} | |} | ||

Latest revision as of 13:13, 19 July 2024

751.32.1 General

751.32.1.1 Material Properties

| Concrete | |||

|---|---|---|---|

| Typically, shall consist of: | |||

| Class B Concrete (Substructure) | = 3.0 ksi | ||

| = 10 | |||

In addition, Class B-1 Concrete (Substructure) may also be used in special cases (See Project Manager).

Modulus of elasticity,

Where:

- f'c in ksi

- wc = unit weight of nonreinforced concrete = 0.145 kcf

- K1 = correction factor for source of aggregate

- = 1.0 unless determined by physical testing

Modulus of rupture,

- LRFD 5.4.2.6

Where:

- f'c is in ksi

Reinforcing Steel

| Minimum yield strength, | = 60.0 ksi | |

| Steel modulus of elasticity, | = 29000 ksi |

751.32.2 Design

751.32.2.1 Limit States and Factors

In general, each component shall satisfy the following equation:

Where:

| = Total factored force effect | |

| = Force effect | |

| = Load modifier | |

| = Load factor | |

| = Resistance factor | |

| = Nominal resistance | |

| = Factored resistance |

Limit States

The following limit states shall be considered for bent design:

- STRENGTH – I

- STRENGTH – III

- STRENGTH – IV

- STRENGTH – V

- SERVICE – I

- FATIGUE

See LRFD Table 3.4.1-1 and LRFD 3.4.2 for Loads and Load Factors applied at each given limit state.

Resistance factors

- STRENGTH limit states, see LRFD 5.5.4.2

- For all other limit states, = 1.00

751.32.3 Details

751.32.3.1 Front Sheet

| Note: | The following are details and dimensions for the plan view of a typical pile cap bent on the front sheet of the bridge plans. Details and dimensions for an encased concrete pile cap bent are similar. |

| Details for unsymmetrical roadways shall require dimensions tying Centerline Lane to Centerline Structure. |

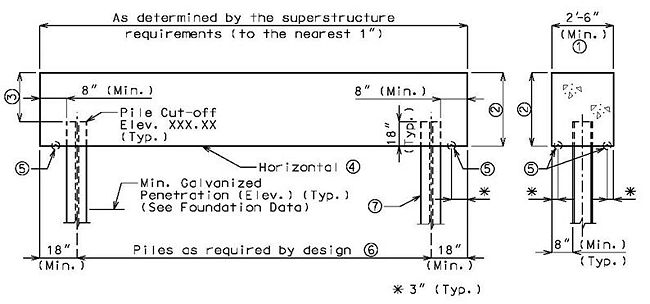

751.32.3.2 Typical Pile Cap Bent

| Part Elevation | Part Section |

|---|---|

| Applicable for both HP piles (shown) and CIP piles | |

| Use 2'-6" minimum or as determined by the superstructure requirements or the minimum support length required for seismic criteria (expansion joint bents only) (3" increments) or the minimum beam width required to meet pile edge distance requirement. | |

| = 3’-0” (Min.) for Wide Flange, Double-Tee Girders, Prestressed Girders and Plate Girders. | |

| Check the clearance of the anchor bolt well to the top of pile. Increase the beam depth if needed. | |

| If the depth at the end of the beam, due to the steps, exceeds 4'-6", the beam bottom should be stepped or sloped. | |

| Use 3/4" drip groove where expansion device is located at bent. Continue to use 1-1/2" clear to reinforcing steel in bottom of beam. 3/4" drip groove shall be formed continuously around all piling at 3" from edge of beam. | |

| Minimum of 3 piles at 10'-0" cts., maximum spacing (1" increments). | |

| Piles shall not be battered. |

751.32.3.2.1 Sway Bracing

(Use when specified on Design Layout or when required by design.)

Guidance for use of sway bracing for steel bearing pile:

(1) When angle slope of bracing becomes less than 15° to the horizontal, omit the diagonal angles and use the horizontal angles only (except on four pile bents, then use alternate shown above).

Note: In case of a large number of piles, see the Structural Project Manager.

