Difference between revisions of "751.14 Steel Superstructure"

m (→751.14.5 Details: re-sized figures) |

(→751.14.4.5 Shear Connector Details: updated per RR3912) |

||

| (47 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| + | [[image:751.14.jpg|right|295px]] | ||

== 751.14.1 General == | == 751.14.1 General == | ||

| Line 22: | Line 23: | ||

When calculating the weight of splice, the following simplified weight shall be used. | When calculating the weight of splice, the following simplified weight shall be used. | ||

| − | Weight per ( | + | Weight per bolt incl. nut (7/8” diameter ASTM F3125 Grade A325 bolt with A563 nut) = 0.95 lb |

| Line 44: | Line 45: | ||

{| | {| | ||

| − | + | |Splices - 7/8” diameter ASTM F3125 Grade A325 Bolt||<math>\, F_{ub}</math>||=120 ksi | |

|- | |- | ||

| − | + | |Diaphragms - 3/4” diameter ASTM F3125 Grade A325 Bolt||<math>\, F_{ub}</math>||=120 ksi | |

|} | |} | ||

| Line 78: | Line 79: | ||

|AASHTO M169 (ASTM A108), ||width="10%"| ||<math>\,F_y</math>|| = 50 ksi||width="10%"| ||<math>\,F_u</math>|| = 60 ksi | |AASHTO M169 (ASTM A108), ||width="10%"| ||<math>\,F_y</math>|| = 50 ksi||width="10%"| ||<math>\,F_u</math>|| = 60 ksi | ||

|} | |} | ||

| + | |||

=== 751.14.1.2 Girder Limits and Preferences === | === 751.14.1.2 Girder Limits and Preferences === | ||

| Line 253: | Line 255: | ||

'''Number of girders.''' For consideration of future stage construction, there may be a minimum number of girders that should be considered. | '''Number of girders.''' For consideration of future stage construction, there may be a minimum number of girders that should be considered. | ||

| − | '''Maximum | + | '''Maximum Form Span.''' Precast panels and transparent forms have maximum span limits that should not be exceeded. For cases where conventional forms or corrugated steel forms are used, it is generally recognized that 12 ft girder spacing is a maximum practical limit to allow for future redecking. |

'''Vertical Clearance and Deflection Requirements.''' It is expected that fewer girder lines would result in deeper girders. Vertical clearance or deflection constraints may dictate the use of more girder lines than optimum, or a shallower web than optimum. | '''Vertical Clearance and Deflection Requirements.''' It is expected that fewer girder lines would result in deeper girders. Vertical clearance or deflection constraints may dictate the use of more girder lines than optimum, or a shallower web than optimum. | ||

| Line 298: | Line 300: | ||

::For constant amplitude fatigue threshold (∆F)TH, see LRFD Table 6.6.1.2.3-1 for applicable detail. For base metal, except noncoated weathering steel, detail category “A” (∆F)TH = 24 ksi and for base metal, noncoated weathering steel, detail category “B” (∆F)TH = 16 ksi. | ::For constant amplitude fatigue threshold (∆F)TH, see LRFD Table 6.6.1.2.3-1 for applicable detail. For base metal, except noncoated weathering steel, detail category “A” (∆F)TH = 24 ksi and for base metal, noncoated weathering steel, detail category “B” (∆F)TH = 16 ksi. | ||

| − | Combination for loads during construction and construction loads shall be evaluated at the Strength Limit State and Service Limit State in accordance with [ | + | Combination for loads during construction and construction loads shall be evaluated at the Strength Limit State and Service Limit State in accordance with [https://epg.modot.org/index.php?title=751.2_Loads#751.2.3.2_Load_Combinations EPG 751.2.3.2] and LRFD 3.4.2. |

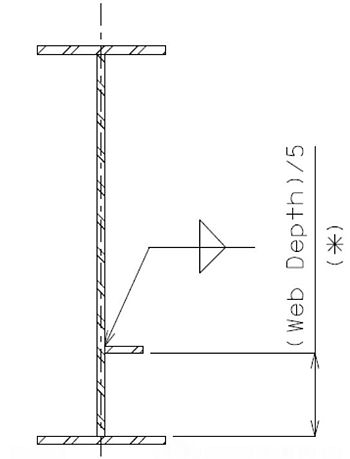

(*) Use for bridges with high DL to LL ratios. Typically, bridges with spans > 200 ft. | (*) Use for bridges with high DL to LL ratios. Typically, bridges with spans > 200 ft. | ||

| Line 317: | Line 319: | ||

The elastic stress at any location on the composite section due to the applied loads shall be the sum of the stresses caused by the loads applied separately at the following three stages: | The elastic stress at any location on the composite section due to the applied loads shall be the sum of the stresses caused by the loads applied separately at the following three stages: | ||

| − | '''Non-Composite Stage –''' The dead load of slab and haunching and | + | '''Non-Composite Stage –''' The dead load of slab and haunching and beam self weight shall be analyzed at this stage. This stage shall also be used for any construction loading checks. The section properties used are of the steel section only. |

| − | '''Long Term Composite Stage –''' The dead load of barrier | + | '''Long Term Composite Stage –''' The dead load of barrier or railing, future wearing surface and any other appurtenances shall be analyzed at this stage. The section properties used are of the composite section of slab and beam assuming an elastic modulus of 3n for the slab. Where “n” is the modular ratio. |

| − | '''Short Term Composite Stage –''' Any live loading shall be analyzed at this stage. The section properties used are of the composite section of slab and | + | '''Short Term Composite Stage –''' Any live loading shall be analyzed at this stage. The section properties used are of the composite section of slab and beam assuming an elastic modulus of “n” for the slab. Where “n” is the modular ratio. |

Composite regions shall be defined as regions where shear connectors are used to connect the steel section to a concrete deck. Simple spans and horizontally curved girders (see below) are designed as composite throughout. | Composite regions shall be defined as regions where shear connectors are used to connect the steel section to a concrete deck. Simple spans and horizontally curved girders (see below) are designed as composite throughout. | ||

| + | <div id="Tension Flanges with Holes"></div> | ||

| + | '''Tension Flanges with Holes''' | ||

| − | + | Compact Design is not allowed in composite positive flexure regions where holes are located in the tension flange. Similarly, in negative flexure regions where holes are present in the tension flange the girders shall not be proportioned with compact or noncompact webs in accordance with LRFD Appendix A6. The placement of bolted field splices near DL contraflexure points will not preclude the use of compact design or LRFD Appendix A6 in adjacent regions. Girders with holes in the tension flange shall further meet the requirements of LRFD 6.10.1.8 Tension Flanges with Holes. | |

| − | |||

| − | Compact Design | ||

| Line 560: | Line 562: | ||

Bolted splices for flexural members shall be designed using slip-critical connections as specified in LRFD 6.13.2.1.1. The connections shall also be proportioned to prevent slip during the erection of the steel and during the casting of the concrete deck. | Bolted splices for flexural members shall be designed using slip-critical connections as specified in LRFD 6.13.2.1.1. The connections shall also be proportioned to prevent slip during the erection of the steel and during the casting of the concrete deck. | ||

| − | The tensile stress on the flange should be checked | + | The tensile stress on the flange should be checked per LRFD 6.10.1.8. |

In bolted slip-critical connections subject to shear, the load is transferred between the connected parts by friction up to a certain level of force that is dependent upon the total clamping force on the faying surfaces and the coefficient of friction of the faying surfaces. As loading is increased to a level in excess of the frictional resistance between the faying surfaces, slip occurs, but failure in the sense does not occur. As a result, slip critical connections are able to resist even greater loads by shear and bearing against the connected material. The strength of the connection is not related to the slip load. Slip resistance, shear resistance and bending shall be computed separately. Any potential greater resistance due to combined effect is ignored. | In bolted slip-critical connections subject to shear, the load is transferred between the connected parts by friction up to a certain level of force that is dependent upon the total clamping force on the faying surfaces and the coefficient of friction of the faying surfaces. As loading is increased to a level in excess of the frictional resistance between the faying surfaces, slip occurs, but failure in the sense does not occur. As a result, slip critical connections are able to resist even greater loads by shear and bearing against the connected material. The strength of the connection is not related to the slip load. Slip resistance, shear resistance and bending shall be computed separately. Any potential greater resistance due to combined effect is ignored. | ||

| Line 568: | Line 570: | ||

'''Slip Resistance''' | '''Slip Resistance''' | ||

| − | + | {|style="padding: 0.3em; margin-left:15px; border:2px solid #a9a9a9; text-align:left; font-size: 95%; background:#f5f5f5" width="300px" align="right" | |

| − | Splices shall be designed as slip critical connections with Class B surface preparation and standard holes. Slip shall be checked against the maximum of the Service-II limit stresses and the Strength-I construction stresses due to slab pouring sequences. All splice bolts shall be 7/8” diameter ASTM A325 | + | |- |

| + | |See [https://www.modot.org/structural-engineering-guidance SEG 20-02] for Galvanized Bolted Connection Design Requirements. | ||

| + | |} | ||

| + | Splices shall be designed as slip critical connections with Class B surface preparation and standard holes. Slip shall be checked against the maximum of the Service-II limit stresses and the Strength-I construction stresses due to slab pouring sequences. All splice bolts shall be 7/8” diameter ASTM F3125 Grade A325 bolts with a minimum pretension of 39 kips upon girder erection. | ||

'''Shear Resistance''' | '''Shear Resistance''' | ||

| − | The Bolt Shear Resistance shall be adequate to resist loads at the Strength-I limit state. | + | The Bolt Shear Resistance shall be adequate to resist loads at the Strength-I limit state. (See [[#751.14.3.1 Loads|Loads]] in this article.) |