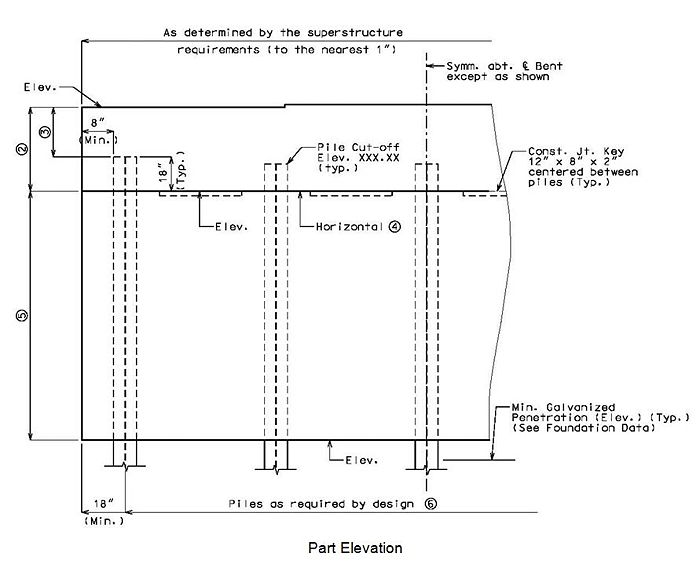

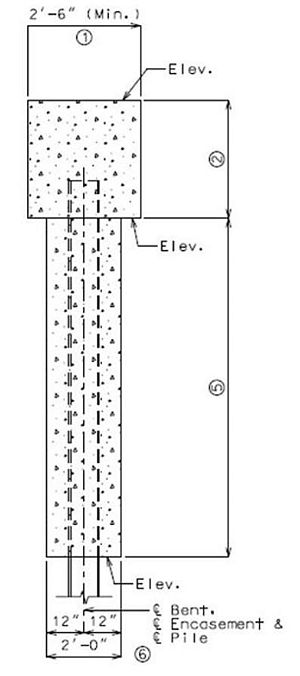

751.32.3.3 Encased Pile Cap Bent

Consideration shall be given to EPG 751.1.2.20 Substructure Type before using this type of structure.

| Part Section |

|---|

| Use 2'-6" minimum or as determined by the superstructure requirements or the minimum support length required for seismic criteria (expansion joint bents only) (3" increments) or the minimum beam width required to meet pile edge distance requirement. | |

| = 3’-0” (Min.) for Wide Flange, Double-Tee Girders, Prestressed Girders and Plate Girders. | |

| Check the clearance of the anchor bolt well to the top of pile. Increase the beam depth if needed. | |

| If the depth at the end of the beam, due to the steps, exceeds 4'-6", the beam bottom should be stepped or sloped. | |

| Height by design. Embed encasement 2 ft. (min.) below the top of the lowest finished groundline elevation, unless a greater embedment is required for bridge design. | |

| Minimum of 3 piles at 10'-0" cts., maximum spacing (1" increments). |

751.32.3.4 Closed Concrete Intermediate Diaphragms

See EPG 751.22.3.7.4 Bent Details for intermediate bent details required for closed concrete intermediate diaphragms.