If a filler plate not less than 0.25” in thickness is used in a flange splice then the Bolt Shear Resistance shall be reduced by the following factor: | If a filler plate not less than 0.25” in thickness is used in a flange splice then the Bolt Shear Resistance shall be reduced by the following factor: | ||

| Line 605: | Line 610: | ||

|colspan="2"| ||valign="top"|Note:||The washer may be located under the nut or bolt head. | |colspan="2"| ||valign="top"|Note:||The washer may be located under the nut or bolt head. | ||

|- | |- | ||

| − | !colspan="2"| ||valign="top" colspan="2"|Critical dimensions for checking thread exclusion<br/>in 7/8” diameter | + | !colspan="2"| ||valign="top" colspan="2"|Critical dimensions for checking thread exclusion<br/>in 7/8” diameter ASTM F3125 Grade A325 bolted connections. |

|} | |} | ||

| Line 621: | Line 626: | ||

Uniform bolt patterns are preferred in all cases except that a staggered pattern may be used for flanges that are 14 and 15 inches wide. A staggered bolt pattern reduces the distance between rows of bolts so panels can be placed along the edges of the plate. | Uniform bolt patterns are preferred in all cases except that a staggered pattern may be used for flanges that are 14 and 15 inches wide. A staggered bolt pattern reduces the distance between rows of bolts so panels can be placed along the edges of the plate. | ||

| − | Bolt tightening clearances may become a problem for thick | + | Bolt tightening clearances may become a problem for thick inner flange splice plates or flange bolt patterns that use a narrow bolt gauge, I, across the web. A thorough review is required to ensure that a 2.5” diameter socket with 1/16” clearance can be used. Typically, when bolt tightening clearances are an issue the bolt gauge, I, needs to be increased but the sealing check shall not be violated. If increasing the bolt gauge is not an option the clearance to web bolts, e, shall be increased the minimum extent necessary to maintain a practical uniform web bolt pattern. |

| − | |||

<center>[[Image:751.14 flange bolt patterns-uniform bolt pattern.gif]]</center> | <center>[[Image:751.14 flange bolt patterns-uniform bolt pattern.gif]]</center> | ||

| Line 651: | Line 655: | ||

# Inner splice plates shall be symmetric for uniform bolt patterns. | # Inner splice plates shall be symmetric for uniform bolt patterns. | ||

| − | + | <div id="751.14.3.1 Loads"></div> | |

'''Loads''' | '''Loads''' | ||

* '''Strength I''' - Splice plates shall be designed to resist a minimum design stress equal to the average of the factored elastic flexural stress at the mid-depth of the flange and the yield strength of the flange <math>\,(F_{yf})</math>, but shall not be less than <math>\, 0.75 F_{yf}</math>. | * '''Strength I''' - Splice plates shall be designed to resist a minimum design stress equal to the average of the factored elastic flexural stress at the mid-depth of the flange and the yield strength of the flange <math>\,(F_{yf})</math>, but shall not be less than <math>\, 0.75 F_{yf}</math>. | ||

| Line 2,881: | Line 2,885: | ||

=== 751.14.3.4 Wide Flange Splice Tables === | === 751.14.3.4 Wide Flange Splice Tables === | ||

| + | Note: In the 15<sup>th</sup> edition of the AISC Steel Construction Manual (2017) the k1 values for many w-shapes increased. The k1 dimension is the distance between the centerline of web and the toe of the fillet into the flange. The inner plates below were designed before this change and as designed may encroach on the toe of the flange fillet. Before using one of the tabulated wide flange splice designs the inner plate shall be checked to ensure it does not encroach on the toe of the flange fillet. | ||

| Line 2,918: | Line 2,923: | ||

|width="40pt"|m | |width="40pt"|m | ||

|- | |- | ||

| − | |rowspan="2"|W27x84**||< 1/4"||10||0.375||18.5||3.5||0.5||18.5||2||19.5||21.75||0.4375||3|| | + | |rowspan="2"|W27x84**||< 1/4"||10||0.375||18.5||3.5||0.5||18.5||2||19.5||21.75||0.4375||3||60||238.3 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||10||0.375||24.5||3.5||0.5||24.5||3||19.5||21.75||0.4375||3|| | + | |other||10||0.375||24.5||3.5||0.5||24.5||3||19.5||21.75||0.4375||3||68||270.6 |

|- | |- | ||

| − | |rowspan="2"|W27x94**||< 1/4"||10||0.5||24.5||3.5||0.625||24.5||3||25.5||21.75||0.5||4|| | + | |rowspan="2"|W27x94**||< 1/4"||10||0.5||24.5||3.5||0.625||24.5||3||25.5||21.75||0.5||4||80||363.5 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||10||0.5||30.5||3.5||0.625||30.5||4||25.5||21.75||0.5||4|| | + | |other||10||0.5||30.5||3.5||0.625||30.5||4||25.5||21.75||0.5||4||88||403.0 |

|- | |- | ||

| − | |rowspan="2"|W27x102**||< 1/4"||10||0.5||24.5||3.5||0.625||24.5||3||25.5||21.75||0.5625||4|| | + | |rowspan="2"|W27x102**||< 1/4"||10||0.5||24.5||3.5||0.625||24.5||3||25.5||21.75||0.5625||4||80||383.2 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

|- | |- | ||

| − | |rowspan="2"|W27x114**||< 1/4"||10||0.5||24.5||3.5||0.75||24.5||3||25.5||21.75||0.5625||4|| | + | |rowspan="2"|W27x114**||< 1/4"||10||0.5||24.5||3.5||0.75||24.5||3||25.5||21.75||0.5625||4||80||395.4 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

|- | |- | ||

| − | |rowspan="2"|W27x129**||< 1/4"||10||0.5625||30.5||3.5||0.875||30.5|| | + | |rowspan="2"|W27x129**||< 1/4"||10||0.5625||30.5||3.5||0.875||30.5||4||31.5||21.75||0.6875||5||100||565.4 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

| Line 2,940: | Line 2,945: | ||

|colspan="15"|** Denotes flange widths less than 12” where P/S Panel placement should be thoroughly investigated. | |colspan="15"|** Denotes flange widths less than 12” where P/S Panel placement should be thoroughly investigated. | ||

|} | |} | ||

| + | |||

| Line 2,978: | Line 2,984: | ||

|width="40pt"|m | |width="40pt"|m | ||

|- | |- | ||

| − | |rowspan="2"|W30x90**||< 1/4"||10.5||0.375||18.5||3.5||0.5||18.5||2||19.5||24||0.4375||3|| | + | |rowspan="2"|W30x90**||< 1/4"||10.5||0.375||18.5||3.5||0.5||18.5||2||19.5||24||0.4375||3||72||262.6 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||10.5||0.375||30.5||3.5||0.5||30.5||4||19.5||24||0.4375||3|| | + | |other||10.5||0.375||30.5||3.5||0.5||30.5||4||19.5||24||0.4375||3||88||328.4 |

|- | |- | ||

| − | |rowspan="2"|W30x99**||< 1/4"||10.5||0.375||24.5||3.5||0.5||24.5||3||19.5||24||0.5||3|| | + | |rowspan="2"|W30x99**||< 1/4"||10.5||0.375||24.5||3.5||0.5||24.5||3||19.5||24||0.5||3||80||312.0 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||10.5||0.375||30.5||3.5||0.5||30.5||4||19.5||24||0.5||3|| | + | |other||10.5||0.375||30.5||3.5||0.5||30.5||4||19.5||24||0.5||3||88||345.0 |

|- | |- | ||

| − | |rowspan="2"|W30x108**||< 1/4"||10.5||0.5||24.5||3.5||0.625||24.5||3||19.5||24||0.5||3|| | + | |rowspan="2"|W30x108**||< 1/4"||10.5||0.5||24.5||3.5||0.625||24.5||3||19.5||24||0.5||3||80||342.4 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||10.5||0.5||36.5||3.5||0.625||36.5||5||19.5||24||0.5||3|| | + | |other||10.5||0.5||36.5||3.5||0.625||36.5||5||19.5||24||0.5||3||96||423.1 |

|- | |- | ||

| − | |rowspan="2"|W30x116**||< 1/4"||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4|| | + | |rowspan="2"|W30x116**||< 1/4"||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4||104||475.7 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4|| | + | |other||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4||104||475.7 |

|- | |- | ||

| − | |rowspan="2"|W30x124**||< 1/4"||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4|| | + | |rowspan="2"|W30x124**||< 1/4"||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4||104||475.7 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4|| | + | |other||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.5625||4||104||475.7 |

|- | |- | ||

| − | |rowspan="2"|W30x132**||< 1/4"||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.625||4|| | + | |rowspan="2"|W30x132**||< 1/4"||10.5||0.5||30.5||3.5||0.75||30.5||4||25.5||24||0.625||4||104||497.4 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

|- | |- | ||

| − | |rowspan="2"|W30x148**||< 1/4"||10.5||0.625||36.5||3.5||0.875||36.5||5||25.5||24||0.625||4|| | + | |rowspan="2"|W30x148**||< 1/4"||10.5||0.625||36.5||3.5||0.875||36.5||5||25.5||24||0.625||4||112||586.0 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

| Line 3,046: | Line 3,052: | ||

|width="40pt"|m | |width="40pt"|m | ||

|- | |- | ||

| − | |rowspan="2"|W33x118**||< 1/4"||11.5||0.5||30.5||3.5||0.625||30.5||4||19.5||27||0.5||3|| | + | |rowspan="2"|W33x118**||< 1/4"||11.5||0.5||30.5||3.5||0.625||30.5||4||19.5||27||0.5||3||94||413.7 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||11.5||0.5||36.5||3.5||0.625||36.5||5||19.5||27||0.5||3|| | + | |other||11.5||0.5||36.5||3.5||0.625||36.5||5||19.5||27||0.5||3||102||455.8 |

|- | |- | ||

| − | |rowspan="2"|W33x130**||< 1/4"||11.5||0.5||30.5||3.5||0.75||30.5||4||25.5||27||0.5625||4|| | + | |rowspan="2"|W33x130**||< 1/4"||11.5||0.5||30.5||3.5||0.75||30.5||4||25.5||27||0.5625||4||112||516.3 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||11.5||0.5||42.5||3.5||0.75||42.5||6||25.5||27||0.5625||4|| | + | |other||11.5||0.5||42.5||3.5||0.75||42.5||6||25.5||27||0.5625||4||128||606.4 |

|- | |- | ||

| − | |rowspan="2"|W33x141**||< 1/4"||11.5||0.625||36.5||3.5||0.875||36.5||5||25.5||27||0.5625||4|| | + | |rowspan="2"|W33x141**||< 1/4"||11.5||0.625||36.5||3.5||0.875||36.5||5||25.5||27||0.5625||4||120||609.2 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||11.5||0.625||42.5||3.5||0.875||42.5||6||25.5||27||0.5625||4|| | + | |other||11.5||0.625||42.5||3.5||0.875||42.5||6||25.5||27||0.5625||4||128||662.1 |

|- | |- | ||

| − | |rowspan="2"|W33x152**||< 1/4"||11.5||0.625||36.5||3.5||0.875||36.5||5||25.5||27||0.625||4|| | + | |rowspan="2"|W33x152**||< 1/4"||11.5||0.625||36.5||3.5||0.875||36.5||5||25.5||27||0.625||4||120||633.6 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

|- | |- | ||

| − | |rowspan="2"|W33x169**||< 1/4"||11.5||0.625||36.5||3.5||1||36.5||5||25.5||27||0.625||4|| | + | |rowspan="2"|W33x169**||< 1/4"||11.5||0.625||36.5||3.5||1||36.5||5||25.5||27||0.625||4||120||651.7 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

| Line 3,108: | Line 3,114: | ||

|width="40pt"|m | |width="40pt"|m | ||

|- | |- | ||

| − | |rowspan="2"|W33x201||< 1/4"||15.75||0.625||24.5||6||0.875||24.5||2||5.75||3||24.5||27||0.6875||4|| | + | |rowspan="2"|W33x201||< 1/4"||15.75||0.625||24.5||6||0.875||24.5||2||5.75||3||24.5||27||0.6875||4||136||669.8 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | |other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | ||

|- | |- | ||

| − | |rowspan="2"|W33x221||< 1/4"||15.75||0.75||30.5||6||0.875||30.5||2||5.75||4||30.5||27||0.75||5|| | + | |rowspan="2"|W33x221||< 1/4"||15.75||0.75||30.5||6||0.875||30.5||2||5.75||4||30.5||27||0.75||5||170||897.7 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | |other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | ||

| Line 3,154: | Line 3,160: | ||

|width="40pt"|m | |width="40pt"|m | ||

|- | |- | ||

| − | |rowspan="2"|W36x135||< 1/4"||12||0.625||30.5||4||0.625||30.5||4||19.5||30||0.5||3|| | + | |rowspan="2"|W36x135||< 1/4"||12||0.625||30.5||4||0.625||30.5||4||19.5||30||0.5||3||100||477.1 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||12||0.625||42.5||4||0.625||42.5||6||19.5||30||0.5||3|| | + | |other||12||0.625||42.5||4||0.625||42.5||6||19.5||30||0.5||3||116||577.4 |

|- | |- | ||

| − | |rowspan="2"|W36x150||< 1/4"||12||0.625||36.5||4||0.75||36.5||5||25.5||30||0.5625||4|| | + | |rowspan="2"|W36x150||< 1/4"||12||0.625||36.5||4||0.75||36.5||5||25.5||30||0.5625||4||128||645.1 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||12||0.625||42.5||4||0.75||42.5||6||25.5||30||0.5625||4|| | + | |other||12||0.625||42.5||4||0.75||42.5||6||25.5||30||0.5625||4||136||698.6 |

|- | |- | ||

| − | |rowspan="2"|W36x160||< 1/4"||12||0.625||36.5||4||0.875||36.5||5||25.5||30||0.5625||4|| | + | |rowspan="2"|W36x160||< 1/4"||12||0.625||36.5||4||0.875||36.5||5||25.5||30||0.5625||4||128||665.8 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

|- | |- | ||

| − | |rowspan="2"|W36x170||< 1/4"||12||0.625||36.5||4||0.875||36.5||5||25.5||30||0.5625||4|| | + | |rowspan="2"|W36x170||< 1/4"||12||0.625||36.5||4||0.875||36.5||5||25.5||30||0.5625||4||128||665.8 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

|- | |- | ||

| − | |rowspan="2"|W36x182||< 1/4"||12||0.75||42.5||4||1||42.5||6||25.5||30||0.625||4|| | + | |rowspan="2"|W36x182||< 1/4"||12||0.75||42.5||4||1||42.5||6||25.5||30||0.625||4||136||810.1 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

|- | |- | ||

| − | |rowspan="2"|W36x194||< 1/4"||12||0.75||42.5||4||1||42.5||6||25.5||30||0.625||4|| | + | |rowspan="2"|W36x194||< 1/4"||12||0.75||42.5||4||1||42.5||6||25.5||30||0.625||4||136||810.1 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | |other||colspan="13"|----------------------------------------- Design by Hand ------------------------------------------ | ||

| Line 3,218: | Line 3,224: | ||

|width="40pt"|m | |width="40pt"|m | ||

|- | |- | ||

| − | |rowspan="2"|W40x149**||< 1/4"||11.75||0.625||30.5||3.5||0.75||30.5||2.625||6.5||4||19.5||33||0.4375||3|| | + | |rowspan="2"|W40x149**||< 1/4"||11.75||0.625||30.5||3.5||0.75||30.5||2.625||6.5||4||19.5||33||0.4375||3||106||478.2 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||11.75||0.625||42.5||3.5||0.75||42.5||2.625||6.5||6||19.5||33||0.4375||3|| | + | |other||11.75||0.625||42.5||3.5||0.75||42.5||2.625||6.5||6||19.5||33||0.4375||3||122||579.1 |

|- | |- | ||

| − | |rowspan="2"|W40x167**||< 1/4"||11.75||0.75||36.5||3.5||1||36.5||2.5||6.75||5||25.5||33||0.5||4|| | + | |rowspan="2"|W40x167**||< 1/4"||11.75||0.75||36.5||3.5||1||36.5||2.5||6.75||5||25.5||33||0.5||4||136||695.1 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||11.75||0.75||48.5||3.5||1||48.5||2.5||6.75||7||25.5||33||0.5||4|| | + | |other||11.75||0.75||48.5||3.5||1||48.5||2.5||6.75||7||25.5||33||0.5||4||152||818.0 |

|- | |- | ||

| − | |rowspan="2"|W40x183**||< 1/4"||11.75||0.75||42.5||3.5||1.125||42.5||2.5||6.75||6||25.5||33||0.5||4|| | + | |rowspan="2"|W40x183**||< 1/4"||11.75||0.75||42.5||3.5||1.125||42.5||2.5||6.75||6||25.5||33||0.5||4||144||777.6 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

| − | |other||11.75||0.75||42.5||3.5||1.125||42.5||2.5||6.75||6||25.5||33||0.5||4|| | + | |other||11.75||0.75||42.5||3.5||1.125||42.5||2.5||6.75||6||25.5||33||0.5||4||144||777.6 |

|- | |- | ||

| − | |rowspan="2"|W40x199***||< 1/4"||15.75||0.625||24.5||5.75||0.75||24.5||2||6.25||3||25.5||33||0.5||4|| | + | |rowspan="2"|W40x199***||< 1/4"||15.75||0.625||24.5||5.75||0.75||24.5||2||6.25||3||25.5||33||0.5||4||152||639.6 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | |other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | ||

|- | |- | ||

| − | |rowspan="2"|W40x211**||< 1/4"||11.75||0.75||48.5||3.5||1.25||48.5||2.5||6.75||7||25.5||33||0.625||4|| | + | |rowspan="2"|W40x211**||< 1/4"||11.75||0.75||48.5||3.5||1.25||48.5||2.5||6.75||7||25.5||33||0.625||4||152||925.7 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | |other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | ||

|- | |- | ||

| − | |rowspan="2"|W40x215***||< 1/4"||15.75||0.625||30.5||5.75||0.875||30.5||2||6.25||4||25.5||33||0.5625||4|| | + | |rowspan="2"|W40x215***||< 1/4"||15.75||0.625||30.5||5.75||0.875||30.5||2||6.25||4||25.5||33||0.5625||4||168||772.4 |

|-style="background:yellow;" | |-style="background:yellow;" | ||

|other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | |other||colspan="15"|------------------------------------------------------- Design by Hand -------------------------------------------------------- | ||

| Line 3,302: | Line 3,308: | ||

The pitch of shear connectors shall be determined to satisfy the fatigue limit state, and the resulting number of shear connectors shall not be less than the number required to satisfy the strength limit state. | The pitch of shear connectors shall be determined to satisfy the fatigue limit state, and the resulting number of shear connectors shall not be less than the number required to satisfy the strength limit state. | ||

| − | |||

| − | |||

Cross-section properties are based on the transformed short-term composite section. Cross-section properties of the composite section shall include concrete slab and steel section. Longitudinal deck reinforcement shall not be considered to be a part of the composite section. Cross-section properties of the non-composite section shall include the steel section only. Negative flexure regions in horizontally curved girders may include the steel reinforcement in the composite section. | Cross-section properties are based on the transformed short-term composite section. Cross-section properties of the composite section shall include concrete slab and steel section. Longitudinal deck reinforcement shall not be considered to be a part of the composite section. Cross-section properties of the non-composite section shall include the steel section only. Negative flexure regions in horizontally curved girders may include the steel reinforcement in the composite section. | ||

| Line 3,311: | Line 3,315: | ||

The effective flange widths for calculating composite sections for interior and exterior girders should be determined by LRFD 4.6.2.6 prior to beginning shear connector design. In order to have a uniform and conservative shear connector design for all girders, the smaller effective flange width, between the interior and exterior girders, should only be used to locate the acceptable areas for placement of additional connectors near point of dead load contraflexure. The larger effective flange width should be used in all other calculations. | The effective flange widths for calculating composite sections for interior and exterior girders should be determined by LRFD 4.6.2.6 prior to beginning shear connector design. In order to have a uniform and conservative shear connector design for all girders, the smaller effective flange width, between the interior and exterior girders, should only be used to locate the acceptable areas for placement of additional connectors near point of dead load contraflexure. The larger effective flange width should be used in all other calculations. | ||

| + | An effective slab thickness shall be used for composite design by deducting from the actual slab thickness a 1” integral, sacrificial wearing surface. | ||

| + | |||

| + | <u>New Bridges or Replacement of Existing Superstructures</u> | ||

| + | |||

| + | The regions of the bridge subjected to positive flexure are to be designed as composite and the regions subjected to negative flexure are to be designed as non-composite. Simple span composite bridges shall be provided with shear connectors throughout the length of the span. Continuous composite bridges are to be designed with shear connectors provided in the positive flexure regions only, with additional connectors required in the regions of permanent load contraflexure. Horizontally curved girders require shear connectors throughout the girder length. | ||

| + | |||

| + | For the initial girder design, composite/noncomposite regions can be approximately assumed as: | ||

| + | <center> | ||

| + | |||

| + | [[Image:751.40 Widen and Repair Design Assumptions- Initial Girder Design.gif|680px]] | ||

| + | </center> | ||

| + | |||

| + | <u>Redeckings</u> | ||

| + | |||

| + | If existing bridge is partially composite, then leave as partially composite unless making full-length composite will reduce or eliminate a load posting subject to Structural Project Manager or Structural Liaison Engineer approval. If the existing bridge is not composite, then make it full-length composite since this will give the maximum capacity of the bridge for the next service life cycle. This guidance applies to either LRFD or LFD redecking designs. Shear connector design should follow same design code used for redecking. | ||