751.32.4 Reinforcement

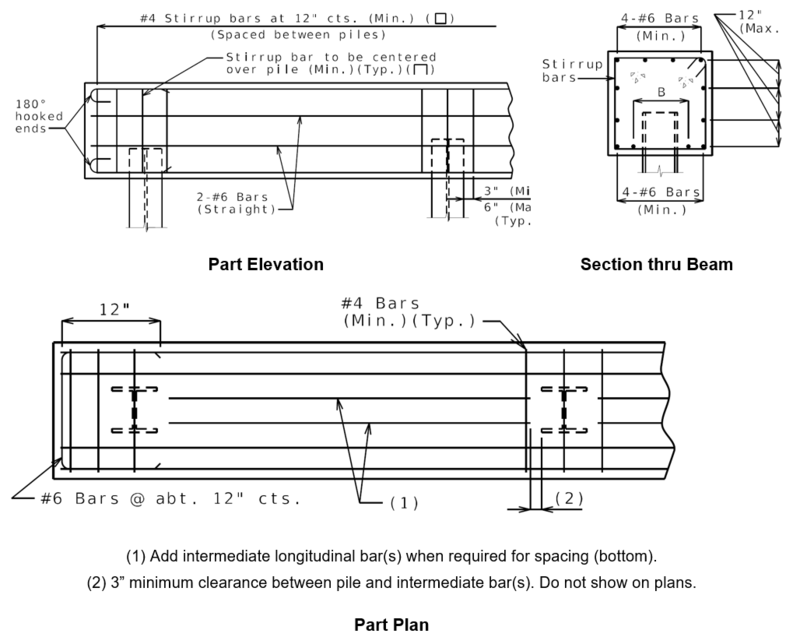

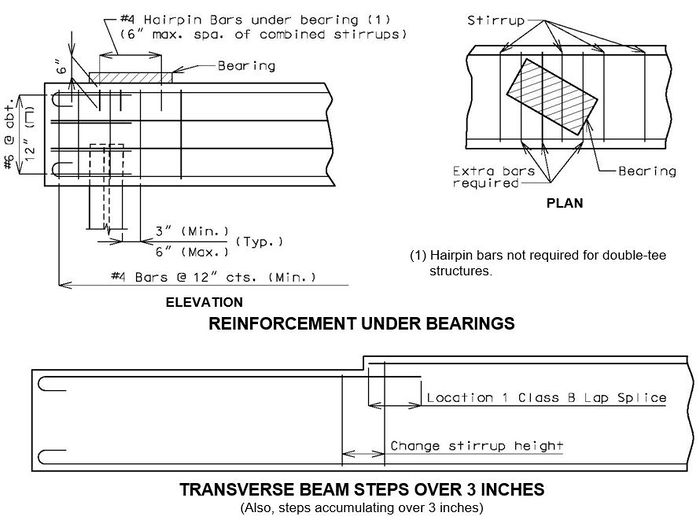

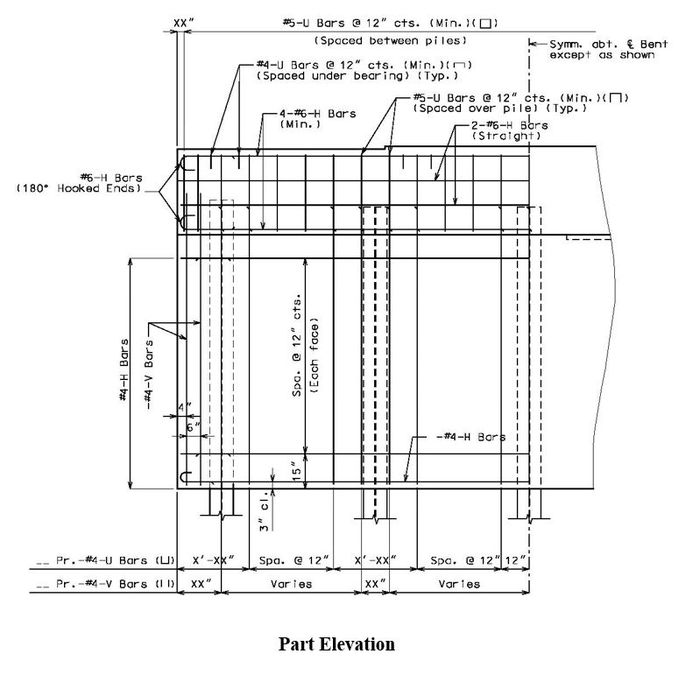

751.32.4.1 Typical Pile Cap Bent

| Note: | Locate #4 bars " |

| For epoxy coated reinforcement requirements, see EPG 751.5.9.2.2 Epoxy Coated Reinforcement Requirements. Details of protective coating and sloping top of beam to drain shall be used when below an expansion device. | |

| When dimension “B” is required to be greater than 15” to clear piles by 1 ½”, typical when HP14 and CIP14 or larger diameter piles are used, add intermediate longitudinal bar(s) between piles. The spacing between intermediate bar(s) and full length bars shall not be greater than required by crack control provisions. Ends of intermediate bar(s) shall be hooked. |

- (1) 6” (Max.), add #6 bars as needed.

- (2) 9” (Max.), add #6 bars at each face as needed.

- (3) Location 2 development length, f'c = 3 ksi:

- 21" (uncoated)

- 32" (epoxy coated)

See EPG 751.5.9.2.8 for development and lap splice lengths not given or lengths for scenarios other than those shown. Provide standard hooks if required.

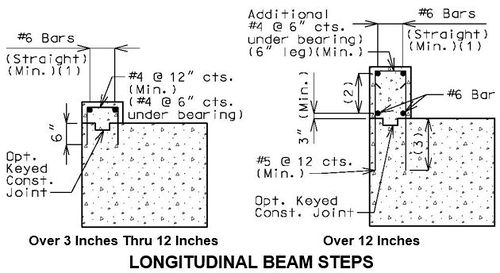

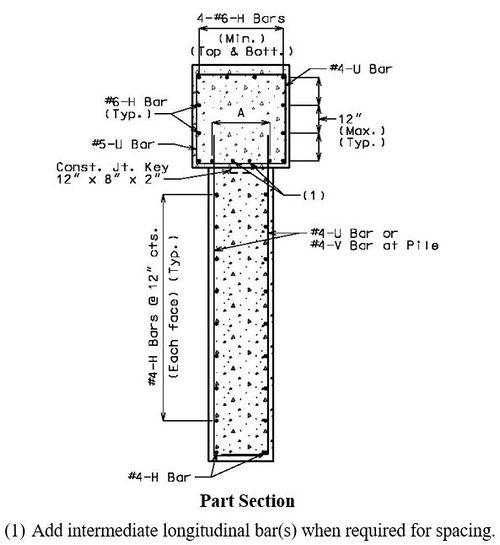

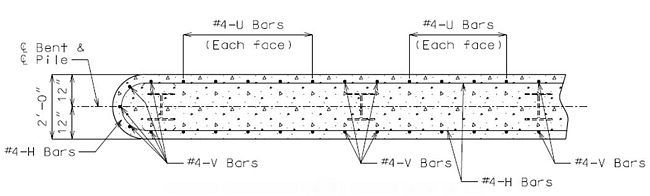

751.32.4.2 Encased Pile Cap Bent

Supplemental details for encased pile cap bents are provided.

| Note: | When dimension “A” is greater than 18” add intermediate longitudal bar(s) between piles. Ends of bar(s) shall be hooked. Keep 3” minimum clearance between the pile and intermediate bar(s) and do not show on the plans. |

| Part Plan |

| Note: | Locate #4 bars " |

| For epoxy coated reinforcement requirements, see EPG 751.5.9.2.2 Epoxy Coated Reinforcement Requirements. Details of protective coating and sloping top of beam to drain shall be used when below an expansion device. |