'''Design Loading''' | '''Design Loading''' | ||

| Line 3,372: | Line 3,391: | ||

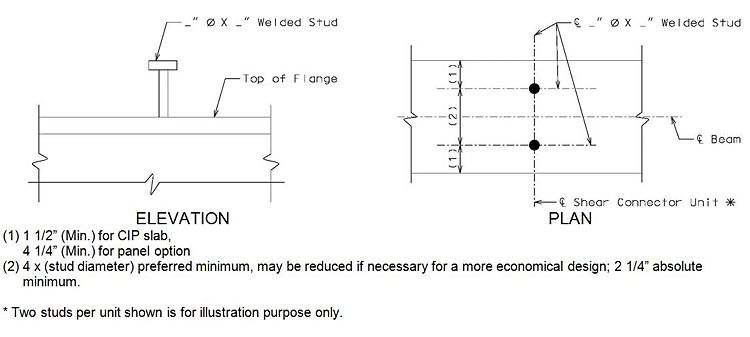

Shear connectors shall be placed by units. A shear connector unit refers to all shear connectors in a given cross-section, spaced transversely across the top flange. Multiple shear connectors per unit may be used if spacing and clearances allow. For horizontally curved girders, when practical, a consistent unit layout and pitch shall be used throughout the span. | Shear connectors shall be placed by units. A shear connector unit refers to all shear connectors in a given cross-section, spaced transversely across the top flange. Multiple shear connectors per unit may be used if spacing and clearances allow. For horizontally curved girders, when practical, a consistent unit layout and pitch shall be used throughout the span. | ||

| + | |||

| + | '''Shear Connector Spacing''' | ||

| + | |||

| + | If it becomes impractical to place the number of shear connectors required by ultimate strength in the specified distance (structures with span ratios greater than 1.5); base the number and spacing of shear connectors on the fatigue analysis only. | ||

| + | |||

| + | For a typical 3-span bridge, the shear connector units can be approximately arranged as below: | ||

| + | |||

| + | [[Image:751.40 Widen and Repair Design Assumptions- Shear Connectors Spacing 2 2 1.gif|center]] | ||

=== 751.14.4.3 Fatigue Design === | === 751.14.4.3 Fatigue Design === | ||

| Line 3,659: | Line 3,686: | ||

!colspan="2" valign="top"|Plan | !colspan="2" valign="top"|Plan | ||

|align="right" valign="top"|[[Image:751.14 circled 4.gif]] | |align="right" valign="top"|[[Image:751.14 circled 4.gif]] | ||

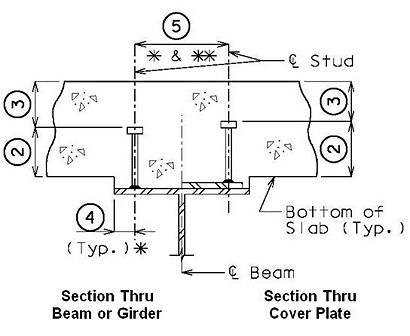

| − | |align="left" valign="top colspan="2"|1 1/2" (Min.) CIP slab | + | |align="left" valign="top colspan="2"|1 1/2" (Min.) CIP slab <br/>4 1/4" (Min.) panel option |

|- | |- | ||

| − | |colspan="2" rowspan="4"|[[Image:751.14 section thru | + | |colspan="2" rowspan="4"|[[Image:751.14.4.5 section thru.jpg|410px]] |

|align="right" valign="top"|[[Image:751.14 circled 5.gif]] | |align="right" valign="top"|[[Image:751.14 circled 5.gif]] | ||

|align="left" valign="top colspan="2"|4 x (Stud diameter) preferred minimum, may be reduced if necessary for a more economical design; 2 1/4" absolute minimum. | |align="left" valign="top colspan="2"|4 x (Stud diameter) preferred minimum, may be reduced if necessary for a more economical design; 2 1/4" absolute minimum. | ||

|- | |- | ||

| − | |align="right"| | + | |align="right"|'''*''' |

|align="left" colspan="2"|Dimensions are not for detailing purposes. | |align="left" colspan="2"|Dimensions are not for detailing purposes. | ||

|- | |- | ||

| − | |align="right"| | + | |align="right"|'''**''' |

|align="left" colspan="2"|Requires the same dimension throughout the span. | |align="left" colspan="2"|Requires the same dimension throughout the span. | ||

|- | |- | ||

| Line 3,674: | Line 3,701: | ||

{|border="1" cellspacing="0" | {|border="1" cellspacing="0" | ||

|- | |- | ||

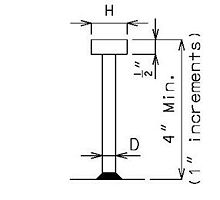

| − | !width="75pt"| | + | !width="75pt"|D||width="75pt"|H |

|- | |- | ||

|3/4"||1 1/4" | |3/4"||1 1/4" | ||

| Line 3,680: | Line 3,707: | ||

|7/8"||1 3/8" | |7/8"||1 3/8" | ||

|} | |} | ||

| − | |align="left"|[[Image:751.14 | + | |align="left"|[[Image:751.14.4.5 D and H.jpg|220px]] |

|- | |- | ||

| − | |||

| − | |||

|colspan="3"| | |colspan="3"| | ||

|} | |} | ||

| Line 3,690: | Line 3,715: | ||

{|border="1" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | {|border="1" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | ||

|- | |- | ||

| − | |colspan="4"| | + | |colspan="4"|Minimum Flange Width For<br/>Given Rows of Studs (in.)<br/>(For decks utilizing prestressed panels) |

|colspan="5"|Weight in Place<br/>Per 100 Studs (lbs) | |colspan="5"|Weight in Place<br/>Per 100 Studs (lbs) | ||

|- | |- | ||

| Line 3,729: | Line 3,754: | ||

|17.50 | |17.50 | ||

|19.00 | |19.00 | ||

| − | |||

| − | |||

|} | |} | ||

| Line 3,737: | Line 3,760: | ||

|- | |- | ||

|rowspan="2"|[[Image:751.14 section thru haunch showing shear connectors.gif]] | |rowspan="2"|[[Image:751.14 section thru haunch showing shear connectors.gif]] | ||

| − | |||

| − | |||

|- | |- | ||

|[[Image:751.14 clearance at expansion device for shear connectors.gif]] | |[[Image:751.14 clearance at expansion device for shear connectors.gif]] | ||

| Line 3,747: | Line 3,768: | ||

!Clearance at<br/>Splice Plate | !Clearance at<br/>Splice Plate | ||

|} | |} | ||

| + | ::[[Image:751.14 circled 6.gif]] For redecks of existing composite bridges #4 hairpin bars required if depth exceeds 2" for existing 4" shear connectors and 3" for existing 5" shear connectors. For new bridges and redecks of non-composite bridges, studs shall provide a minimum 2” slab embedment avoiding the need of hairpin bars. | ||

| − | |||

| + | '''Shear Connector Unit''' | ||

| + | |||

| + | [[image:751.14.4.5 shear connector.jpg|center|750px]] | ||

| + | |||

| + | |||

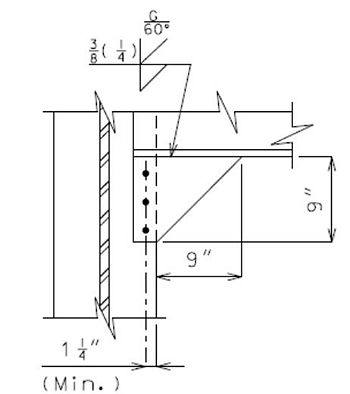

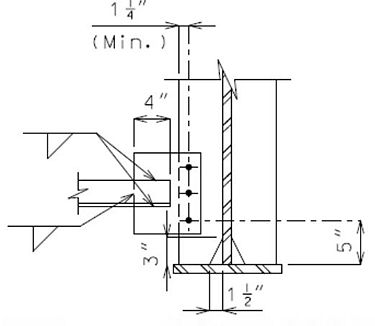

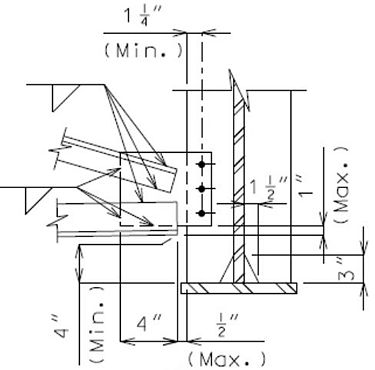

| + | '''P/C P/S Panel Forms on Steel Structures''' | ||

| + | |||

| + | Evaluate the viability of the use of P/S panels on tangent and curved structures on a case by case basis and use or include as an option to a CIP slab where deemed appropriate. | ||

| + | |||

| + | Whenever panels are used, the minimum top flange width shall be 12" for plate girders and 10" for wide flange beams. | ||

| + | |||

| + | Steel girders shall be cambered when using P/S Panels. Minimum joint filler thickness is 1", except over splice plates, in which case use 1/4" minimum. Maximum joint filler thickness is 2", except over splice plates, in which case use 1". | ||

| + | |||

| + | Shear connectors shall have a minimum height equal to the top of panel. | ||

| + | |||

| + | Shear connectors shall be spaced by units and shear connectors in each unit shall be placed along centerline (<math>\, C_{\!\!\!\!L}</math>) of girder. On wide flange widths, two lines of connectors may be used if spacings and clearances allow. | ||

| + | |||

| + | Additional shear connectors, N<sub>ac</sub>, at point of contraflexure may be placed in units normal to centerline of girder as space allows or in a single row along centerline of girder as shown below: | ||

| + | |||

| + | <center> | ||

| + | [[Image:751.40 Widen and Repair Design Assumptions- PCP on Steel Shear Connector.gif]] | ||

| + | </center> | ||

| + | |||

| + | |||

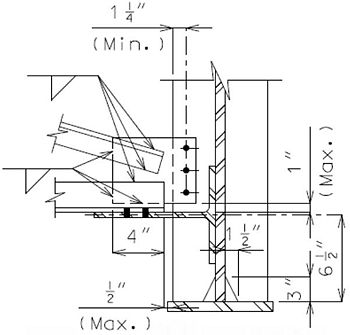

| + | P/S strands shall extend 3" minimum and 6" maximum past edge of precast prestressed panel and not closer than 1" to the adjacent panels. | ||

| + | |||

| + | Panel end at splices shall be notched to avoid bolt heads as shown below: | ||

| − | + | <center> | |

| + | [[Image:751.40 Widen and Repair Design Assumptions- PCP on Steel Shear Connector- B.gif]] | ||

| + | </center> | ||

| − | + | [[Image:751.40 circled 1.gif]] 3/4" min. wide bearing edge for panel at splice, typ. | |

| − | + | [[Image:751.40 circled 2.gif]] 1-1/4" min. (Typ.) | |

| + | [[Image:751.40 circled 3.gif]] 4 x (Stud diameter) preferred minimum, may be reduced if necessary for a more economical design; 2-1/4" absolute minimum. | ||

| − | |||

| − | + | '''*''' In order to meet [[Image:751.40 circled 1.gif]] and [[Image:751.40 circled 2.gif]] above, it is necessary to have an edge bolt distance of 2" or greater for splice plate. | |

| + | Minimum joint filler thickness is 1" except over splice plates in which case use 1/4" minimum. Use 3/4" joint filler width for panels over splice plates. When joint filler is less than 1/2" thick over splice plate, the contractor is required to make the width of joint filler at splice the same width as panel on splice. | ||

| − | + | Maximum difference in top of flange thickness should be checked so that joint filler thickness does not exceed 2". | |

| − | + | == 751.14.5 Details == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

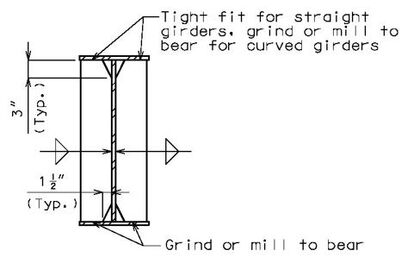

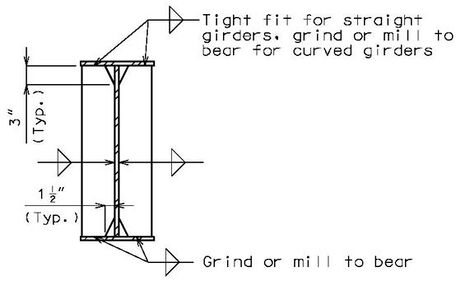

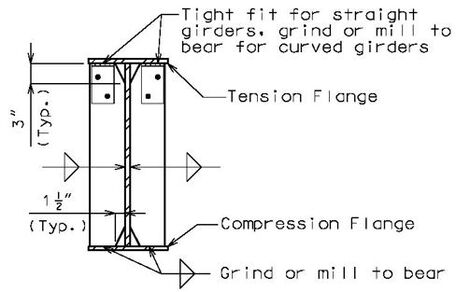

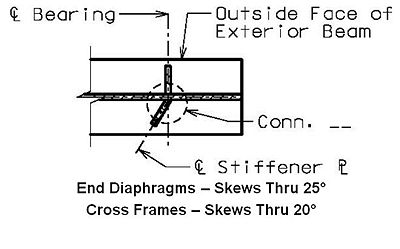

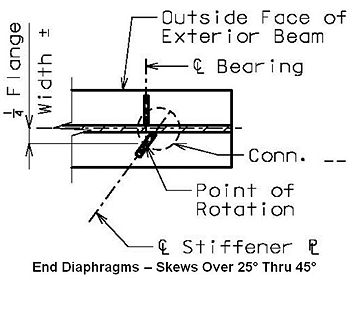

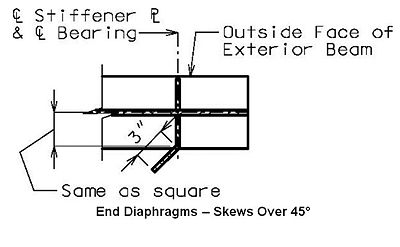

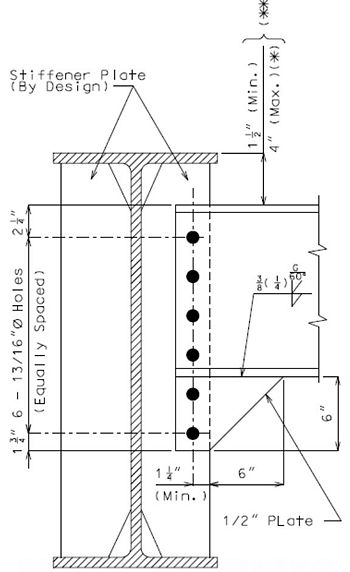

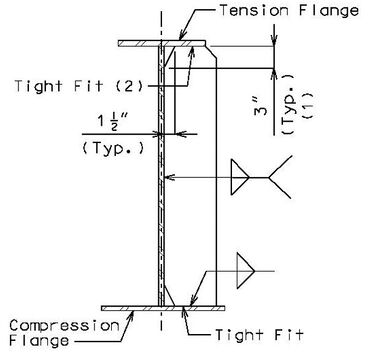

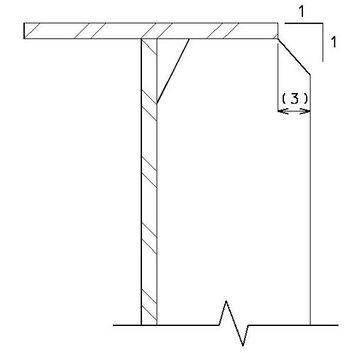

| + | === 751.14.5.1 Bearing Stiffeners === | ||

| + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. Refer to [[#751.14.5.5 Transverse Stiffeners |EPG 751.14.5.5 Transverse Stiffeners]] for beveled plate guidance for unequal flange widths. | ||

| + | |||

| + | The preferred welded connection to flange is more prone to fatigue than the bolted connection. Girder shall be sized to reduce fatigue stresses to allow for preferred detail. If resizing is impractical the bolted connection shall be used. | ||

| − | + | Size bearing stiffener plate by design (1/2" thick minimum). See [[#751.14.2.6 Other Requirements|EPG 751.14.2.6 Other Requirements]]. | |

| − | |||

| − | <center> ''' | + | [[Image:751.14.5.1.1.jpg|420px|center]] |

| + | <center>'''Bearing Stiffener -<br/>No Attachments'''</center> | ||

| + | |||

| + | [[Image:751.14.5.1.2.jpg|470px|center]] | ||

| + | <center>'''Bearing Stiffener -<br/>Diaphragms or Cross Frames Attached<br/>'''(Preferred detail)</center> | ||

| − | < | + | <div id="Holes in the tension flange1"></div> |

| + | [[Image:751.145.1.3.jpg|470px|center]] | ||

| + | <center>'''Intermediate Bearing Stiffener -<br/>Cross Frames Attached<br/>'''(Optional detail<sup>'''1'''</sup>)<br/><sup>'''1'''</sup> Holes in the tension flange restricts girder design in accordance with [[#751.14.2.2 Analysis Methods|EPG 751.14.2.2 Analysis Methods]]</center> | ||

| − | |||

| − | + | '''Locations''' | |

| − | + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. | |

| + | [[Image:751.14.5.1 End Skews Thru 25.jpg|400px|center]] | ||

| + | [[Image:751.14.5.1 End Skews 25 to 45.jpg|360px|center]] | ||

| − | |||

| − | + | [[Image:751.14.5.1 End Skews over 45.jpg|400px|center]] | |

| + | [[Image:751.14.5.1 End all Skews.jpg|400px|center]] | ||

'''Welds for Optional Stiffener Locations''' | '''Welds for Optional Stiffener Locations''' | ||

| + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. | ||

<center> [[Image:751.14 connection a.gif]] </center> | <center> [[Image:751.14 connection a.gif]] </center> | ||

| Line 3,818: | Line 3,875: | ||

<center> '''Connection “C”''' </center> | <center> '''Connection “C”''' </center> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| Line 3,879: | Line 3,930: | ||

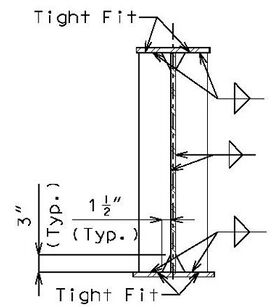

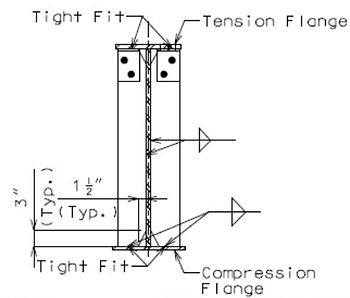

=== 751.14.5.2 Int. Diaphragms and Cross Frames === | === 751.14.5.2 Int. Diaphragms and Cross Frames === | ||

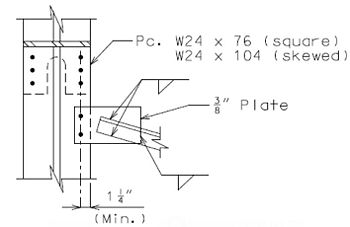

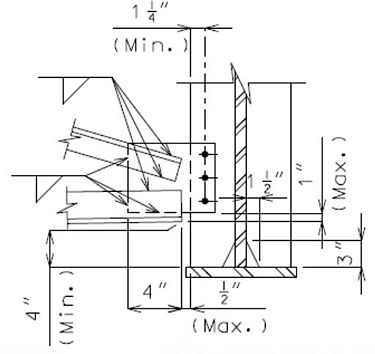

| + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. Refer to [[#751.14.5.5 Transverse Stiffeners |EPG 751.14.5.5 Transverse Stiffeners]] for beveled plate guidance for unequal flange widths. | ||

| + | |||

| + | The preferred welded connection to flange is more prone to fatigue than the bolted connection. Girder shall be sized to reduce fatigue stresses to allow for preferred detail. If resizing is impractical, the bolted connection shall be used. When the bolted connection is used, the top and bottom tension or compression flanges shall be shown on the "Elevation of Girder" detail on plans. | ||

| + | |||

| + | Minimum connection plate size is 5 1/2" x 1/2”. Width of plate shall be increased as required by 1/2" increments. Thickness of plate shall be increased as required by 1/8" increments. | ||

| + | |||

| + | [[Image:751.14.5.2.1.jpg|center|280px]] | ||

| + | <center>'''Intermediate Diaphragm Connection Plate<br/>'''(Preferred detail)</center> | ||

| + | |||

| + | <div id="Holes in the tension flange2"></div> | ||

| + | [[Image:751.14 Intermediate Diaphragm Connection Plate Optional.jpg|center|350px]] | ||

| + | <center>'''Intermediate Diaphragm Connection Plate<br/>'''(Optional detail<sup>'''1'''</sup>)<br/><sup>'''1'''</sup> Holes in the tension flange restricts girder design in accordance with [[#751.14.2.2 Analysis Methods|EPG 751.14.2.2 Analysis Methods]] | ||

| + | |||

| + | |||

| + | Connection Angle Details (See table below for "A" and "B" values.)</center> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{|border="0" cellpadding="3" align="center" style="text-align:center" | {|border="0" cellpadding="3" align="center" style="text-align:center" | ||

| Line 3,912: | Line 3,962: | ||

{|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | ||

|- | |- | ||

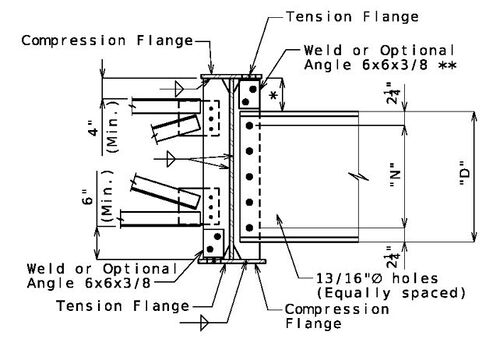

| − | |[[Image:751.14 | + | |[[Image:751.14.5.2_diaphragm_details.jpg|500px]] |

|- | |- | ||

| | | | ||

| Line 3,918: | Line 3,968: | ||

|- | |- | ||

|valign="top" align="right" width="10pt"|*||align="left" width="350pt" |When angles are required verify clearance for cross slope.<br/>6 1/4" (Min.) for wide flanges<br/>6 1/2" (Min.) for plate girders | |valign="top" align="right" width="10pt"|*||align="left" width="350pt" |When angles are required verify clearance for cross slope.<br/>6 1/4" (Min.) for wide flanges<br/>6 1/2" (Min.) for plate girders | ||

| + | |- | ||

| + | |valign="top" align="right" width="10pt"|**||align="left" width="350pt" |Holes in the tension flange restricts girder design in accordance with [[#751.14.2.2 Analysis Methods|EPG 751.14.2.2 Analysis Methods]] | ||

|} | |} | ||

|- | |- | ||

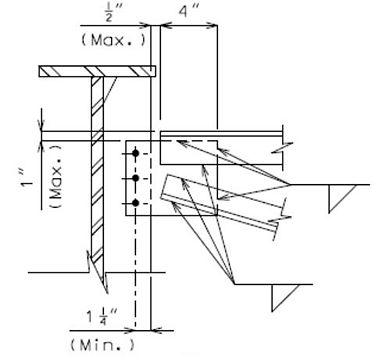

||See table below for "D" and "N" values. | ||See table below for "D" and "N" values. | ||

|- | |- | ||

| − | |[[Image:751.14 diaphragm connection | + | |[[Image:751.14 diaphragm connection.jpg|375px]] |

|- | |- | ||

!Diaphragm Connection at Stiffener Detail | !Diaphragm Connection at Stiffener Detail | ||

| Line 3,928: | Line 3,980: | ||

{|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | {|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | ||

|- | |- | ||

| − | |valign="top"|Note:||align="left" width="400pt" |The above details are assumed adequate for straight girders. Horizontally curved girders require design for torsional effects (see Analysis of Horizontally Curved Girders) | + | |valign="top"|Note:||align="left" width="400pt" |The above details are assumed adequate for straight girders. Horizontally curved girders require design for torsional effects (see [[#Analysis of Horizontaly Curved Girders|Analysis of Horizontally Curved Girders]]). |

|} | |} | ||

| Line 3,934: | Line 3,986: | ||

{|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | ||

|- | |- | ||

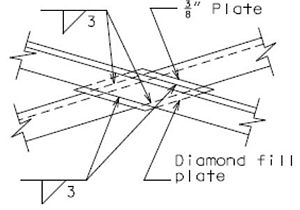

| − | |[[Image:751.14 diaphragm fill plate detail - preferred | + | |[[Image:751.14 diaphragm fill plate detail - preferred.jpg|300px]] |

| − | |[[Image:751.14 diaphragm fill plate detail - optional | + | |[[Image:751.14 diaphragm fill plate detail - optional.jpg|300px]] |

|- | |- | ||

!Fill Plate Detail - Preferred||Optional Fill Plate Detail for Contractor | !Fill Plate Detail - Preferred||Optional Fill Plate Detail for Contractor | ||

|} | |} | ||

{|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | {|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | ||

| − | |||

| − | |||

|} | |} | ||

| + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" | {|border="1" cellspacing="0" align="center" style="text-align:center;" | ||

| Line 3,980: | Line 4,031: | ||

|valign="top" align="right" width="10pt"|***||align="left" width="500pt" |S = girder spacing along diaphragm skew | |valign="top" align="right" width="10pt"|***||align="left" width="500pt" |S = girder spacing along diaphragm skew | ||

|- | |- | ||

| − | |colspan="2" width="510pt" align="left"|Diaphragms and cross frames used as primary members must be checked for torsion effects. (See Analysis of Horizontally Curved Girders) | + | |colspan="2" width="510pt" align="left"|Diaphragms and cross frames used as primary members must be checked for torsion effects. (See [[#Analysis of Horizontaly Curved Girders|Analysis of Horizontally Curved Girders]]) |

|} | |} | ||

| Line 3,987: | Line 4,038: | ||

!align="left"|ATTENTION DETAILER: | !align="left"|ATTENTION DETAILER: | ||

|- | |- | ||

| − | |align="left"|Intermediate diaphragm connection plates shall be detailed for Connection “A” for skews thru 20˚.<br/>Details of Connection “A” are shown | + | |align="left"|Intermediate diaphragm connection plates shall be detailed for Connection “A” for skews thru 20˚.<br/>Details of Connection “A” are shown in [[#751.14.5.1 Bearing Stiffeners|EPG 751.14.5.1 Bearing Stiffeners]]. |

|} | |} | ||

| Line 3,994: | Line 4,045: | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" | {|border="1" cellspacing="0" align="center" style="text-align:center;" | ||

|- | |- | ||

| − | !W21 thru W30||colspan="8"| | + | !W21 thru W30||colspan="8"|Beam Spacing, ft. |

|- | |- | ||

!width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | !width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | ||

| Line 4,016: | Line 4,067: | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" | {|border="1" cellspacing="0" align="center" style="text-align:center;" | ||

|- | |- | ||

| − | !W33||colspan="8"| | + | !W33||colspan="8"|Beam Spacing, ft. |

|- | |- | ||

!width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | !width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | ||

| Line 4,038: | Line 4,089: | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" | {|border="1" cellspacing="0" align="center" style="text-align:center;" | ||

|- | |- | ||

| − | !W36||colspan="8"| | + | !W36||colspan="8"|Beam Spacing, ft. |

|- | |- | ||

!width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | !width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | ||

| Line 4,060: | Line 4,111: | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" | {|border="1" cellspacing="0" align="center" style="text-align:center;" | ||

|- | |- | ||

| − | !W40 thru W44||colspan="8"| | + | !W40 thru W44||colspan="8"|Beam Spacing, ft. |

|- | |- | ||

!width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | !width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | ||

| Line 4,090: | Line 4,141: | ||

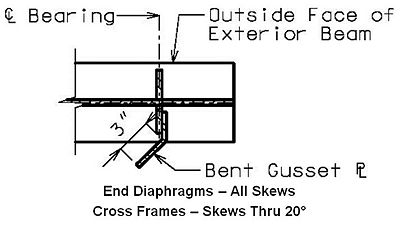

| − | <center> [[Image:751.14 End Diaphragm Connections | + | <center> [[Image:751.14 End Diaphragm Connections.jpg|350px]] </center> |

| − | |||

| − | |||

| − | |||

| + | <center> '''End Diaphragm Connections for W27 thru W40 Beams'''<br/>Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance.</center> | ||

{|align="center" | {|align="center" | ||

|- | |- | ||

| − | |align="right" valign="top"|(*)||align="left" width="400pt"|Slope diaphragms when structure is superelevated or when 4” maximum depth is exceeded. See [[751.13 Expansion Devices]] for the details of end diaphragms on a structure. | + | |align="right" valign="top"|(*)||align="left" width="400pt"|Slope diaphragms when structure is superelevated or when 4” maximum depth is exceeded. See [[751.13 Expansion Devices|EPG 751.13 Expansion Devices]] for the details of end diaphragms on a structure. |

|- | |- | ||

|align="right" valign="top"|(**)||align="left" width="400pt"|Modify if necessary to clear the anchor bolts of the flat plate bearing or connection bolts of the expansion device. | |align="right" valign="top"|(**)||align="left" width="400pt"|Modify if necessary to clear the anchor bolts of the flat plate bearing or connection bolts of the expansion device. | ||

| Line 4,141: | Line 4,190: | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" | {|border="1" cellspacing="0" align="center" style="text-align:center;" | ||

|- | |- | ||

| − | !Webs | + | !Webs ≥ 42"||colspan="8"|Girder Spacing, ft. |

|- | |- | ||

!width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | !width="100pt"|Skew, deg.||width="75pt"|7||width="75pt"|7.5||width="75pt"|8||width="75pt"|8.5||width="75pt"|9||width="75pt"|9.5||width="75pt"|10||width="75pt"|10.5 | ||

| Line 4,163: | Line 4,212: | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" cellpadding="2" | {|border="1" cellspacing="0" align="center" style="text-align:center;" cellpadding="2" | ||

|+'''Bottom Horizontal Members for Web Depths ≥ 42”''' | |+'''Bottom Horizontal Members for Web Depths ≥ 42”''' | ||

| − | !Webs | + | !Webs ≥ 42"||colspan="8"|Girder Spacing, ft. |

|- | |- | ||

!width="100pt"|Skew, deg.||width="125pt"|7||width="125pt"|7.5||width="125pt"|8||width="125pt"|8.5||width="125pt"|9||width="125pt"|9.5||width="125pt"|10||width="125pt"|10.5 | !width="100pt"|Skew, deg.||width="125pt"|7||width="125pt"|7.5||width="125pt"|8||width="125pt"|8.5||width="125pt"|9||width="125pt"|9.5||width="125pt"|10||width="125pt"|10.5 | ||

| Line 4,183: | Line 4,232: | ||

{|border="1" cellspacing="0" align="center" style="text-align:center;" cellpadding="2" | {|border="1" cellspacing="0" align="center" style="text-align:center;" cellpadding="2" | ||

|+'''Diagonal Members for Web Depths > 48”''' | |+'''Diagonal Members for Web Depths > 48”''' | ||

| − | !Webs | + | !Webs ≤ 60"||colspan="8"|Girder Spacing, ft. |

|- | |- | ||

!width="100pt"|Skew, deg.||width="125pt"|7||width="125pt"|7.5||width="125pt"|8||width="125pt"|8.5||width="125pt"|9||width="125pt"|9.5||width="125pt"|10||width="125pt"|10.5 | !width="100pt"|Skew, deg.||width="125pt"|7||width="125pt"|7.5||width="125pt"|8||width="125pt"|8.5||width="125pt"|9||width="125pt"|9.5||width="125pt"|10||width="125pt"|10.5 | ||

| Line 4,241: | Line 4,290: | ||

For diaphragms and cross-frames designed as primary members in horizontally curved girders: | For diaphragms and cross-frames designed as primary members in horizontally curved girders: | ||

| − | <math>\, \frac{Kl}{r} \le 120</math> | + | :::<math>\, \frac{Kl}{r} \le 120</math> |

| − | Primary members shall also be designed for torsional effects. (See Analysis of Horizontally Curved Girders) | + | Primary members shall also be designed for torsional effects. (See [[#Analysis of Horizontaly Curved Girders|Analysis of Horizontally Curved Girders]]) |

| Line 4,263: | Line 4,312: | ||

|colspan="2"| | |colspan="2"| | ||

|- | |- | ||

| − | |[[Image:751.14 end diaphragm - | + | |[[Image:751.14 end diaphragm - 36 thru 40.jpg|350px]] |

| − | |[[Image:751.14 end diaphragm - | + | |[[Image:751.14 end diaphragm - 42 thru 48.jpg|375px]] |

|- | |- | ||

!Detail "D"||Detail "E" | !Detail "D"||Detail "E" | ||

| Line 4,272: | Line 4,321: | ||

{|align="center" | {|align="center" | ||

|- | |- | ||

| − | |valign="top"|(*)||align="left"|Slope diaphragms when a structure is superelevated or when the 4" maximum depth is | + | |valign="top"|(*)||align="left"|Slope diaphragms when a structure is superelevated or when the 4" maximum depth is exceeded. |

|} | |} | ||

| − | + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. | |

{|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | ||

| Line 4,285: | Line 4,334: | ||

|colspan="2"| | |colspan="2"| | ||

|- | |- | ||

| − | |[[Image:751.14 end diaphragm - | + | |[[Image:751.14 end diaphragm - over 48 detail c.jpg|350px]] |

| − | |[[Image:751.14 end diaphragm - | + | |[[Image:751.14 end diaphragm - over 48 detail a.jpg|375px]] |

|- | |- | ||

!Detail "C"||Detail "A" | !Detail "C"||Detail "A" | ||

| Line 4,294: | Line 4,343: | ||

{|align="center" | {|align="center" | ||

|- | |- | ||

| − | |valign="top"|(*)||align="left"|Slope diaphragms when a structure is superelevated or when the 4" maximum depth is | + | |valign="top"|(*)||align="left"|Slope diaphragms when a structure is superelevated or when the 4" maximum depth is exceeded. |

|} | |} | ||

| − | + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. | |

{|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | ||

| Line 4,307: | Line 4,356: | ||

|colspan="2"| | |colspan="2"| | ||

|- | |- | ||

| − | |[[Image:751.14 end diaphragm - | + | |[[Image:751.14 end diaphragm - over 48 finger plate detail d.jpg|350px]] |

| − | |[[Image:751.14 end diaphragm - | + | |[[Image:751.14 end diaphragm - over 48 finger plate detail a.jpg|375px]] |

|- | |- | ||

!Detail "D"||Detail "A" | !Detail "D"||Detail "A" | ||

|} | |} | ||

| + | Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. | ||

| + | |||

| + | ===751.14.5.5 Transverse Stiffeners === | ||

| + | Transverse stiffeners are also referred to as intermediate web stiffeners. | ||

| + | |||

| + | Minimum stiffener size is 5 1/2" x 1/2”. Width of plate shall be increased as required by 1/2" increments. Thickness of plate shall be increased as required by 1/8" increments. | ||

| + | |||

| + | Transverse stiffeners shall be used on inside face of exterior girders and in successive alignment along either side of interior girders. | ||

| + | |||

| + | When transverse stiffeners are used, top and bottom tension or compression flanges shall be shown on the "Elevation of Girder" detail on plans. | ||

| − | |||

{|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="3" align="center" style="text-align:center" cellspacing="0" | ||

|- | |- | ||

| − | |[[Image:751.14 | + | |[[Image:751.14.5.5.1.jpg|370px]] |

|- | |- | ||

!Int. web Stiffener (One Side Only)<br/>Variable Flange Width | !Int. web Stiffener (One Side Only)<br/>Variable Flange Width | ||

|colspan="2"| | |colspan="2"| | ||

|- | |- | ||

| − | |[[ | + | |Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. |

|- | |- | ||

| − | !Details | + | |[[Image:751.14.5.5.2.jpg|350px]] |

| + | |- | ||

| + | !Details of Beveled Plate for Int. Web Stiffener, Bearing<br/>Stiffener and Intermediate Diaphragm Connection Plates | ||

|} | |} | ||

{|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | {|border="0" cellpadding="5" cellspacing="1" align="center" style="text-align:center" | ||

|- | |- | ||

| − | + | |(1)||align="left" |Check LRFD 6.10.11.1.1 for clip limits. | |

|- | |- | ||

| − | + | |(2)||align="left" |Attach to flange when stiffener is also used as a diaphragm connection plate. | |

|- | |- | ||

| − | + | |(3)||align="left" width="600pt" |When dimension exceeds 1/2", bevel stiffener plate. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| Line 4,356: | Line 4,401: | ||

|- | |- | ||

|valign="top" width="400" align="left"|When longitudinal stiffeners are required they shall be used on the outside of exterior girders and in successive alignment along either side of interior girders. | |valign="top" width="400" align="left"|When longitudinal stiffeners are required they shall be used on the outside of exterior girders and in successive alignment along either side of interior girders. | ||

| − | |rowspan="5"|[[Image:751.14 longitudinal web stiffener | + | |rowspan="5"|[[Image:751.14 longitudinal web stiffener.jpg|350px]] |

|- | |- | ||

|valign="top" width="400" align="left"|The placement of longitudinal stiffeners may interfere with bolting the diaphragm or cross frame in place. Should this occur, it will be necessary to clip the longitudinal stiffeners as shown below. | |valign="top" width="400" align="left"|The placement of longitudinal stiffeners may interfere with bolting the diaphragm or cross frame in place. Should this occur, it will be necessary to clip the longitudinal stiffeners as shown below. | ||

| Line 4,367: | Line 4,412: | ||

|- | |- | ||

| | | | ||

| − | !Longitudinal Web Stiffener<br/>(One Side Only) | + | !Longitudinal Web Stiffener<br/>(One Side Only)<br>Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. |

|} | |} | ||

| Line 4,416: | Line 4,461: | ||

|- | |- | ||

|[[Image:751.14 lateral bracing detail c.gif]] | |[[Image:751.14 lateral bracing detail c.gif]] | ||

| − | |[[Image:751.14 lateral bracing detail a | + | |[[Image:751.14 lateral bracing detail a.jpg|350px]] |

|- | |- | ||

!Detail "C"||Detail "A" | !Detail "C"||Detail "A" | ||

| Line 4,423: | Line 4,468: | ||

|- | |- | ||

|align="right" valign="top"|Note:||width="300pt" align="left"|Lateral Bracing T-Gusset shall be cut to required depth from W27 x 94, or T-Gusset can be built from plates in shop. | |align="right" valign="top"|Note:||width="300pt" align="left"|Lateral Bracing T-Gusset shall be cut to required depth from W27 x 94, or T-Gusset can be built from plates in shop. | ||

| + | |- | ||

| + | |Refer to [[#751.14.5.10 Weld Design and Detail Guidance|EPG 751.14.5.10]] for weld design and detail guidance. | ||

|} | |} | ||

| Line 4,454: | Line 4,501: | ||

===751.14.5.8 Protective Coating Requirements=== | ===751.14.5.8 Protective Coating Requirements=== | ||

| − | Coating requirements for new steel girder bridge shall be in accordance with [http://www.modot. | + | Coating requirements for new steel girder bridge shall be in accordance with [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=14 Sec 1080] and [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=14 Sec 1081]. See [[751.1 Preliminary Design#751.1.2.9.2 Steel Girder Options|EPG 751.1.2.9.2]], [[751.6_General_Quantities#751.6.2.11_Structural_Steel_Protective_Coatings_.28Non-weathering_Steel.29|EPG 751.6.2.11]] and [[751.6 General Quantities#751.6.2.12 Structural Steel Protective Coatings (Weathering Steel)|EPG 751.6.2.12]] for additional guidance. |

| − | System G is | + | System G (three-coat system) is the preferred system for both non-weathering and weathering steel structures ([http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=14 Sec 1081]). System G typically is not preferred when overlapping an existing vinyl coating but may be allowed if the existing coating is determined to be in good condition. System G uses a solvent based finish coat which may cause issues when overlapping an existing solvent-based vinyl coating system (System C) because it may re-wet the existing coating and cause delamination of the base coat. If the existing coating is in good condition as determined by paint pull-off tests the intermediate epoxy coating will provide a reliable barrier between the solvent-based coatings. Consult the structural project manager or structural liaison engineer before using System G near existing vinyl coatings. |

| − | System | + | System G has replaced calcium sulfonate as the preferred overcoating system. To ensure sufficient bond of the existing coating, adhesion pull-off tests shall be performed in accordance with ASTM D4541. If the adhesion test fails, as determined by the engineer of record, then overcoating shall not be allowed and recoating should be considered. |

| − | See [ | + | System H (three-coat system) is typically used when the bond for System G is considered questionable where recoating operations will take place near an existing vinyl coating system (System C). System H uses a waterborne acrylic for the intermediate and finish field coats that does not tend to interfere with the solvent-based vinyl coating. |

| + | |||

| + | System I (two-coat system) may be used for non-weathering and weathering steel and should be based on the following guidance: | ||

| + | |||

| + | :(a) System I should be considered in areas where the aesthetics of a coating system over the long term is unusually more critical than System G. While System G and I provide long term protection, System I has excellent gloss retention and UV resistance. System I is a context sensitive design (CSD) solution. CSD follows from project scoping and is subject to the project core team protocols. | ||

| + | |||

| + | ::(1) Consider for locations where the structure is more visible or the public has leisurely time for more than just a casual glance, for example structures near a ballpark or a pedestrian bridge. Using same rationale, bridges that are tall or have wide girder spacing or a low number of girders where more of the superstructure is visible could also be candidates. | ||

| + | |||

| + | ::(2) Consider the image consciousness of the surroundings in conjunction with rather than solely the protection of the structure which is equally provided by both systems. Maintenance of either System G or I should be considered the same. | ||

| + | |||

| + | :(b) System I is a polysiloxane finish coat that is normally applied directly over an inorganic or organic zinc primer with no intermediate coating. Since the system is a two-coat system, it may be applied in less time which can influence critical path scheduling and impacts to the driving public. For example, it may be possible for a contractor to get in and out quicker than if they were to use a three-coat system. MoDOT coating policy as described in Standard Specification Section 1081 requires different field coating requirements based on the type of bridge crossing. For roadway grade separations, it is required that interior girders have only a single field coat in order to satisfy that all girders on a roadway grade separation bridge have at least two coatings for protection. In the case of System I, the Standard Specifications require that a System G epoxy intermediate field coat be applied to all interior girders and the interior of fascia girders and that the System I polysiloxane finish coating be applied to the exterior of the facia girders only. This is based on a system I polysiloxane coating cost being greater than a system G epoxy coating on a per-gallon cost basis. It also requires that the contractor be given the option to substitute the System I finish coat in place of a System G intermediate coat. If CSD determines that the polysiloxane should be applied to all girders, then the general notes for coatings and the quantities on the contract plans will need to reflect the revised coating requirements. | ||

| + | |||

| + | :(c) System I is approved for use on state highway projects beginning February 2011. Alternate bidding is encouraged if guideline (a) is not required to be met and with approval of the Structural Project Manager or Structural Liaison Engineer and the project core team. | ||

| + | |||

| + | System G, H or I typically require an inorganic or organic zinc primer per Sec 1081. Inorganic zinc shall be used for new steel fabrication. For recoating operations, organic zinc primer should be considered as a direct replacement for the inorganic zinc required in the specifications. Organic zinc primers require a lower level of surface preparation (SSPC-SP6: commercial blast cleaning vs SSPC-SP10: near white blast cleaning) and are generally easier to apply in the field than inorganic zinc primers. Only organic zinc primers that can provide a Class B slip coefficient are allowed for use in recoating operations. | ||

| + | |||

| + | See [https://epg.modot.org/index.php?title=751.50_Standard_Detailing_Notes#A4._Protective_Coatings EPG 751.50 A4. Protective Coatings] for standard detailing notes and guidance on how they are used. | ||

| + | |||

| + | Epoxy-mastic primers may be used for overcoating lead-based coatings if the existing coating is determined to be in good condition, but this is considered a short-term solution in comparison to System G overcoating. Consult the structural project manager or structural liaison engineer before using epoxy-mastics near existing lead-based coatings. | ||

| + | |||

| + | Galvanized non-weathering structural steel beams, girders, bracing and diaphragms may be used as required or allowed by alternate, on a case-by-case basis, with approval of the Structural Project Manager or Structural Liaison Engineer and the project core team. | ||

| + | |||

| + | When galvanized structural steel is required, place note EPG 751.50 (A4a1.8.2a) on the plans. Do not use notes EPG 751.50 (A4a1.1 – A4a1.7). When galvanized structural steel is bid as an alternate, place notes EPG 751.50 (A4a1.8.1a, A4a1.8.1b, and A4a1.8.1c) on the plans under the applicable coating new steel notes EPG 751.50 (A4a1.1-A4a1.7). | ||

===751.14.5.9 Weathering Steel=== | ===751.14.5.9 Weathering Steel=== | ||

| − | Use of weathering steel may require special detailing as specified in the referenced documents in [ | + | Use of weathering steel may require special detailing as specified in the referenced documents in [https://epg.modot.org/index.php?title=751.1_Preliminary_Design#751.1.2.9_Girder_Type_Selection EPG 751.1.2.9 Girder Type Selection]. |

| + | |||

| + | ====751.14.5.9.1 Drip Bar Guidance==== | ||

| + | |||

| + | '''General''' | ||

| + | |||

| + | The purpose of a drip bar placed on the bottom flange is to intercept and deflect water and debris. Drip bars should be installed on new, or retrofitting existing weathering steel where a need is discovered. | ||

| + | |||

| + | Drip bars should be utilized for three reasons: | ||

| + | |||

| + | 1. To protect girders and beams from sustained and accumulated (heavy) water flow along the web-flange crease that can promote deterioration by wearing action (due to particulate matter and debris) and long term moisture retention along the crease and along the lower web whereby water is drawn up the sides of the lower web by capillary action which is observable in the field as constantly "wetted" sides or permanent discoloration. For a new girder or beam, this can retard the development of or reduce the efficacy of the protective oxide coating. | ||

| + | |||

| + | 2. To protect bearing devices from sustained moisture due to accumulating water and debris. | ||

| + | |||

| + | 3. To protect substructure from long term staining. (For the short term, temporary protective coating is utilized during weathering steel construction; see [[:Category:711 Protective Coatings for Exposed Concrete Surfaces|EPG 711 Protective Coatings for Exposed Concrete Surfaces]].) | ||

| + | |||

| + | '''Guidance''' | ||

| + | |||

| + | Drip bars shall not be provided on flat structures (0.0 % grade) unless in the case of long spans where permanently cambered girders or beams can produce a water flow. | ||

| + | |||

| + | Drip bars shall be placed skewed on top of bottom flange and preferably placed squared on bottom of bottom flange. | ||

| + | |||

| + | Drip bars shall not be provided directly over railroads, roadways and walkways. | ||

| + | |||

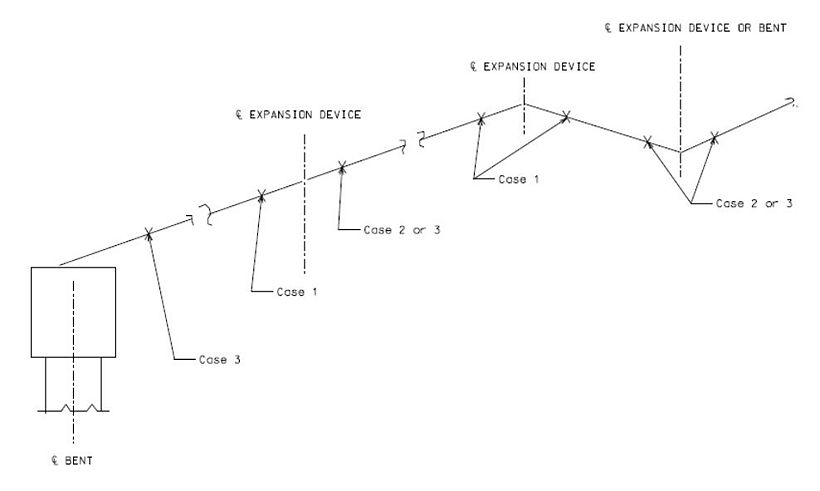

| + | '''(Case 1) To protect girders and beams:''' Drip bars should be located at the downgrade side of open or closed expansion devices between 5 ft. from the center of the expansion device and to within 1 ft. from the end of the partial coating limit (to ensure the drip bars are coated) for <u>all girders or beams</u> within a span. | ||

| + | |||

| + | '''(Case 2) To protect girder and beam ends, bearings <u>and</u> bearing stiffeners:''' Drip bars should be located at the upgrade side of bearings at the exterior faces of exterior girders or beams at about 4 ft. away from the face of the bent for downhill runs of 100 ft. or longer span girders or beams. | ||

| + | |||

| + | '''(Case 3) To protect substructure:''' Drip bars should be located adjacent to the upgrade side of the bent at the exterior faces of exterior girders or beams at about 4 ft. away from the face of the bent for downhill runs of 100 ft. or longer span girders or beams to prevent stain marks on the substructure in either urban or context sensitive designs, for example where the aesthetics of the structure is considered important. For aesthetics reasons drip bars adjacent to substructure may be provided where the structure is over railroad, water or near integral abutments. | ||

| + | |||

| + | Fatigue analysis of girder or beam for welded connection of drip bars shall be required in the event that there will be effective stress cycles in tension and/or stress reversal on the welds. Bolted drip angle details may be considered instead of welded drip bars details as an alternative. | ||

| + | |||

| + | [[image:751.14.5.9.1.jpg|center|820px]] | ||

| + | {| style="margin: 1em auto 1em auto" text align:left width="700" | ||

| + | |- | ||